Fused salt stop device, using method and application

A cut-off device and molten salt technology, applied to valve details, engine components, mechanical equipment, etc., can solve problems such as complex operation, short service life, complex structure, etc., and achieve the effect of large heating area, long service life and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

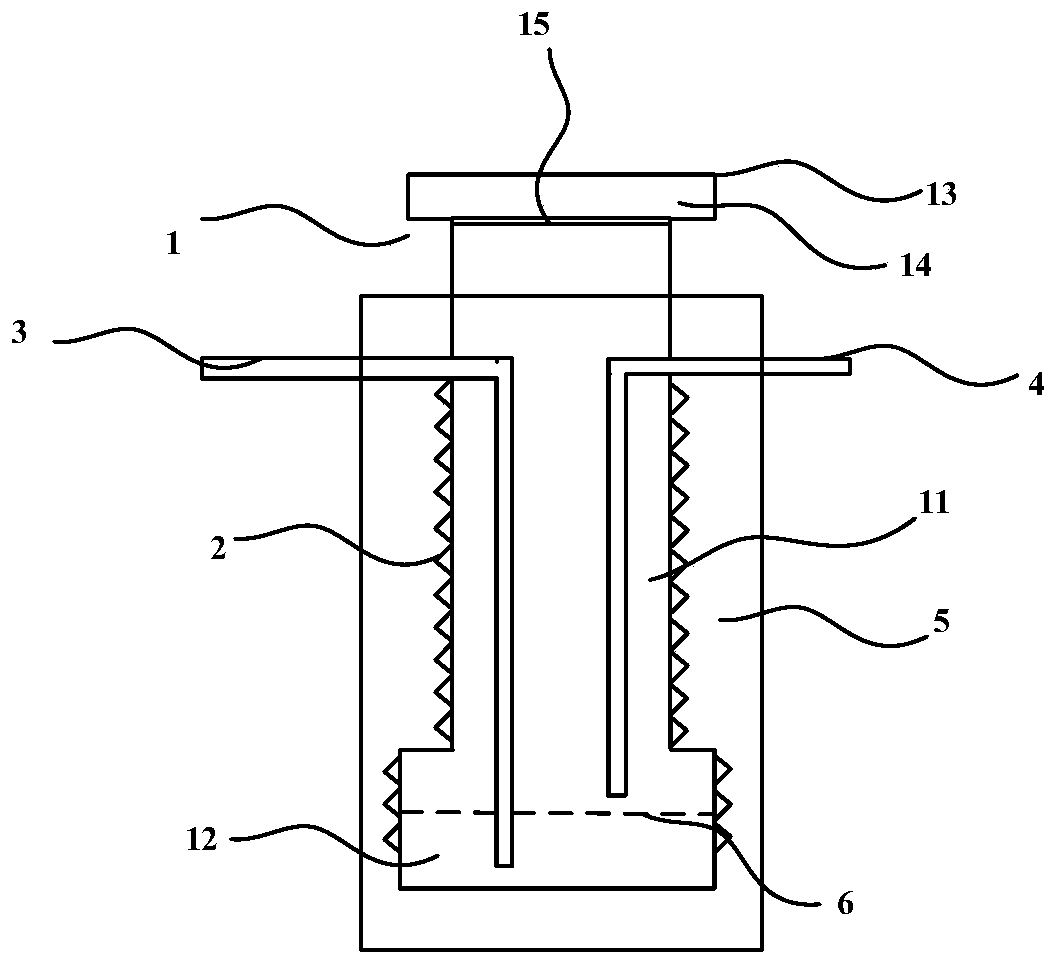

[0050] 1. A molten salt cut-off device is provided in this embodiment, such as figure 1 As shown, it includes a sealed container 1 for loading molten salt 6, an electric heating system 2 for heating the outer wall of the sealed container 1; a first conduit 3 and a second conduit 4; Insulation layer 5 for the outer layer of system 2. The materials used in the molten salt cut-off are all high temperature resistant materials.

[0051] Wherein, the top of the sealed container 1 is provided with a sealing member 13 matching the sealed container 1 , and the sealing member 13 includes a sealing flange 14 and a sealing ring 15 . The airtight container 1 comprises a coaxially arranged neck chamber 11 and a bottom chamber 12 for storing molten salt, the cross sections of the neck chamber 11 and the bottom chamber 12 are circular, and the neck chamber 11 The inner diameter is 50 mm and the inner diameter of the bottom chamber 12 is 100 mm. Wherein the electric heating system 2 is used...

Embodiment 2

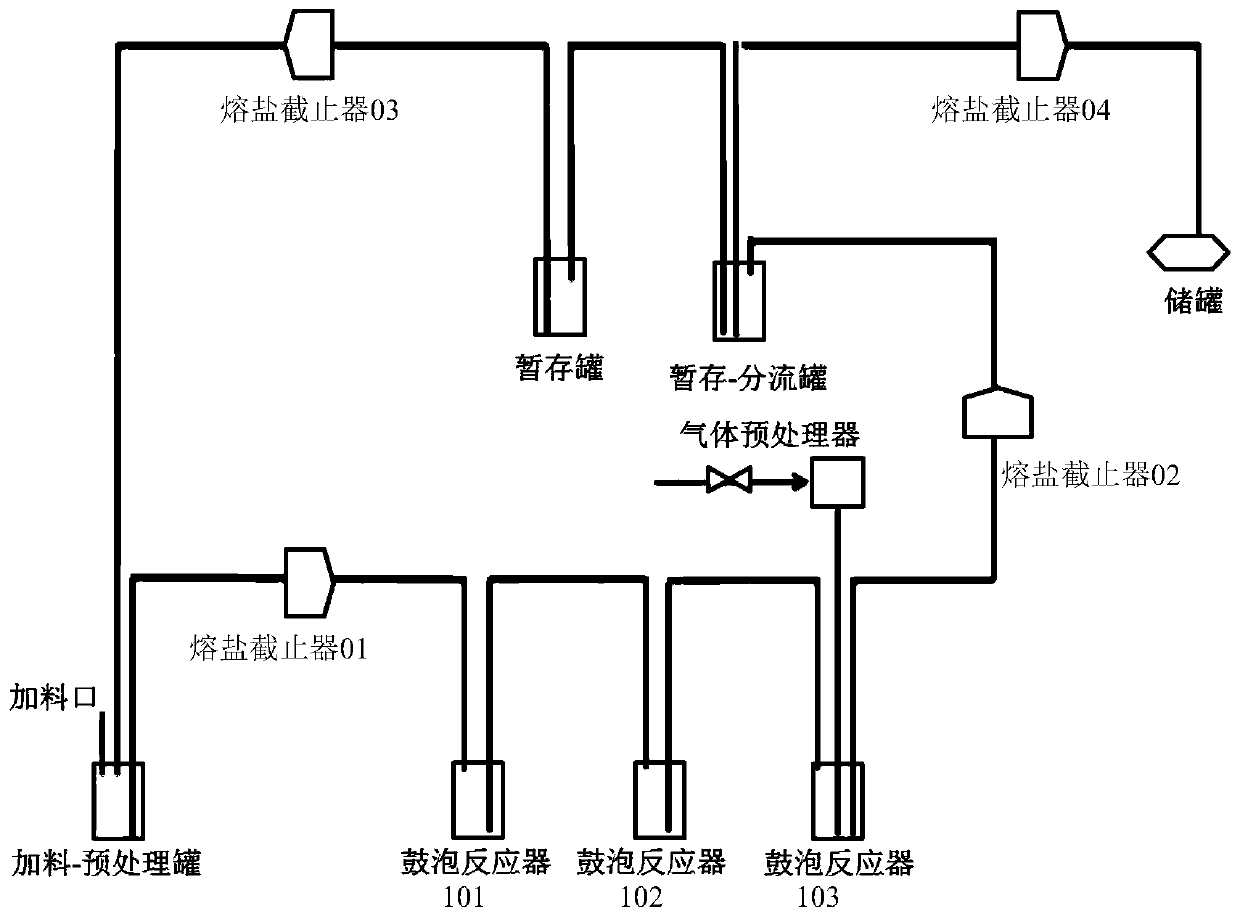

[0058] This embodiment provides an application of the above-mentioned molten salt cut-off device in a FLiNaK molten salt production system.

[0059] Such as figure 2 As shown, the molten salt cut-off device in this embodiment is set in the FLiNaK molten salt production system, which specifically includes the following steps: (1) setting the temperature of each process section according to the process requirements, including feeding-pretreatment tank, each bubbling Reactor, temporary storage-splitter tank, temporary storage tank, storage tank, each molten salt cut-off device and conduits along the way; confirm that the working status of each molten salt cut-off device is "cut off", that is, the molten salt in the molten salt cut-off device is solid (2) inject the material to be purified of LiF, NaF, and KF ternary mixed molten salt from the feed port into the feed-pretreatment tank, and obtain the liquid material after pretreatment; (3) turn on the heat source to make The mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com