High-tap-density multi-element oxide precursor and preparation method and preparation system thereof

A technology of tap density and preparation system, applied in chemical instruments and methods, nickel compounds, chemical/physical processes, etc., can solve problems such as high energy density of lithium-ion batteries and low tap density of materials, and achieve good results , Strong raw material adaptability, effect of increasing particle size and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

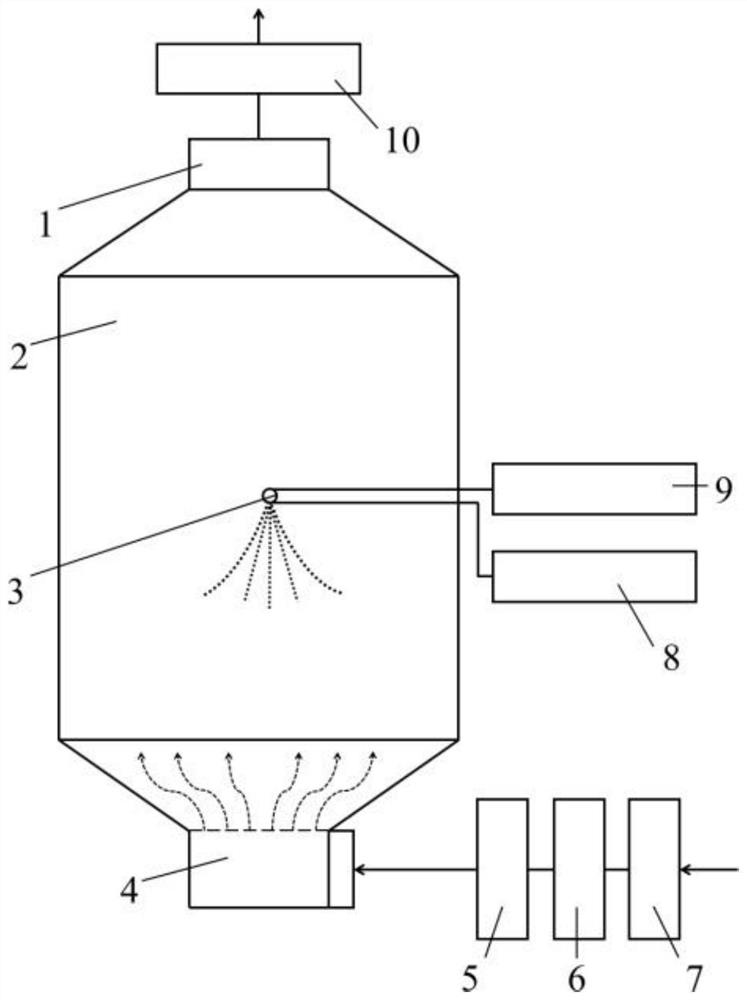

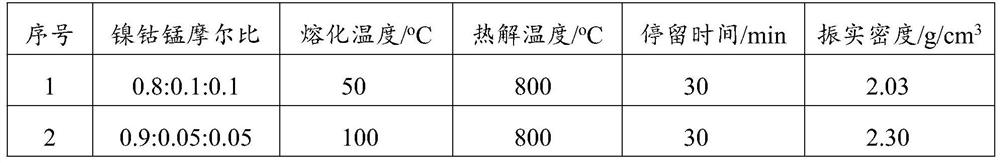

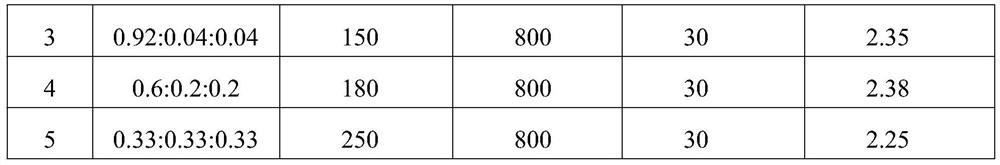

[0038] This embodiment adopts as figure 1 The preparation system shown prepares the NCM ternary positive electrode precursor, specifically including the following steps:

[0039]Step 1 Furnace preheating: Turn on the heater 5 to raise the temperature to 800°C, then turn on the blower 7 to filter the air through the filter 6 and preheat the cavity of the fluidized bed 2 through the fluidization gas inlet 4, and the cavity of the fluidized bed 2 The temperature in the body is controlled at 800°C;

[0040] Step 2 heating and melting: nickel chloride hexahydrate, cobalt chloride hexahydrate, and manganese chloride tetrahydrate weigh a total of 500g according to a certain stoichiometric ratio, place them in the liquid delivery device 8, heat to 60-250°C, and Stir while melting to form a uniform sub-molten salt liquid;

[0041] Step 3 Spray pyrolysis: After the spray pyrolysis device is running stably, the sub-molten salt liquid obtained in step 2 is injected into the dual-fluid a...

Embodiment 2

[0047] This embodiment adopts as figure 1 The preparation system shown prepares the NCM622 ternary cathode precursor, which specifically includes the following steps:

[0048] Step 1 Furnace preheating: Turn on the heater 5 to raise the temperature to 650-950°C, then turn on the blower 7 to filter the air through the filter 6 and preheat the cavity of the fluidized bed 2 through the fluidizing gas inlet 4, and the fluidized bed 2. The temperature in the cavity is controlled at 650-950°C;

[0049] Step 2 Heating and melting: Nickel chloride hexahydrate, cobalt chloride hexahydrate, and manganese chloride tetrahydrate are weighed in a stoichiometric ratio of 0.6:0.2:0.2 to weigh a total of 500g, placed in liquid delivery device 8, and heated to 125°C , stirring while melting to form a uniform sub-molten salt liquid;

[0050] Step 3 Spray pyrolysis: After the spray pyrolysis device is running stably, the sub-molten salt liquid obtained in step 2 is injected into the dual-fluid ...

Embodiment 3

[0056] This embodiment adopts as figure 1 The preparation system shown prepares Al-doped NCM811 ternary cathode precursor, which specifically includes the following steps:

[0057] Step 1 Furnace preheating: Turn on the heater 5 to raise the temperature to 850°C, then turn on the blower 7 to filter the air through the filter 6 and preheat the cavity of the fluidized bed 2 through the fluidization gas inlet 4, and the cavity of the fluidized bed 2 The temperature in the body is controlled at 850°C;

[0058] Step 2 Heating and melting: Nickel chloride hexahydrate, cobalt chloride hexahydrate, and manganese chloride tetrahydrate are weighed in a stoichiometric ratio of 0.85:0.1:0.05, and a total of 500g is weighed, placed in the liquid delivery device 8, and heated to 150°C , stirring while melting to form a uniform sub-molten salt liquid;

[0059] Step 3 Spray pyrolysis: After the spray pyrolysis device is running stably, the sub-molten salt liquid obtained in step 2 is inject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com