High-saturation magnetic flux, high-direct current superposition and low-loss soft magnetic material and preparation method thereof

A high DC superposition, soft magnetic material technology, applied in the direction of inorganic material magnetism, can solve problems such as deterioration, and achieve the effect of promoting crystal grains, high Curie temperature, and uniform grain distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

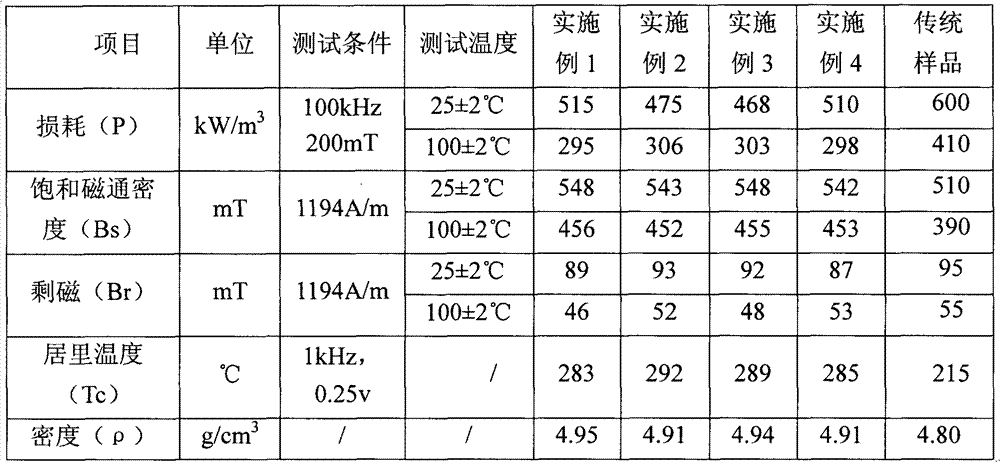

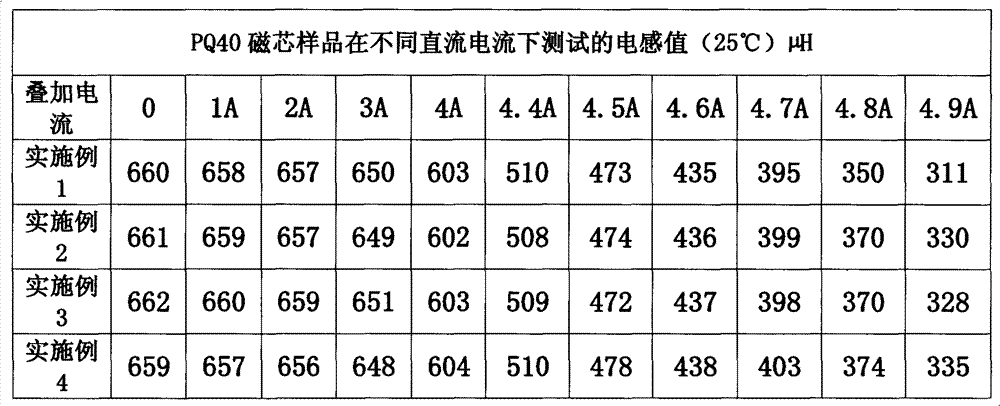

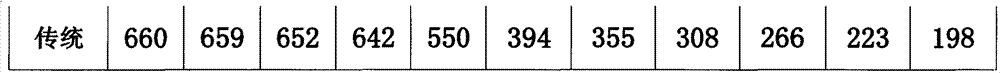

Examples

Embodiment 1

[0031] Weigh Fe 2 o 3 : 53.8mol%, Mn 3 o 4 (calculated as MnO): 38.2mol%, ZnO: 8.0mol% of the three raw materials, then add an appropriate amount of deionized water to the sand mill for a sand mill for 35 minutes, and add an appropriate amount 10-15 minutes before the end of the sand mill PVA solution, and then carry out a spray granulation;

[0032] Spray granulate the slurry after sanding once, and then put it into the pre-fired furnace for pre-burning. The temperature in the pre-fired furnace is controlled at 830°C, and the pre-fired furnace is kept warm for 3.5 hours;

[0033] Proportioning of the content of sub-components to the pre-burned main component, relative to the total weight of the main component, WO 3 0.04wt%, NiO 0.008wt%, ZrO 2 0.05wt%, CaCO3 (calculated as CaO) is 0.03wt%, Nb 2 o 5 0.05wt%, TiO 2 0.13wt%, CO 2 o 3 0.05wt%, MoO 3 0.01wt%, V 2 o 5 0.05wt%;

[0034] Then put the powder containing the main and auxiliary components into the sand mill...

Embodiment 2

[0038] Weigh Fe 2 o 3 : 54.8mol%, Mn 3 o 4 (calculated as MnO): 40.4mol%, ZnO: 4.8mol% of the three raw materials, then add an appropriate amount of deionized water to the sand mill for a sand mill for 40 minutes, and add an appropriate amount 10-15 minutes before the end of the sand mill PVA solution, and then carry out a spray granulation;

[0039] Spray granulate the slurry after sanding once, and then put it into the pre-fired furnace for pre-burning. The temperature in the pre-fired furnace is controlled at 860°C, and the pre-fired furnace is kept warm for 3 hours;

[0040] For the pre-burned main component and then carry out the ratio of the auxiliary component content, WO 3 0.01wt%, NiO 0.03wt%, ZrO 2 0.02wt%, CaCO 3 (calculated as CaO) is 0.04wt%, Nb 2 o 5 0.02wt%, TiO 2 0.06wt%, C O2 o 3 0.25wt%, MoO 3 0.01wt%, V 2 o 5 0.03wt%;

[0041] Then put the powder containing the main and auxiliary components into the sand mill and add deionized water and defoam...

Embodiment 3

[0045] Weigh Fe 2 o 3 : 54.5mol%, Mn 3 o 4 (calculated as MnO): 39.8mol%, ZnO: 5.7mol% of the three raw materials, then add an appropriate amount of deionized water to the sand mill for a sand mill for 45 minutes, and add an appropriate amount 10-15 minutes before the end of the sand mill PVA solution, and then carry out a spray granulation;

[0046] Spray granulate the slurry after sanding once, and then put it into the pre-fired furnace for pre-burning. The temperature in the pre-fired furnace is controlled at 890 ° C, and the heat preservation of the pre-fired furnace lasts for 2.5 hours;

[0047] For the pre-burned main component and then carry out the ratio of the auxiliary component content, WO 3 0.02wt%, NiO 0.02wt%, ZrO 2 0.04wt%, CaCO 3 (calculated as CaO) is 0.01wt%, Nb 2 o 5 0.04wt%, TiO 2 0.08wt%, C O2 o 3 0.15wt%, MoO 3 0.03wt%, V 2 o 5 0.02wt%;

[0048] Then put the powder containing the main and auxiliary components into a sand mill and add deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com