Green and environment-friendly drilling plugging agent and using method thereof

A technology of green environmental protection and plugging agent, applied in chemical instruments and methods, drilling composition and other directions, can solve problems such as large shrinkage of cement, water leakage, and inappropriate plugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

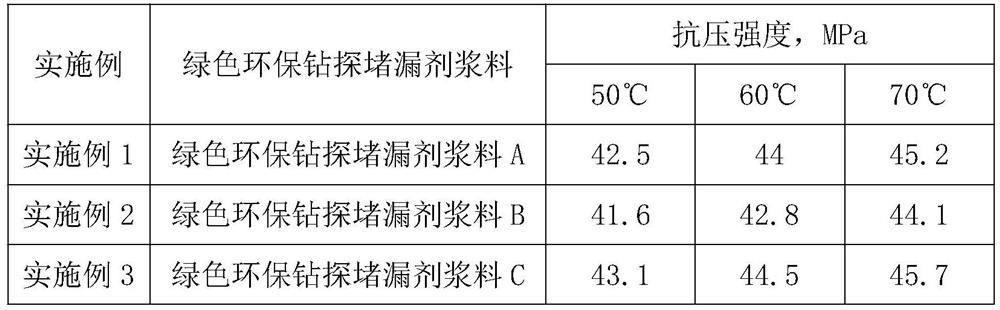

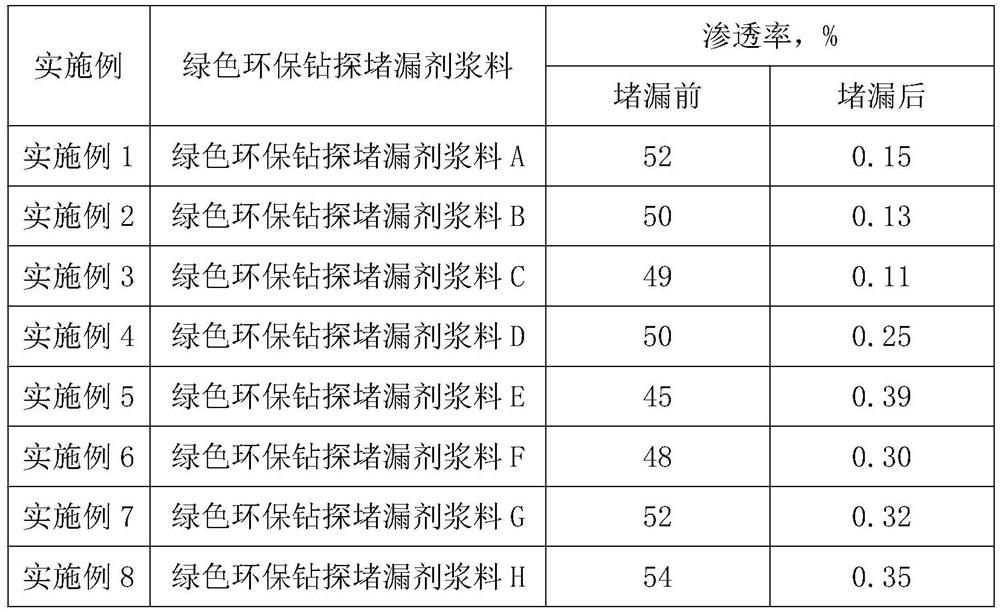

Examples

Embodiment 1

[0024] Raw materials: 100 parts of cement, 10 parts of nano silicon oxide, 10 parts of nano calcium carbonate, 10 parts of hollow microspheres, 30 parts of elastic sponge particles, 10 parts of flexible graphite, 40 parts of asbestos fiber, 3 parts of retarder, fluid loss reducer 3 parts, 30 parts of sodium hydroxide;

[0025] Among them, the cement is 42.5 Portland cement; the pore density of elastic sponge particles is 10PPI, and the particle size is less than 5mm; the particle size of flexible graphite is 100-200 mesh; the retarder is iron chromium salt; the fluid loss reducer is carboxymethyl cellulose; The fiber is composed of short asbestos fibers of 1-5mm and long asbestos fibers of 5-10mm according to the mass ratio of 2:1.

Embodiment 2

[0027] Raw materials: 200 parts of cement, 5 parts of nano-silica, 15 parts of nano-calcium carbonate, 5 parts of hollow microspheres, 40 parts of elastic sponge particles, 5 parts of flexible graphite, 80 parts of asbestos fiber, 5 parts of retarder, fluid loss reducer 5 parts, 50 parts of sodium hydroxide;

[0028] Among them, the cement is 42.5 Portland cement; the pore density of elastic sponge particles is 10PPI, and the particle size is less than 5mm; the particle size of flexible graphite is 100-200 mesh; the retarder is iron chromium salt; the fluid loss reducer is carboxymethyl cellulose; The fiber is composed of short asbestos fibers of 1-5mm and long asbestos fibers of 5-10mm according to the mass ratio of 2:1.

Embodiment 3

[0030] Raw materials: 150 parts of cement, 8 parts of nano-silica, 12 parts of nano-calcium carbonate, 8 parts of hollow microspheres, 30 parts of elastic sponge particles, 8 parts of flexible graphite, 60 parts of asbestos fiber, 3 parts of retarder, fluid loss reducer 3 parts, 40 parts of sodium hydroxide;

[0031] Among them, the cement is 42.5 Portland cement; the pore density of elastic sponge particles is 10PPI, and the particle size is less than 5mm; the particle size of flexible graphite is 100-200 mesh; the retarder is iron chromium salt; the fluid loss reducer is carboxymethyl cellulose; The fiber is composed of short asbestos fibers of 1-5mm and long asbestos fibers of 5-10mm according to the mass ratio of 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com