Soft carbon fiber composite material with three-dimensional textured surface and manufacturing method thereof

A composite material and carbon fiber technology, which is applied in the field of soft carbon fiber composite materials and its manufacturing, can solve the problems of poor combination of existing carbon fiber fabrics and thermoplastic resins, and achieve the effect of increasing applicability and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

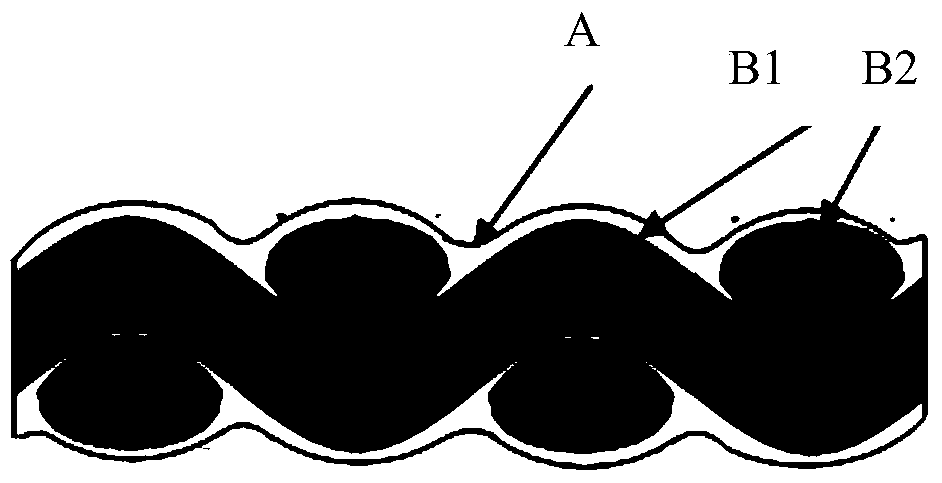

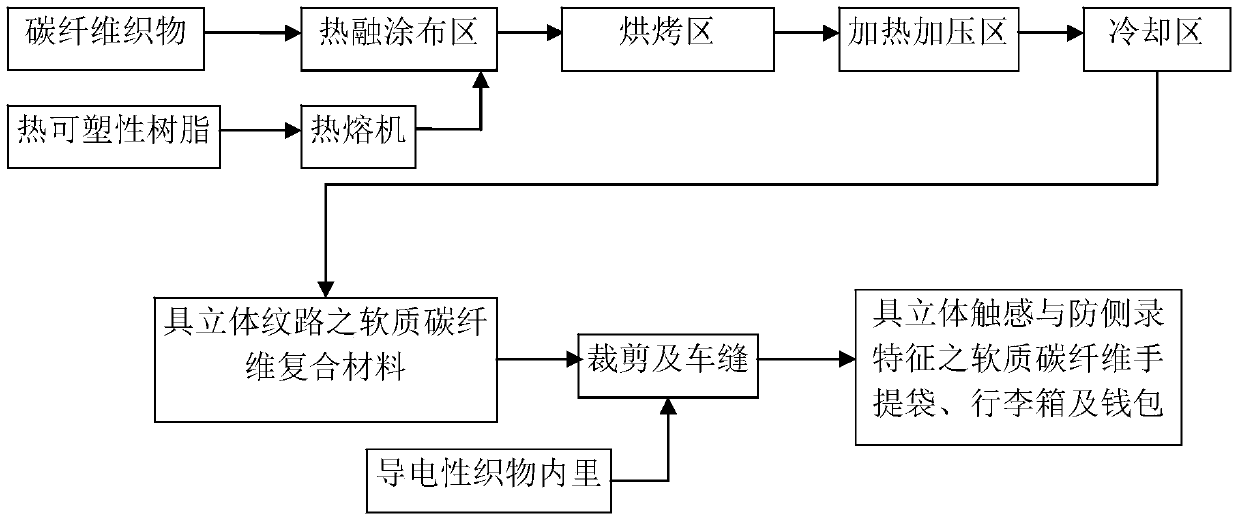

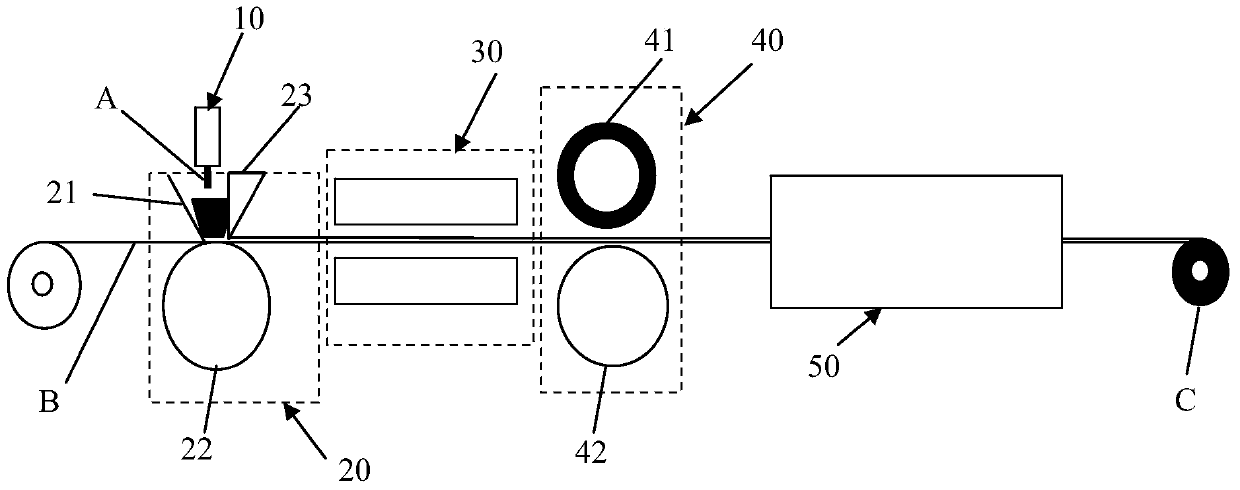

[0061] Provide a polyurea ester resin (TPU) of Shore A (Shore A) 65 and a carbon fiber twill fabric with a thickness of 0.28mm and a weight per square meter of 248g, and the polyurea ester resin is heated to 180 ℃ with a hot melt machine to melt, And it is coated on the surface of the carbon fiber twill fabric with a combination of rollers and a doctor blade, and then baked at 205 ° C for 40 seconds through infrared rays, so that the polyurea ester resin infiltrates the fibers of the carbon fiber twill fabric, and then by containing a hardness of Xiao The roller group of the rubber roller with Shore A 65 and the steel roller is heated at 160℃ and pressurized at 16kgf / cm2, so that the thermoplastic resin is fully distributed in the carbon fiber fabric, and the surface presents a three-dimensional texture ; Finally, the carbon fiber twill fabric coated with polyurea ester resin is cooled at 7°C, the production line speed is 2m / min, and the cooling dwells for 30 seconds, so that t...

example 8

[0073] The soft carbon fiber composite materials obtained from Examples 1 to 7 can be post-processed and sewn together with the inner lining of the conductive fabric to make products such as handbags, luggage and wallets. The following table 2 compares the general cowhide, the existing glass fiber silver-plated, the conductive fabric provided by the applicant in TW1325907 (copper electroplating on the surface of polyester cloth), the soft carbon fiber composite material obtained in Example 1, and the above conductive fabric (as Inside) and the EMI shielding properties of the soft carbon fiber composite material obtained in Example 1 after sewing. It can be seen from Table 2 that the soft carbon fiber composite material of the present invention has quite good EMI shielding properties, and if the soft carbon fiber composite material of the present invention is combined with the conductive fabric, the shielding effect of the original conductive fabric can be increased, so it can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com