Patents

Literature

73results about How to "Guarantee process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

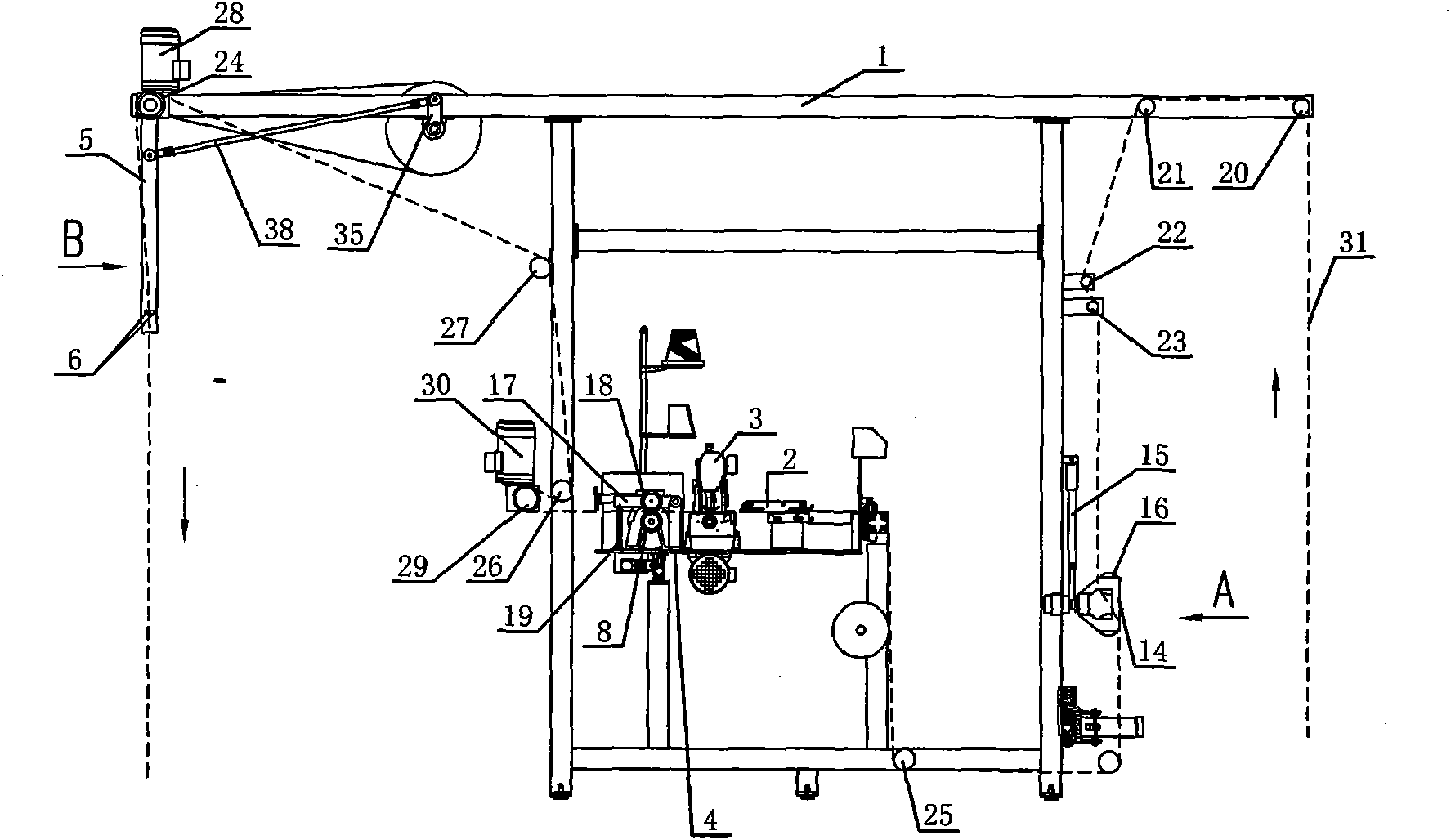

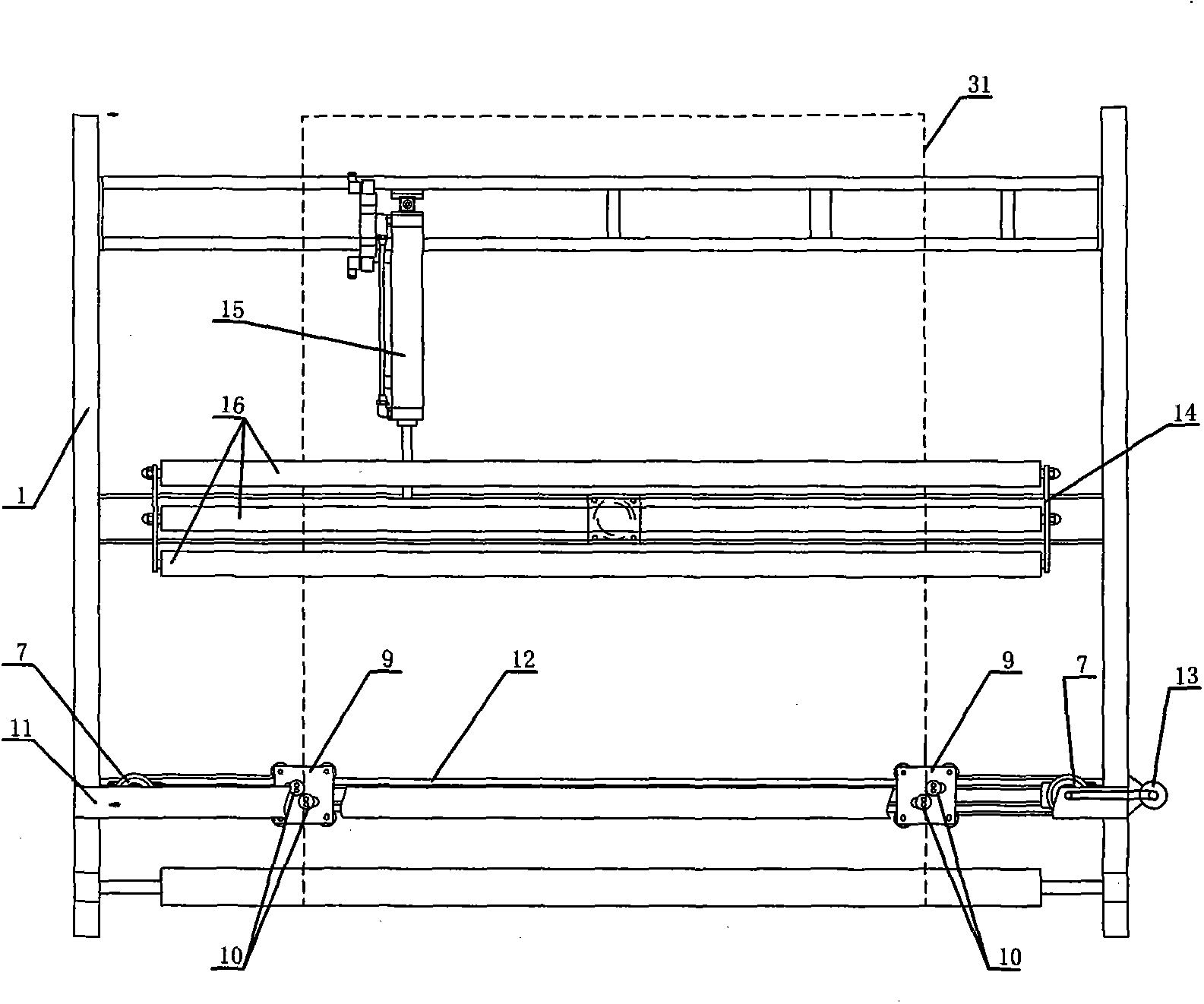

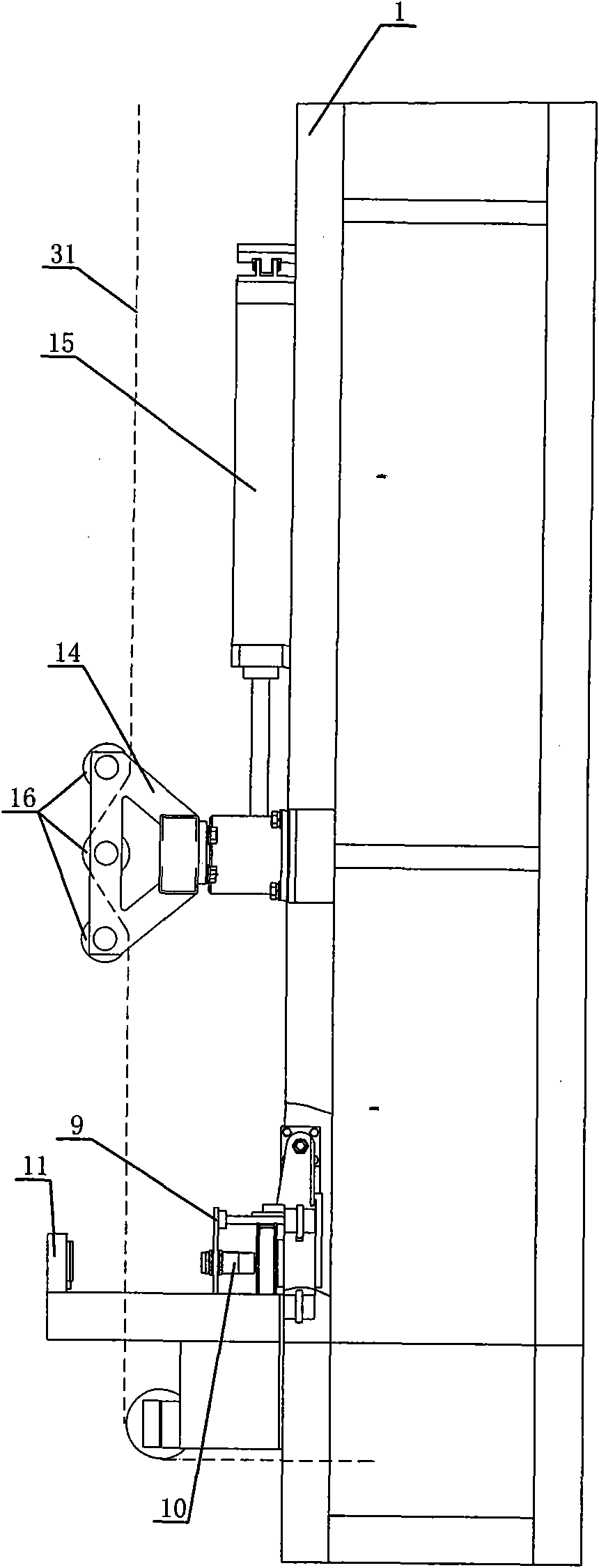

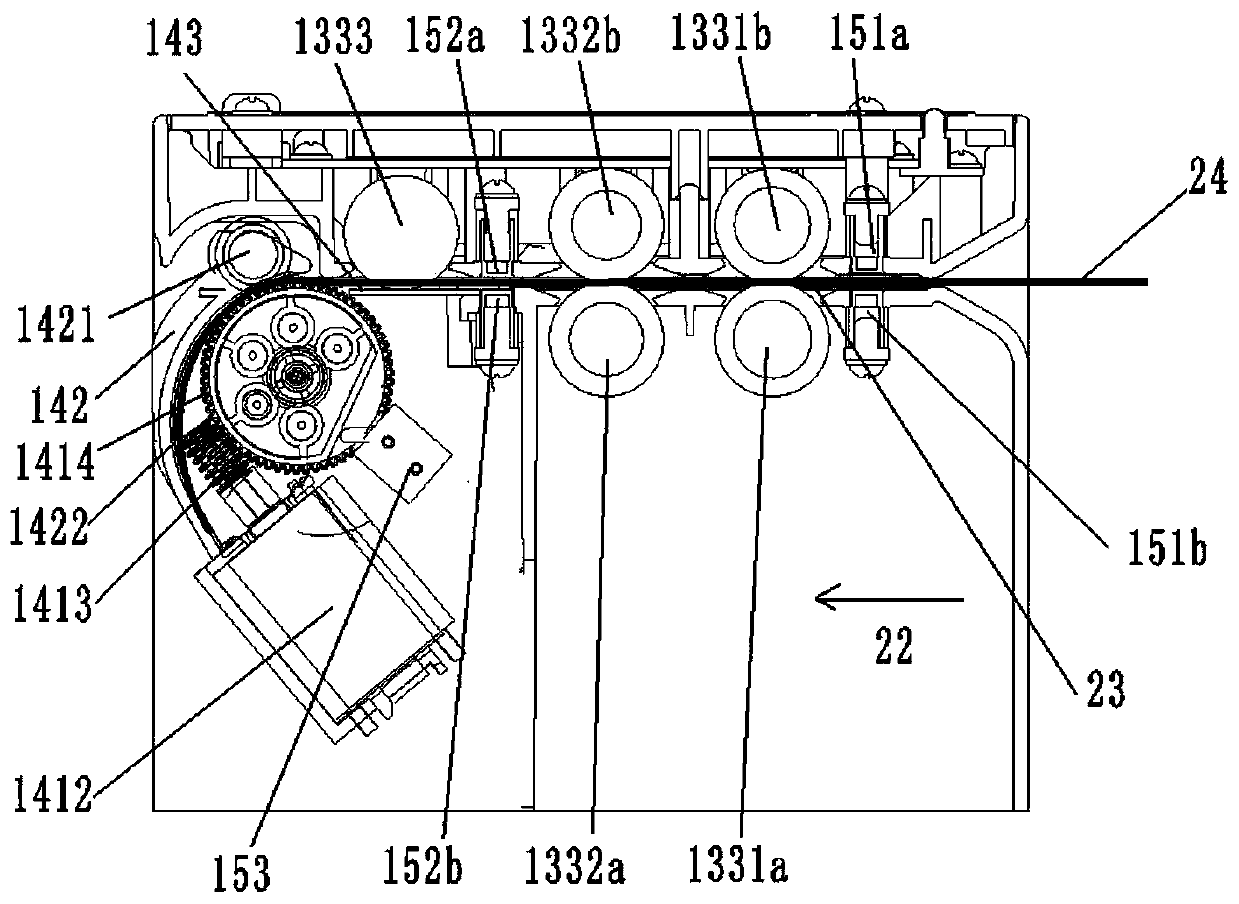

Full automatic deviation rectifying device for cloth

InactiveCN103482395APrevent deviationImprove the correction effectWebs handlingEngineeringMechanical engineering

The invention discloses a full automatic deviation rectifying device for cloth. The device comprises a cloth feed guiding roller group connected to a rack, wherein the cloth feed guiding roller group is provided with a cloth feed deviation rectifying device which comprises two supports, each support is provided with a position finding optoelectronic switch, the rack is provided with reflectors which correspond to the position finding optoelectronic switches in position, the rack is provided with a deviation rectifying roller rack which is arranged along the breadth direction of the cloth, the middle part of the deviation rectifying roller rack is hinged to the rack through a hinge shaft, the deviation rectifying roller rack is provided with at least two deviation rectifying rollers which are arranged in an upper and lower staggered manner along the running direction of the cloth, the rack is also provided with a deviation rectifying air cylinder arranged along the advancing direction of the cloth, the hinged part of a piston rod of the deviation rectifying air cylinder and the deviation rectifying roller rack is positioned at one side of the middle part of the deviation rectifying roller rack, and the position finding optoelectronic switches and a deviation rectifying power mechanism are controlled by a PLC. The full automatic deviation rectifying device can be used for effectively preventing the cloth from being deviated in the running process, has a good deviation rectifying effect and can effectively ensure the subsequent edge cutting or edge covering working procedure.

Owner:GAOMI ZHONGHE GARMENT

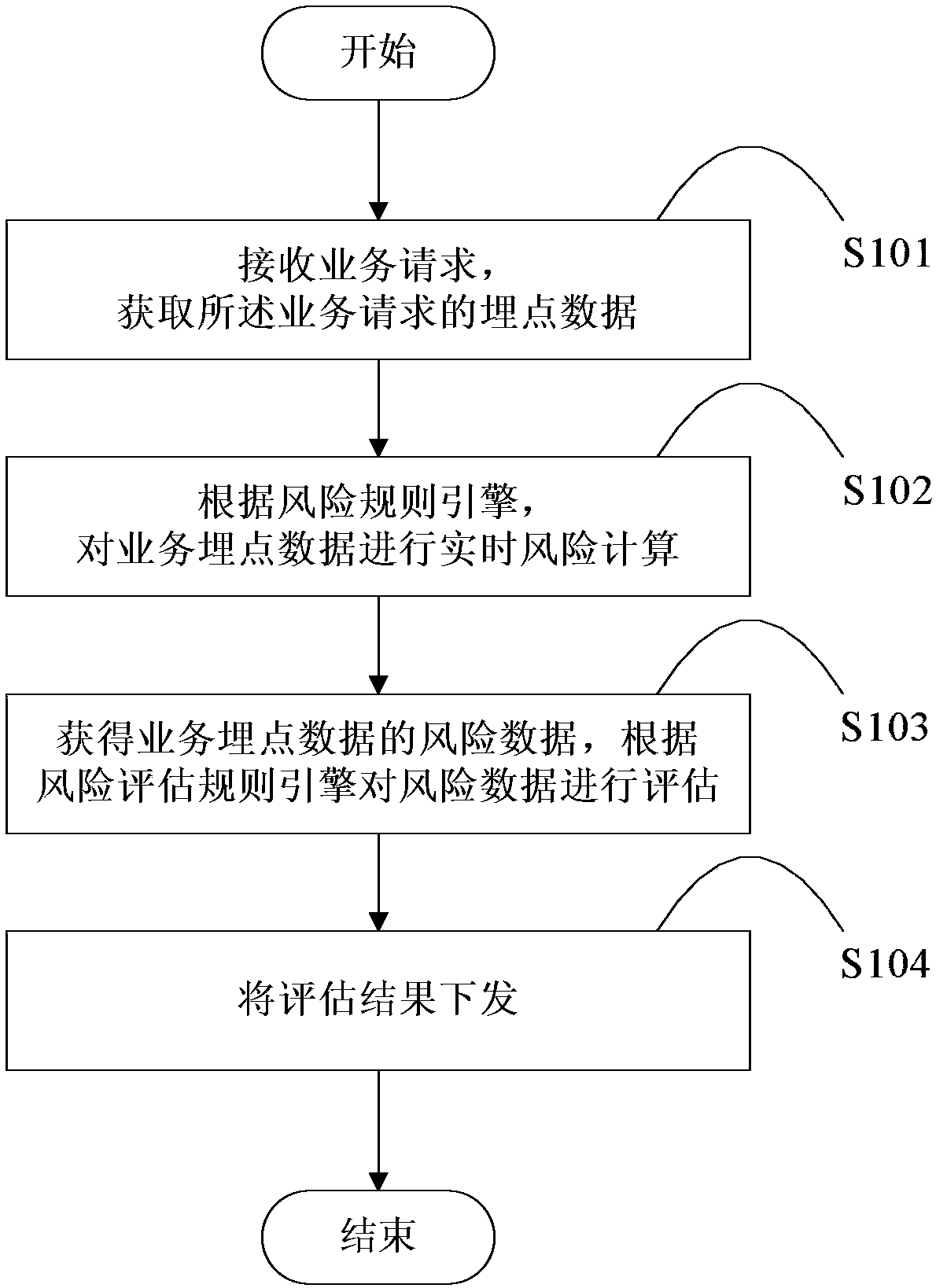

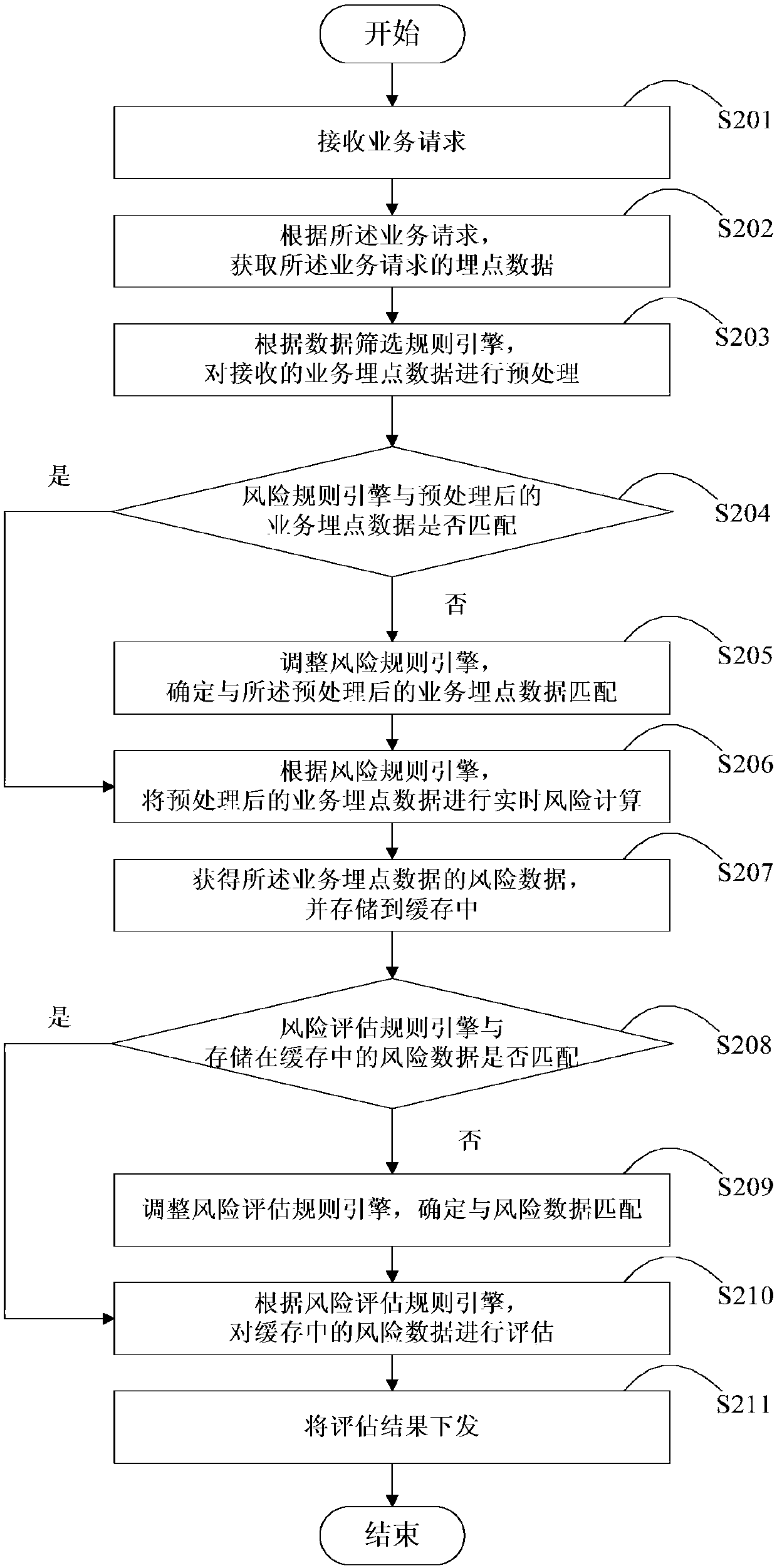

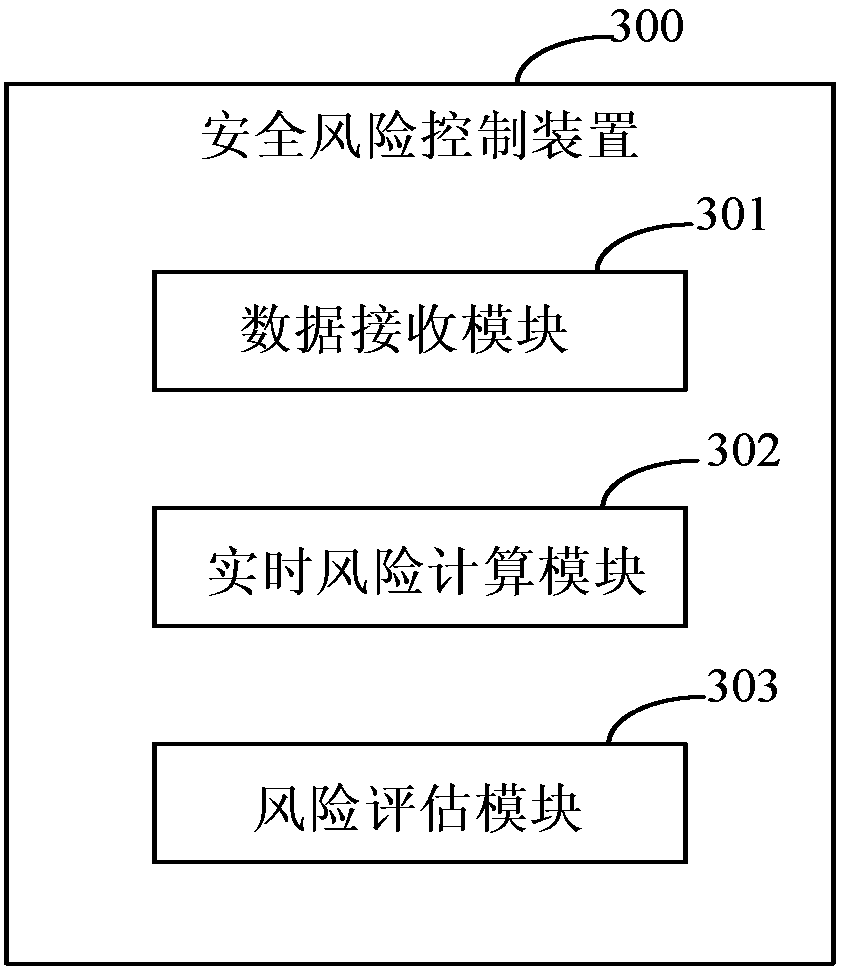

Safety risk control method and device

The invention discloses a safety risk control method and device and relates to the field of computer technology. One concrete implementation method of the method includes receiving a service request,acquiring buried point data of the service request; performing real time risk calculation on the service buried point data according to a risk rule engine; acquiring risk data of the service buried point data and performing evaluation on the risk data according to a risk evaluation rule engine so as to deliver an evaluation result. The implementation method can solve problems of high cost and slowresponse of a prior risk control system.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

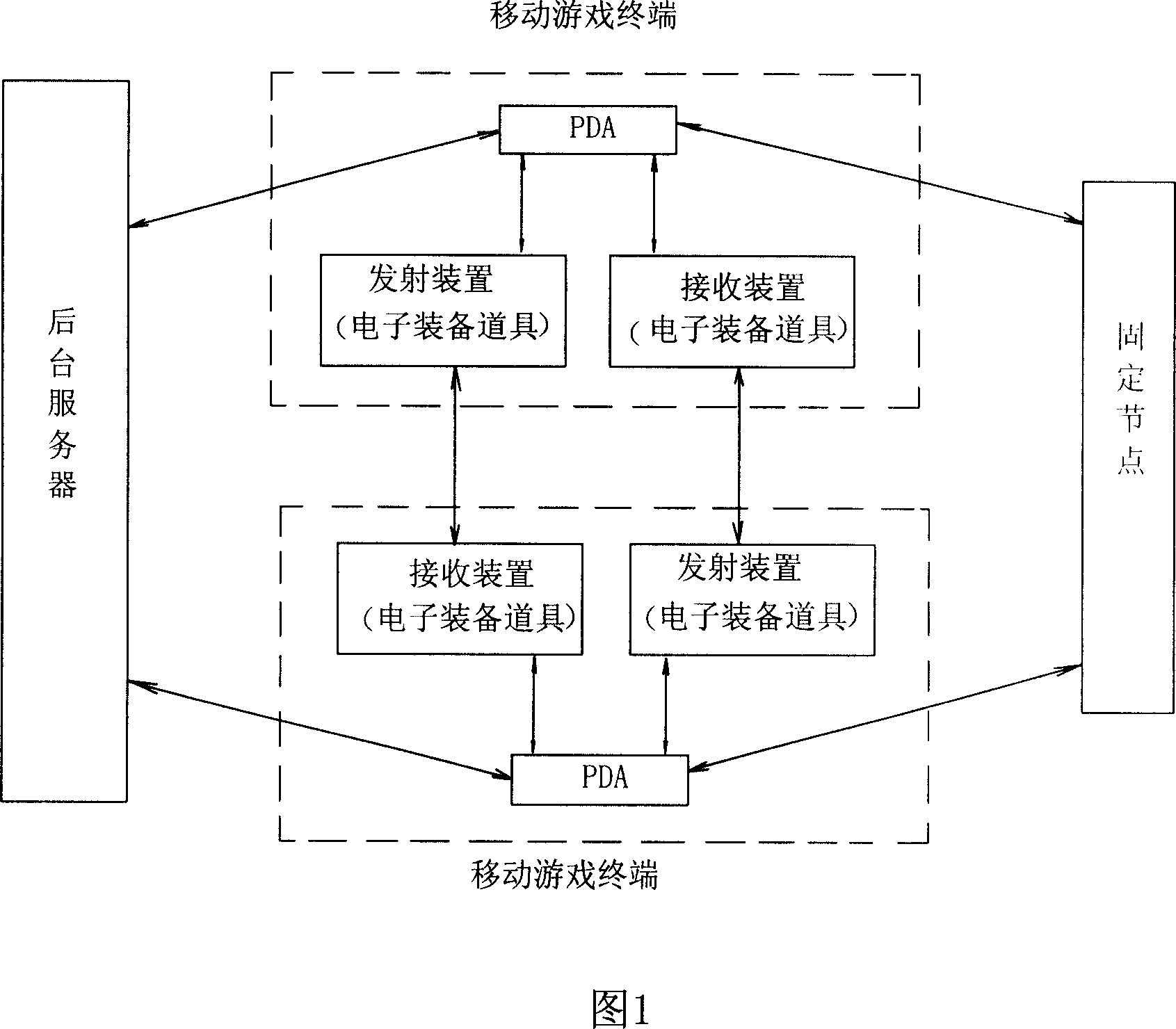

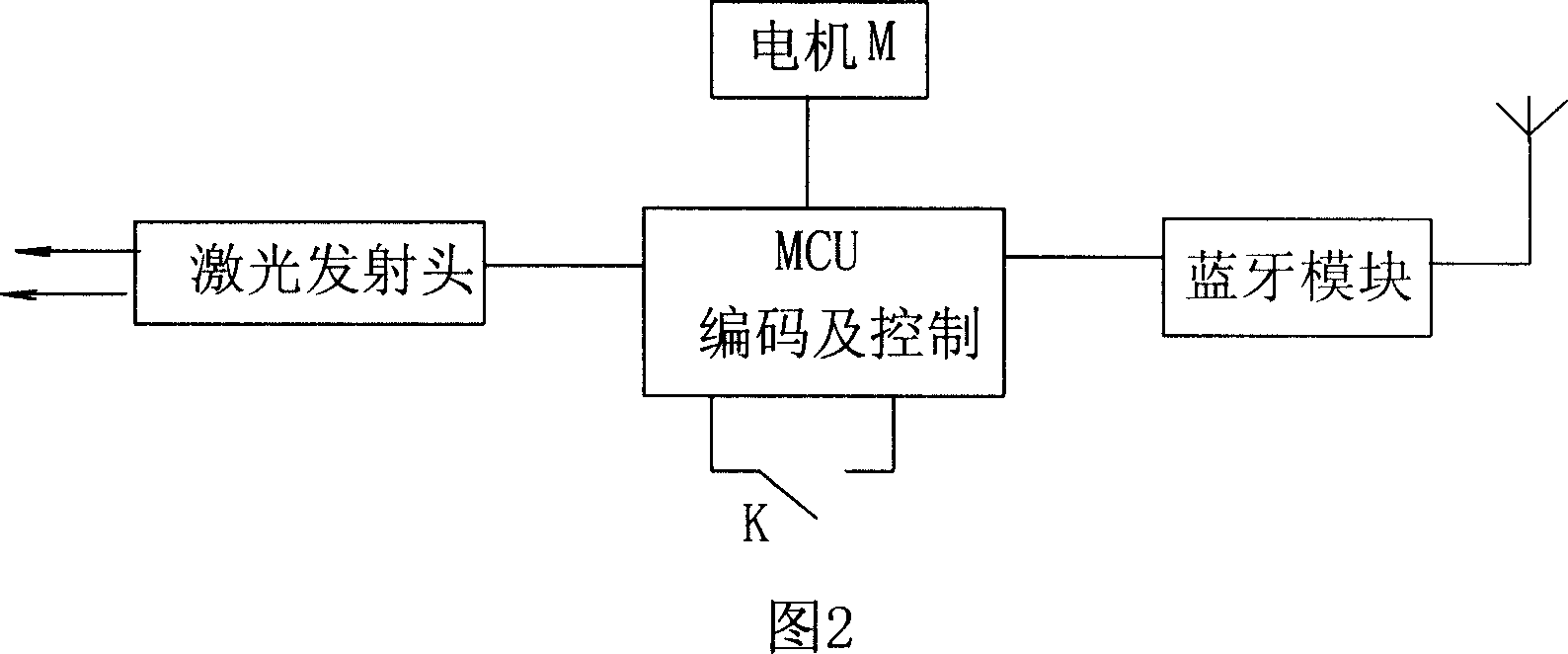

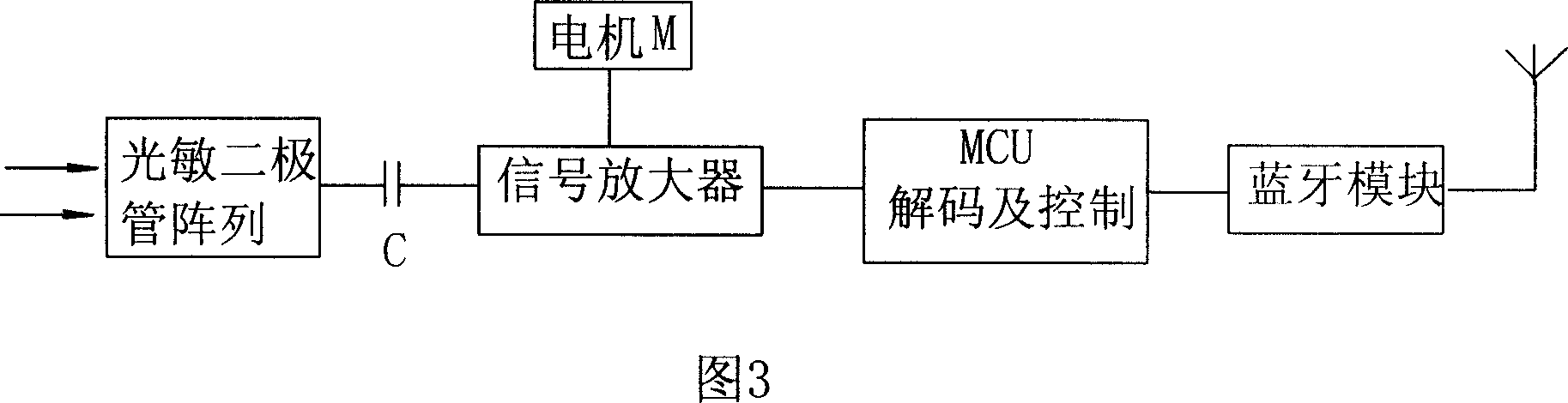

Method and system for limited background interactive game

InactiveCN1932828APleasant experienceEasy to carrySpecial data processing applicationsThree-dimensional spaceBluetooth

The method and system for mutual game with limited real-image, for setting background server and player that can move in three-dimensional space. Each player owns PDA palmtop computer connecting with background server in wireless local area network standard. It is a background server with center controlling function and owns game ending movable in limited three-dimensional space. The game ending is PDA palmtop computer and each of them connects with background server in wireless local area network standard. The endings respectively set with sending equipment in wireless information to other player and accepting ending to incept the wireless information form other players. The sending and accepting ending connects with PDA palmtop computer's ending respectively by Bluetooth. This can make player move in the limited three-dimensional space freely to carry real-image mutual game.

Owner:北京时代美兆数字科技有限公司

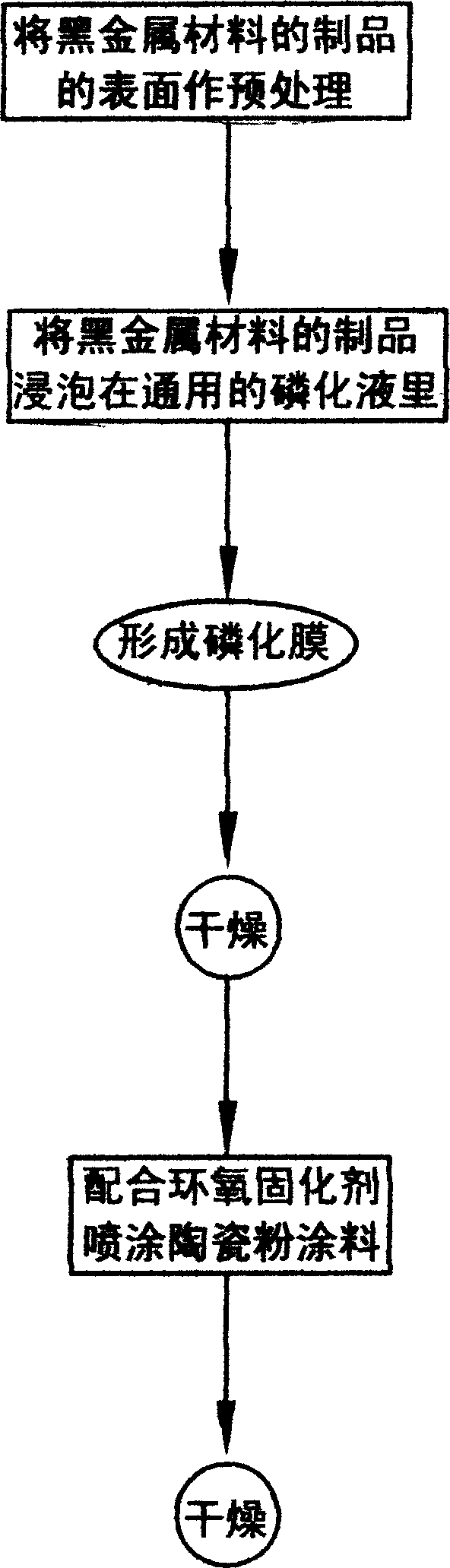

Technological process of making ferrous metal surface anticorrosive, antiwear, antishock and insulating

The technological process of making ferrous metal surface become anticorrosive, antiwear, antishock and insulating includes the following steps: surface pre-treatment of the ferrous metal product to eliminate oil, bur and rust; soaking the product inside phosphorizing solution for 5-60 min to form one layer of highly attached phosphide film; drying; spraying ceramic powder paint comprising cermet powder 35-85 wt%, epoxy resin 15-55 wt% and toughening agent 1-20 wt%, to the surface of the product; and curing naturally or via heating.

Owner:邹志尚

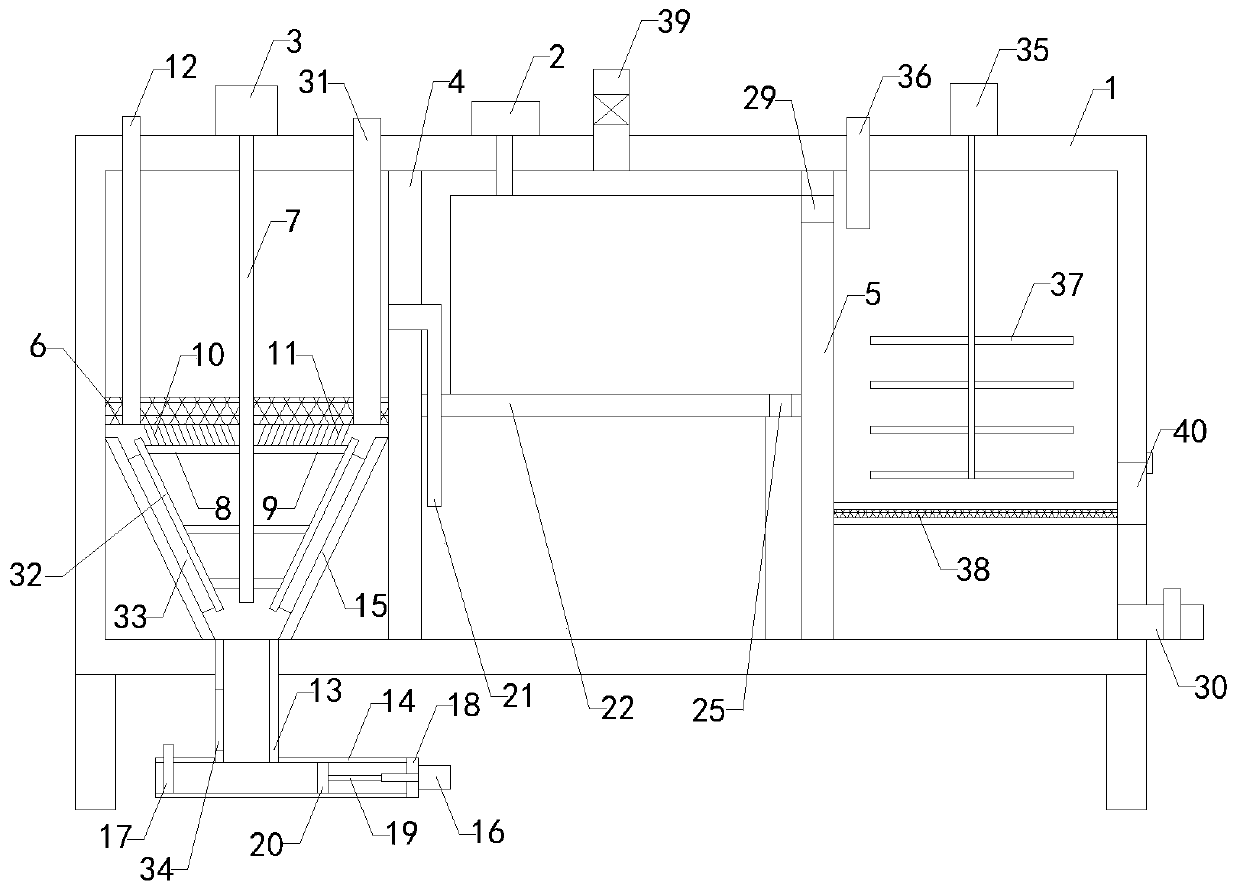

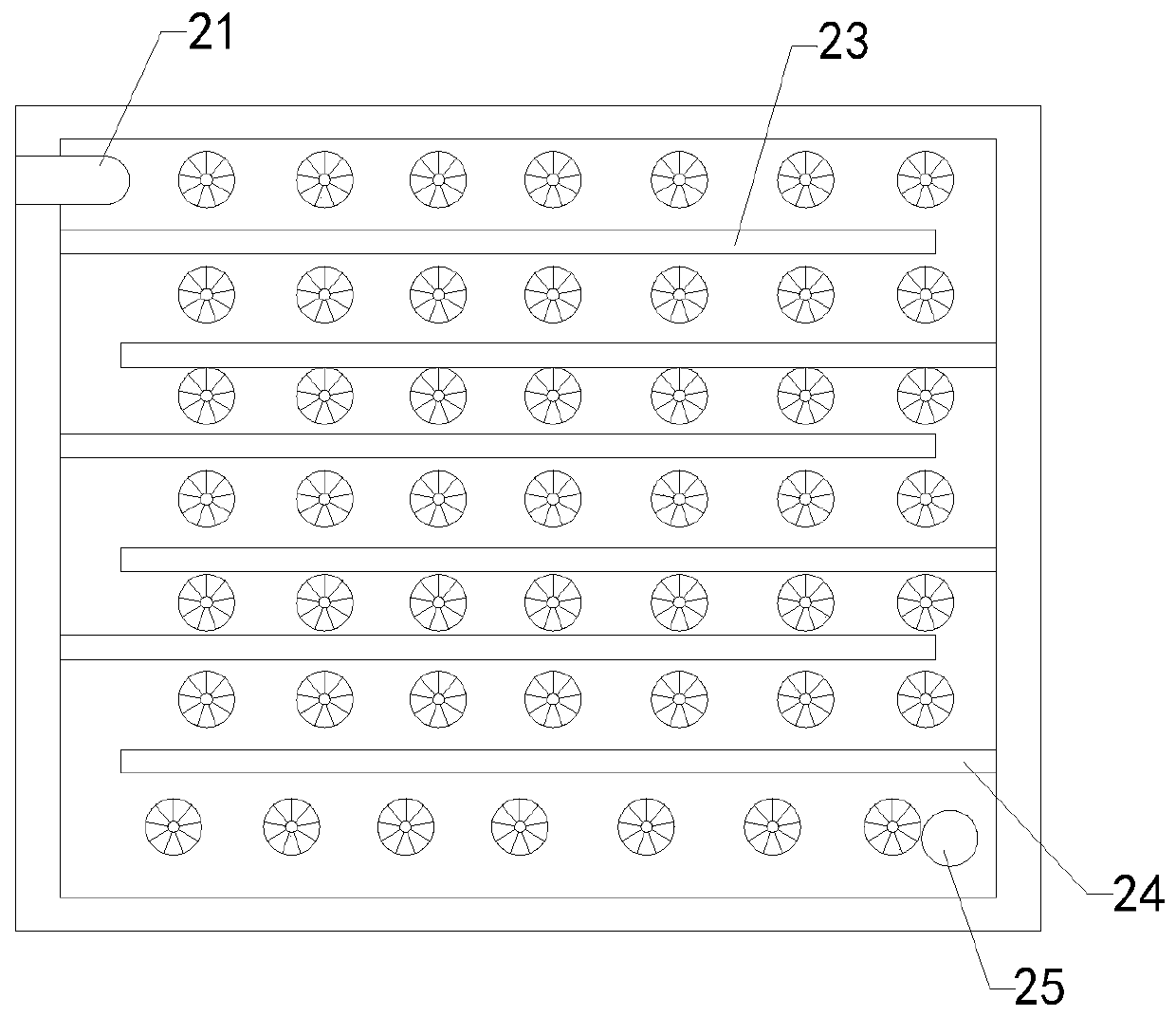

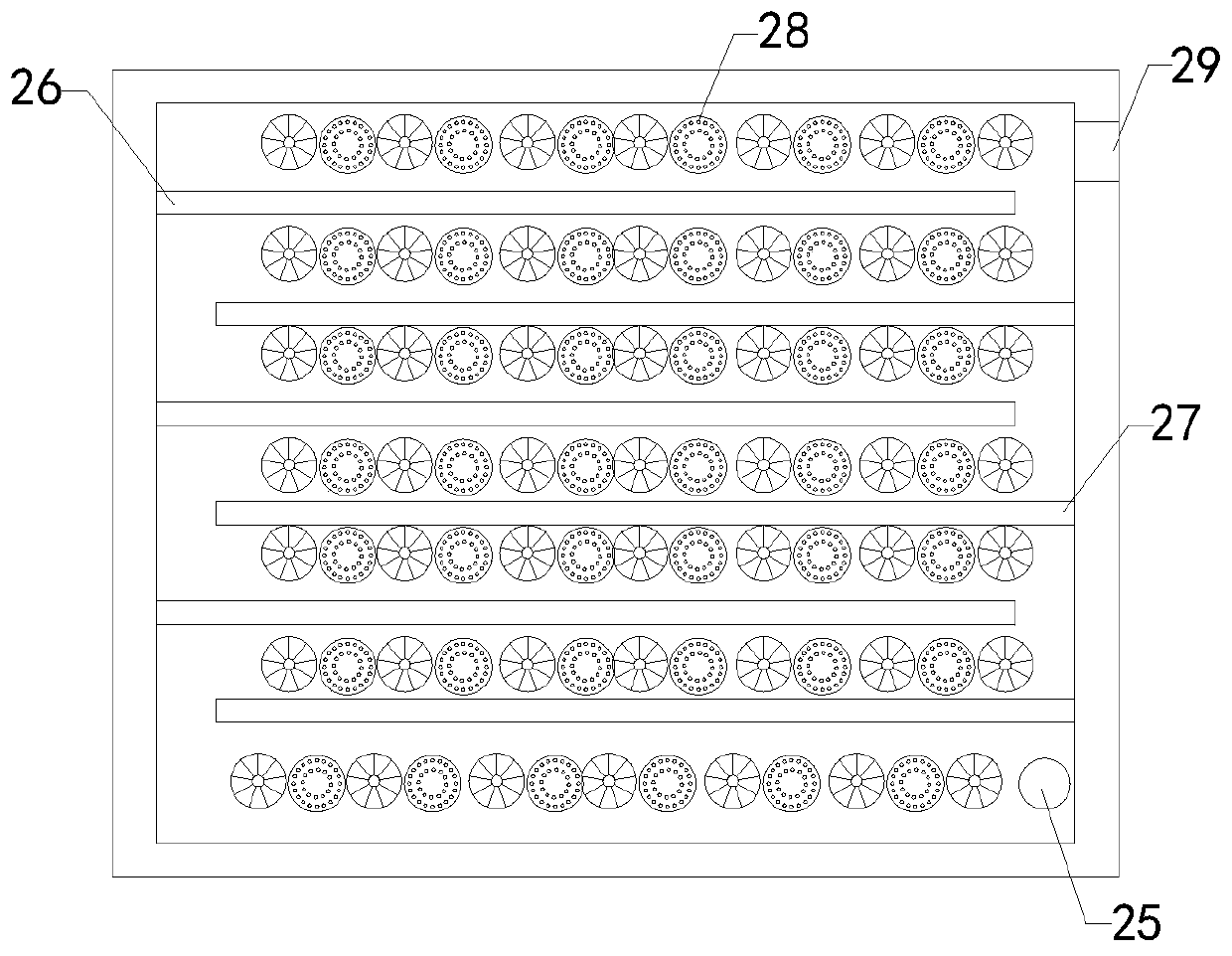

Organic matter removal device for water body ecological maintenance

InactiveCN109851164AAvoid blockageImprove processing efficiencyWater contaminantsMultistage water/sewage treatmentDraining tubeDecomposition

The invention relates to the technical field of water body purification accessory devices. The invention relates to an organic matter removal device, in particular to an organic matter removal devicefor water ecological maintenance. The device can effectively prevent the filter screen from being blocked by impurities in sewage, ensures the sewage treatment process, improves the practicability, isconvenient to clean sludge in the filter cavity, improves the use reliability, effectively shortens the decomposition time of the sewage in the oxidation cavity, and improves the sewage treatment working efficiency. The organic matter purification device comprises a box body and an aeration device. A placing cavity is formed in the box body. The device further comprises a gear motor, a first separation plate, a second separation plate, fa ilter screen, a rotating shaft, multiple sets of left stirring rods, multiple sets of right stirring rods, a left cleaning brush, a right cleaning brush, awater inlet pipe, a drainage pipe, a sludge pipe, a flow guide pipe, a telescopic cylinder, a gate plate, a fixing plate, a telescopic rod, a sealing plate, a third separation plate, multiple sets offirst left flow guide plates, multiple sets of first right flow guide plates, multiple sets of second left flow guide plates, multiple sets of second right flow guide plates, multiple sets of aerationdiscs, and a drainage pipe.

Owner:HEFEI GREENERY GARDENS ENG

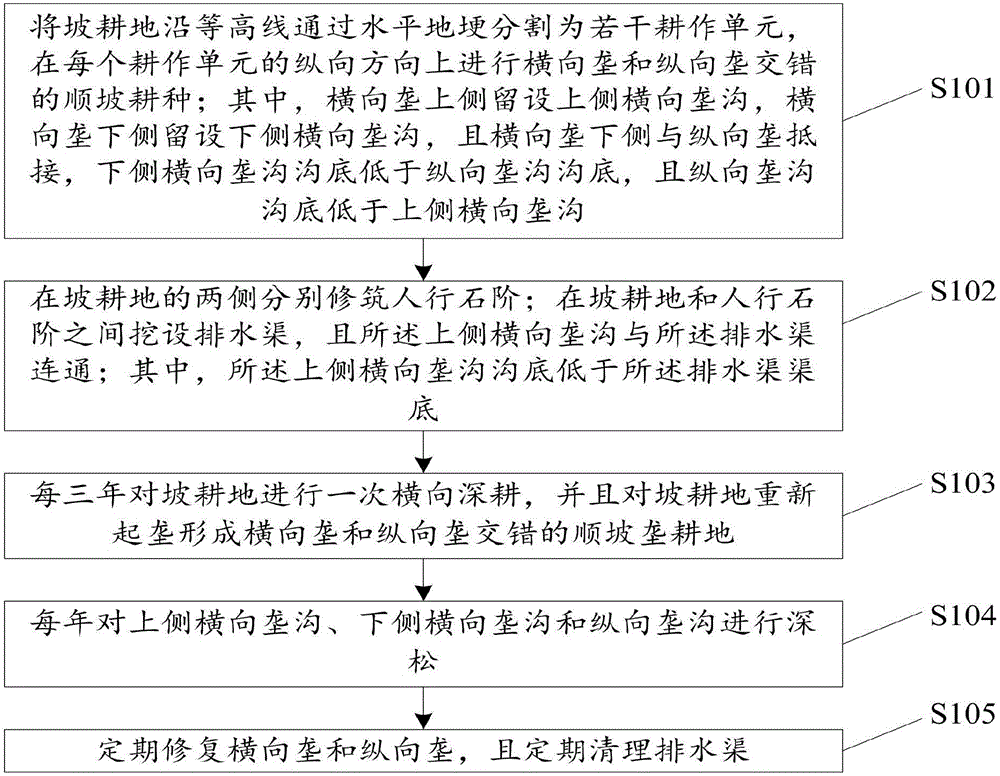

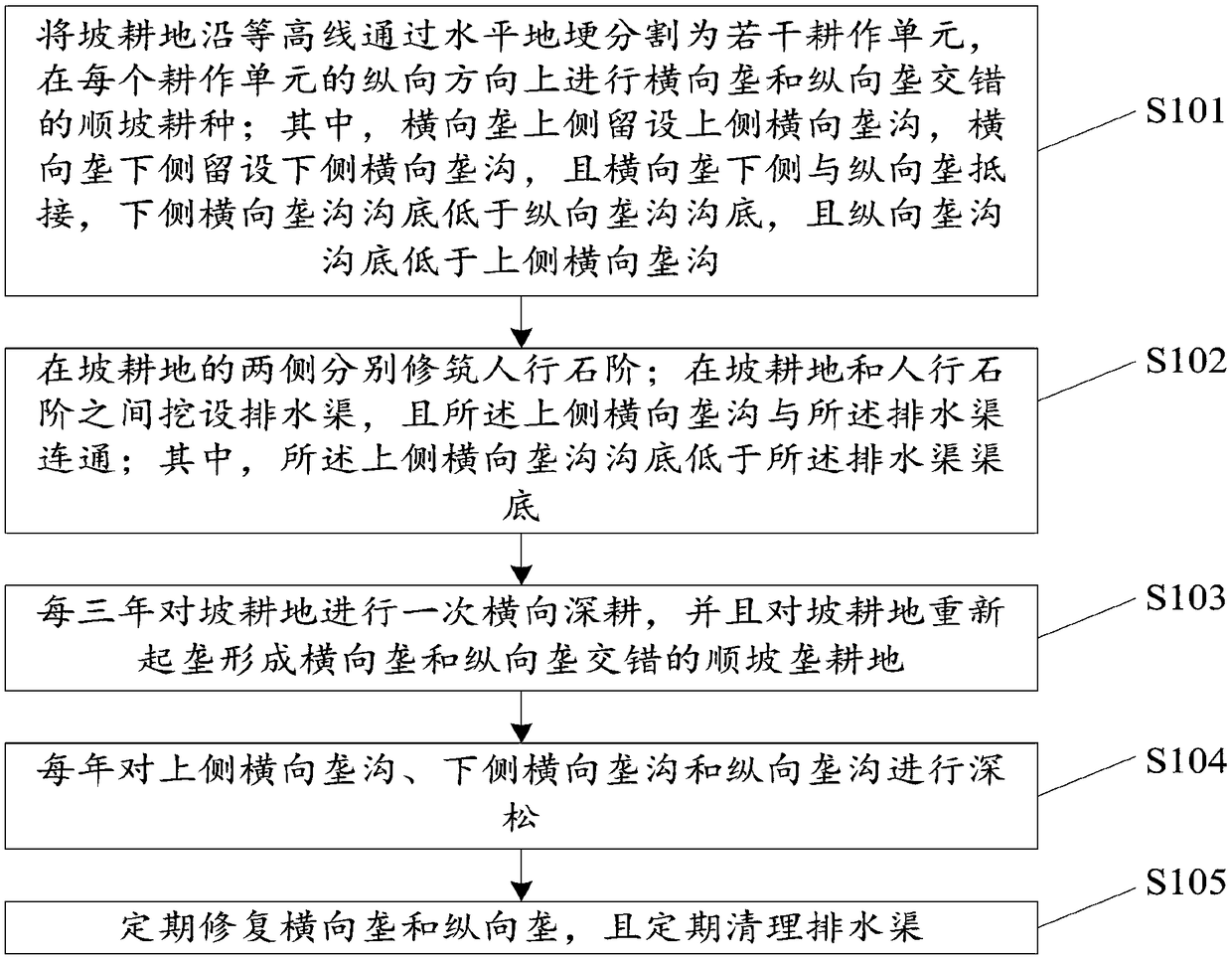

Tillage combination method for soil and water conservation of sloping farmland

InactiveCN106817943AAvoid churnReduce churnClimate change adaptationSoil-working methodsLongitudinal furrowScarification

The invention discloses a tillage combination method for soil and water conservation of sloping farmland, relating to the field of tillage methods for soil and water conservation. The tillage combination method comprises that slope land is divided into several farming units along the contour lines though level terraces; alternate sloping tillage of longitudinal tillage and transverse tillage are performed in the longitudinal direction of each tillage unit; pedestrian stone steps are constructed on both sides of sloping farmland; a drainage ditch is dug between the sloping fields and the pedestrian stone steps and transverse furrows and drainage channels are connected; every three years, the transverse tillage is performed on the sloping farmland and the slope is ridged again; the furrows are deeply scarified each year; After heavy rainfall, transverse furrow and longitudinal furrow are repaired and the drainage ditch is cleaned. The tillage combination method combines short ridge farming, the terraces, the pedestrian stone steps, the drainage ditch, deep tillage and deep scarification, periodic repairing furrow and cleaning drains regularly to form a new tillage combination of sloping farmland, so as to reach the purpose of soil and water conservation of sloping land and crop yield increasing.

Owner:JILIN ACAD OF AGRI SCI

Method for monitoring height of step formed by photosensitive mask etched silicon carbide material in real time

ActiveCN103247549AGuaranteed device performanceSpeed up the processSemiconductor/solid-state device testing/measurementMask layerMaterials science

The invention discloses a method for monitoring the height of a step formed by photosensitive mask etched silicon carbide material in real time, the method comprises the following steps: a plurality of step height monitoring patterns are arranged on a silicon carbide material and are etched together with to-be-etched patterns, when the etching height is required to be detected, the photosensitive mask layer on the periphery of one of step height monitoring patterns is removed, so that monitoring of step height is performed. The method ensures real time monitoring and precision control of step height when the silicon carbide is etched through a drying method by utilizing a manner that the step height monitoring pattern areas are not developed after being exposed for many times, thereby effectively ensuring improvement of the performance of devices and operation of process flow.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

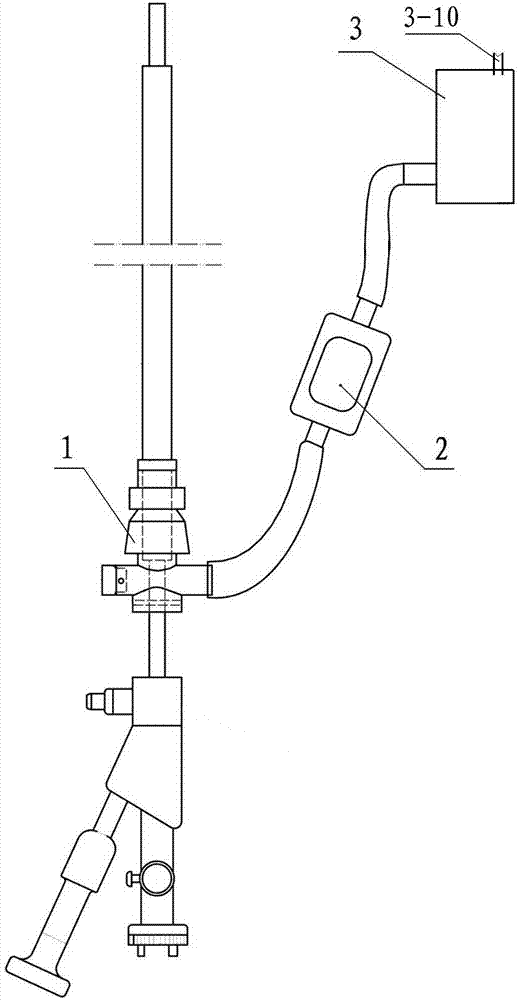

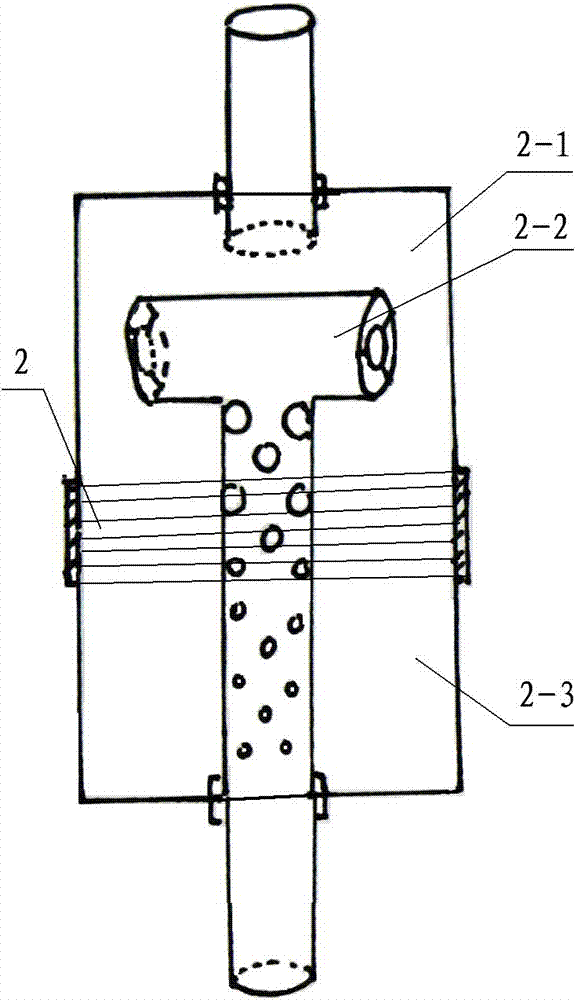

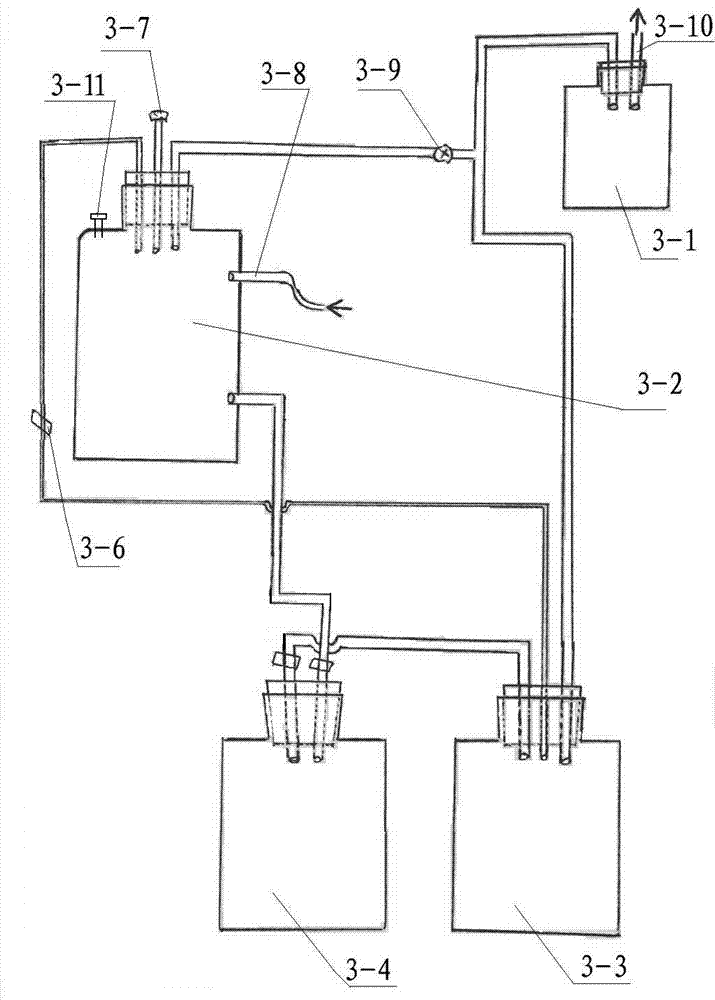

Broken stone collection and filtration device with convection negative-pressure channel

PendingCN106937876AAvoid cloggingNegative pressure continues to be stableSurgeryIntravenous devicesMedical equipmentSuction force

The invention discloses a broken stone collection and filtration device with a convection negative-pressure channel, and relates to the technical field of medical equipment. The broken stone collection and filtration device comprises a broken stone collection and filtration device and a negative-pressure collection system, wherein the broken stone collection and filtration device comprises a cavity formed by connecting an upper cavity body and a lower cavity body through threads; the upper cavity is provided with a connector communicated with a broken stone mixed solution outlet; the cavity is internally provided with a filtering column with one end stretching out of the lower cavity body; a plurality of through holes with pore diameters which are gradually reduced are formed in a column body of the filtering column; the negative-pressure collection system comprises a main negative-pressure bottle communicated with a negative-pressure source, a sedimentation bottle communicated with the main negative-pressure bottle, and a negative-pressure buffering bottle; a mixed solution inputting pipe and a flow fine tuning valve are arranged at the upper part of the sedimentation bottle, and a storage bottle is communicated with the lower part of the sedimentation bottle; the negative-pressure buffering bottle is communicated with the sedimentation bottle and the storage bottle. By adopting the broken stone collection and filtration device disclosed by the invention, the problems that tangible things in a mixed solution flowing out in a stone surgery are easily mutually stuck and accumulated on a filter screen and blocking is caused, so that a negative-pressure suction force in a surgery pipeline is weakened and even disappeared are solved, and definitely effective and visible continuous negative-pressure suction is kept.

Owner:庞广富

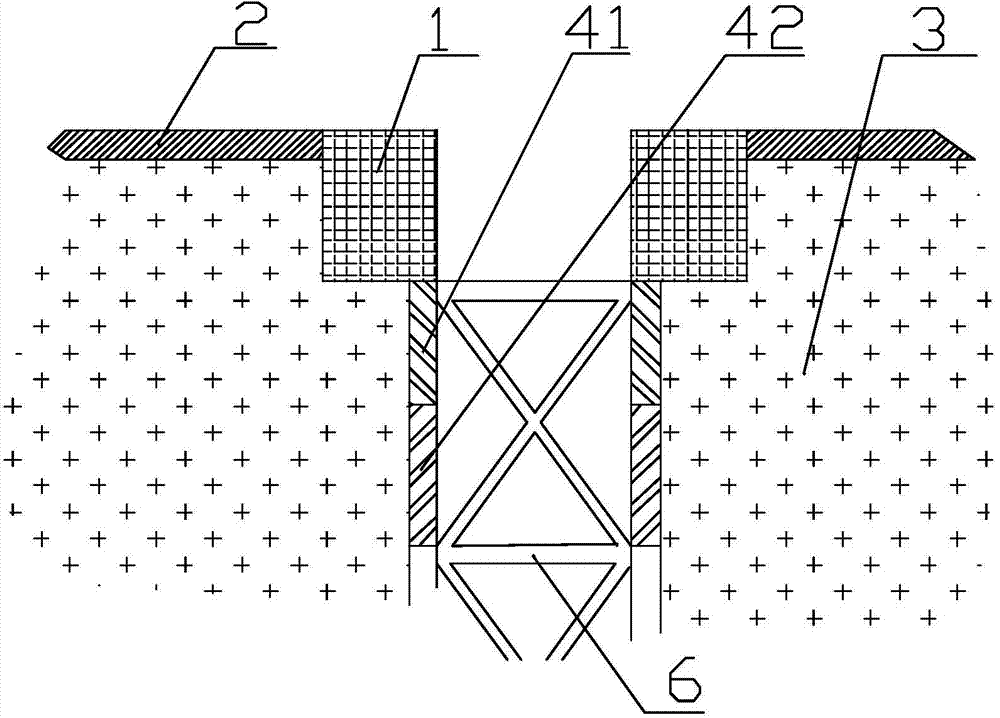

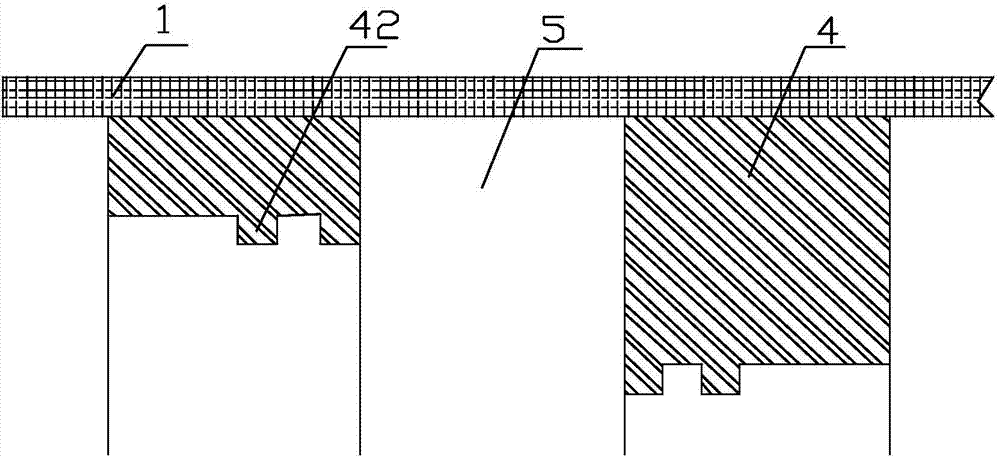

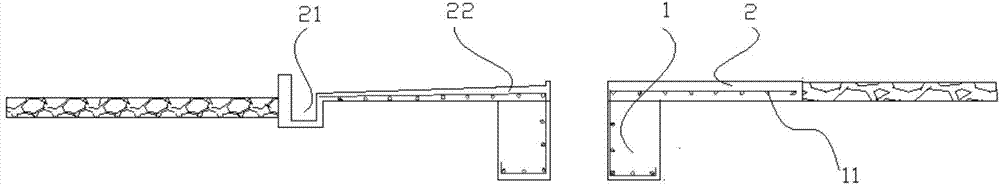

Process for constructing impervious concrete wall by using open excavation and inverted construction method

ActiveCN103866787AEasy constructionHigh speedArtificial islandsUnderwater structuresStress relaxationProcess control

The invention discloses a process for constructing an impervious concrete wall by using an open excavation and inverted construction method. The process comprises the steps of constructing guide grooves and a construction platform, segmentally constructing lining walls from top to bottom and pouring an impervious wall from bottom to top. The process is adapted to the perpendicular open excavation of an ultra-long, ultra-deep and large-section impervious wall structure; compared with those of an impervious concrete wall constructed by a conventional method, groove holes constructed by an open excavation and inverted construction grooving process have the advantage that high-flow regime concrete has better compaction effects on the lining walls and soil bodies on the two sides, so that the stress relaxation conditions of the soil bodies on the two sides are changed, and changes in the permeation boundary conditions of the impervious concrete wall are small; the impervious concrete wall constructed by the open excavation and inverted construction method has tangible construction quality, and procedure and process control is ensured, so that the problems of high hole collapse rate and low grooving efficiency of the groove holes during the construction of a loose sandy gravel layer impervious concrete wall are solved, and the joint quality of the impervious concrete wall is ensured.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

Drying method and preparation method for lost foam

ActiveCN110102709ANot prone to cracking problemsAvoid destructionFoundry mouldsFoundry coresAgricultural engineeringSaturated water vapor

The invention discloses a drying method for a lost foam, and the drying method comprises the following steps of: step 1, sending a coated foam mold to a coating drying room, and pre-drying the coatedfoam mold under the condition of circulating hot air, wherein the temperature of the circulating hot air is 30-35 DEG C, the wind speed is 1.5M / S-2.5M / S, the wind pressure is 0.1Pa-0.6Pa, the humidityof the drying room is 30%-35%, and the drying time is 2h-3h; step 2, sending the foam mold pre-dried in the step 1 to a stokehold drying room, and drying the foam mold under the condition of the circulating hot air, wherein the temperature of the circulating hot air is 30-50 DEG C, the wind speed is 0.5M / S-1.5M / S, the wind pressure is 0.1Pa-0.6Pa, the humidity of the drying room is 15%-20%, and the drying time is 6h-8h. The invention further discloses a preparation method for the lost foam. The invention has the organic combination of realizing the humidity, the flow of air and the temperature, prevents the saturated water vapor in the coating from being in an expanded state, and the water loss outside the coating being dried and shrunk quickly to cause the phenomenon of coating cracking.

Owner:安徽南凯元机械有限公司

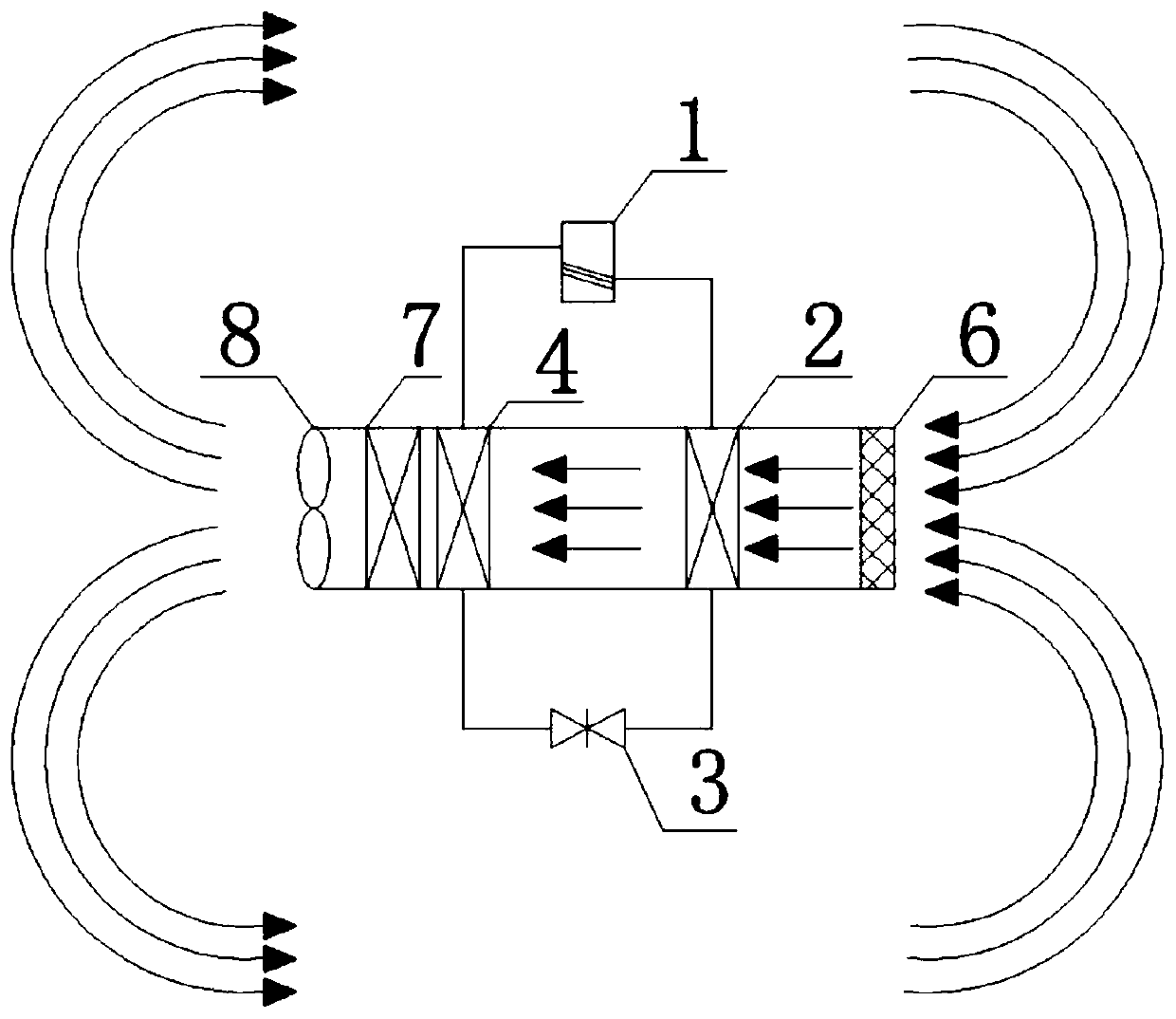

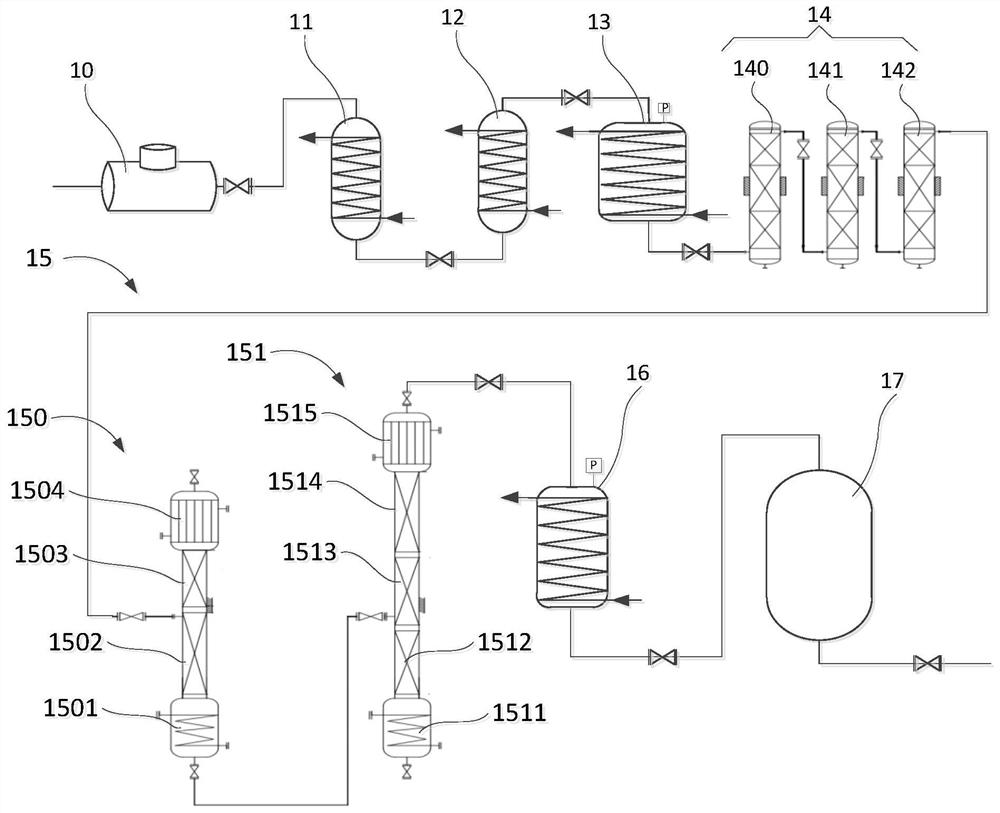

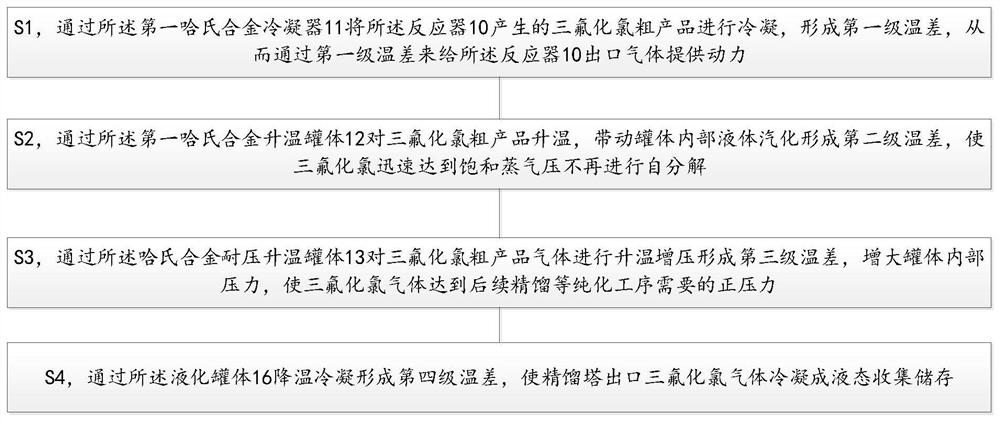

Electronic grade chlorine trifluoride purification system and temperature difference power control method thereof

InactiveCN112875648ASolve power problemsWon't cause entryInter-halogen compoundsThermodynamicsPressure stabilization

The invention provides an electronic grade chlorine trifluoride purification system and a temperature difference power control method. The purification system comprises a first hastelloy condenser, a first hastelloy heating tank body, a hastelloy pressure-resistant heating tank body, a three-stage metal adsorbent layer bed, a two-stage low-temperature rectification device, a liquefaction tank body and a pressure stabilization tank body which are connected in sequence, wherein the feeding end of the first hastelloy condenser is arranged at the top end of the first hastelloy condenser and is communicated with the reactor, and the discharging end of the first hastelloy condenser is arranged at the bottom end of the first hastelloy condenser and is connected with the feeding end of the first hastelloy heating tank body; and the first hastelloy condenser is used for condensing a chlorine trifluoride crude product generated by the reactor, so that power is provided for gas at an outlet of the reactor through temperature difference.

Owner:FUJIAN DEER TECH CORP

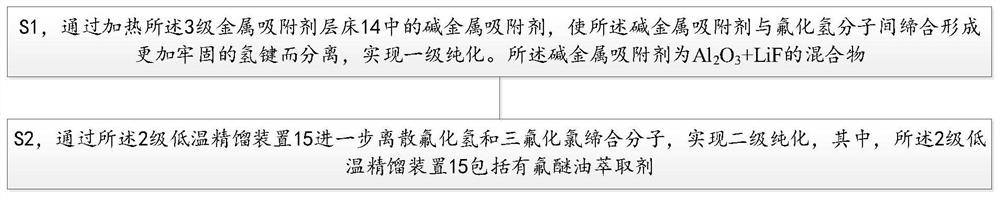

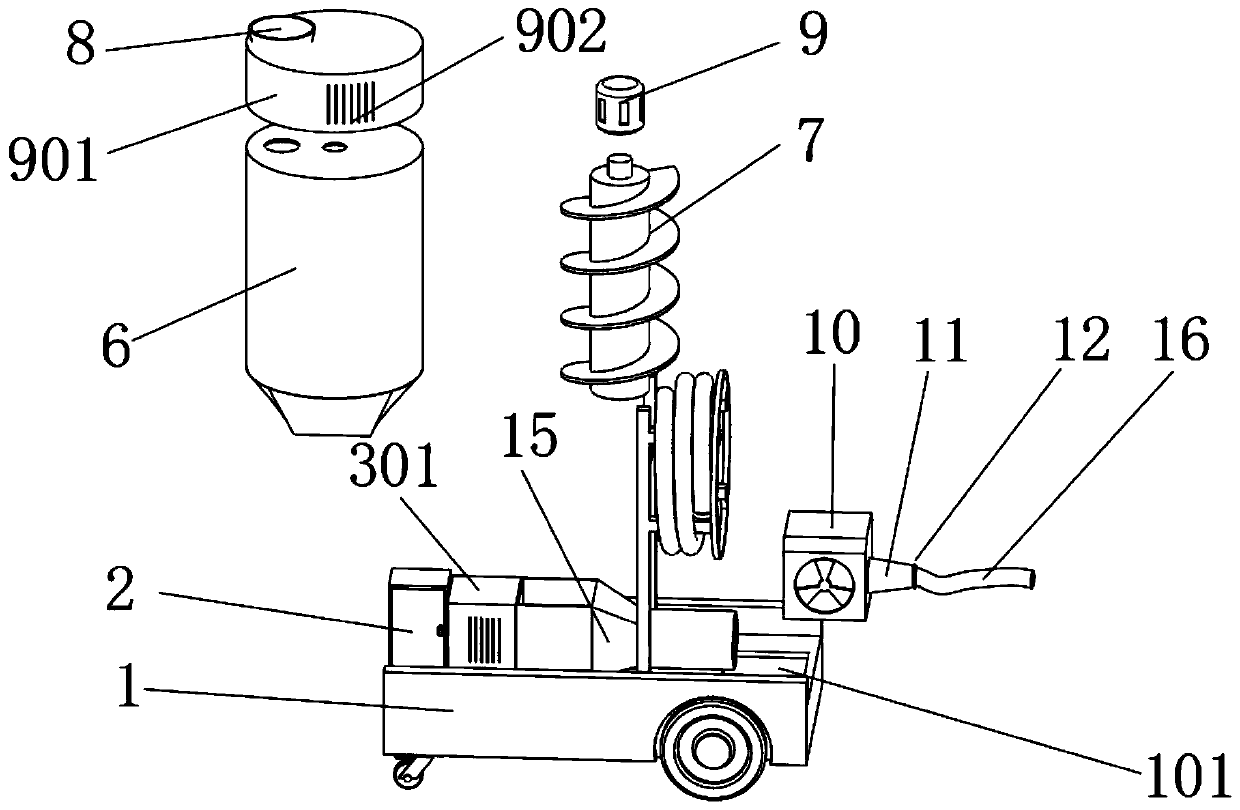

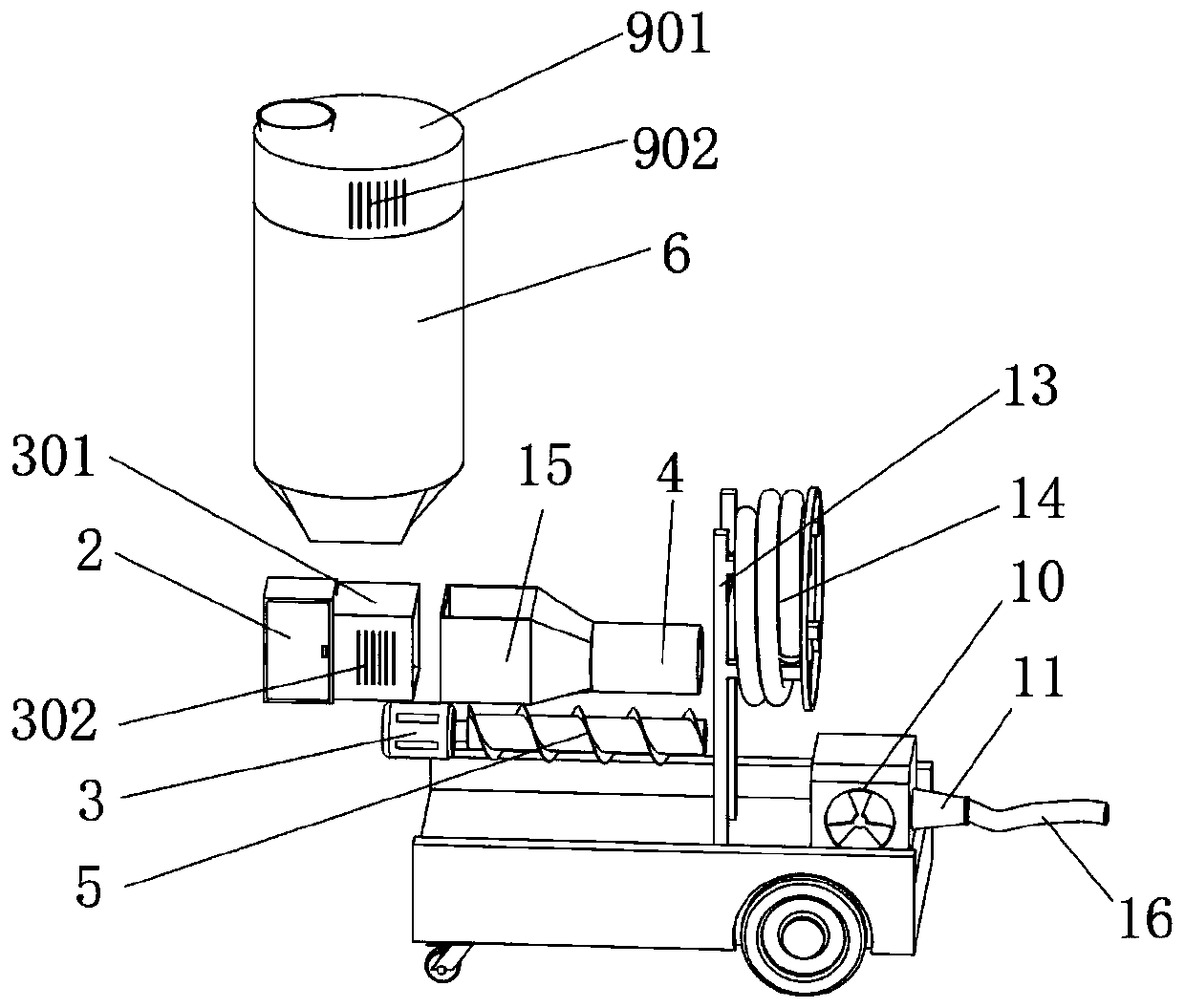

Efficient concrete pouring machine

PendingCN111140014AIncrease the lengthAvoid damageFoundation engineeringBuilding material handlingArchitectural engineeringElectric machinery

The invention discloses an efficient concrete pouring machine and relates to the technical field of plastic processing. The efficient concrete pouring machine comprises a trolley body, one side of thetop of the trolley body is provided with a control cabinet, the side, close to the middle portion of the trolley body, of the control cabinet is provided with a second motor, the output end of the second motor is provided with a horizontal stirring tank, one inner cavity of the horizontal stirring tank is provided with a horizontal threaded rod, the top of the side, close to the second motor, ofthe horizontal stirring tank is provided with a vertical stirring tank, one inner cavity of the vertical stirring tank is provided with a vertical threaded rod, the top of the vertical stirring tank is fixedly provided with a material feeding hopper and a first motor, the side, away from the second motor, of the horizontal stirring tank is provided with a concrete pump, the other side of the concrete pump is provided with a material outlet pipe, and the other side of the material outlet pipe is provided with a hose clamping buckle. The efficient concrete pouring machine has the beneficial effects that under pressurizing of the concrete pump and pushing of the horizontal threaded rod, the pouring lifting range is increased, occurrence of the material outlet blockage phenomenon is avoided, and the course of pouring construction is guaranteed.

Owner:合肥市日月新型材料有限公司

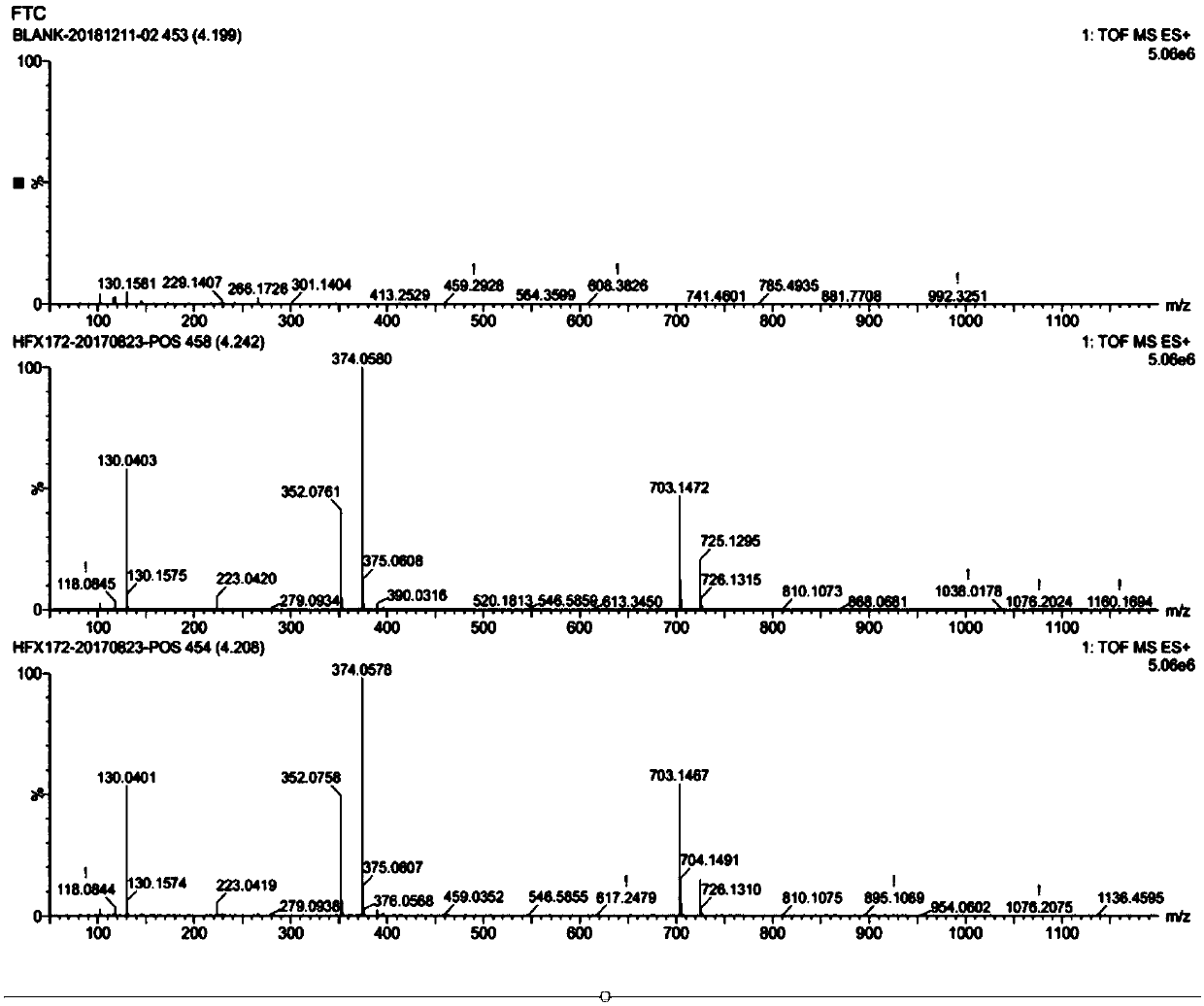

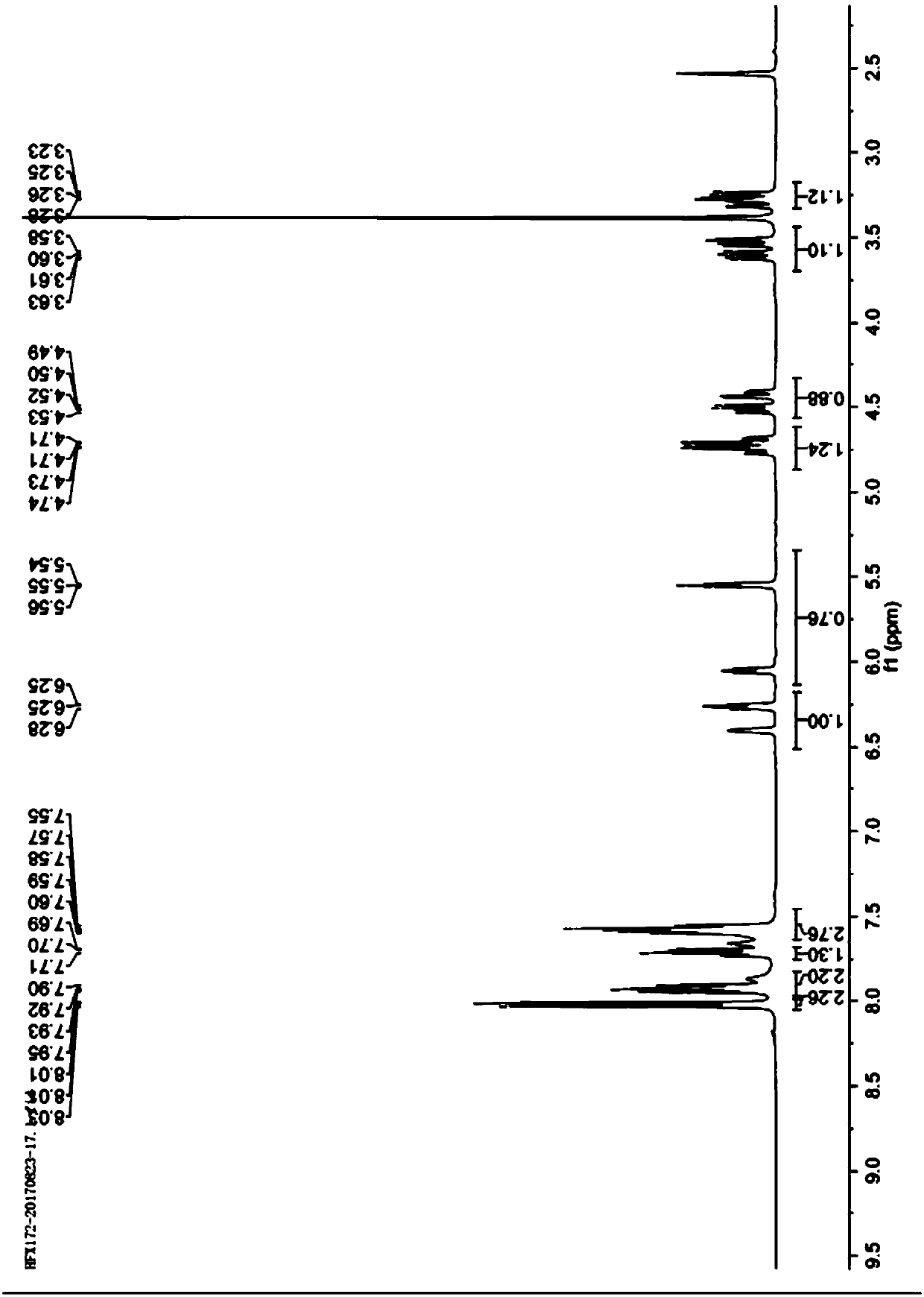

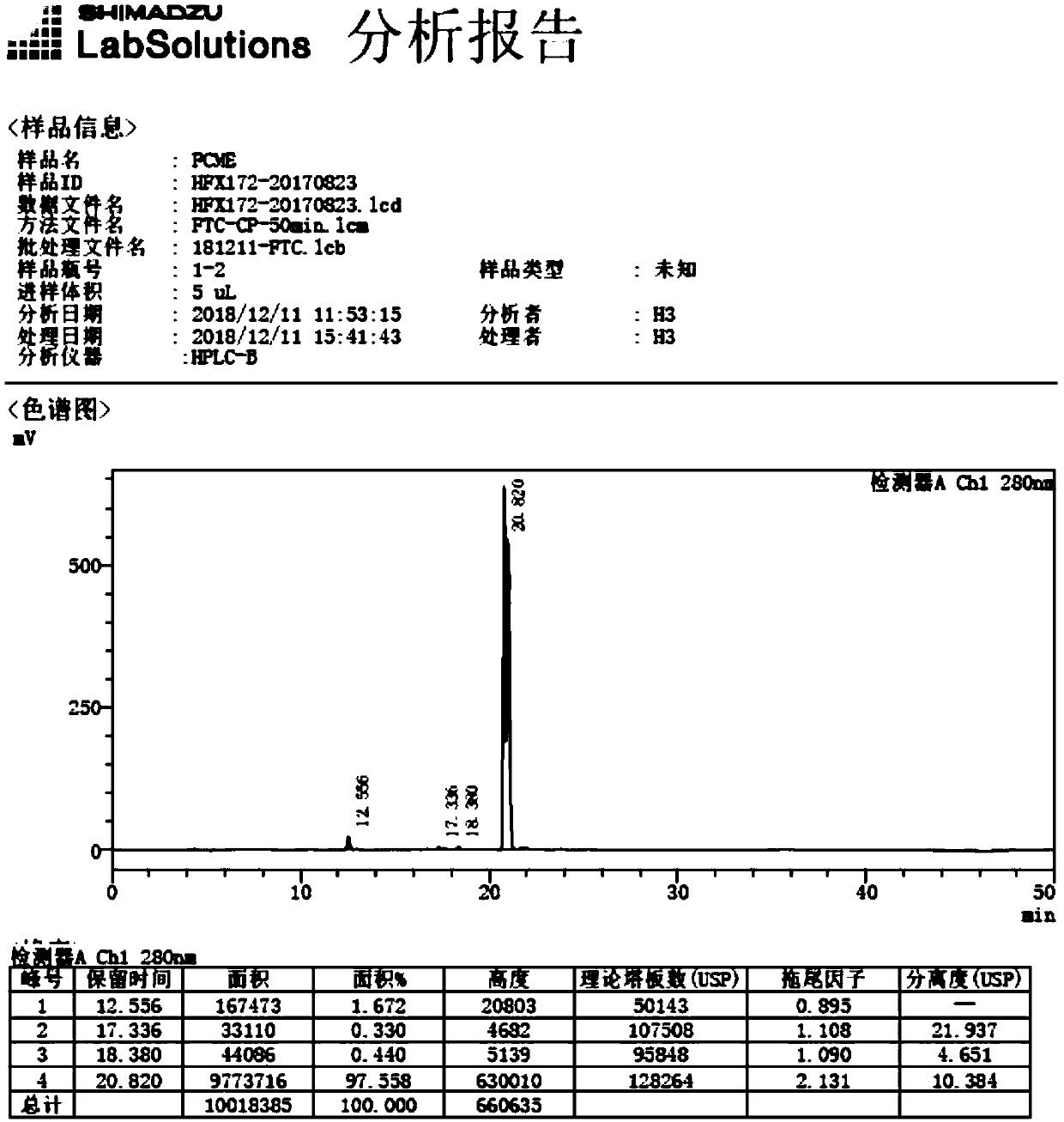

Preparation method for emtricitabine isomer

ActiveCN109553610AGuarantee processQuality assuranceOrganic chemistry methodsBulk chemical productionEmtricitabineAcetylation

The invention discloses a preparation method for an embritabine isomer. The preparation method comprises the following steps: with Solketal as a starting material, allowing the Solketal to undergo a six-step reaction of esterification, hydrolysis, oxidation, condensation cyclization, acetylation and glycosylation condensation so as to synthesize four mixture intermediates of emtricitabine; and splitting the four isomer intermediates into a cis-isomer mixture and a trans-isomer mixture through a chiral reagent. According to the invention, by adoption of a simple starting material, a mixture forsplitting key intermediates of four optical isomers of the emtricitabine is synthesized through the six-step reaction, and chiral acid is utilized to split the four isomers into a mixture of cis andtrans isomers, so the preparation method provided by the invention has the advantages of simple and convenient operation, high yield and high isomer chiral purity.

Owner:JIANGXI FUSHINE PHARMA CO LTD

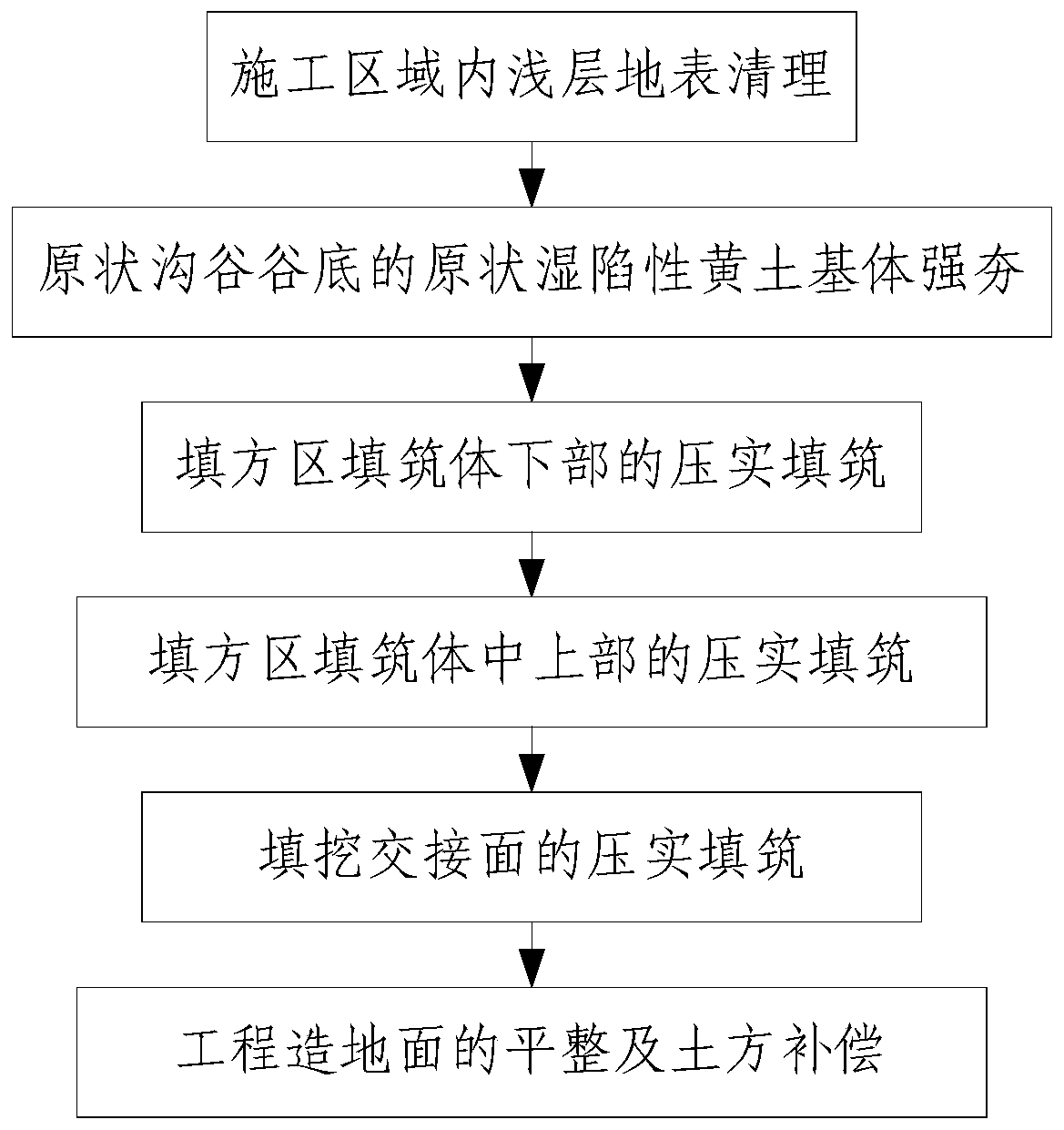

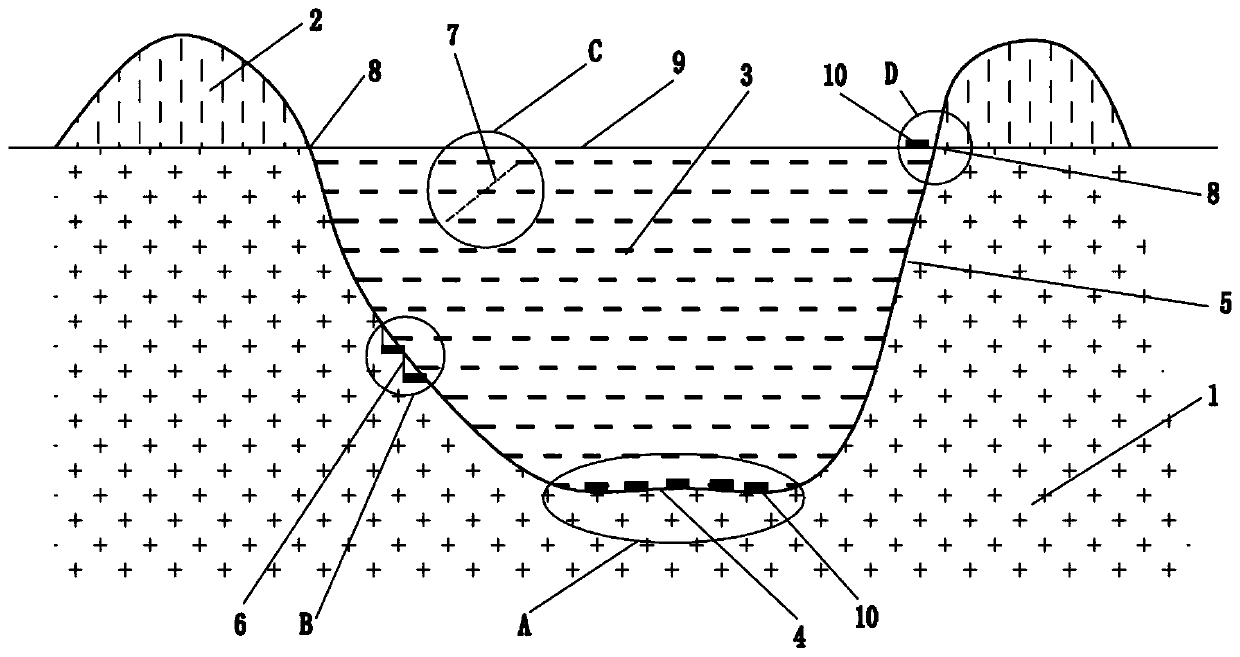

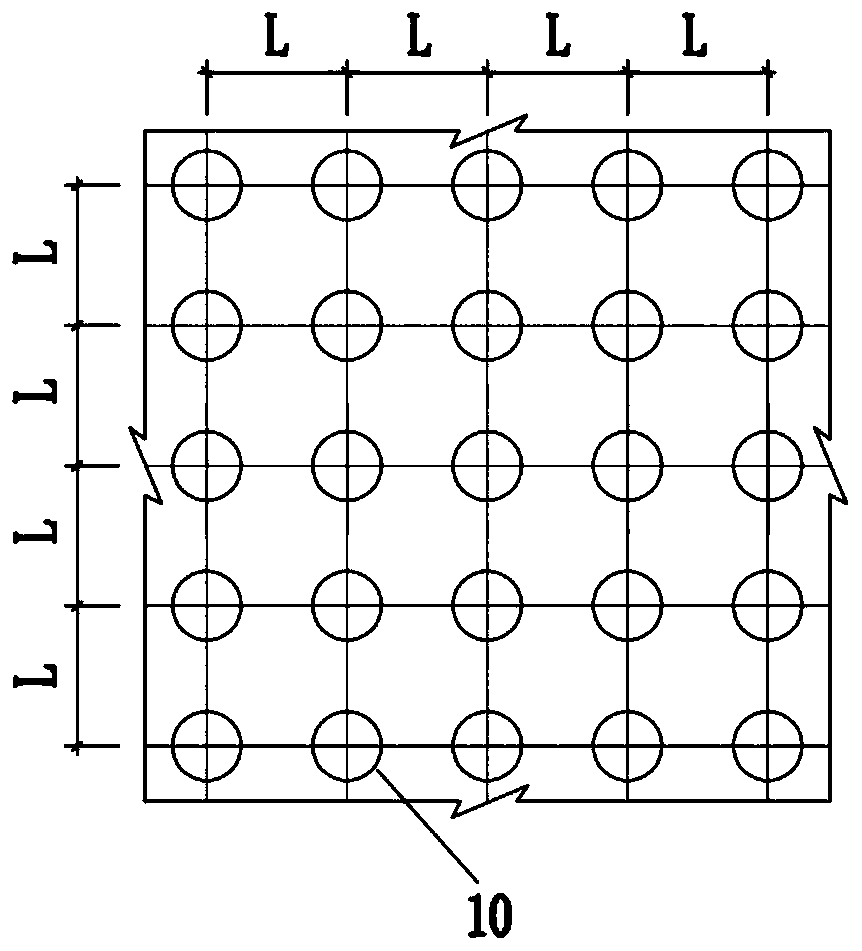

Comprehensive compaction filling method for reclaiming lands in loess hilly-gully regions by filling

ActiveCN109797730AOvercome the difficulties of site terrain conditionsGood construction foundationEmbankmentsSoil preservationLand utilizationLand reclamation

The invention discloses a comprehensive compaction filling method for reclaiming lands in loess hilly-gully regions by filling. The method herein comprises the steps of I, cleaning superficial surfaceof a construction area; II, performing dynamic compaction on intact collapsible loess base at the bottom of an intact gully; III, performing compaction filling on the lower portion of a filling region filler; IV, performing compaction filling on the upper middle of the filling region filler; V, performing compaction filling on a filling-digging junction; VI, leveling an engineering land-reclaiming plane, and compensating earth. Different construction schemes are taken for the different heights of the filling region filler; key factors for local weak planes at the different heights of the filling region filler are comprehensively controlled; response can be precisely provided to the accident-prone area during the filling and compaction for reclaiming lands in the loess hilly-gully regionsby filling; the quality of complex land reclamation projects by filling and land utilization safety are effectively guaranteed, and significant economic and social benefits are attained.

Owner:中国机械设备工程股份有限公司 +1

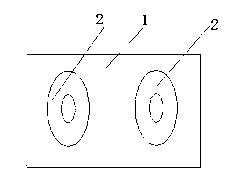

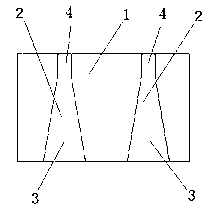

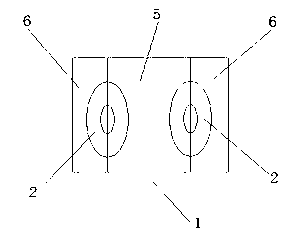

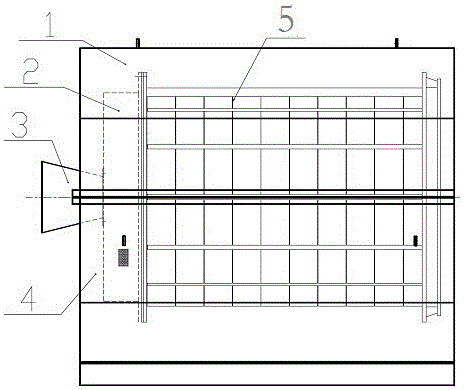

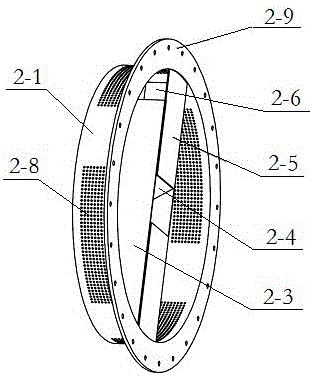

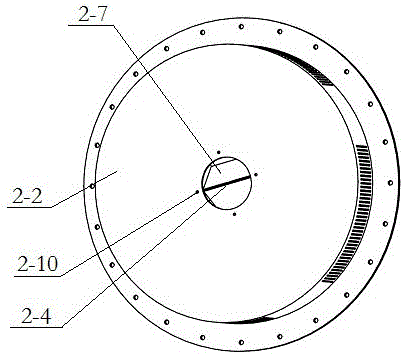

Molding drawing die of U-shaped elliptical or approximately elliptical condensation pipe, and machining method of molding drawing die

The invention relates to a molding drawing die of a U-shaped elliptical or approximately elliptical condensation pipe, and a machining method of the molding drawing die. The molding drawing die is characterized in that two drawing die holes are formed in the molding drawing die and are positioned in a same horizontal line; an interval between the two drawing die holes is equal to distance between two condensation pipes of the U-shaped elliptical condensation pipe; an inlet section of each drawing die hole is a conical section of which the cross section is elliptical; the tail end of the inlet section is smoothly connected with an outlet shaping section; the shaping section is an elliptical straight pipe section. The molding drawing die is characterized in that the conicity of the conical section of which the cross section is elliptical is 8.1 DEG; the length of a short shaft at an inlet of the elliptical conical section is greater than the diameter of a circular pipe; the conical length is 24mm; the length of an elliptical forming linear section is 6mm, and the cross section of the elliptical straight pipe section of the shaping section is zero tolerance relative to the elliptical condensation pipe. The molding drawing die has the advantages that the machined elliptical condensation pipe is accurate in appearance dimension, smooth in surface and invariable in wall thickness; process flows of subsequent welding and fin penetration of the elliptical condensation pipe are ensured.

Owner:姚斌 +1

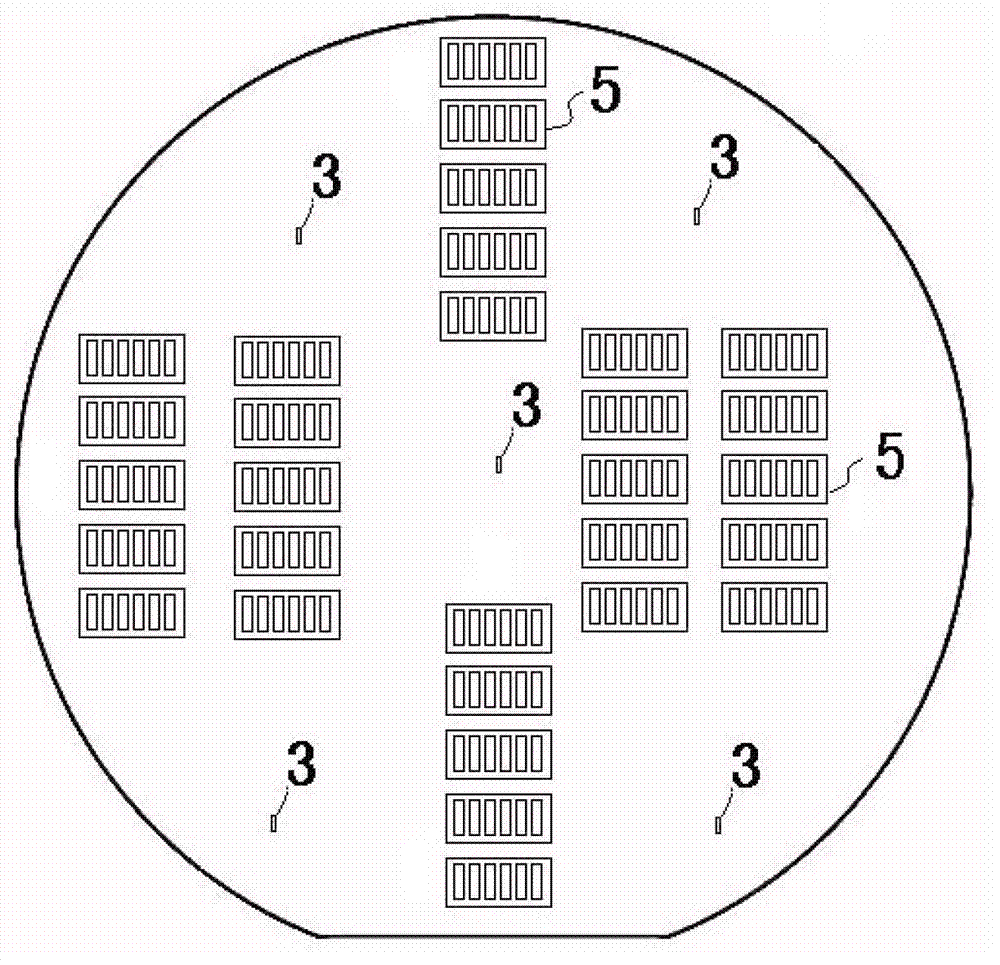

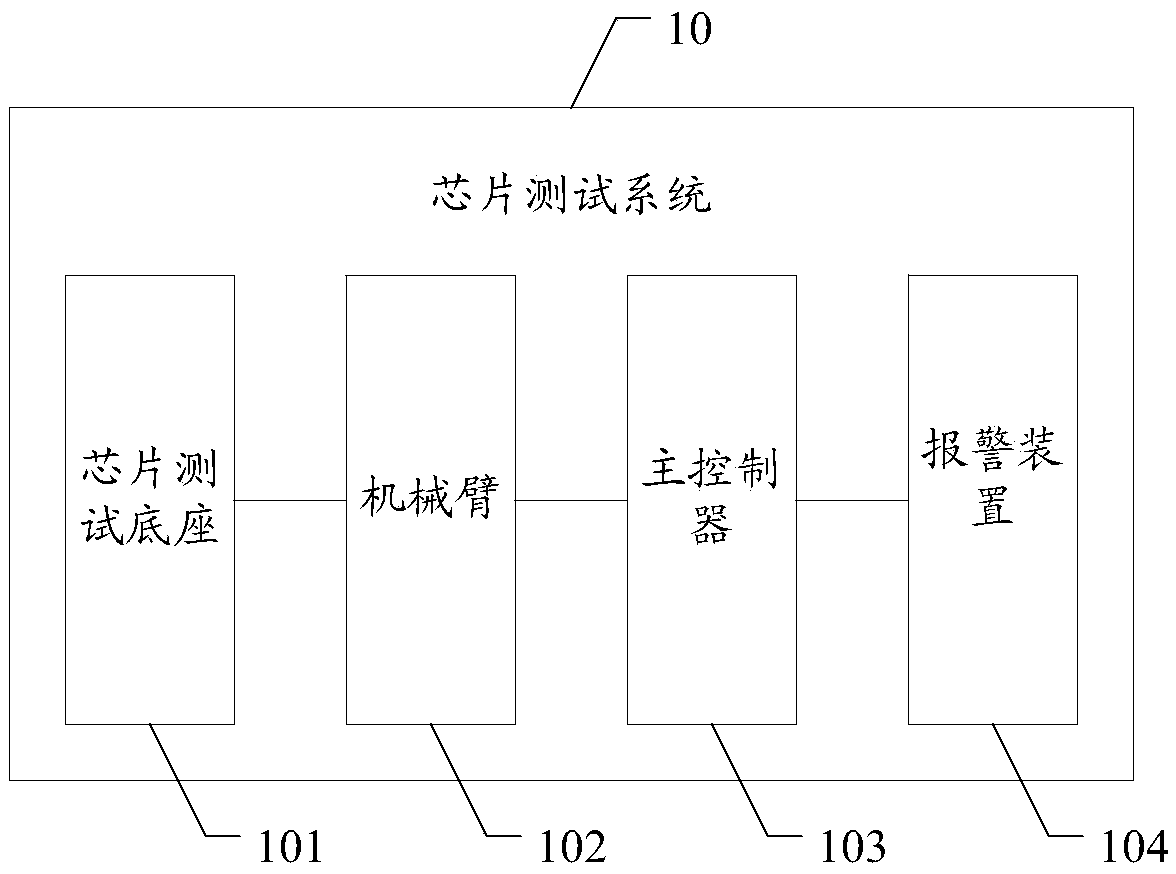

Chip test system

InactiveCN108828275AGuarantee processExpected service lifeMeasurement instrument housingAlarm deviceEmbedded system

A chip test system comprises a chip test pedestal, a mechanical arm, an alarm device and a main controller. The surface of the chip test pedestal is provided with a corresponding identifier; the mechanical arm is configured to perform operation of the chip when a control command output by the main controller is received to put the chip at the chip test pedestal or separate the chip from the chip test pedestal; the mechanical arm is provided with an identifier identification sensor configured to identify the identifier of the chip test pedestal when the mechanical arm performs operation of thechip and send the identification information obtained through identification to the main controller; the main controller is suitable for receiving of the identification information sent by the mechanical arm and record the number of current usage times of the chip test pedestal; and the main controller outputs alarm signals to the alarm device when it is detected that the number of the current usage times of the chip test pedestal reaches the preset maximum number of times. The technical scheme provides a standard for when the chip test pedestal should be maintained or replaced.

Owner:SUZHOU TF AMD SEMICON CO LTD

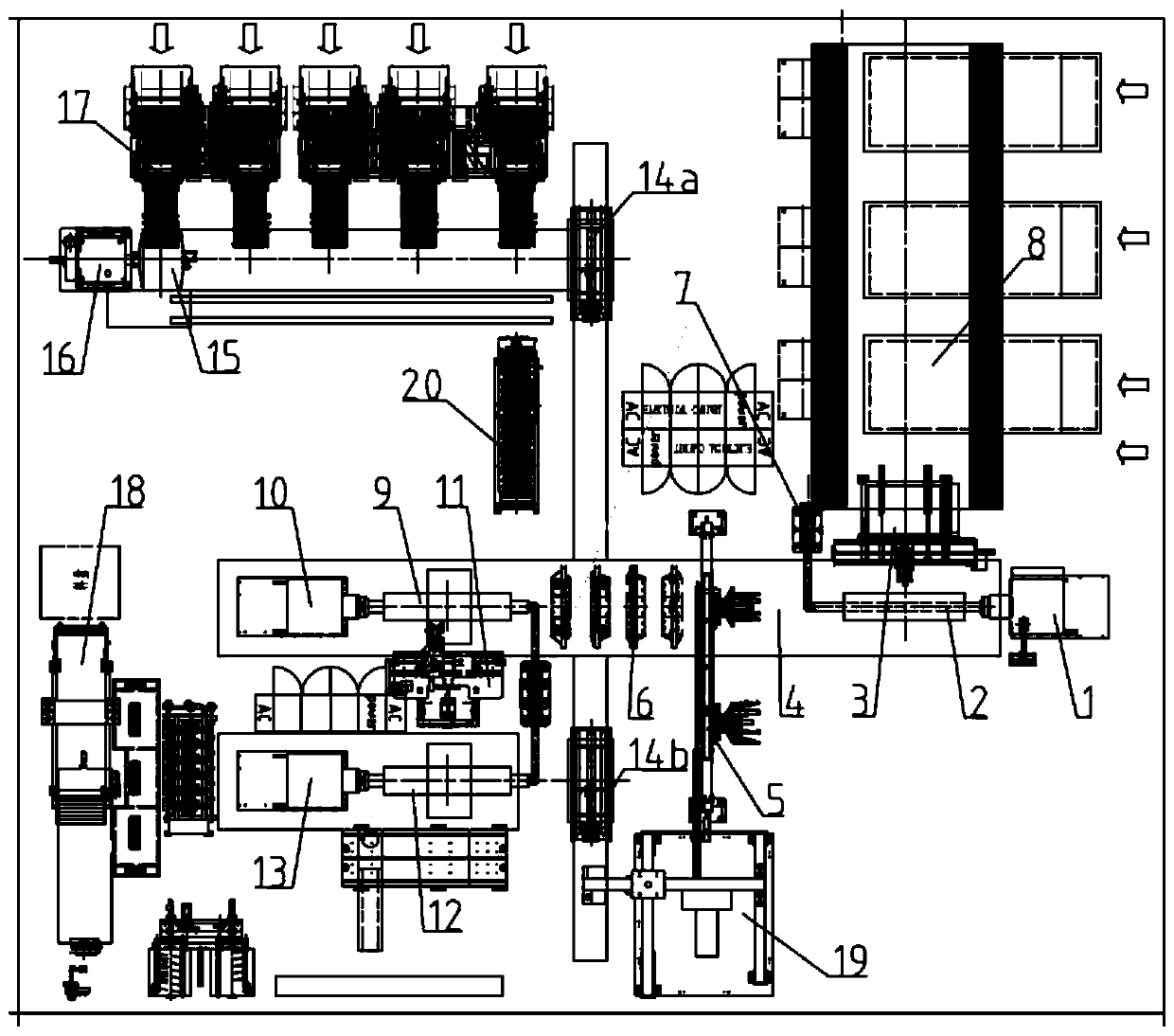

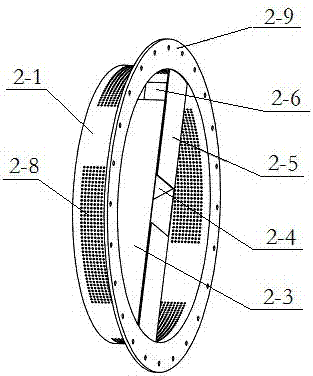

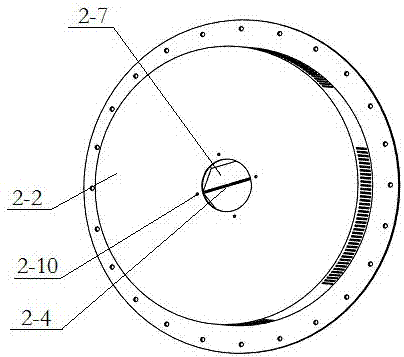

Forming device and tire forming method

Owner:TIANJIN SAIXIANG TECH CO LTD

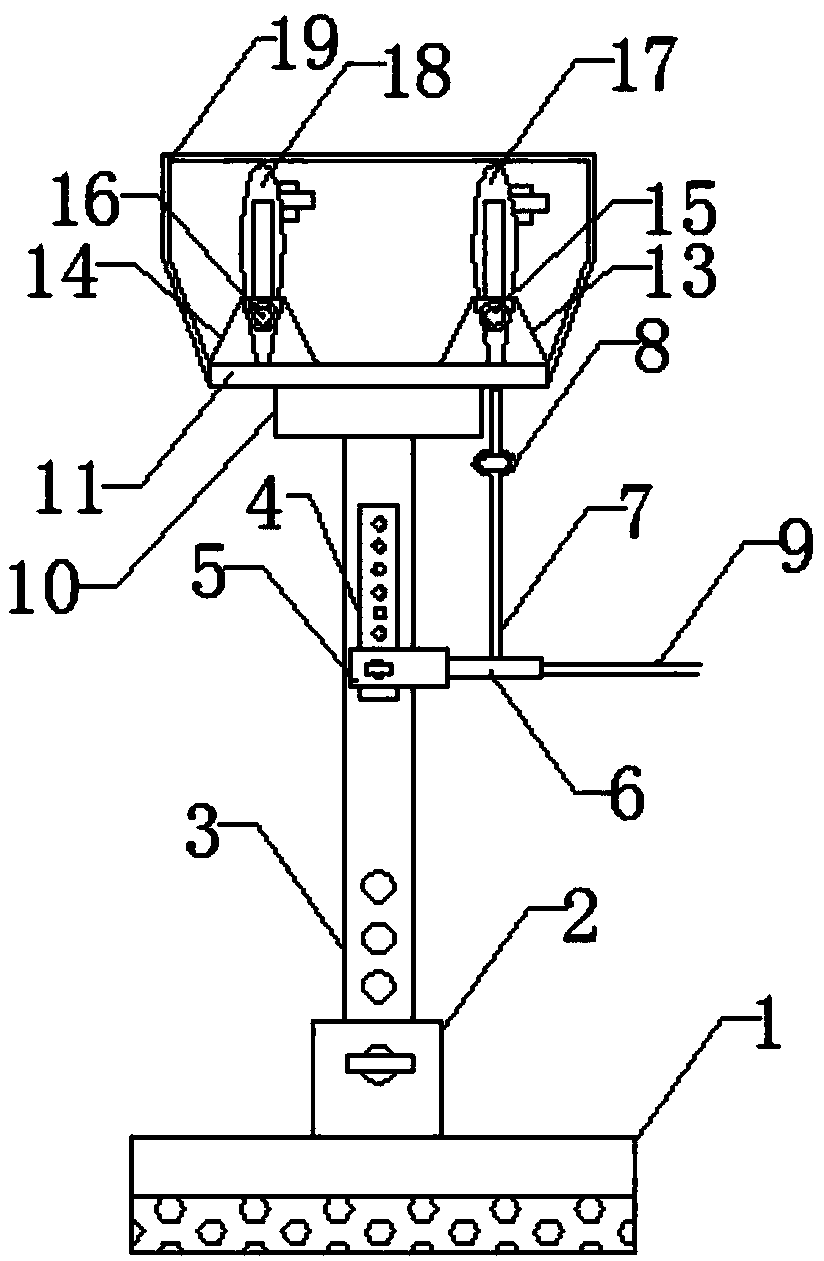

Surgical clinical analgesia device for medical treatment

InactiveCN107693889AGuarantee processHeight adjustableMedical devicesFlow monitorsEngineeringCheck valve

The invention discloses a clinical analgesic device for medical operation, which comprises a base and a fixed plate. A hollow sleeve is arranged on the top of the base. The top of the hollow sleeve is fixedly connected with a telescopic rod through an adjusting screw. A slide block is slidably connected to the inside of the chute, and one end of the slide block is provided with a one-way valve, and the liquid outlet of the one-way valve is fixedly connected with the liquid outlet of the infusion tube. The present invention is equipped with a bearing seat, a fixed plate and a liquid storage tank. When the liquid storage tank fails during the operation, the staff rotates the fixed plate to separate the faulty liquid storage tank from the lower liquid hose and make the lower liquid soft. The tube is connected to the liquid outlet control valve of the spare liquid storage tank to ensure the normal progress of the operation. The telescopic rod, chute and slider are provided to facilitate the medical staff to quickly adjust the height of the clinical analgesic device according to the needs of the site.

Owner:杭州笑口常开贸易有限公司

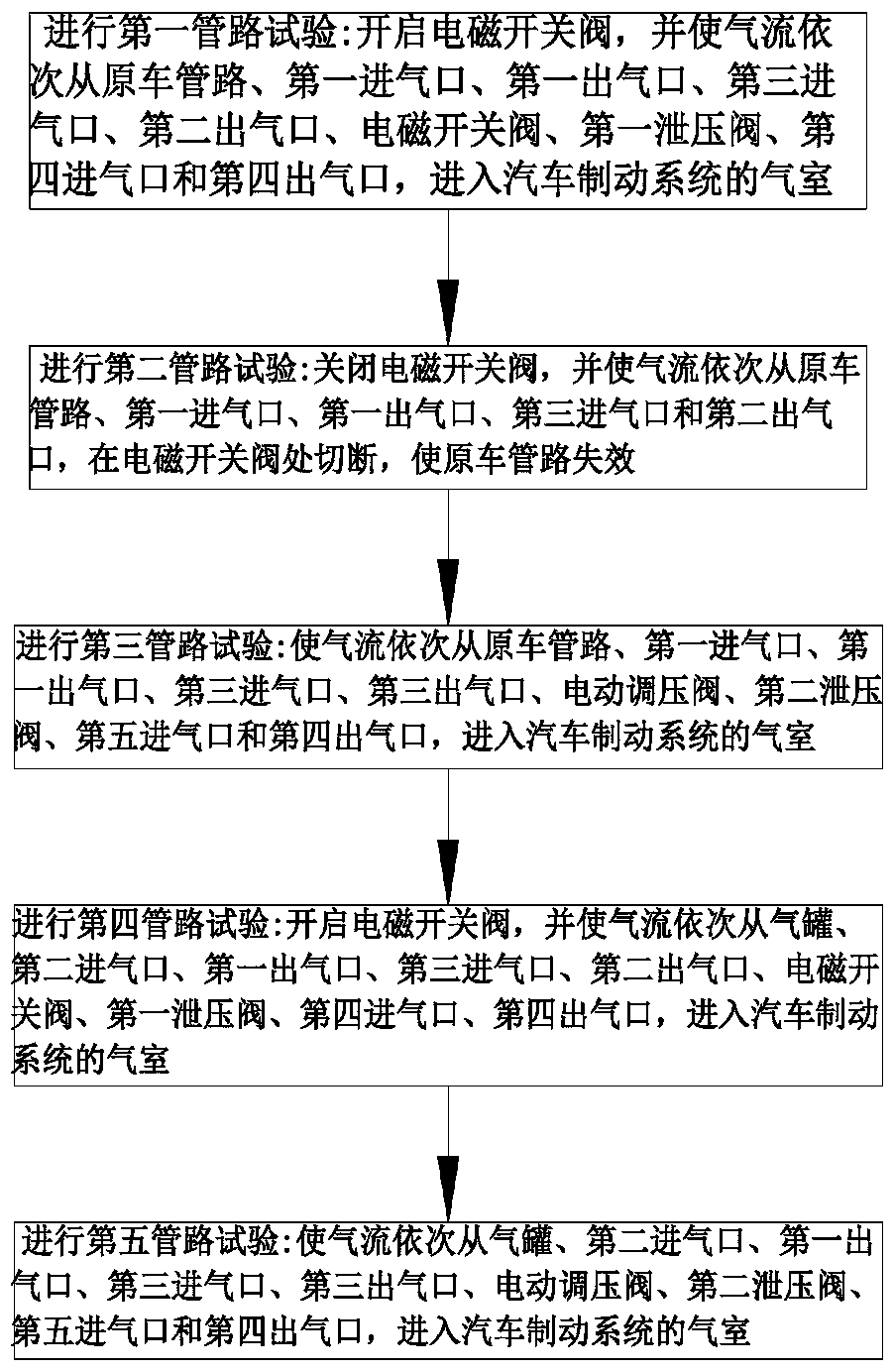

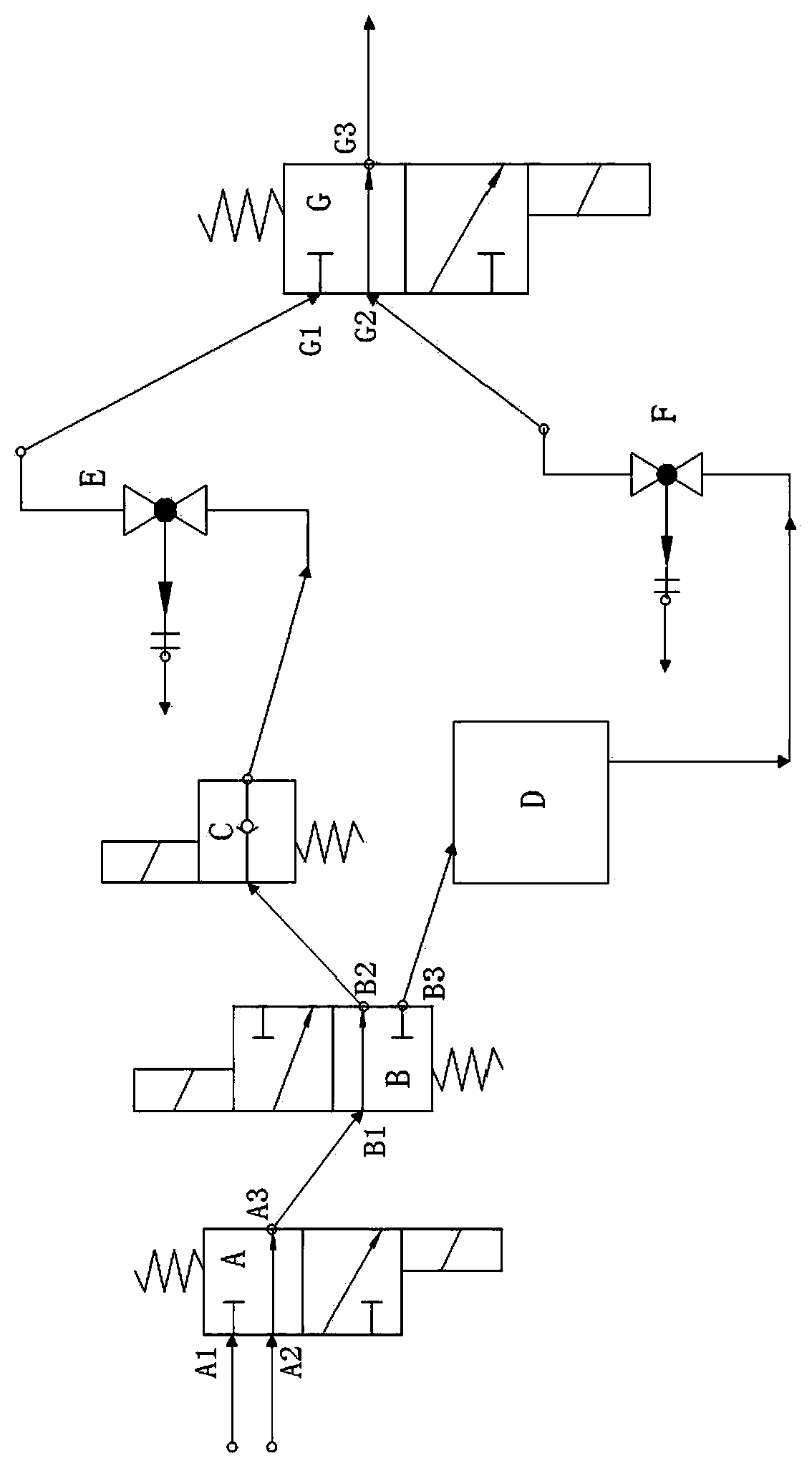

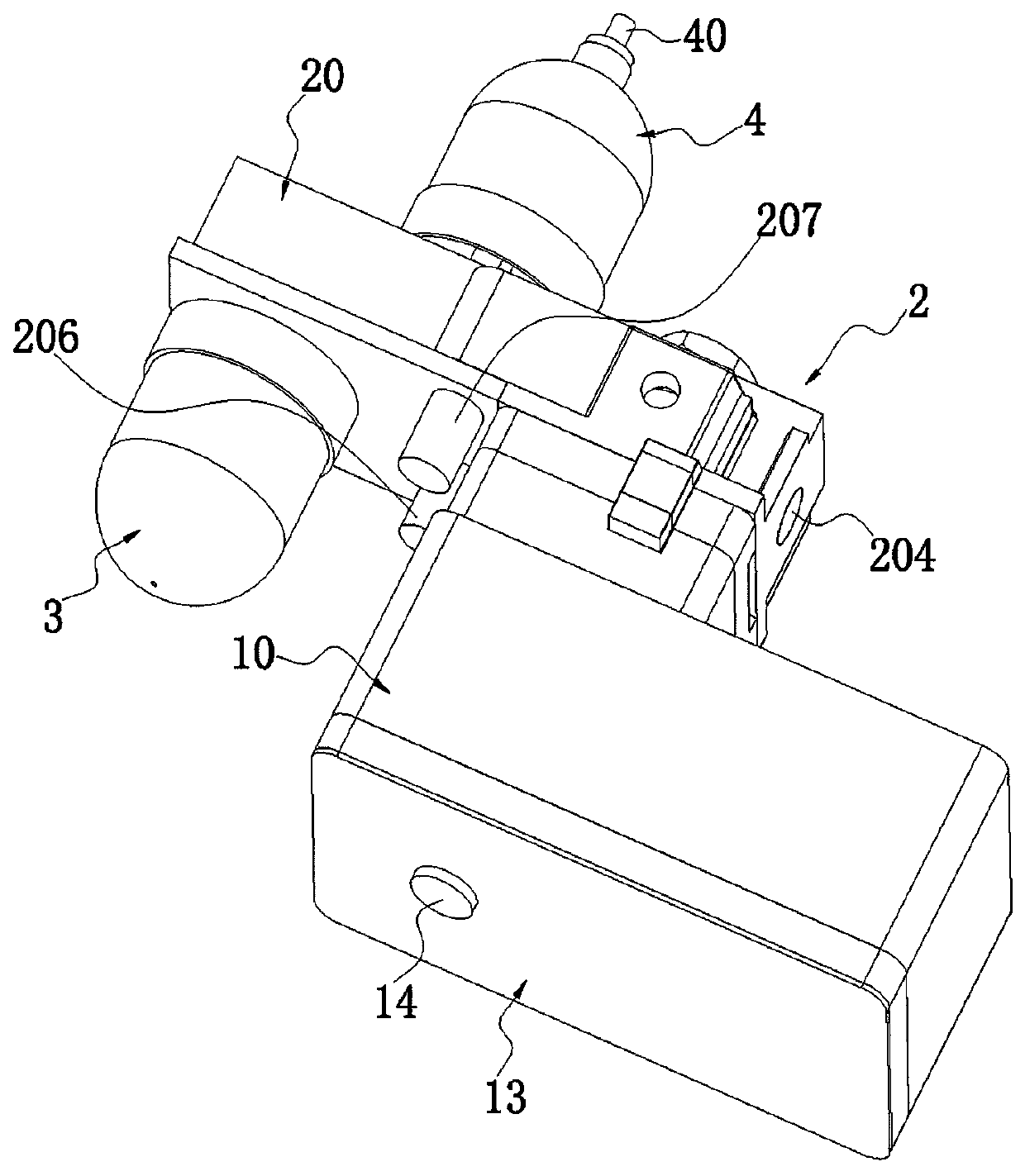

Automobile air brake system adhesion coefficient utilization rate test device and method

The invention relates to the technical field of automobile test devices, and discloses an automobile air brake system adhesion coefficient utilization rate test device and method. The test device comprises an air inlet selection valve, a pipeline cut-off valve, an electromagnetic switch valve, an electric pressure regulating valve, a first pressure release valve, a second pressure release valve and an air outlet selection valve, wherein the air inlet selection valve is provided with a first air inlet, a second air inlet and a first air outlet; the first air inlet can be used for being connected with an original automobile pipeline of an automobile brake system, and the second air inlet can be used for being connected with an air tank; the pipeline cut-off valve is provided with a third airinlet, a second air outlet and a third air outlet; the third air inlet is communicated with the first air outlet;theair outlet selection valve is provided with a fourth air inlet, a fifth air inlet and a fourth air outlet; the fourth air inlet is communicated with the first pressure release valve; the fifth air inlet is communicated with the second pressure release valve; and the fourth air outlet can be used for being connected with an air chamber. The device has the advantages that the test device is simple, multiple in functions and high in test efficiency; the electric pressure regulatingvalve can be manually and electrically regulated, and is convenient to regulate and high in regulating precision.

Owner:中汽研汽车检验中心(常州)有限公司

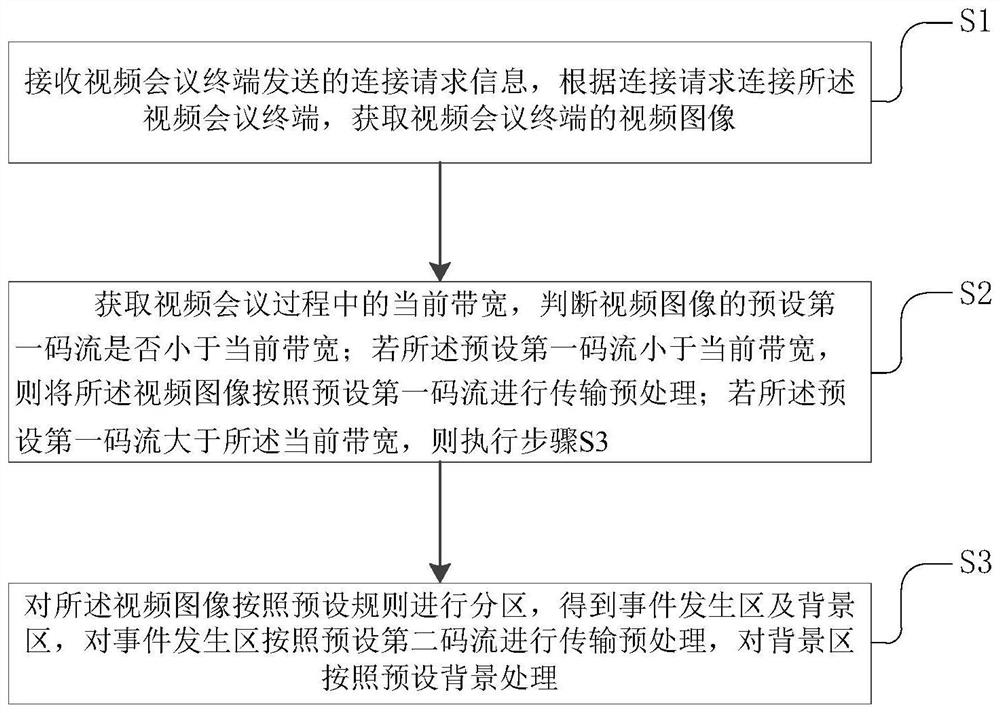

Video conference code stream transmission method and equipment, and storage medium

PendingCN113225519AGuarantee processMeet real-time requirementsTelevision conference systemsTwo-way working systemsReal-time computingControl cell

Owner:GUANGZHOU LANGO ELECTRONICS TECH CO LTD

Discharge screening device for ball mill

A discharge screening device for a ball mill relates to a screening device for milled material. The discharge screening device comprises a drum screen which rotates together with a mill drum, wherein a discharge end of the drum screen is connected with a reject discharging screen; the reject discharging screen comprises a cylindrical screen body, of which one end is open and the other end is closed; a discharge opening is formed in a baffle at the closed end; a bell mouth is arranged outside the cylindrical screen body; a reject bin is arranged in the cylindrical screen body; the discharge opening is located at one end of the reject bin; a feed opening is formed in each of two sides of the reject bin; material discharged from the drum screen into the reject discharging screen falls into the reject bin via the two feed openings in two sides of the reject bin in the rotation process of the reject discharging screen respectively; two inclined plates are arranged in the reject bin; and the two inclined plates are used for guiding the material, which falls into the reject bin via the two feed openings, to flow into the discharge opening at the other end of the reject bin to be discharged via the bell mouth. The discharge screening device can improve the accuracy of material separation of a drum screening device and effectively finish separation of oversize products and undersize products.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

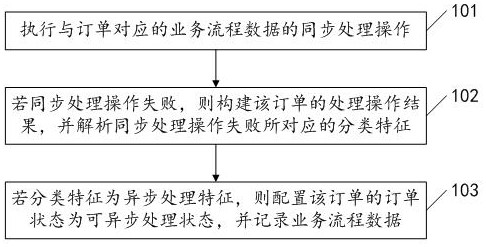

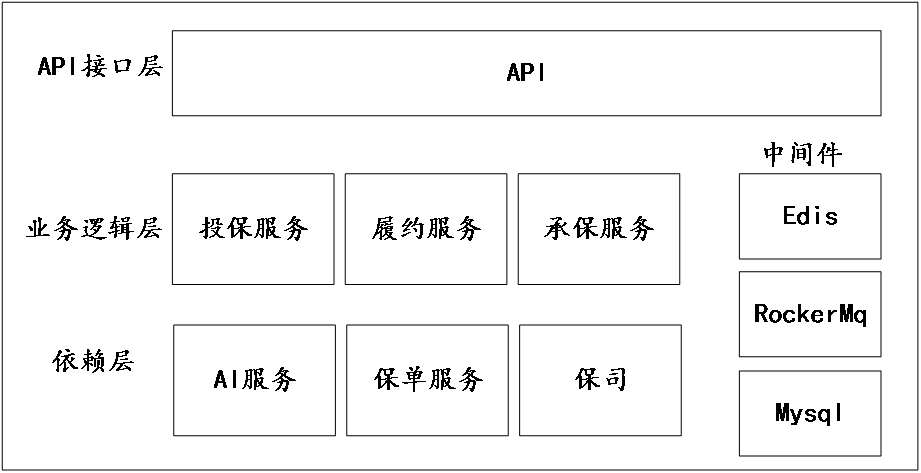

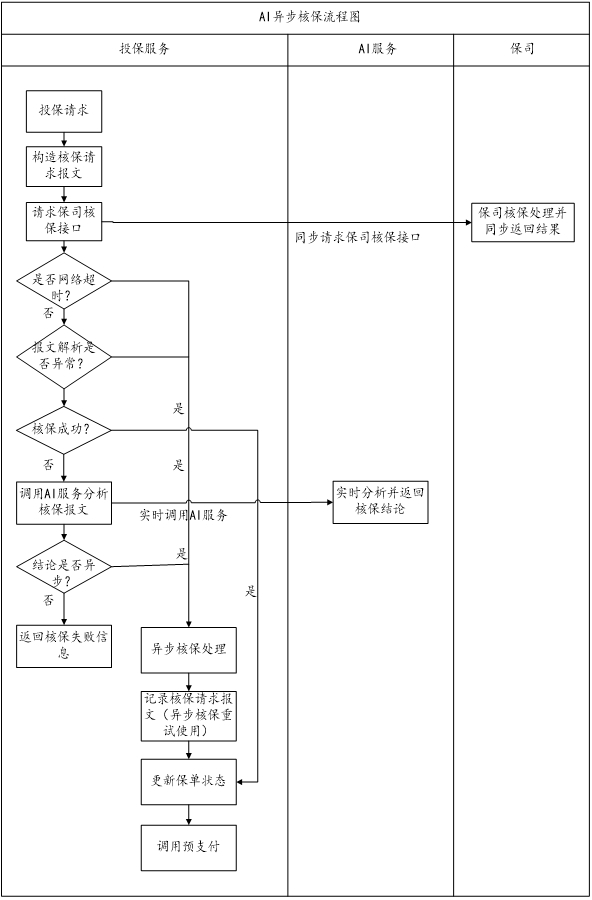

Asynchronous processing method and device for business process data

ActiveCN113297357AGuarantee processImprove effectivenessFinanceNatural language data processingSoftware engineeringOrder status

The invention discloses an asynchronous processing method and device for business process data, a computer storage medium and a terminal, relates to the technical field of data processing, and mainly solves the technical problem that whether asynchronous processing is carried out or not cannot be accurately judged at present, so that the asynchronous processing effectiveness of the business process data is reduced. The method comprises the following steps: executing a synchronous processing operation of business process data corresponding to an order; if the synchronous processing operation fails, constructing a processing operation result of the order, analyzing classification features corresponding to the failure of the synchronous processing operation, wherein the processing operation result is used for indicating to execute next business operation matched with the business process data; and if the classification feature is an asynchronous processing feature, configuring the order state of the order to be an asynchronous processing state, and recording the business process data so as to execute the synchronous processing operation of the business process data again. The method and device are mainly used for asynchronous processing of business process data.

Owner:北京水滴科技集团有限公司

A discharge screening device for a ball mill

A discharge screening device for a ball mill relates to a screening device for milled material. The discharge screening device comprises a drum screen which rotates together with a mill drum, wherein a discharge end of the drum screen is connected with a reject discharging screen; the reject discharging screen comprises a cylindrical screen body, of which one end is open and the other end is closed; a discharge opening is formed in a baffle at the closed end; a bell mouth is arranged outside the cylindrical screen body; a reject bin is arranged in the cylindrical screen body; the discharge opening is located at one end of the reject bin; a feed opening is formed in each of two sides of the reject bin; material discharged from the drum screen into the reject discharging screen falls into the reject bin via the two feed openings in two sides of the reject bin in the rotation process of the reject discharging screen respectively; two inclined plates are arranged in the reject bin; and the two inclined plates are used for guiding the material, which falls into the reject bin via the two feed openings, to flow into the discharge opening at the other end of the reject bin to be discharged via the bell mouth. The discharge screening device can improve the accuracy of material separation of a drum screening device and effectively finish separation of oversize products and undersize products.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

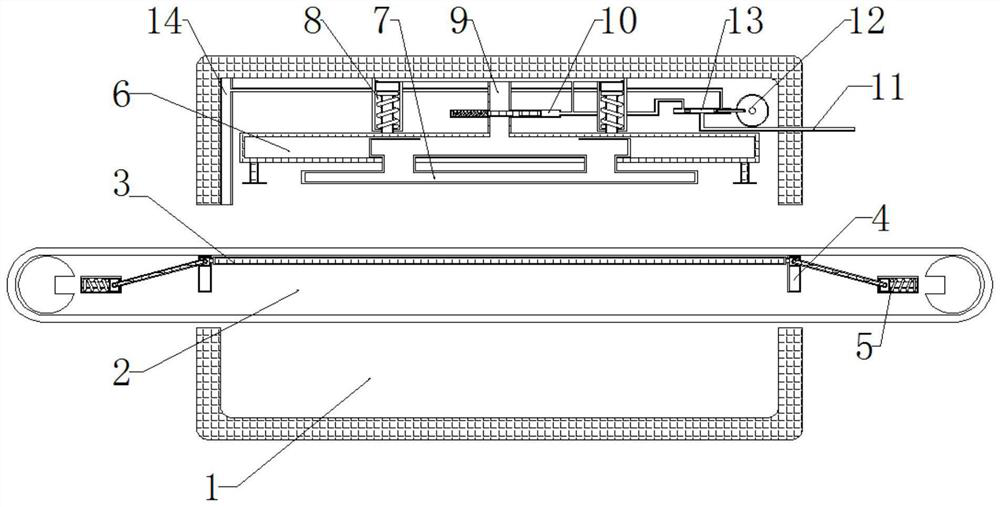

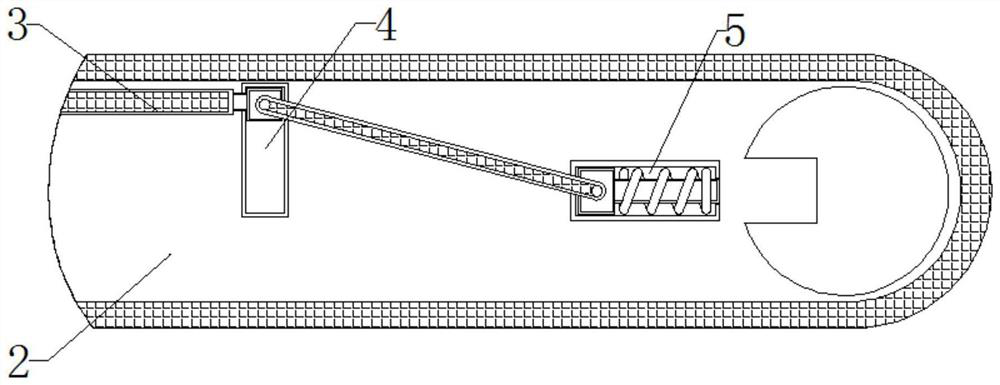

Leather processing device capable of quickly and automatically clamping, quantitatively injecting protective oil and quickly smearing

InactiveCN111635968AQuick applicationGuaranteed processing effectLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingStructural engineeringProcess engineering

The invention relates to the technical field of leather processing, and discloses a leather processing device capable of quickly and automatically clamping, quantitatively injecting protective oil andquacking smearing. The device comprises a processing machine, a conveying belt is movably connected to the interior of the processing machine; a clamping plate is movably connected to the interior ofthe conveying belt, a fixed rail is movably connected to the interior of the conveying belt, a clamping rail is movably connected to the interior of the conveying belt, a movable plate is movably connected to the interior of the processing machine, a smearing plate is movably connected to the lower portion of the movable plate, and a positioning rail is movably connected to the interior of the processing machine. When the through hole position of the quantitative sliding block makes contact with the pipe opening position of the oil inlet pipe, protective oil in the oil inlet pipe enters the movable sliding block in the movable plate through the through hole position of the quantitative sliding block and then enters the smearing plate through the movable sliding block, and thus the operation of quantitatively entering the protective oil is achieved, and the process effect is guaranteed.

Owner:杭州赴戎科技有限公司

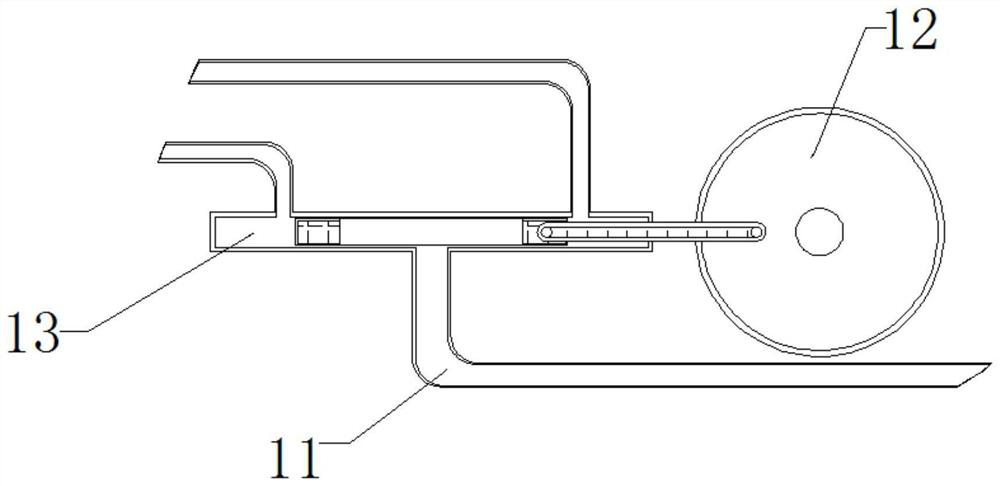

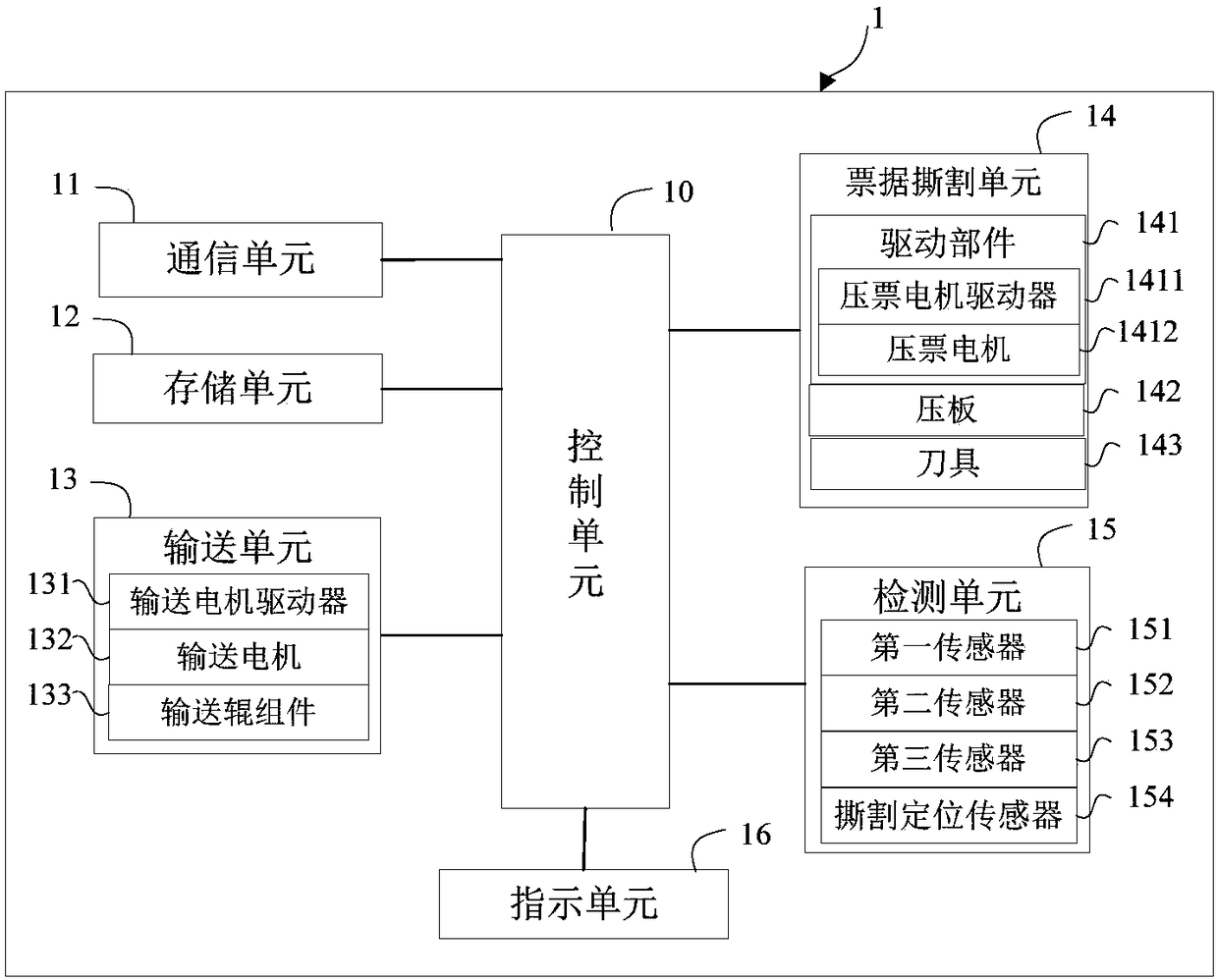

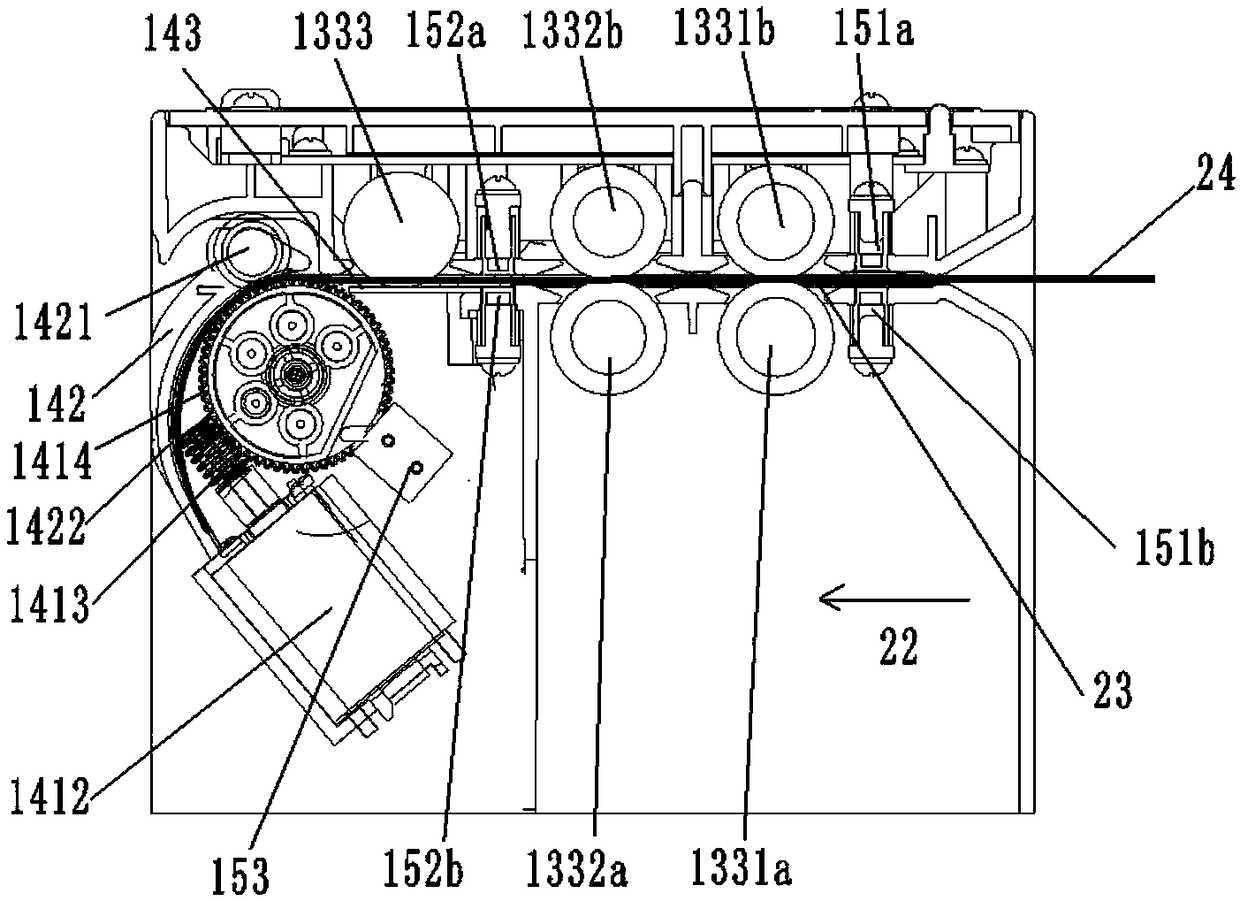

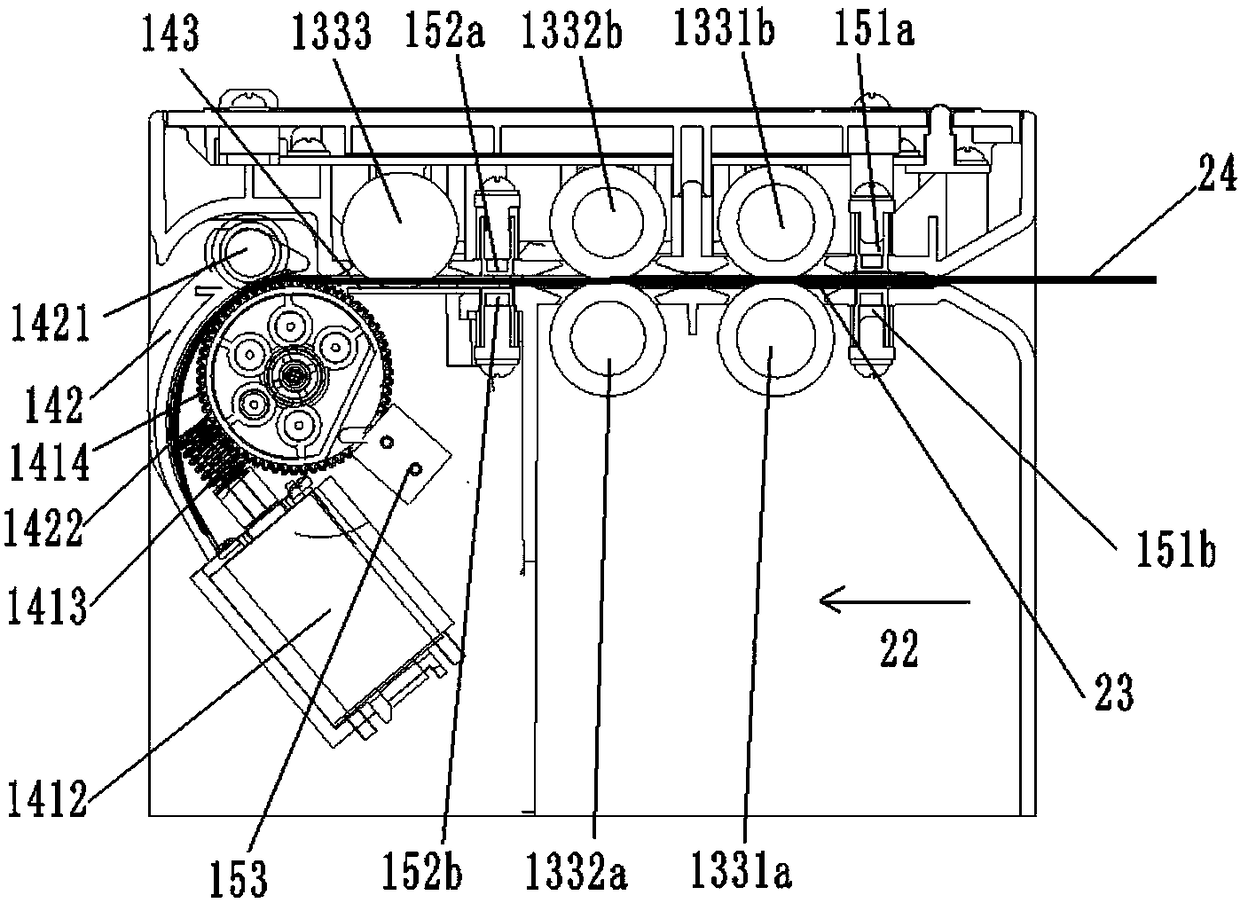

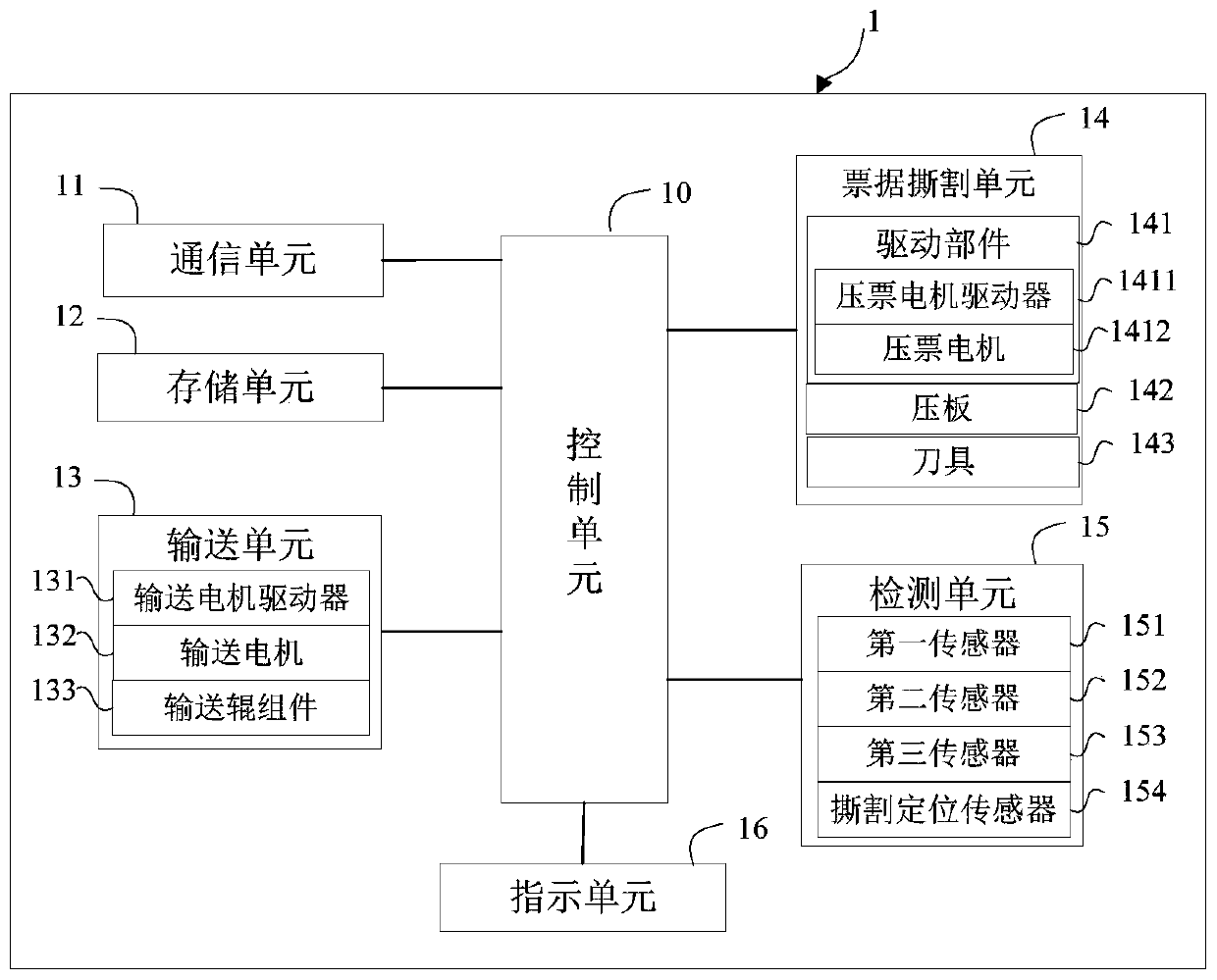

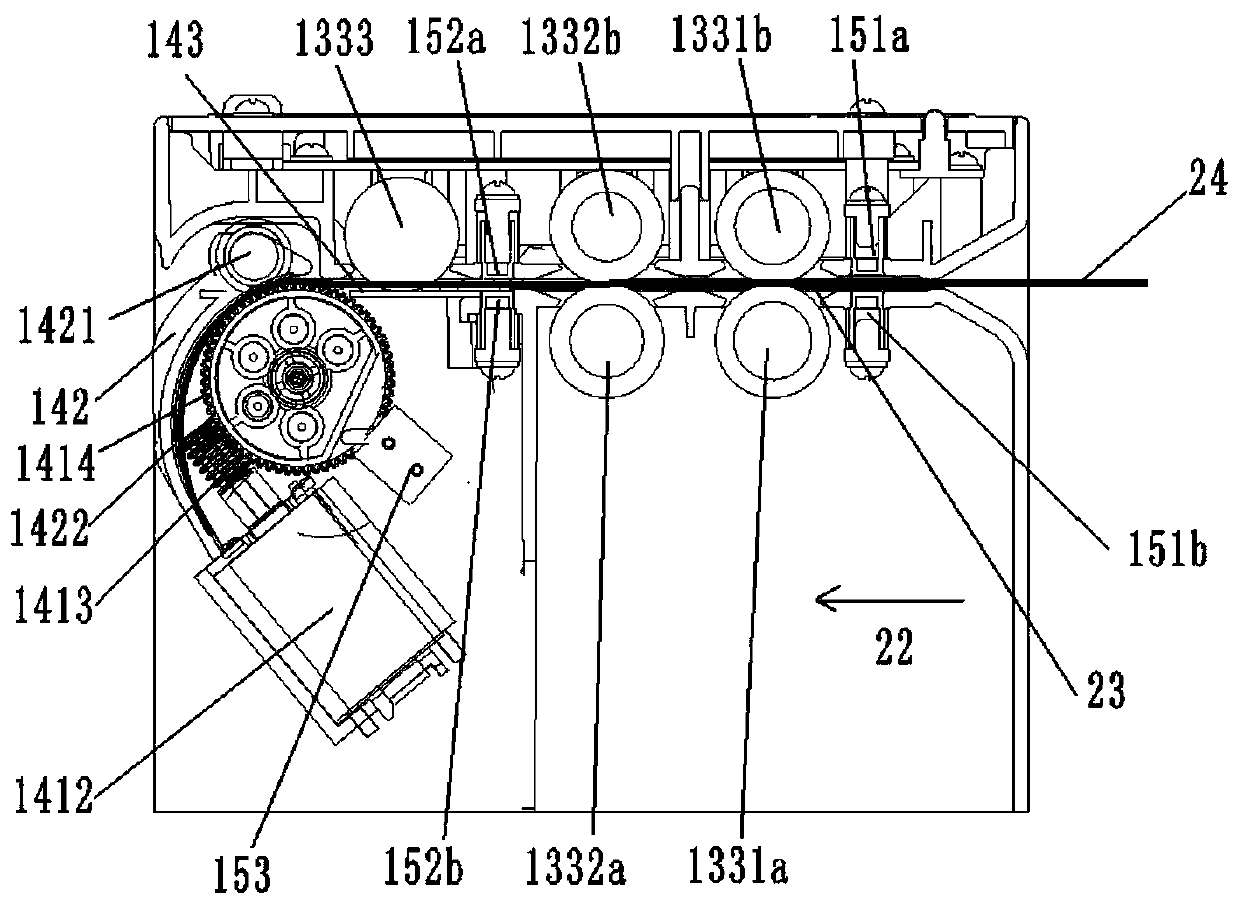

Method for controlling ticket distributing device and ticket distributing device

ActiveCN108205850AGuarantee processIncrease success rateLottery apparatusCoin-freed apparatus detailsFront edgeSelf-service

The invention provides a method for controlling a ticket distributing device and a ticket distributing device, relating to the technical field of self-service ticket sale. The method comprises following steps: driving the ticket strip to move in the forward direction so that the separation line between the first ticket and the second ticket on the ticket belt reaches or passes through the tearingposition; the first ticket is adjacent to the second ticket and the first ticket is at the lower course of the first ticket in the forward direction; controlling to execute the ticket splitting operation so that the first ticket is separated from the second ticket; driving the ticket strip to move a first preset distance in the forward direction so that the front edge of the second ticket passes through the tearing position. The invention can improve the success rate of ticket distribution, and effectively solve the problem that the ticket distribution failure may occur in the self-service ticketing equipment in the prior art.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

User data processing method

InactiveCN106326774AReduce access pressurePrevent leakageDigital data protectionExpiration TimeUser input

The invention discloses a user data processing method, which comprises the following steps of setting a plurality of primary databases and a plurality of secondary databases, wherein the primary databases are databases with priority for access; when acquiring a preset command input by a user, switching a conventional domain interface into a safety domain interface, wherein application programs in the conventional domain interface and the safety domain interface are respectively installed and operated between each first database and each second database, and each first database and each second database are mutually isolated; when a user registers, storing user data into one primary database, and setting expiration time; when exceeding the expiration time set in the primary database, deleting the data in a primary sever, storing the data into one secondary database, and resetting the expiration time.

Owner:JIANGSU MINGTONG TECH

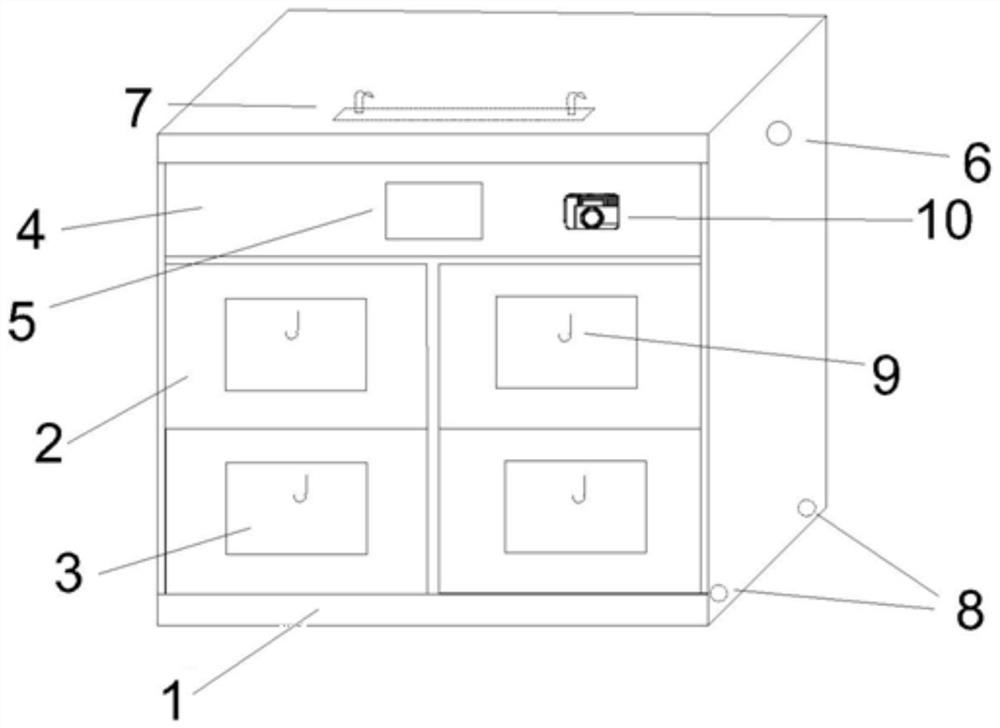

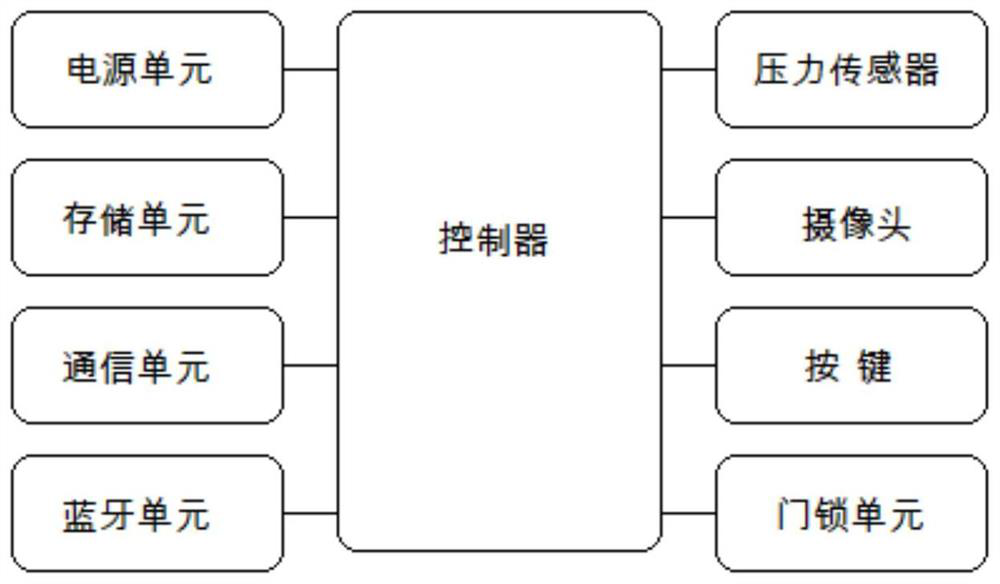

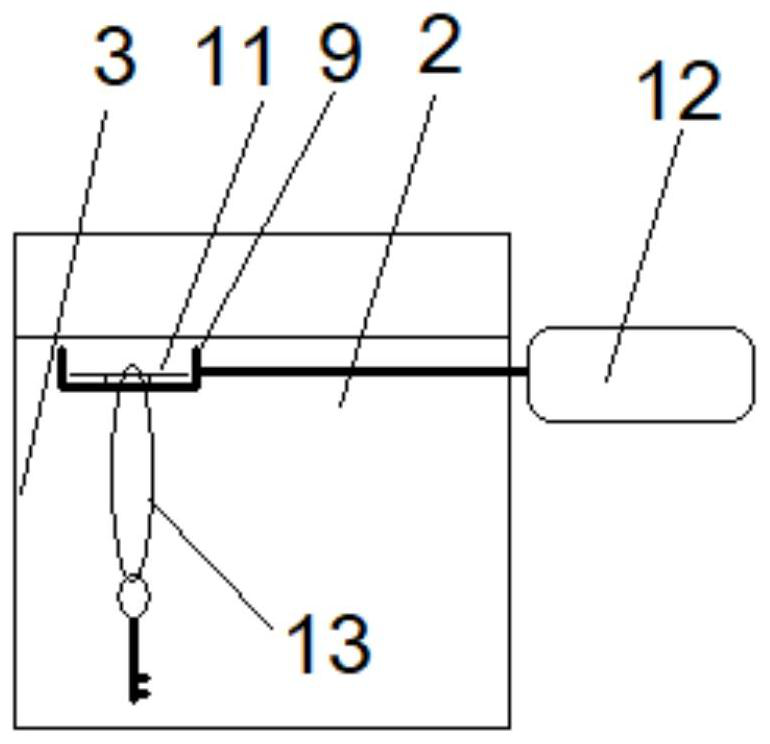

Intelligent key cabinet system based on Bluetooth communication and control method thereof

PendingCN112196376AGuaranteed orderGuarantee processLocks for portable objectsNon-mechanical controlsEmbedded systemMobile phone

The invention discloses an intelligent key cabinet system based on Bluetooth communication. A box body is provided with a control bin and at least one storage bin used for storing keys, a hook is arranged in each storage bin, the keys are hung on the hooks through key rings, and the hooks are connected to electric cylinders on the back faces in the storage bins through connecting rods. The electric cylinders push the hooks to extend out of or retract into the storage bins, a controller and a Bluetooth unit are fixed in the control bin, the controller is connected with each electric cylinder through a signal line, and the controller is connected with the Bluetooth unit through a signal line and communicates with user mobile phones through the Bluetooth unit. The system has the functions ofsensing and judging the keys inside, has the function of receiving receipts no matter when the keys are taken away or put back temporarily, can conveniently perform opening and closing through Bluetooth connection, achieves full-process management and control, and can guarantee the sequence and process of operation work.

Owner:WUHU POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER +1

A farming combination method for soil and water conservation in sloping farmland

InactiveCN106817943BAvoid churnReduce churnClimate change adaptationSoil-working methodsLongitudinal furrowScarification

Owner:JILIN ACAD OF AGRI SCI

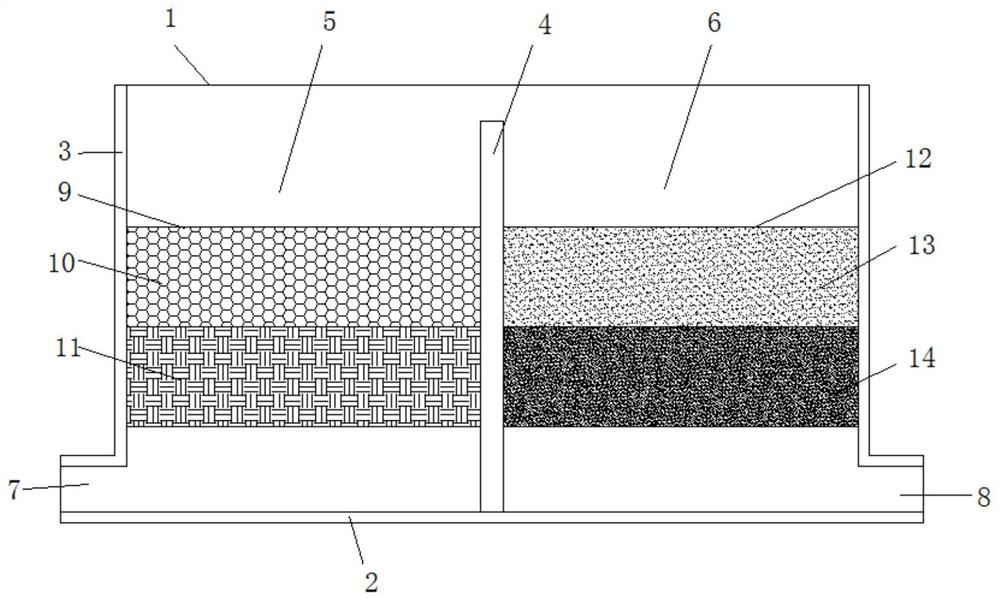

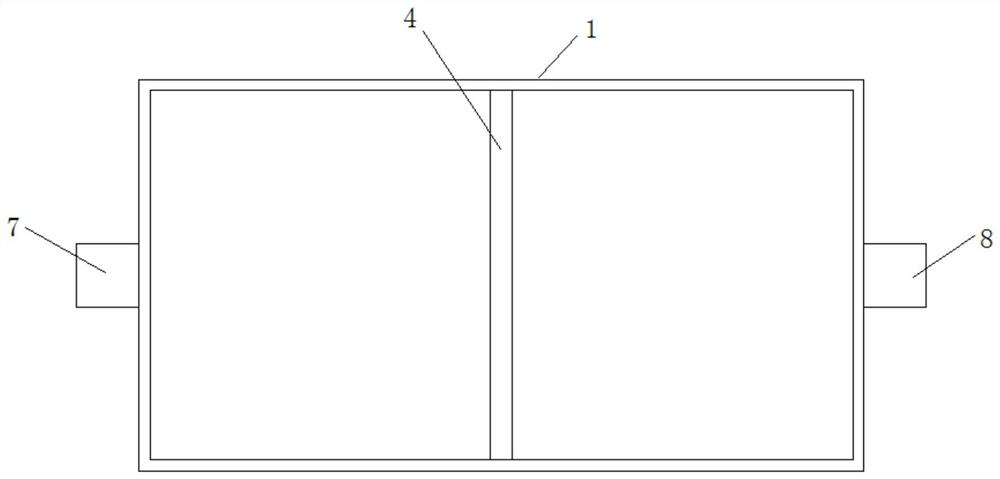

Sewage filter tank

InactiveCN111908635ASmall footprintGood filtering effectWater contaminantsTreatment involving filtrationSmall footprintSewage

The invention discloses a sewage filter tank, which comprises a tank body; the tank body comprises a bottom and side walls, wherein the bottom of the tank body is provided with a water separation plate, two sides of the water separation plate are respectively connected with the side walls at two sides of the tank body to divide the tank body into a first filter tank and a second filter tank, wherein the bottom of the first filter tank is provided with a water inlet, and the bottom of the second filter tank is provided with a water outlet; the top of the water-stop sheet is lower than the sidewall; a first filter unit is arranged in the first filter tank, and a second filter unit is arranged in the second filter tank. The sewage filtering tank is small in occupied area and good in filtering effect.

Owner:马鞍山领瞻机械科技有限公司

Control method of ticket distribution device and ticket distribution device

ActiveCN108205850BGuarantee processIncrease success rateLottery apparatusCoin-freed apparatus detailsTicketSimulation

A ticket dispensing method and device, relating to the technical field of self-service ticketing. The method comprises: driving a ticket belt to move in a forward direction so that a separation line between a first ticket and a second ticket on the ticket belt reaches or passes through a tear-cut position (S210), the first ticket being adjacent to the second ticket and positioned at the downstream of the second ticket in the forward direction; controlling and executing the tear-cut action so that the first ticket is separated from the second ticket (S220); and driving the ticket belt to move a first predetermined distance in the forward direction so that the front edge of the second ticket passes through the tear-cut position (S230).

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com