Piezoelectric ceramic material in bismuth laminar composite structure and preparation method of piezoelectric ceramic material

A technology of piezoelectric ceramics and composite structures, applied in the field of materials, can solve the problems of difficult control of sample uniformity and stability, difficulty in preparing ceramic bodies with uniform structure, and difficulty in regulating comprehensive electrical properties, so as to facilitate large-scale industrial production and easy compounding System components, the effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 of the present invention provides a piezoelectric ceramic material with a bismuth layered composite structure, whose general chemical formula is: [Ca 1-x Me x Bi 2 Nb 2-2y Me' 2y o 9 ] 1-z -[Bi 3-a Me a (TiNb) 1-b Me' 2b o 9 ] z ;

[0028] Among them, Me and Me' are doping elements suitable for different lattice positions, Me is one or more of Li, Mn, Ce, and Me' is one or more of Ta and W; x, y , z, a, b are mole fractions respectively, 0≤x≤0.05, 0≤y≤0.05, 0≤a≤0.05, 0≤b≤0.05, 0.2≤z≤0.8.

[0029] The piezoelectric ceramic material with bismuth layered composite structure provided by the embodiment of the present invention has a very high Curie temperature, excellent piezoelectric performance and adjustable comprehensive electrical performance, and can be used in various high-temperature piezoelectric devices.

Embodiment 2

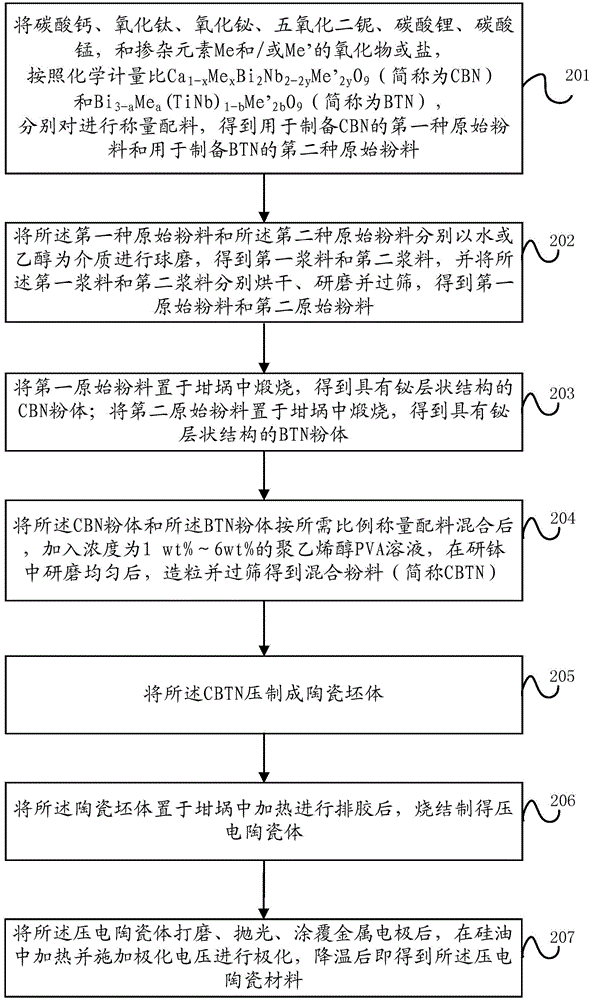

[0031] This embodiment provides the preparation method of the bismuth layered structure piezoelectric ceramic material in the above-mentioned embodiment 1, such as figure 1 shown, including:

[0032] Step 201, calcium carbonate, titanium oxide, bismuth oxide, niobium pentoxide, lithium carbonate, manganese carbonate, and the oxide or salt of the doping element Me and / or Me', according to the stoichiometric ratio Ca 1-x Me x Bi 2 Nb 2-2y Me' 2y o 9 (referred to as CBN) and Bi 3-a Me a (TiNb) 1-b Me'2b o 9 (abbreviated as BTN), carry out weighing batching respectively, obtain the first kind of raw powder that is used to prepare CBN and the second kind of raw powder that is used to prepare BTN;

[0033] Among them, Me and Me' are doping elements suitable for different lattice positions, Me is one or more of Li, Mn, Ce, and Me' is one or more of Ta and W; x, y , z, a, b are mole fractions respectively, 0≤x≤0.05, 0≤y≤0.05, 0≤a≤0.05, 0≤b≤0.05, 0.2≤z≤0.8.

[0034] Step 202...

Embodiment 3

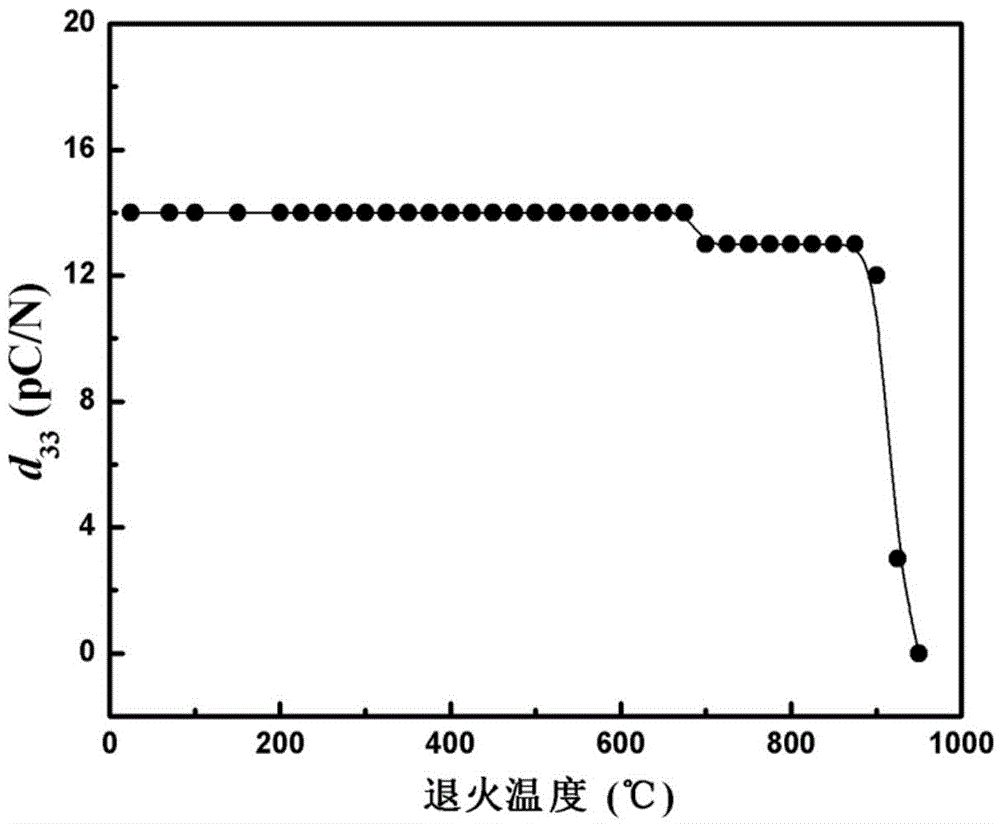

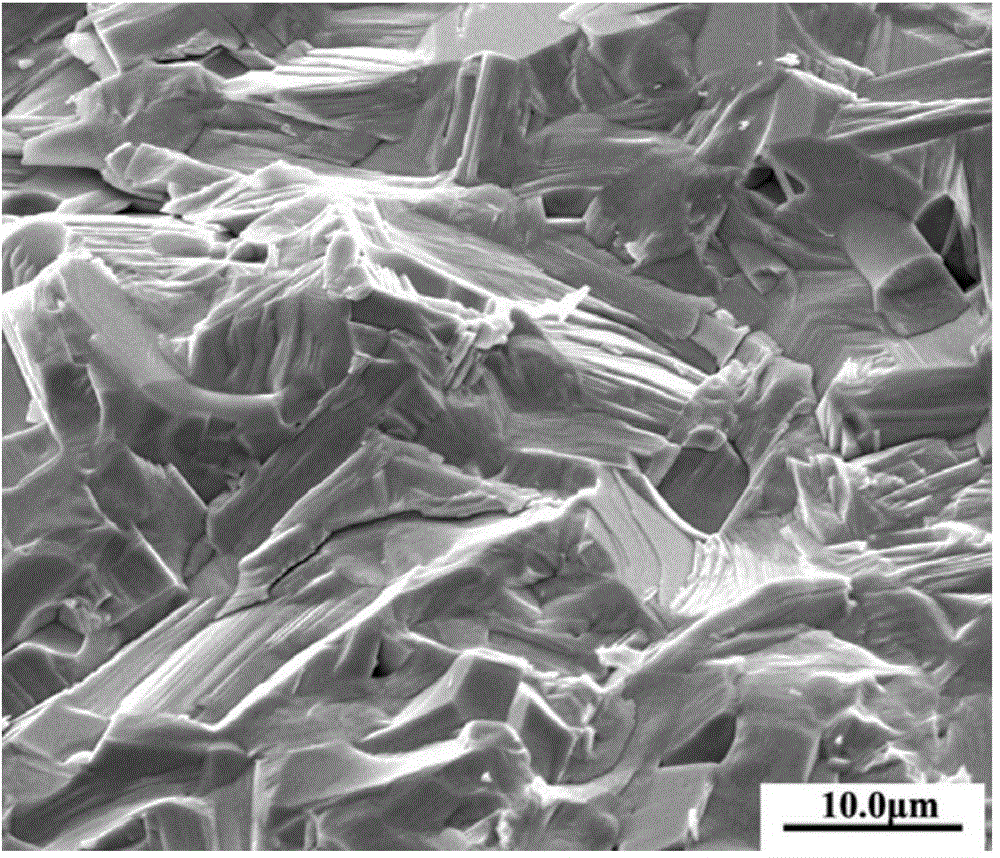

[0048] Using calcium carbonate, bismuth oxide, titanium oxide, niobium pentoxide, lithium carbonate and manganese carbonate as raw materials, according to the chemical formula Ca 0.95 Li 0.025 mn 0.025 Bi 2 Nb 2 o 9 and Bi 2.95 Li 0.02 mn 0.03 TiNbO 9 The ingredients were prepared separately, and the prepared CBN doped with Li and Mn and the BTN powder doped with Li and Mn were put into different ball milling tanks, and ball milled with absolute ethanol as the medium for 10 hours, then dried and the powders Put them into crucibles respectively, and calcined at 800°C for 3 hours to obtain powders of CBN and BTN respectively; 0.7 BTN 0.3 Mix the ratio into an agate mortar, add polyvinyl alcohol solution and grind for 20 minutes, pass through a 200-mesh sieve and age for 10 hours, and press it under a pressure of 150MPa to form a disc with a diameter of 1.2cm and a thickness of about 1.2mm. After debinding the green body, it was sintered at 1020°C for 3 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com