Automatic welding device for medical protective clothing

A technology of protective clothing and automatic welding, applied in the field of medical protective clothing, can solve the problems of difficulty in realizing ultrasonic automatic welding, and achieve the effect of efficient and convenient use and flexible and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

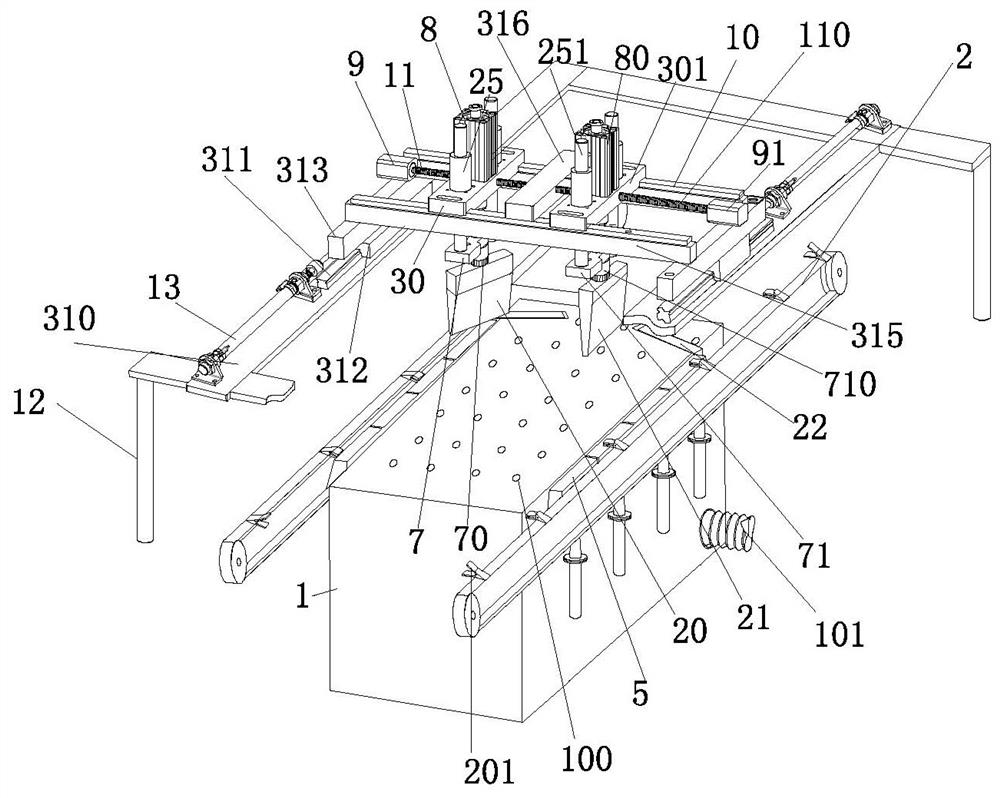

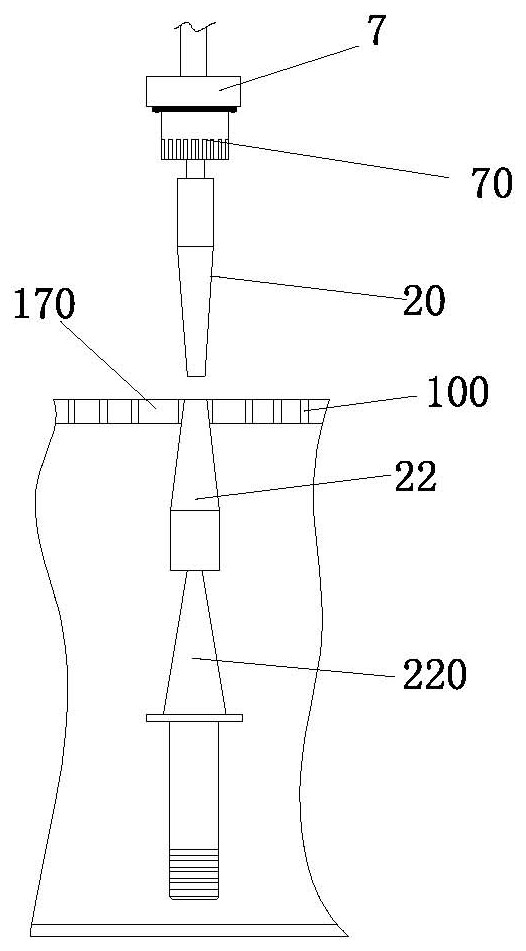

[0027] Example 1: Reference Figure 1-4 , an automatic welding device for medical protective clothing, including a cabinet-type workbench 1, and the two sides of the cabinet-type workbench 1 are respectively provided with side-mounted ultrasonic die heads 5, and the ultrasonic die head is connected to the top of the ultrasonic vibrator 220.

[0028] A conveyor belt 2 is provided on the outside of the side-mounted ultrasonic die head 5, and an electromagnetic clip 201 is provided on the conveyor belt 2. Supports 12 are provided on both sides of the cabinet-type workbench 1, and a top plate 310 is provided on the top of the support 12. , and a more stable structure is: the top of the bracket 12 is connected to the top plate 310 through the gantry frame 321 .

[0029] A guide rail 311 is fixed on the top plate 310, and a slider 312 is arranged on the guide rail 311. One end of the slider 312 is connected with the telescopic mechanism 13 on the top. The telescopic mechanism is one...

example 2

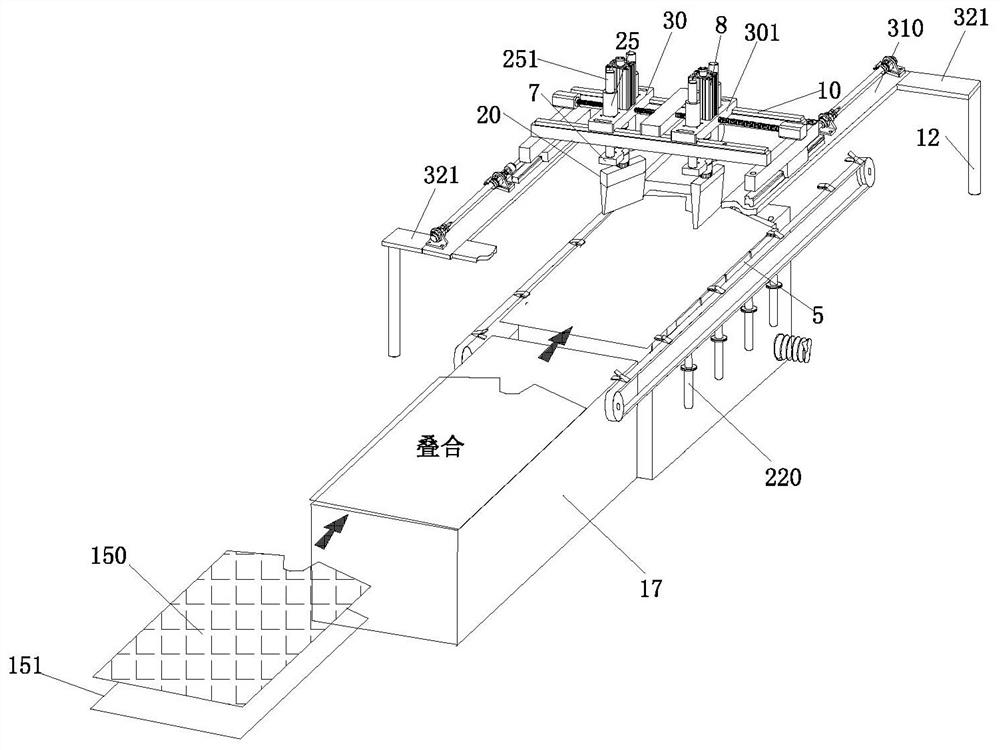

[0037] Example 2: Reference Figure 1-4 , on the basis of example 1, the cabinet type workbench 1 front part is connected with the stacking workbench 17, and the upper cutting piece 150 of the protective clothing body and the lower cutting piece 151 of the protective clothing body are placed on the folding workbench 17. The conveyor belt 2 is extended to the front end of the stacking workbench 17, and the non-woven fabric is cut into the upper cutting piece 150 of the protective clothing body and the lower cutting piece 151 of the protective clothing body, after being stacked on the folding workbench 17, open When the electromagnetic clip 201 passes through the stacking workbench 17, the clip is closed, and the upper part 150 of the protective clothing body and the lower part 151 of the protective clothing body are clamped as a whole to be transported forward, and then passed through the working panel of the cabinet type workbench 1. At the same time, the panel 170 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com