A kind of soft magnetic material and its preparation method and application in automotive electronic system

A soft magnetic material, magnetic flux density technology, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, circuit, etc., to achieve the effect of high saturation magnetic flux density, uniform grain growth and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

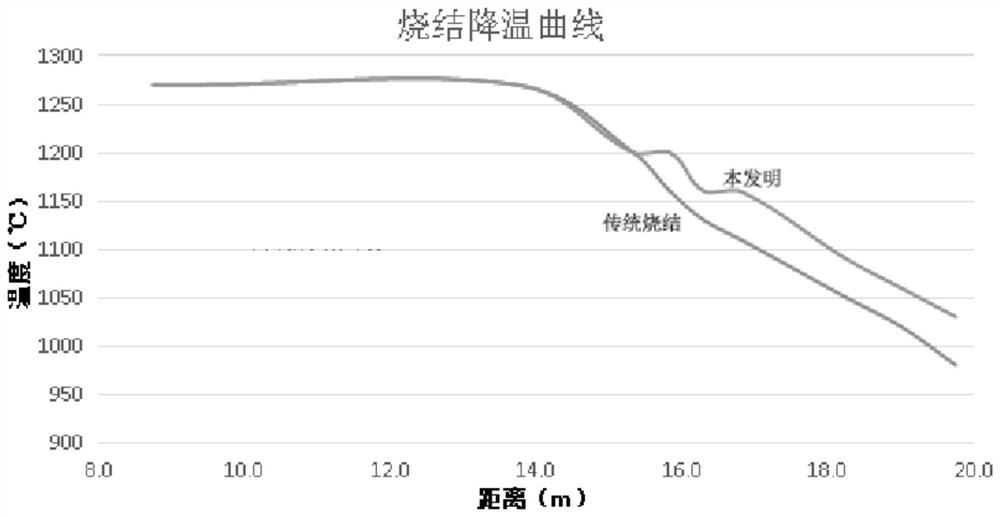

Method used

Image

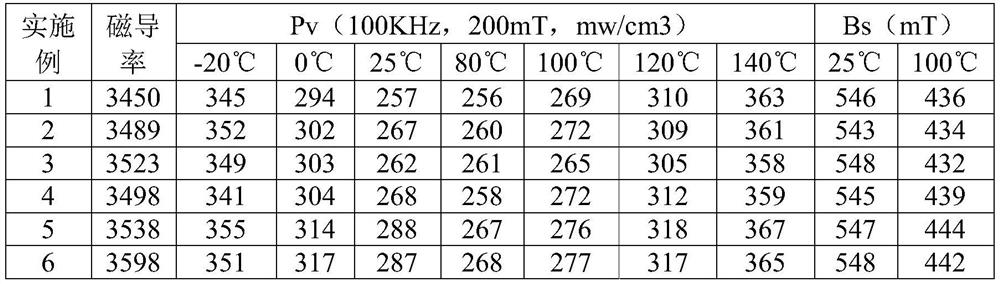

Examples

Embodiment 1

[0039] A soft magnetic material comprising the following main components: Fe 2 o 3 55.5mol%; MnO34.5mol%; ZnO10mol%; relative to the total weight of the main component, it also contains the following content of secondary components: 0.03wt% CaCO 3 , 0.08wt%TiO 2 , 0.03wt% Nb 2 o 5 , 0.02wt% ZrO 2 , 0.03wt%V 2 o 5 , 0.02wt% SnO, 0.35wt% Co 2 o 3 , 0.02wt% NiO.

[0040] Its preparation method comprises the following steps:

[0041] S1. Weigh the raw material of the main component, then add a certain proportion of deionized water in the sand mill for mixing and crushing, crush for 30 minutes, and circulate and mix for 10 minutes, then add a certain amount of PVA solution for spray granulation;

[0042] S2. Put the spray material into the pre-burning furnace, and heat it at 870°C for 3 hours for pre-burning;

[0043] S3. Add the following auxiliary components according to the weight percentage of the pre-fired material to the pre-fired material, and then put the powder ...

Embodiment 2

[0047] A soft magnetic material comprising the following main components: Fe 2 o 3 55.2mo1%; MnO34.8mo1%; ZnO10mo1%; Relative to the total weight of the main component, it also contains the following subcomponents: 0.03wt% CaCO 3 , 0.1wt%TiO 2 , 0.03wt%Nb 2 o 5 , 0.02wt% ZrO 2 , 0.03wt%V 2 o 5 , 0.013wt% SnO, 0.35wt% Co 2 o 3 , 0.05wt% NiO.

[0048] Its preparation method comprises the following steps:

[0049] S1. Weigh the raw material of the main component, then add a certain proportion of deionized water in the sand mill for mixing and crushing, crush for 30 minutes, and circulate and mix for 10 minutes, then add a certain amount of PVA solution for spray granulation;

[0050] S2. Put the spray material into the pre-burning furnace, and heat it at 850° C. for 3 hours to carry out pre-burning;

[0051] S3. Add the following auxiliary components according to the weight percentage of the pre-fired material to the pre-fired material, and then put the powder into the...

Embodiment 3

[0055] A soft magnetic material comprising the following main components: Fe 2 o 3 55.5mol%; MnO34.8mol%; ZnO9.7mol%; relative to the total weight of the main component, it also contains the following content of secondary components: 0.03wt% CaCO 3 , 0.1wt%TiO 2 , 0.03wt%Nb 2 o 5 , 0.02wt% ZrO 2 , 0.02wt%V 2 o 5 , 0.013wt% SnO, 0.4wt% Co 2 o 3 , 0.05wt% NiO.

[0056] Its preparation method comprises the following steps:

[0057] S1. Weigh the raw material of the main component, then add a certain proportion of deionized water in the sand mill for mixing and crushing, crush for 30 minutes, and circulate and mix for 10 minutes, then add a certain amount of PVA solution for spray granulation;

[0058] S2. Put the spray material into the pre-burning furnace, and heat it at 890° C. for 3 hours to carry out pre-burning;

[0059] S3. Add the following auxiliary components according to the weight percentage of the pre-fired material to the pre-fired material, and then put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com