Flux composition and brazing sheet

A technology of flux and composition, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of rising cost, expensive Cs, low practicability, etc., and achieve high strength, light weight, wettability Improves and improves the effect of brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Mix KF and AlF at a mass ratio of 1:1 3 , to obtain [A] flux composition. Add 20 parts by mass of BaF as [B] additive with respect to 100 parts by mass of this [A] flux composition 2 and mixed to obtain the flux composition of Example 1.

Embodiment 2~11

[0073] Except having set [B] additive to the kind and content (parts by mass) shown in Table 1, it prepared similarly to Example 1, and obtained the flux composition of Examples 2-11.

[0074] 〔Evaluation〕

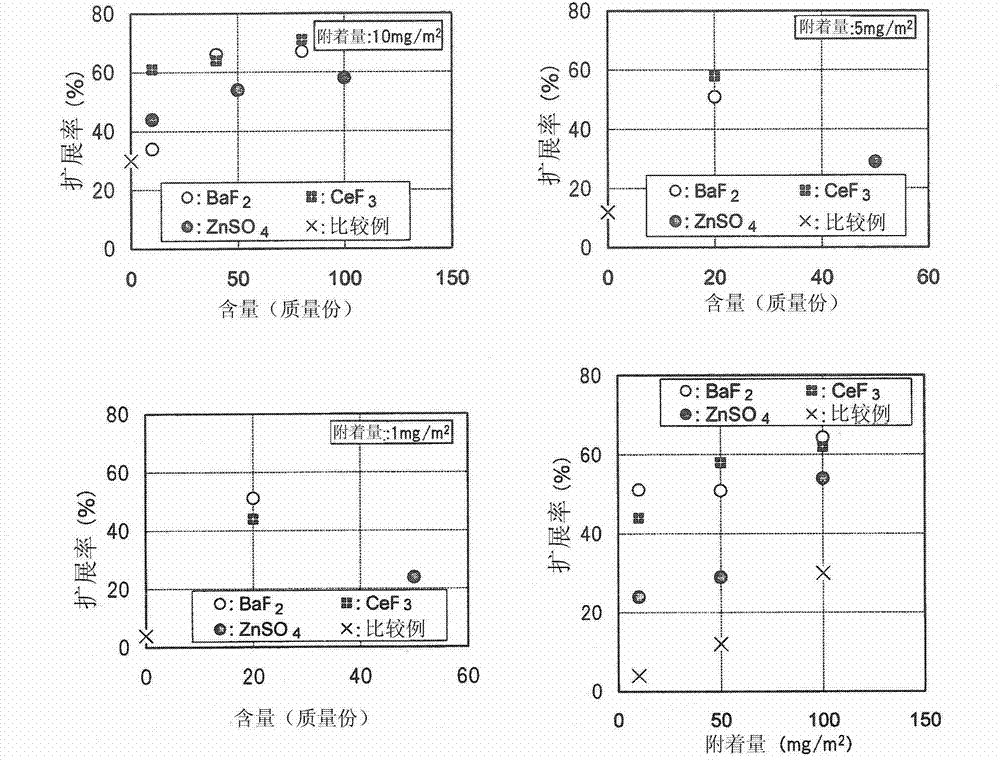

[0075] In 100 mL of ion-exchanged water, 0.04 g of each obtained flux composition was prepared and suspended to obtain a suspension containing the flux composition. The above-mentioned suspension was dropped on the center of a plate-shaped Al-Mg alloy (Mg content: 0.6% by mass) with a diameter of 20 mm so that the flux composition had a diameter of 5 mm, and dried. In addition, the mass of the plate alloy is measured before and after the flux composition is attached, and the dropping amount is adjusted so that the amount of the flux composition attached (solid content) becomes 1 to 10 g / m 2 . Thereafter, the plate-shaped alloy to which the flux composition was adhered was heated at 600° C. for 10 minutes in an atmosphere having a dew point of −40° C. and an oxygen concen...

Embodiment 12

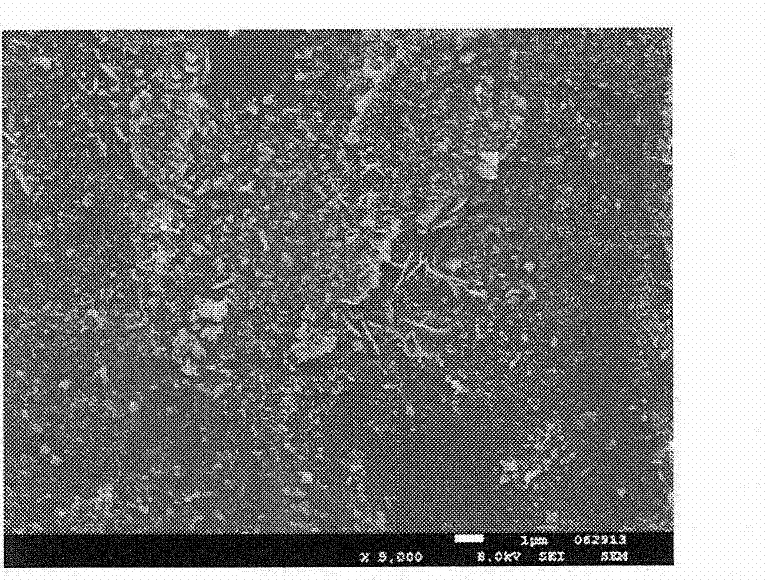

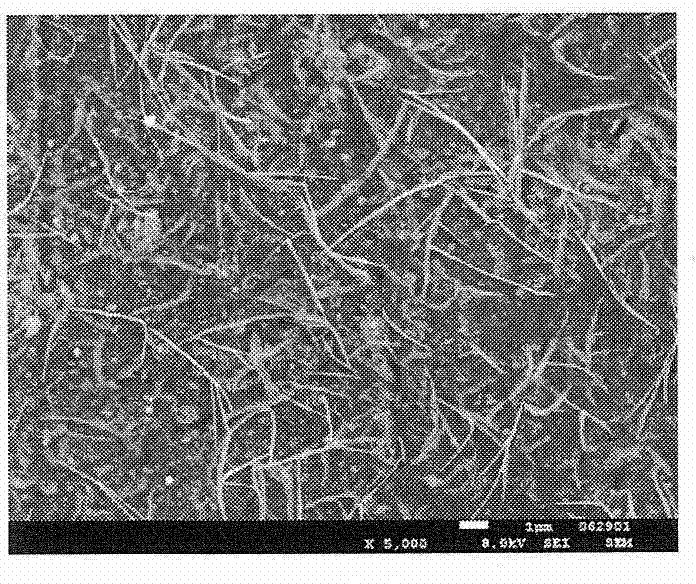

[0083] Use 30 parts by mass of BaF as [B] additive 2 , except that, the same adjustment as in Example 1 was performed to obtain the flux composition of Example 12. Using the flux composition obtained in Example 12, the plate-shaped alloy was heated in the same manner as the evaluation method described above, and after cooling, the surface was observed with a scanning electron microscope (SEM). The observed image is shown in figure 2 middle. In addition, the observed image of the surface of the plate-shaped alloy after heating when the flux composition containing only the [A] flux component of Comparative Example 1 is used is shown in image 3 middle.

[0084] Depend on figure 2 As can be seen from the photographs in the figure, when the flux composition obtained in Example 12 was used, precipitation of needle-shaped high melting point compounds was hardly observed. On the other hand, if image 3 As shown in the photo, when the flux composition of Comparative Example 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com