Novel double-electrode direct-current arc system for melting wastes

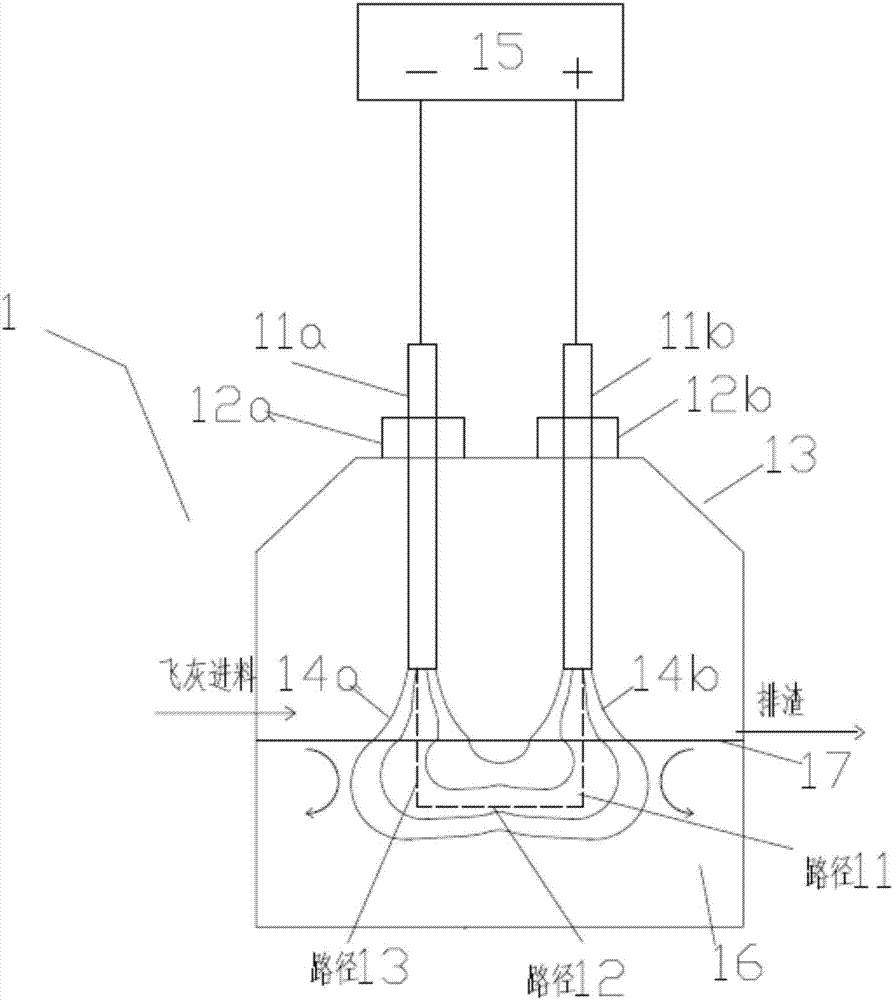

A DC arc and double-electrode technology, which is applied in the field of new double-electrode DC arc system, can solve the problems that are not obvious in Figure 1, it is difficult to accurately adjust the heating and temperature of the molten pool, and the stirring of the molten pool is insufficient, so as to speed up the melting ability, The effect of maximizing melting rate and optimizing unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

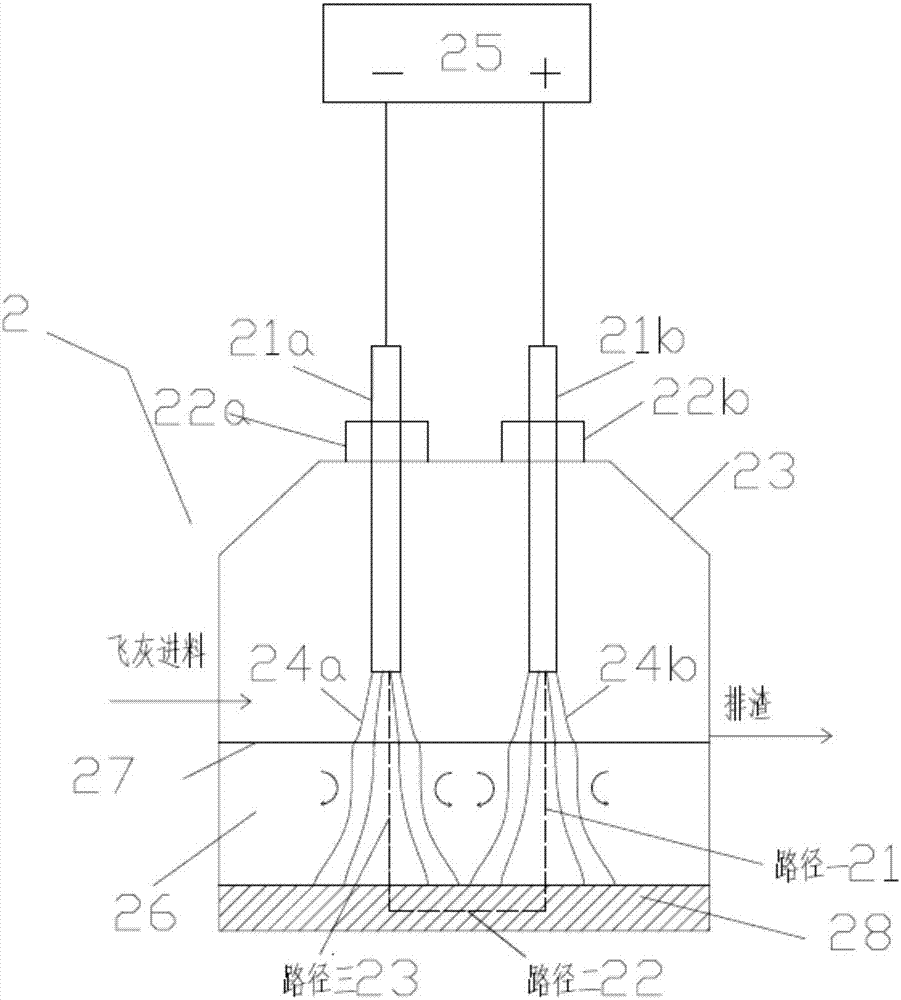

[0044] As an implementation, the double electrodes are arranged symmetrically along the central axis of the melting furnace, and are arranged on a plane passing through the central axis with the fly ash feed port and the slag discharge port, such as figure 2 shown.

[0045] The typical material of the double electrode is graphite, which is rod-shaped. Either hollow graphite rods or solid graphite rods can be used. When the hollow graphite rod is used, the hollow channel of the electrode rod can be fed with working gas to stabilize the arc. Typical working gases are argon and nitrogen; when solid graphite electrodes are used, no working gas is required. The bottom conductive member 28 is paved with conductive refractory material or graphite disc, with a typical thickness of 200mm. A certain amount of arc ignition agent (typically steel balls or coke) is put into the furnace body, and the two electrodes 21a, 21b are contacted with the arc ignition agent to start the arc thro...

no. 2 example

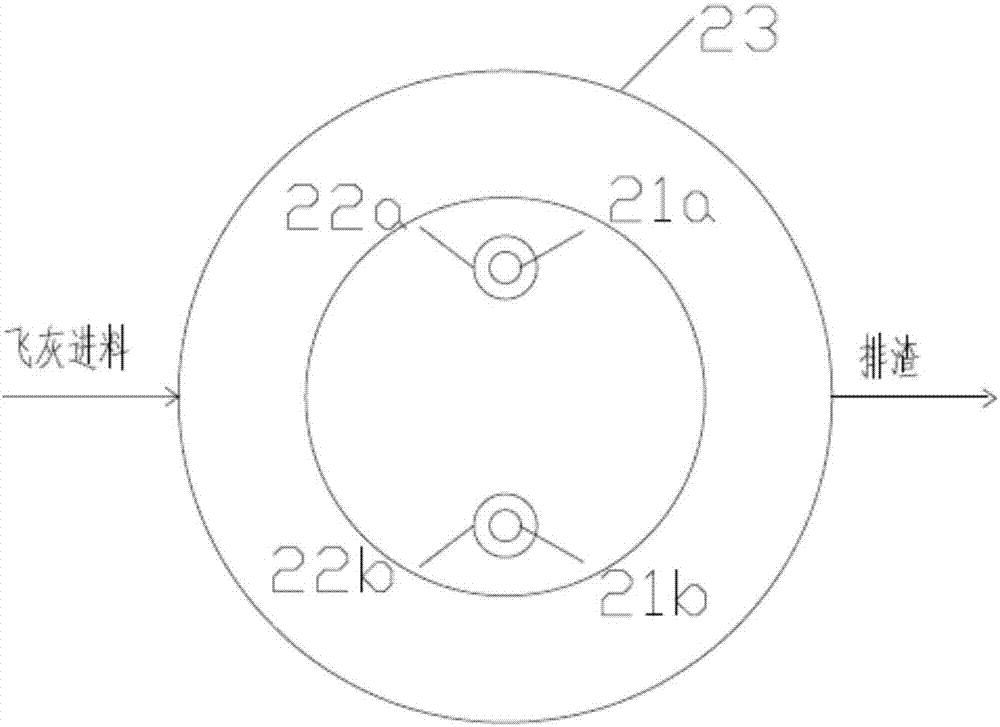

[0047] As a second embodiment, the double electrodes 21a and 21b are symmetrically arranged along the central axis of the melting furnace, and the fly ash feed port and the slag discharge port are arranged on a plane passing through the central axis. The plane where the double electrodes are located is perpendicular to the plane where the fly ash inlet and slag outlet are located, such as image 3 shown. The double electrodes and the bottom conductive member 28 are the same as those in the first embodiment. Different from Embodiment 1, the lifting system 22a, 22b contacts the graphite disc to start the arc, pulls up the electrode to maintain the arc, and puts in the fly ash raw material after the graphite is red hot to make it melt. When the molten pool rises to the level of the slag outlet, the fully melted fly ash slag overflows out of the slag outlet and is cooled.

[0048] According to the above two embodiments, the system can more effectively melt the fly ash pool, maxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com