3D printer of wax part

A 3D printer and parts technology, which is applied to 3D object support structures, processing heating elements, and accessories for processing main materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

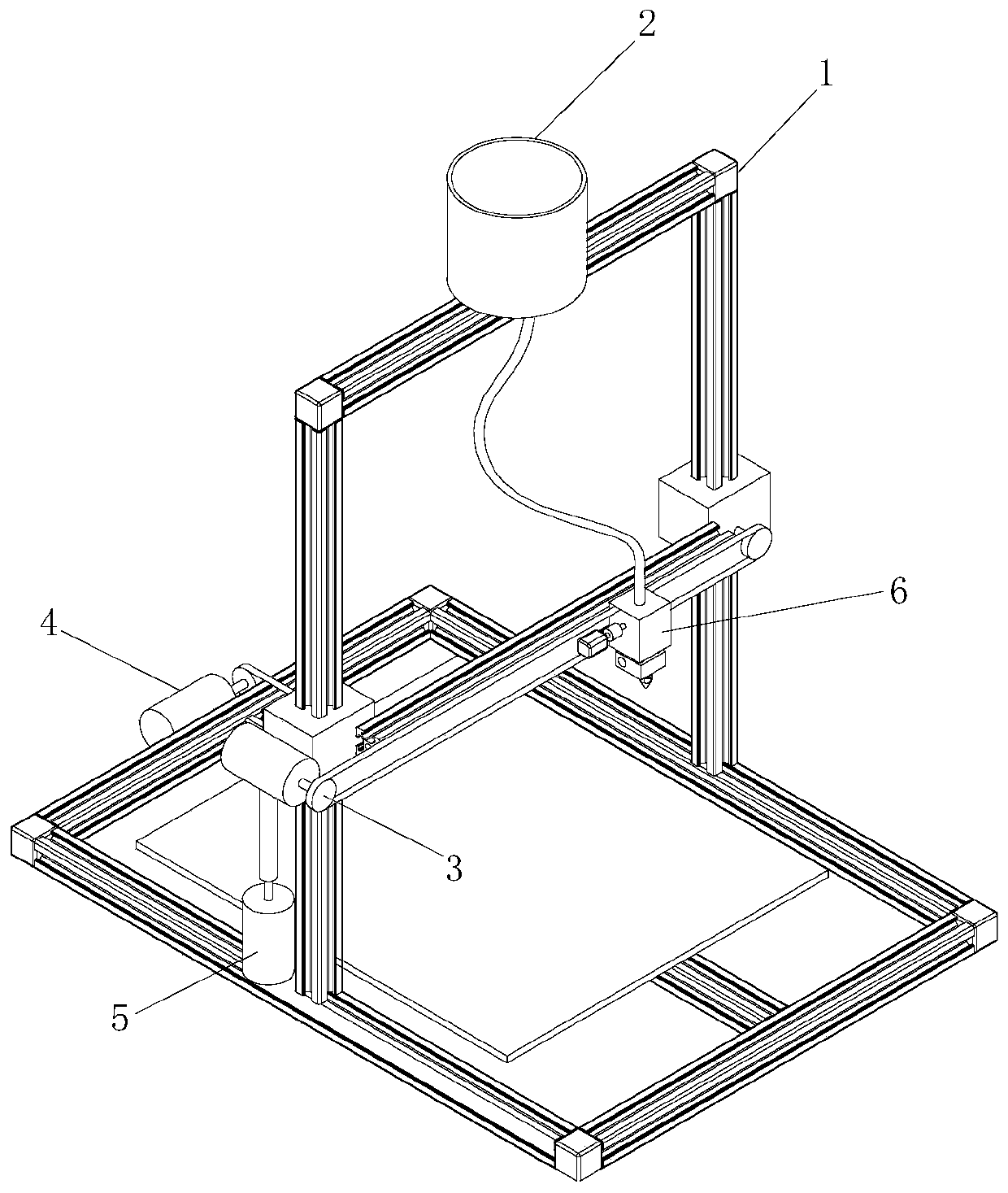

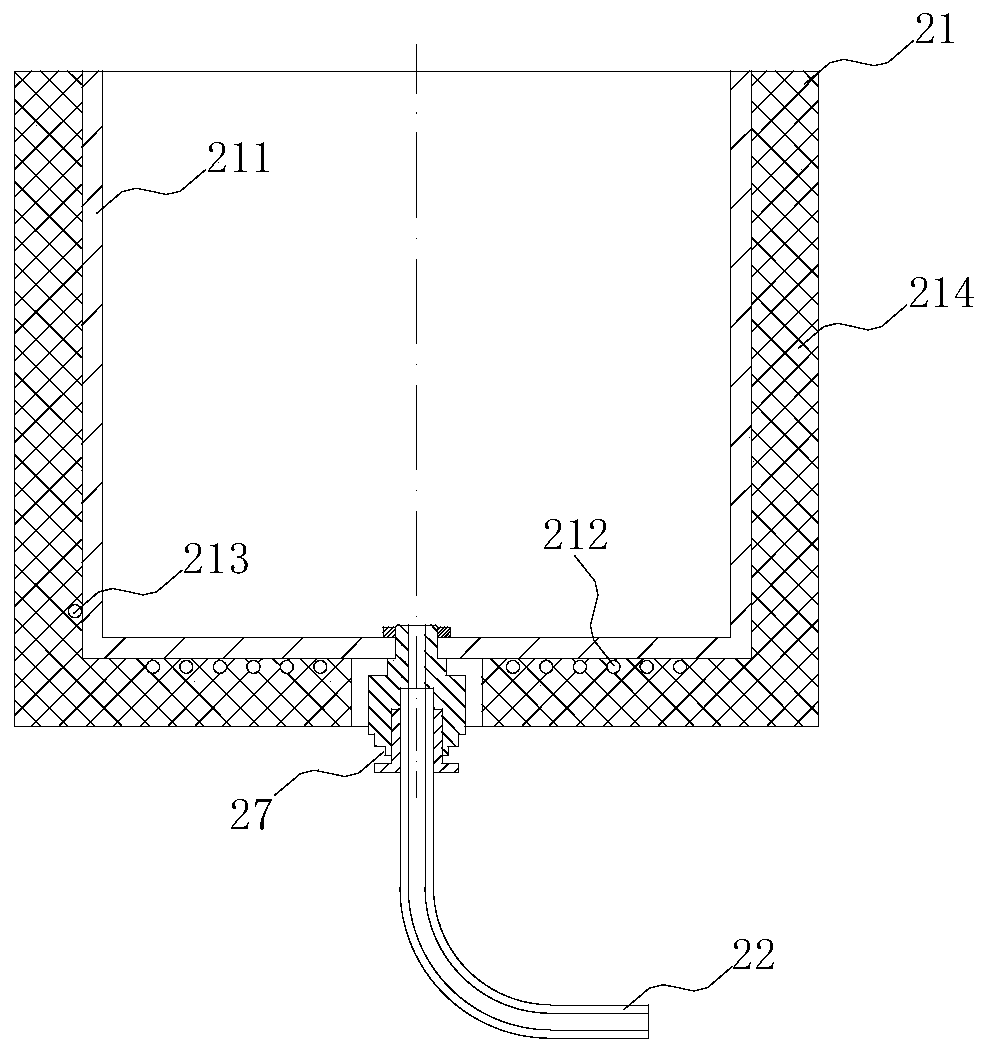

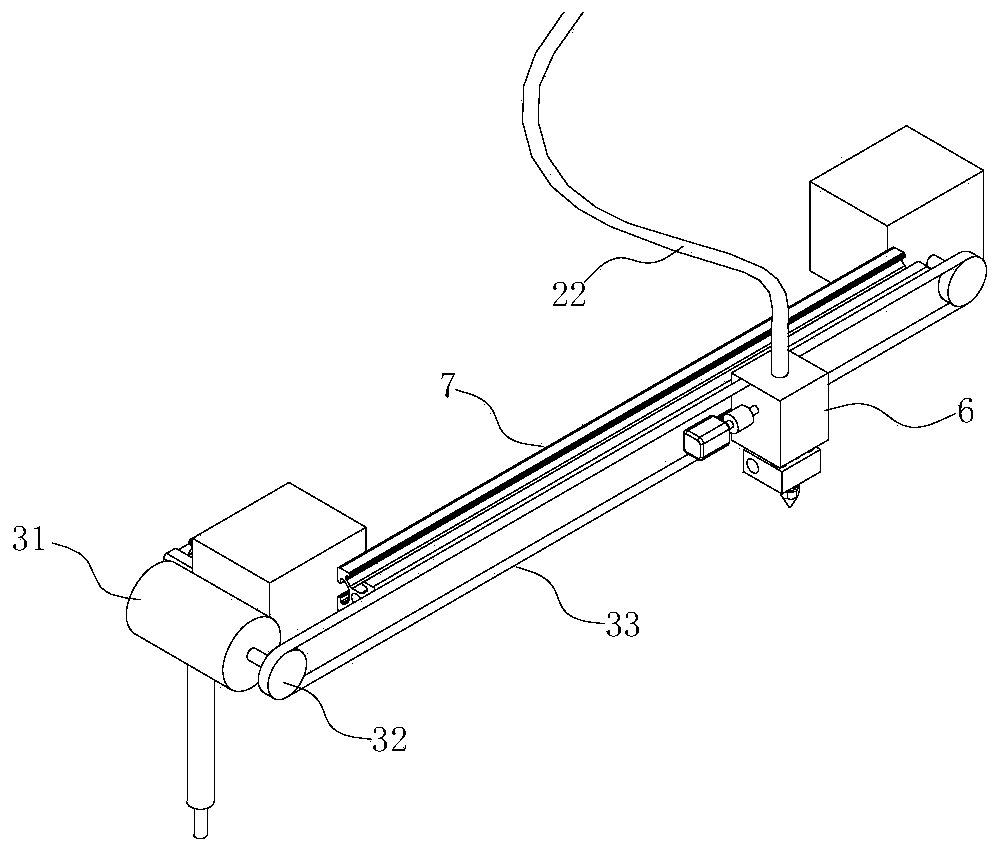

[0036] like Figure 1 to Figure 6 As shown, the 3D printer for wax parts in this embodiment has a frame, a filament extrusion system and a space motion system. Frame 1 is set on the outside of the wax parts 3D printer to form a frame structure. There is a printing bed 8 under the frame 1. The space above the printing bed 8 is the printing space. The printing carriage 6 can move freely in the printing space above the printing bed. , so as to complete the printing conveniently. The space motion system of the 3D printer is the same as the space motion system of the FDM three-dimensional printer. The space motion system has a first direction motion mechanism 3, a second direction motion mechanism 4, a third direction motion mechanism 5, and a printing cart 6. The printing cart 6 is on the beam. If set above, the printing carriage 6 can move freely in the printing space; wherein the first direction is the X-axis direction, the second direction is the Y-axis direction, and the thir...

Embodiment 2

[0043] like Figure 7 to Figure 12 As shown, this embodiment provides a 3D printer for wax parts, which has a frame, a consumable extrusion system and a space motion system. Frame 1 is set on the outside of the wax parts 3D printer to form a frame structure. The frame structure is columnar as a whole. There is a printing bed 8 under the frame 1. The printing bed 8 can be a circular flat structure. The printing trolley 6 is on the printing bed 8. Move freely in the printing space above. Specifically, the frame 1 can also be provided with three parallel columns, the columns are vertically arranged with the printing bed, and the columns are connected and fixed by connecting columns. The space motion system is a cylindrical coordinate space motion system. The space motion system has a first direction motion mechanism 3, a second direction motion mechanism 4, a third direction motion mechanism 5, and a printing carriage 6. The printing carriage 6 moves in the printing space. Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com