Process for constructing impervious concrete wall by using open excavation and inverted construction method

A technology of concrete anti-seepage wall and construction technology, which is applied in construction, artificial islands, water conservancy projects, etc. It can solve the problems of deformation and damage of guide walls, easy collapse of tank walls, and easy leakage of slurry, so as to achieve low project cost and ensure the quality of joints , the effect of less disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is specifically described below by the embodiment, and the present embodiment is only used to further illustrate the present invention, can not be interpreted as the restriction to the scope of protection of the present invention, some non-essential improvements and improvements that those skilled in the art make according to the above-mentioned content Adjustment also belongs to the protection scope of the present invention.

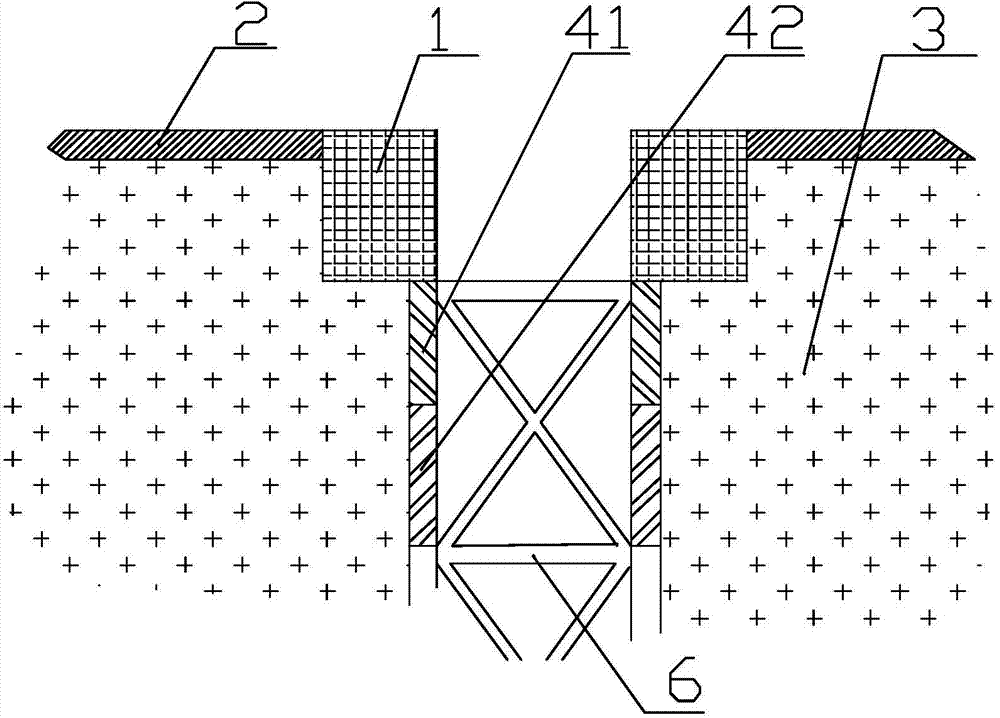

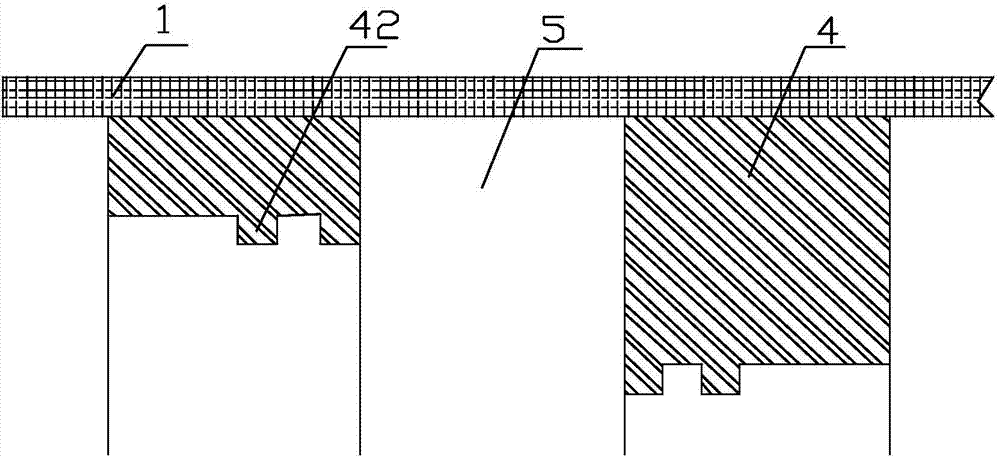

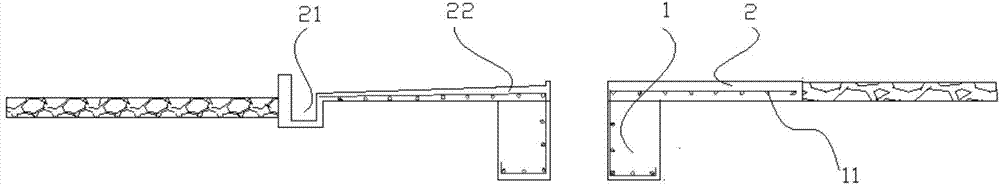

[0033] combine Figure 1 to Figure 6 .

[0034] The process method of the present invention is specifically applied in the construction of a concrete anti-seepage wall of a hydropower station in Tibet. The concrete anti-seepage wall of the hydropower station is constructed in a loose sand and pebble stratum, and the new type of ultra-long, ultra-deep, zero-expansion coefficient open-cut reverse construction of the present invention is adopted. The groove-forming method of the method can be combined into grooves comprehensiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com