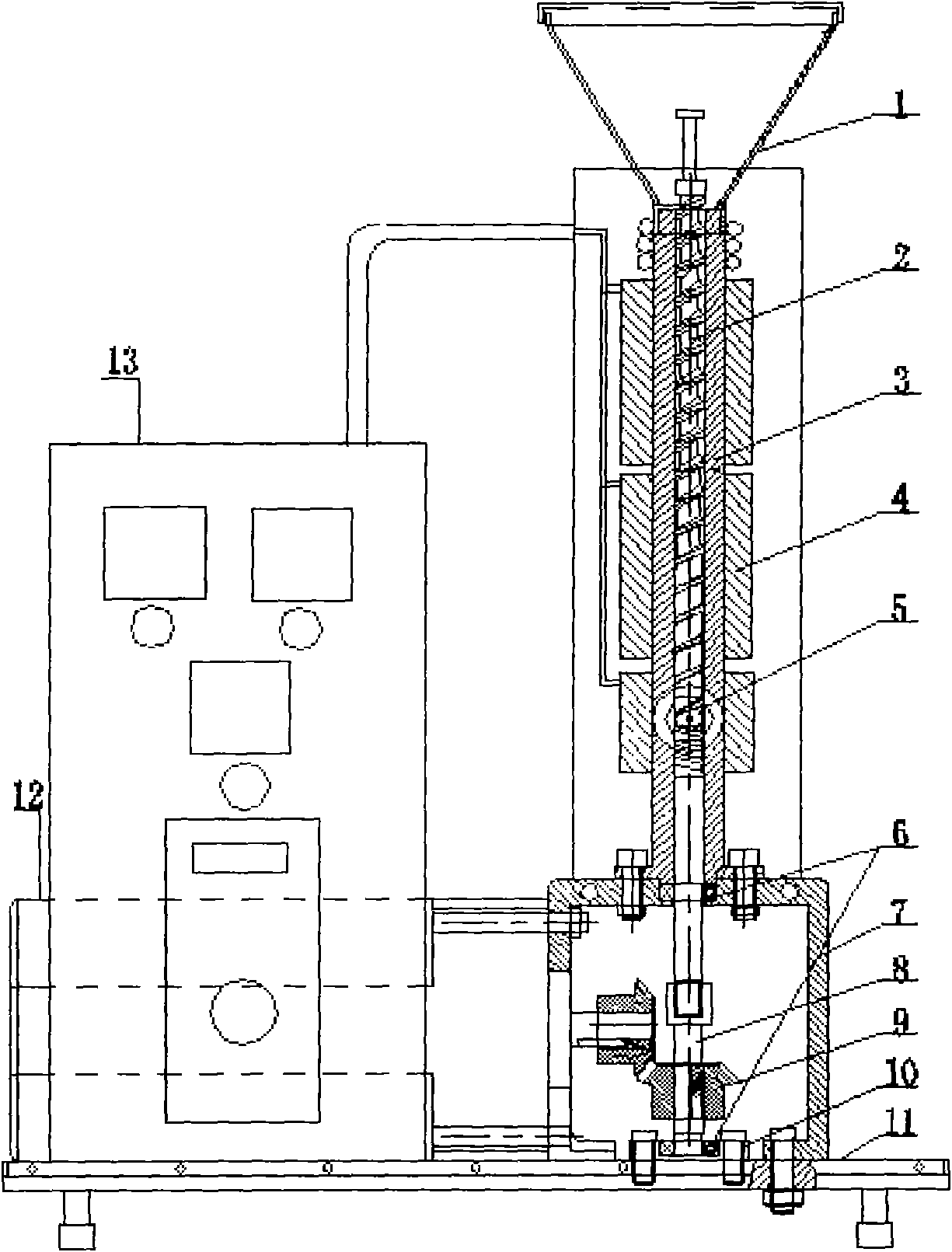

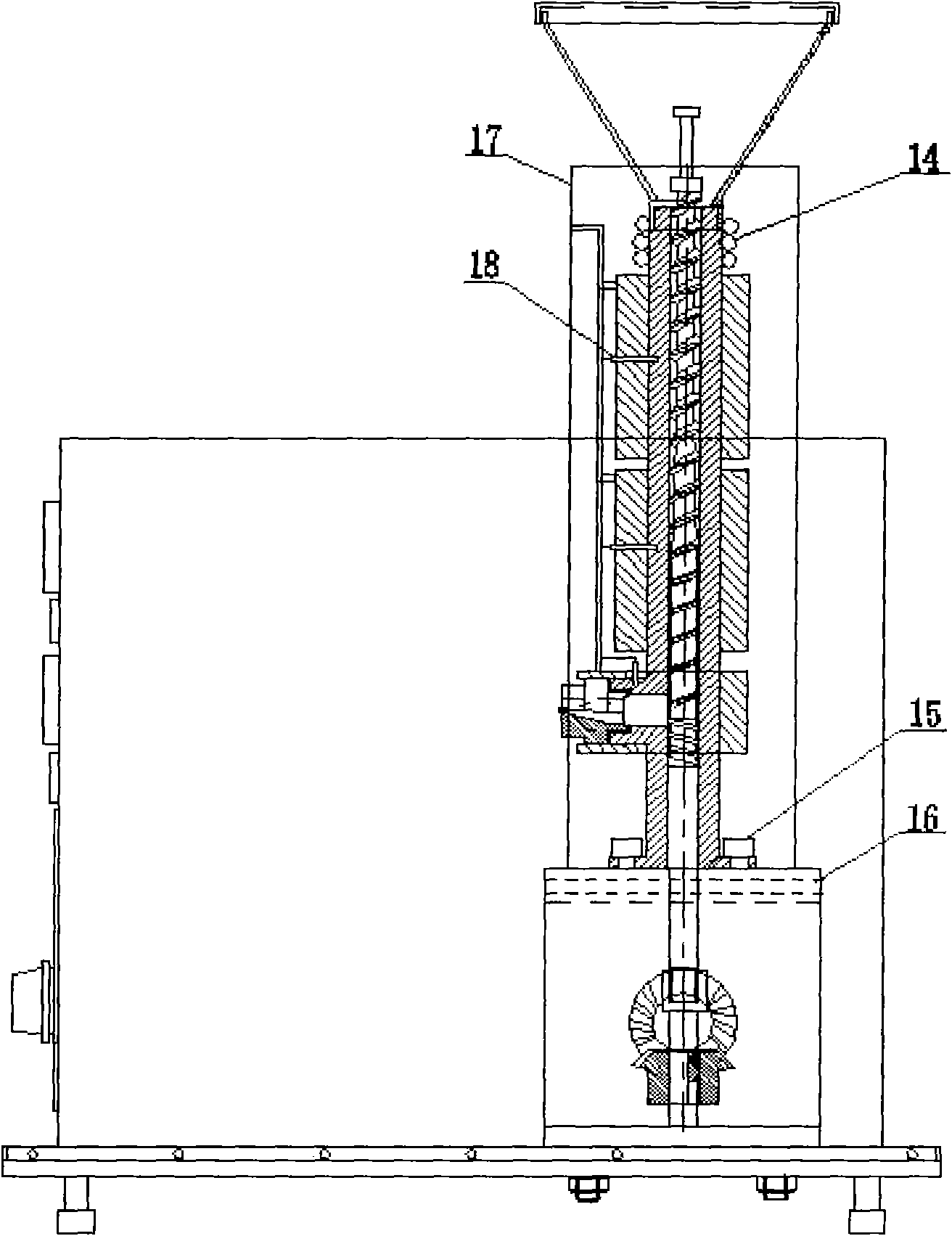

Small micro high-temperature mixing extrusion vertical testing machine

A technology of high-temperature mixing and testing machines, applied in the direction of material inspection products, etc., can solve the problems of large equipment, high processing temperature, and large consumption of raw materials, and achieve the effects of high automation, high working temperature, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Turn on the power of the main machine, connect the cooling water system and heating system, and set the operating temperature to 350°C / 370°C / 340°C (from the feeding port to the machine head) in sequence. Speed the motor until the rotating speed is 50rpm, slowly add the polyimide / polyetheretherketone mixture (the mass fraction of polyimide is 60wt%) into the hopper, and the material is compacted, plasticized, melted and mixed in the barrel, and then passed through the machine The head is extruded, and the extrudate spline is finally obtained. After the experiment is completed, adjust the speed control motor to 0rpm, pull out the screw, and clean the material, or directly use the cleaning material to extrude and clean the screw. After the operation is completed, turn off the heating system and the power supply of the main engine, and stop the cooling water after the whole machine cools down to room temperature.

Embodiment 2

[0013] Turn on the power of the main machine, connect the cooling water system and heating system, and set the operating temperature to 390°C / 420°C / 370°C (from the feeding port to the machine head) in sequence, wait for the temperature to rise to the operating temperature, then keep the temperature for 30 minutes, and turn on the regulator Speed motor until the rotating speed is 40rpm, slowly add the nano-montmorillonite / thermoplastic polyimide mixture (the mass fraction of montmorillonite is 10wt%) into the hopper, and the material is compacted, plasticized, melt-mixed in the barrel and passed through the machine The head is extruded, and the extrudate spline is finally obtained. After the experiment is completed, adjust the speed of the speed regulating motor to 0rpm, pull out the screw to clean the material, or directly use the screw to clean the material to extrude the screw. After the operation is completed, turn off the heating system and the power supply of the main e...

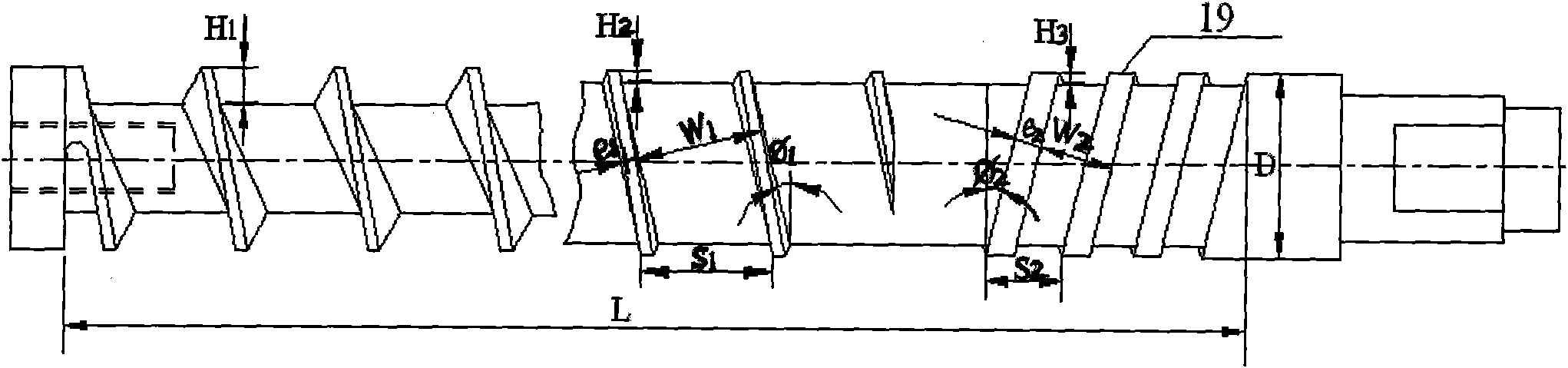

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Thread lead angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com