Method for shaping throat liner lining

A molding method and lining technology, which is applied in the molding field of throat liner lining, can solve the problems of high density of tungsten-infiltrated copper material, easy fracture of thin-walled parts, difficult processing and molding, etc., so as to save raw materials, simplify subsequent processing procedures, The effect of convenient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The first preferred embodiment: a method for forming a throat liner lining of the present invention mainly includes the following steps:

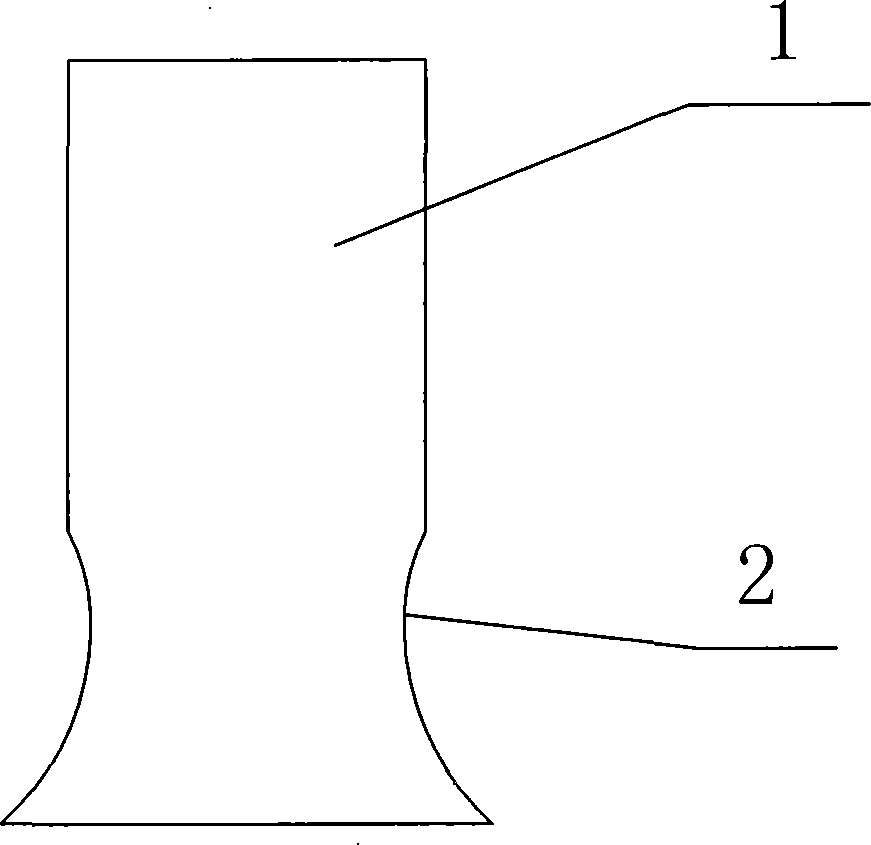

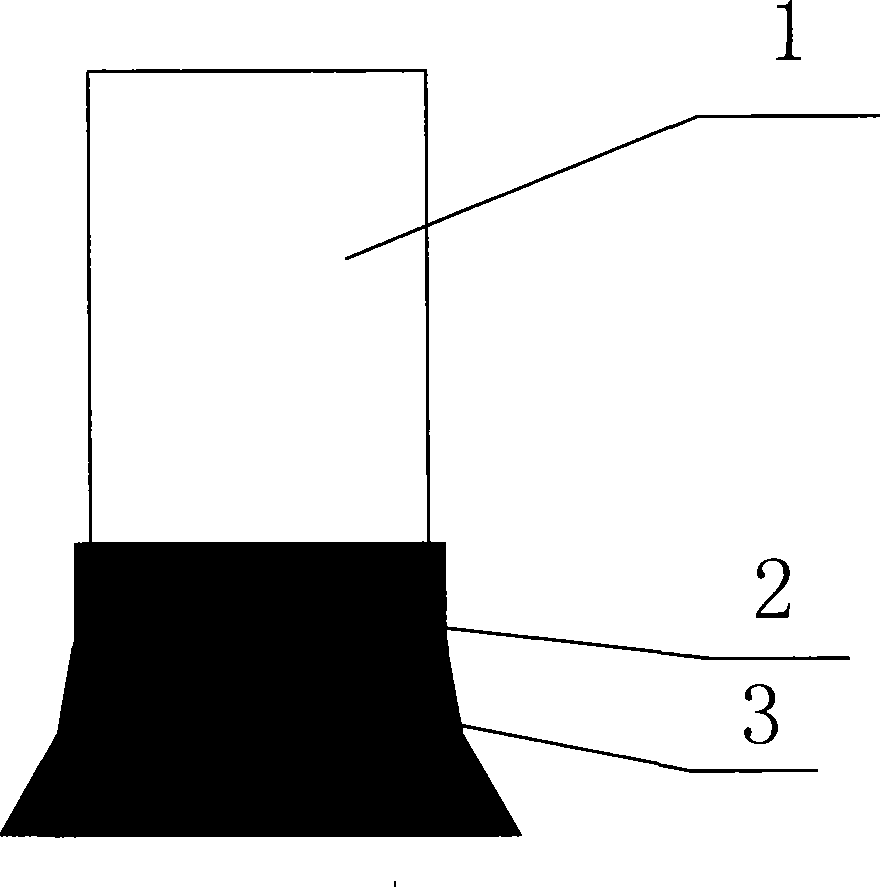

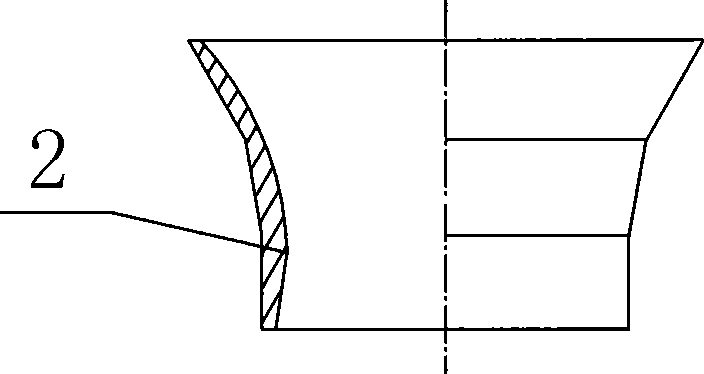

[0024] The first step: such as figure 1 As shown, a graphite inner core mold with a stable shape and structure with a clamping portion 1 at the end is processed according to the internal structure of the throat lining to be manufactured, that is, the material of the inner core mold is graphite. The structure and shape of the made graphite inner core mold correspond to the internal structure of the throat lining to be made and have a certain strength. Its shape and structure are stable, which can ensure that the inner core mold does not deform during the molding process. , Does not break. The graphite inner core mold is a solid mold, and the smoothness of its outer surface is higher than or equal to the smoothness of the inner surface of the manufactured product. The manufactured inner core mold is a solid mold, and in practice, it can a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com