Comprehensive compaction filling method for reclaiming lands in loess hilly-gully regions by filling

A gully area and filling technology, applied in filling, construction, soil protection, etc., can solve problems affecting project quality, safety and practicability, low natural water content, differential settlement of filling-excavation transition zone, etc., to overcome the site Difficult Effects of Terrain Conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

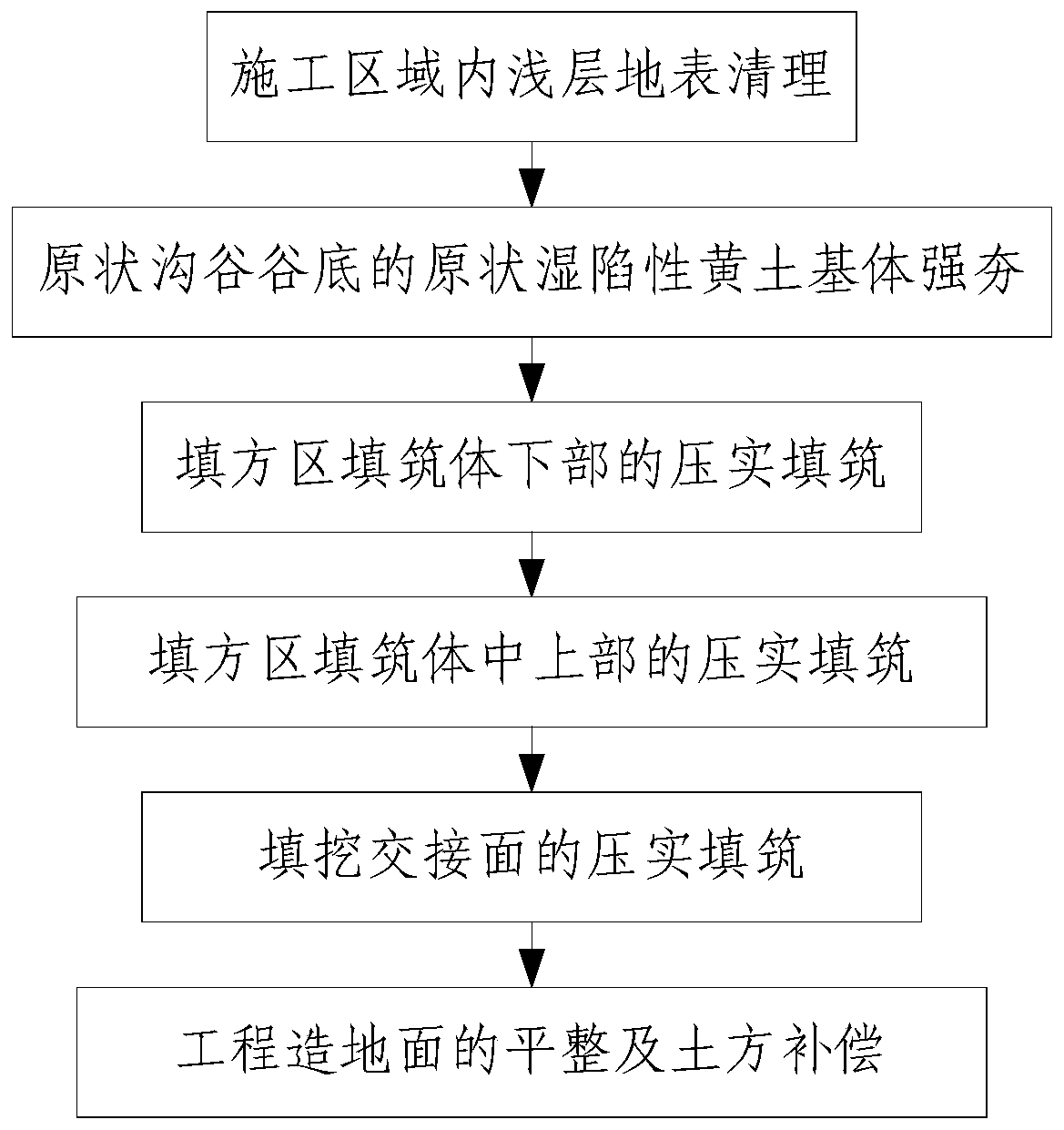

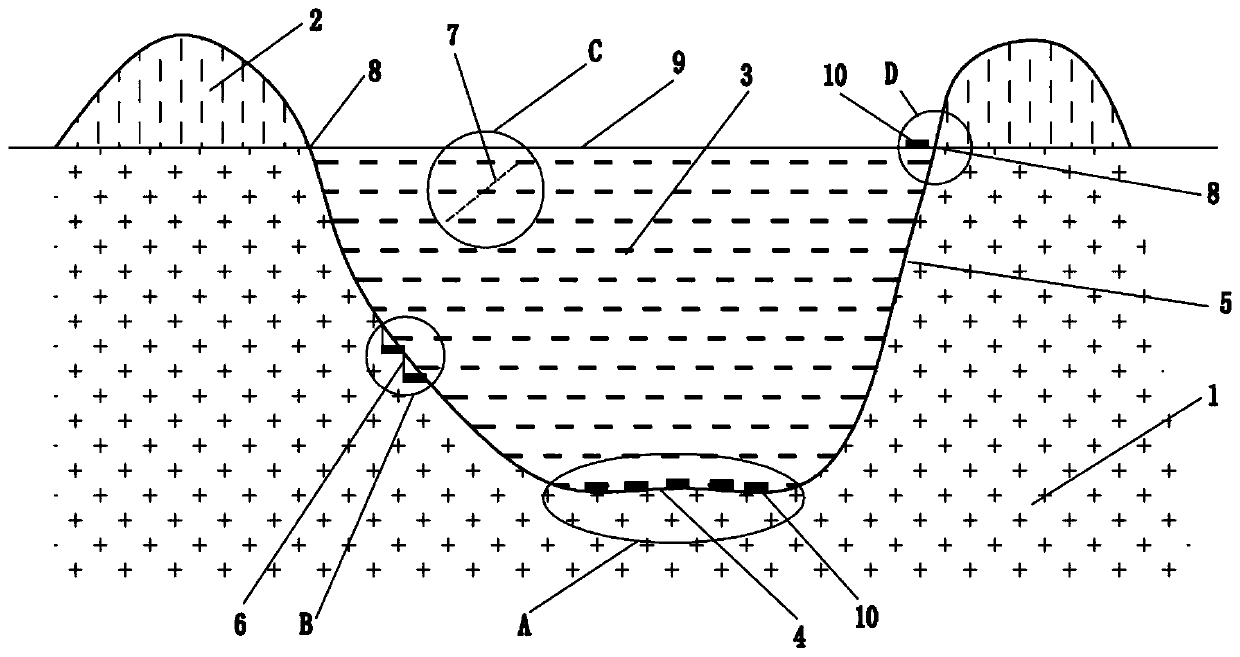

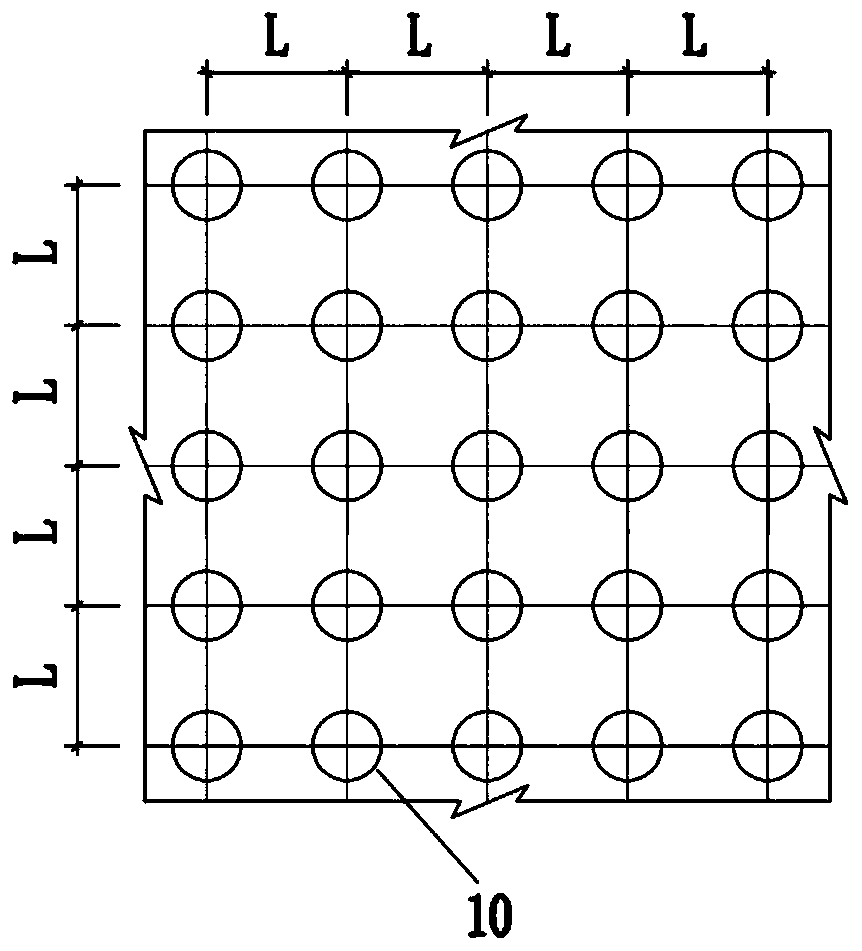

[0059] Such as Figure 1 to Figure 9 As shown, a kind of loess hilly gully area filling land comprehensive compaction filling method of the present invention comprises the following steps:

[0060] Step 1. Clean up the shallow surface in the construction area: transplant and protect the trees in the construction area, classify the shallow surface soil according to the organic matter content, and clean up the shallow surface in the construction area;

[0061] In this embodiment, the shallow topsoil described in step 1 is the topsoil within 20cm from the surface; the process of classifying the shallow topsoil according to the organic matter content: testing the organic matter content of the shallow topsoil 1. Surface soil with organic matter content not greater than 3% shall be transported and compacted as general soil; surface soil with organic matter content greater than 3% shall be transported to green areas or designated temporary locations for storage.

[0062] It should b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com