Electrolyte conveying device for microelectronic processing

A transportation device and electrolyte technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of affecting the microelectronics processing process, affecting the fluid flow rate, and transporting more electrolytes, so as to facilitate subsequent processing and use, Ensure normal operation and improve transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

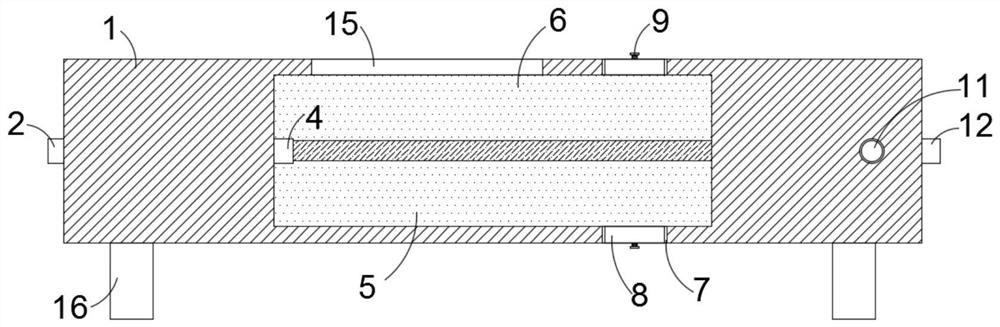

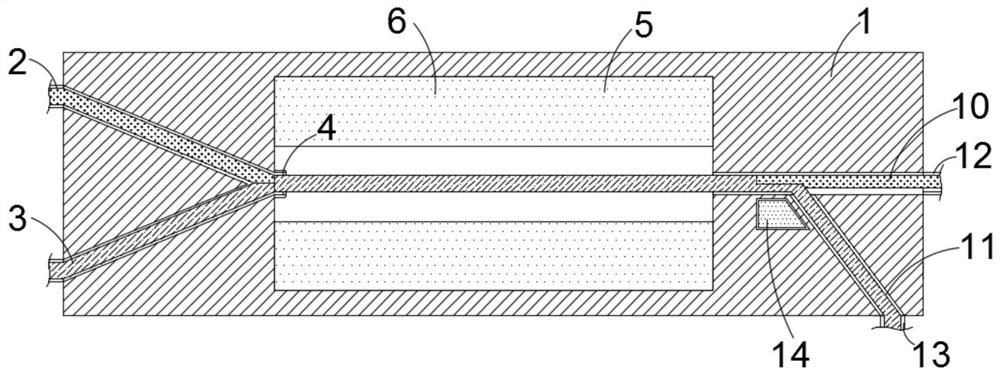

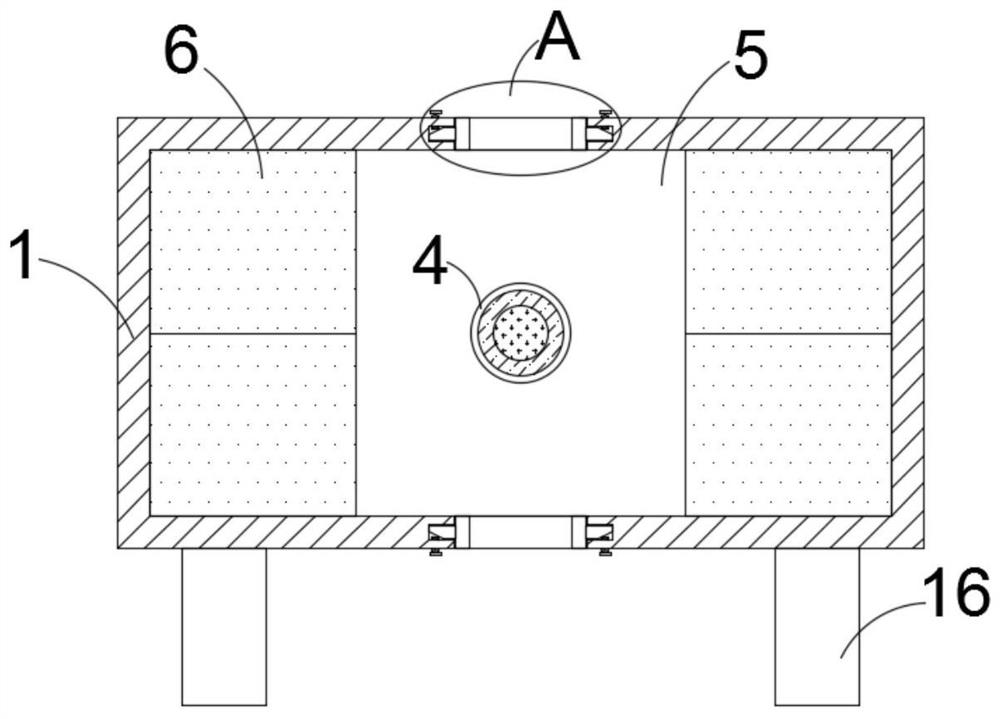

[0022] refer to Figure 1-4 , an electrolyte transportation device for microelectronics processing, comprising a casing 1, a transportation cavity 5 is opened in the casing 1, an infusion channel 3 is arranged in the casing 1, and the infusion channel 3 is arranged in a V shape in the transportation cavity 5, two liquid inlets 2 are fixedly arranged on the side wall of the housing 1, and the two liquid inlets 2 are connected with one end of the infusion channel 3, and the transport chamber 5 is close to the side of the infusion channel 3 A converging port 4 is fixedly arranged on the side wall, and the converging port 4 is connected with the end of the infusion channel 3 away from the liquid inlet 2. The transport chamber 5 is fixedly provided with two sets of magnet strips 6, and the two sets of magnet bars 6 are symmetrically arranged at the converging port. 4, and each group of magnet strips 6 includes two magnet strips 6 stacked together. The liquid channel 10, the liquid...

Embodiment 2

[0026] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that two cut-off magnetic blocks 19 are added, that is, two clamping openings 7, two clamping openings 7, and two clamping openings are opened on the side walls on both sides of the housing 1. Two clamping plates 8 are slidingly arranged inside the mouth 7, and a pushing mechanism corresponding to the clamping plates 8 is provided on the housing 1. The pushing mechanism includes four bolts 9, and two side walls on both sides of the clamping mouth 7 Two telescopic slots 18 are symmetrically opened on the top, and a push plate 17 is fixedly arranged on the side wall of each clamping plate 8 close to the telescopic slot 18, and four push plates 17 are respectively slidably arranged in the four telescopic slots 18. , four bolts 9 respectively penetrate through the two side walls of the housing 1 and communicate with the four telescopic grooves 18, and the two side walls of the housing 1 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com