Method for preparing positive electrode material of lithium ion battery through fluidized sintering

A lithium-ion battery and positive electrode material technology, applied in the field of lithium-ion battery positive electrode material preparation, can solve problems such as uneven temperature distribution, furnace junction, and difficult atmosphere control, and achieve stable atmosphere in the furnace, improved batch stability, and production The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

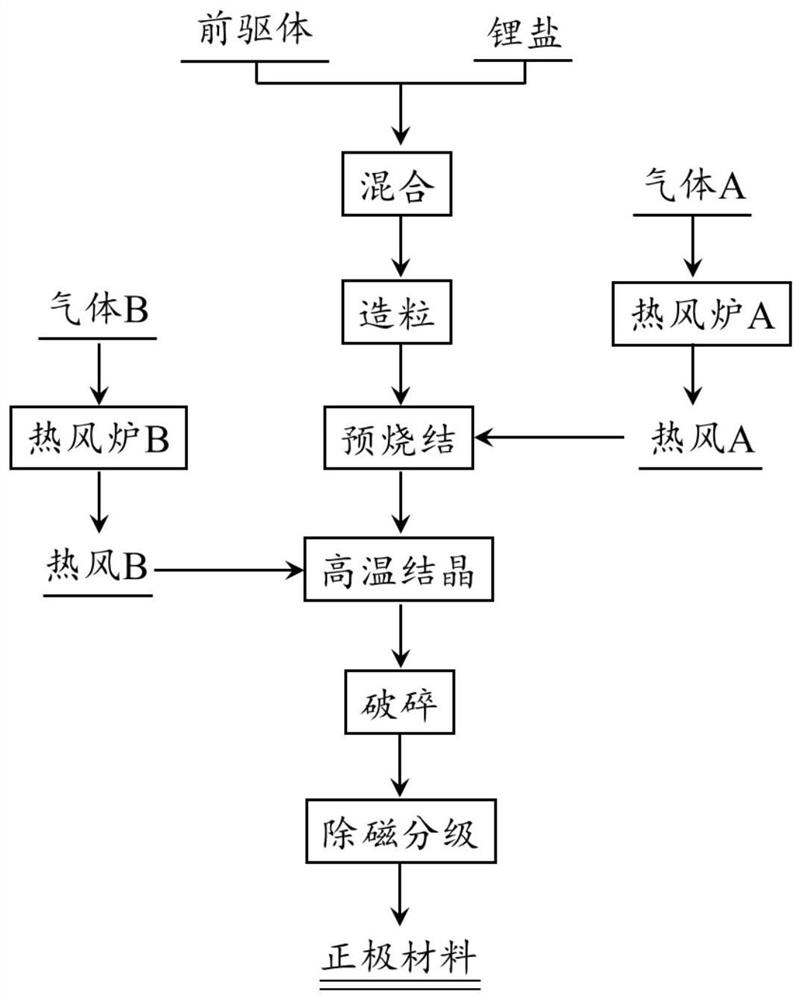

[0040] Such as figure 1 As shown, the embodiment of the present invention provides a kind of method that fluidized sintering prepares lithium-ion battery cathode material, comprises the following steps:

[0041] Step 1, mixing ingredients:

[0042] Precursor FePO 4 with Li 2 CO 3After weighing according to the stoichiometric ratio of 1.05:1, add it to the high-speed mixer at the same time for mixing;

[0043] Step 2, granulation:

[0044] Put the uniformly mixed material into a roller press granulator for granulation, so that the size of the obtained spherical granular material is 50um<d<5mm, and the particle size of less than 20% of the spherical granular material is <250um; Add 2wt.% water vapor as binder in the process;

[0045] Step 3, fluidized pre-sintering:

[0046] The granular material obtained in step 2 is pre-sintered in a fluidized fluidized furnace, and the hot gas A heated by an external combustion type hot blast stove is passed into the boiling furnace, w...

Embodiment 2

[0054] Step 1, mixing ingredients:

[0055] Precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 Weigh it with LiOH according to the stoichiometric ratio of 1.1:1, and add it to the high-speed mixer for mixing;

[0056] Step 2, granulation:

[0057] The uniformly mixed material is granulated by a roller granulator, so that the size of the obtained spherical granular material is 50um<d<5mm, and the particle size of less than 20% of the spherical granular material is <300um; Add 2wt.% water vapor as binder in the process;

[0058] Step 3: Fluidized pre-sintering:

[0059] The fluidized flash roaster is used for pre-sintering, and the hot gas A heated by the external combustion type hot blast stove is passed into the fluidized flash roaster, wherein the hot gas A is air, the temperature is 750°C, and the pre-sintering time t 1 For 120 minutes, the gas enters the fluidized flash roaster countercurrently relative to the granular material, so that the granular material is in a fluidized st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com