Full automatic deviation rectifying device for cloth

A deviation rectification device and fully automatic technology, applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problems of easy deviation of the cloth during the running process, difficult to ensure the edge wrapping and trimming, etc., to achieve good deviation rectification effect. , the effect of preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

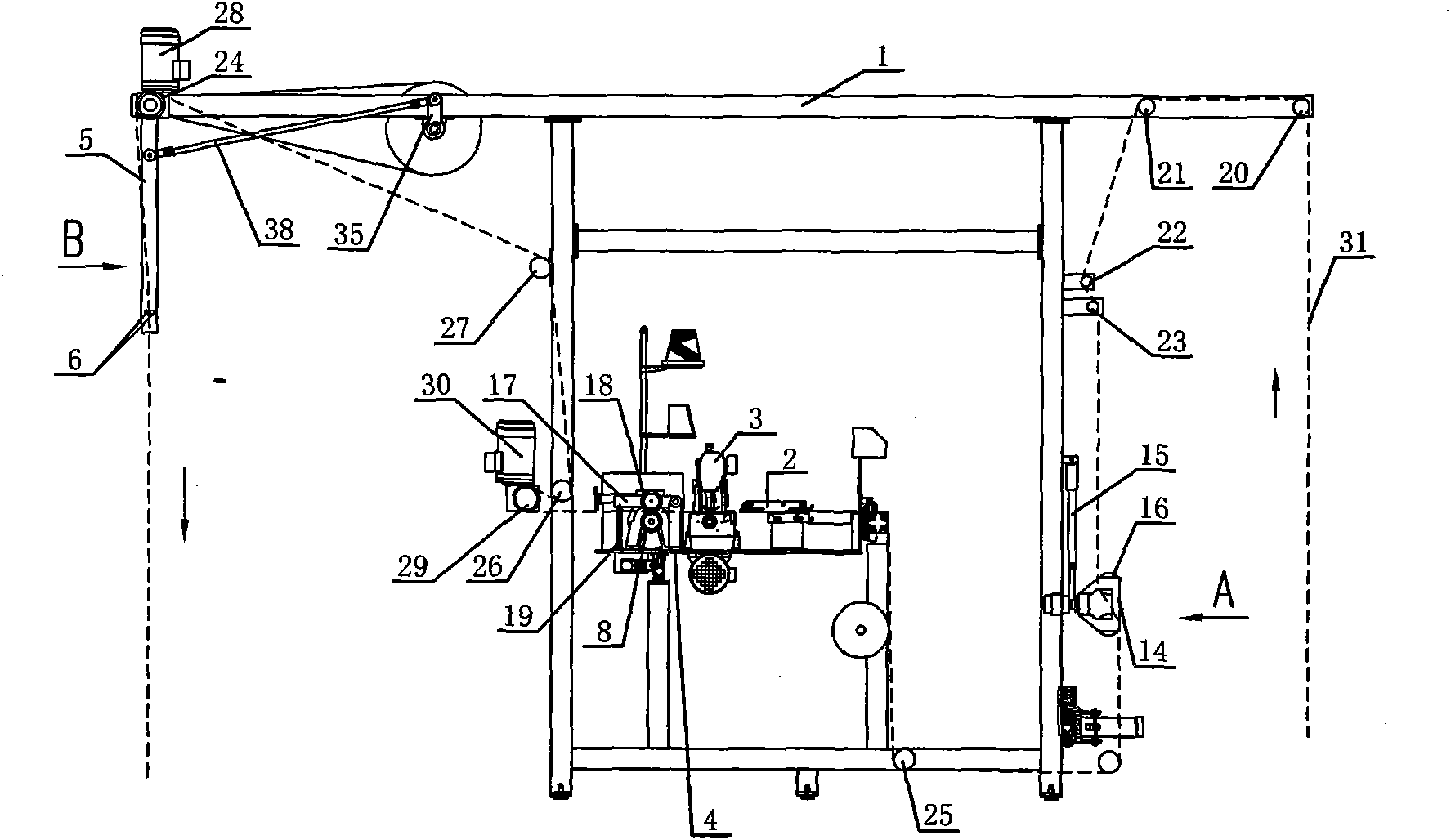

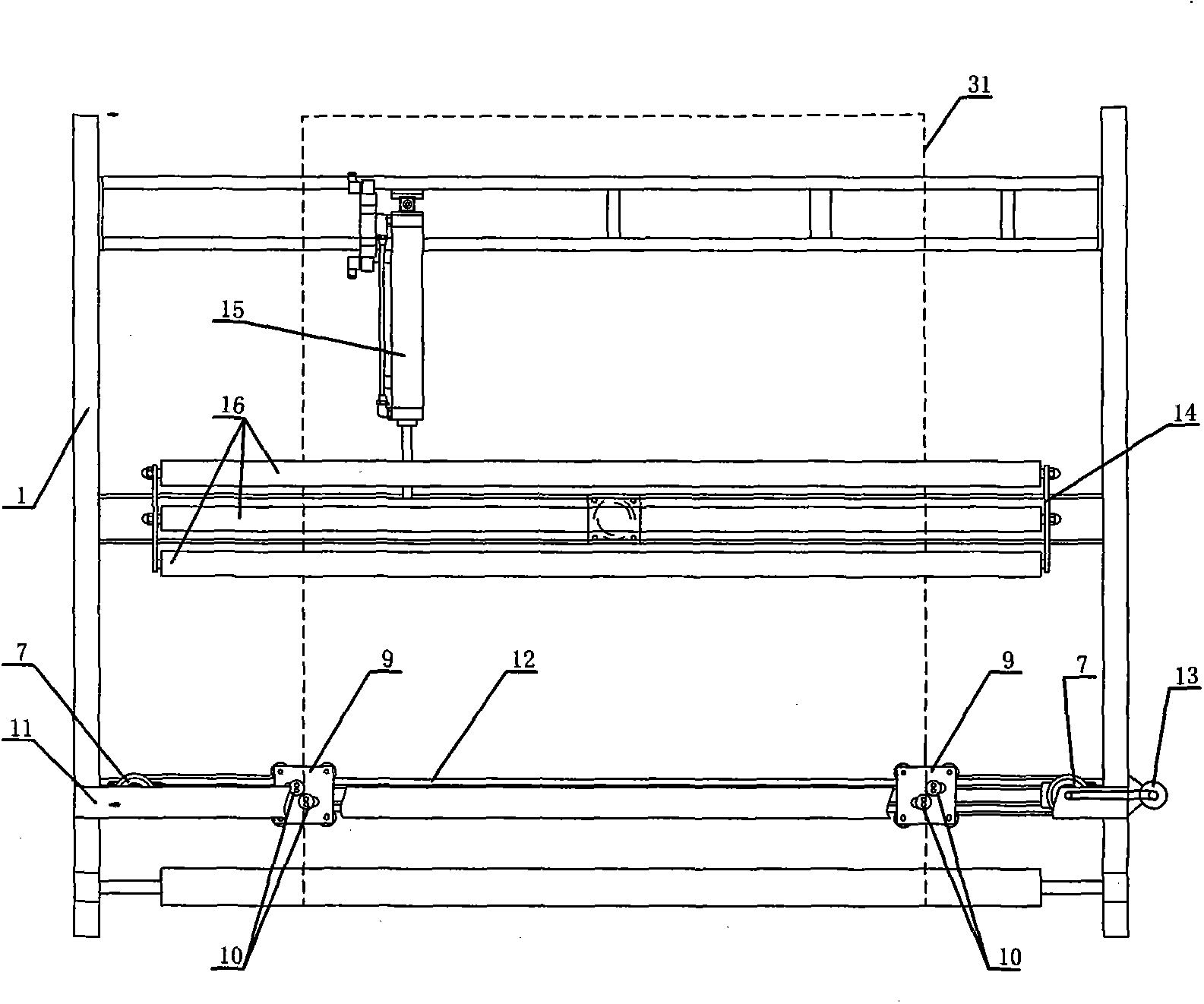

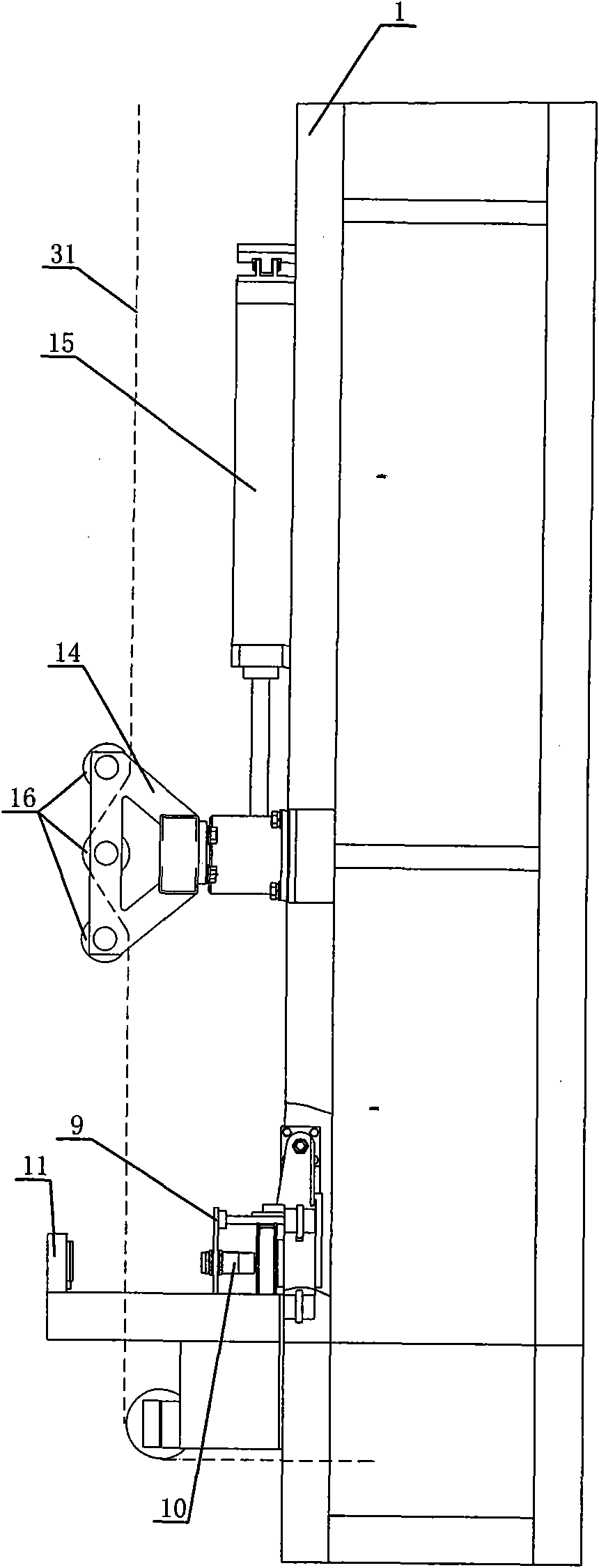

[0013] The present invention distinguishes the front and rear according to the direction of the cloth, with the cloth feeding direction as the front and the cloth outlet direction as the rear, and the direction of the cloth 31 is as follows: figure 1 Shown in the middle arrow, the cloth 31 shown in the figure is a dotted line. Such as figure 1 As shown, the cloth automatic deviation correction device includes a cloth feeding guide roller group connected to the frame 1, such as figure 1 , figure 2 and image 3 As shown, the cloth feeding guide roller group is provided with a cloth feeding deviation correction device, and the cloth feeding deviation correction device includes two brackets 9 that are relatively arranged on the frame 1 along the cloth width direction and driven by the deviation correction power mechanism. Position-measuring photoelectric switch 10 is installed, and reflector 11 corresponding to the position of position-measuring photoelectric switch 10 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com