Preparation method for VN/Ag wide-temperature-area lubricating composite films

A composite film, wide temperature range technology, applied in the field of preparation of VN/Ag wide temperature range lubricating composite film, to achieve the effect of simple preparation process, continuous and reliable lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

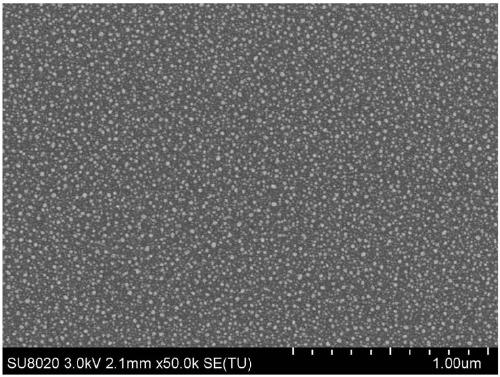

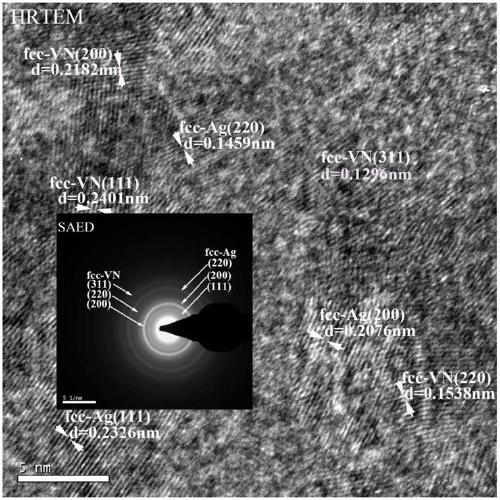

[0024] The preparation method of a VN / Ag wide temperature range lubricating composite film in this example uses a single-beam pulsed laser deposition technology to prepare a VN / Ag wide temperature range lubricating composite film on the substrate to be deposited with the VN / Ag composite target as the target ,Specific steps are as follows:

[0025] (1) Treatment of substrate to be deposited:

[0026] First, after removing the impurities attached to the surface of the Inconel718 alloy substrate to be deposited, ultrasonic cleaning was performed in acetone and absolute ethanol for 10 minutes, dried with nitrogen, and stored in vacuum;

[0027] (2) VN / Ag composite target:

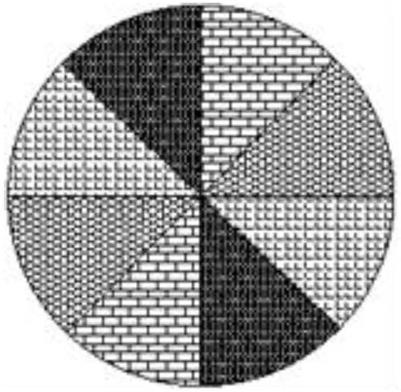

[0028] Take the VN target and the Ag target with a purity of 99.99%, respectively, and cut the VN target and the Ag target into equal parts with a diamond wire cutting machine to obtain several VN targets with the same central angle (for example, the central angle in this embodiment is 45 degrees). Segment, A...

Embodiment 2

[0034]The preparation method of a VN / Ag wide temperature range lubricating composite film in this example uses a single-beam pulsed laser deposition technology to prepare a VN / Ag wide temperature range lubricating composite film on the substrate to be deposited with the VN / Ag composite target as the target ,Specific steps are as follows:

[0035] (1) Treatment of substrate to be deposited:

[0036] First, after removing the impurities attached to the surface of the Inconel718 alloy substrate to be deposited, ultrasonic cleaning was performed in acetone and absolute ethanol for 20 minutes, dried with nitrogen, and stored in vacuum;

[0037] (2) VN / Ag composite target:

[0038] Take the VN target and the Ag target with a purity of 99.99%, respectively, and cut the VN target and the Ag target into equal parts with a diamond wire cutting machine to obtain several VN targets with the same central angle (for example, the central angle in this embodiment is 30 degrees). segment, Ag...

Embodiment 3

[0044] The preparation method of a VN / Ag wide temperature range lubricating composite film in this example uses a single-beam pulsed laser deposition technology to prepare a VN / Ag wide temperature range lubricating composite film on the substrate to be deposited with the VN / Ag composite target as the target ,Specific steps are as follows:

[0045] (1) Treatment of substrate to be deposited:

[0046] First, after removing the impurities attached to the surface of the Inconel718 alloy substrate to be deposited, ultrasonic cleaning was performed in acetone and absolute ethanol for 16 minutes, dried with nitrogen, and stored in vacuum;

[0047] (2) VN / Ag composite target:

[0048] Take the VN target and the Ag target with a purity of 99.99%, respectively, and cut the VN target and the Ag target into equal parts with a diamond wire cutting machine to obtain several VN targets with the same central angle (for example, the central angle in this embodiment is 60 degrees). Segment, A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com