Method and device for laser manufacturing polyamide three-dimensional objects

A technology of three-dimensional objects and polyamide, which is applied in processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve problems such as difficult to achieve effects, and achieve the effect of fine three-dimensional characteristic structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

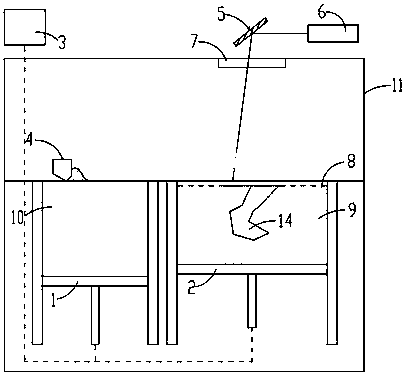

[0038] Embodiment 1: A polyamide three-dimensional part is manufactured by using a Nd:YAG laser with a wavelength of 1064 nm.

[0039] The material used is the polyamide powder material FS3200 of Hunan Farsoon High-Tech Co., Ltd., and it is fully mixed with aluminum powder with a particle size distribution of 5-40 μm. The volume percentage of FS3200 is 90%, and the aluminum powder is 10%. The device used is the selective laser sintering equipment FS403 of Hunan Farsoon High-Tech Co., Ltd. and correspondingly modified. The matching equipment is equipped with a Nd:YAG laser with a wavelength of 1064nm.

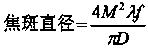

[0040] During the manufacturing process, the layer thickness of the powder coating material is set to 0.1mm, the preheating temperature of the material is about 180°C, the laser power is about 40-80W, the laser spot is controlled at 40-60μm, and the speed is controlled at about 10m / s The laser irradiates the cross-sectional area of the three-dimensional part. When one layer i...

Embodiment 2

[0041] Embodiment 2: Manufacturing carbon fiber-polyamide three-dimensional parts by using a solid-state laser with a wavelength of 532nm.

[0042] The material used is the polyamide powder material FS3400CF of Hunan Farsoon High-Tech Co., Ltd., which contains polyamide powder with a volume fraction of 80% and carbon fiber powder with a volume fraction of 20%, and the carbon fiber diameter is 50-100 microns. The device used is the selective laser sintering equipment FS403 of Hunan Farsoon High-Tech Co., Ltd. and correspondingly modified. The matching equipment is equipped with a solid-state laser with a wavelength of 532 nm.

[0043] During the manufacturing process, the layer thickness of the powder coating material is set to 0.1mm, the preheating temperature of the material is about 180°C, the laser power is about 40-80W, the laser spot is controlled at 40-60μm, and the speed is controlled at about 12m / s The laser irradiates the cross-sectional area of the three-dimensiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com