Ultrahigh-Bs (saturation magnetic flux density) low-loss MnZn powder ferrite material and making method thereof

A technology of ferrite material and manufacturing method, which is applied in the field of MnZn soft magnetic ferrite material and manufacturing, can solve the problems of high power loss, high manufacturing cost, and no advantages, and achieve accurate composition of fired products, low cost, and increased Effect of Zn Vapor Pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

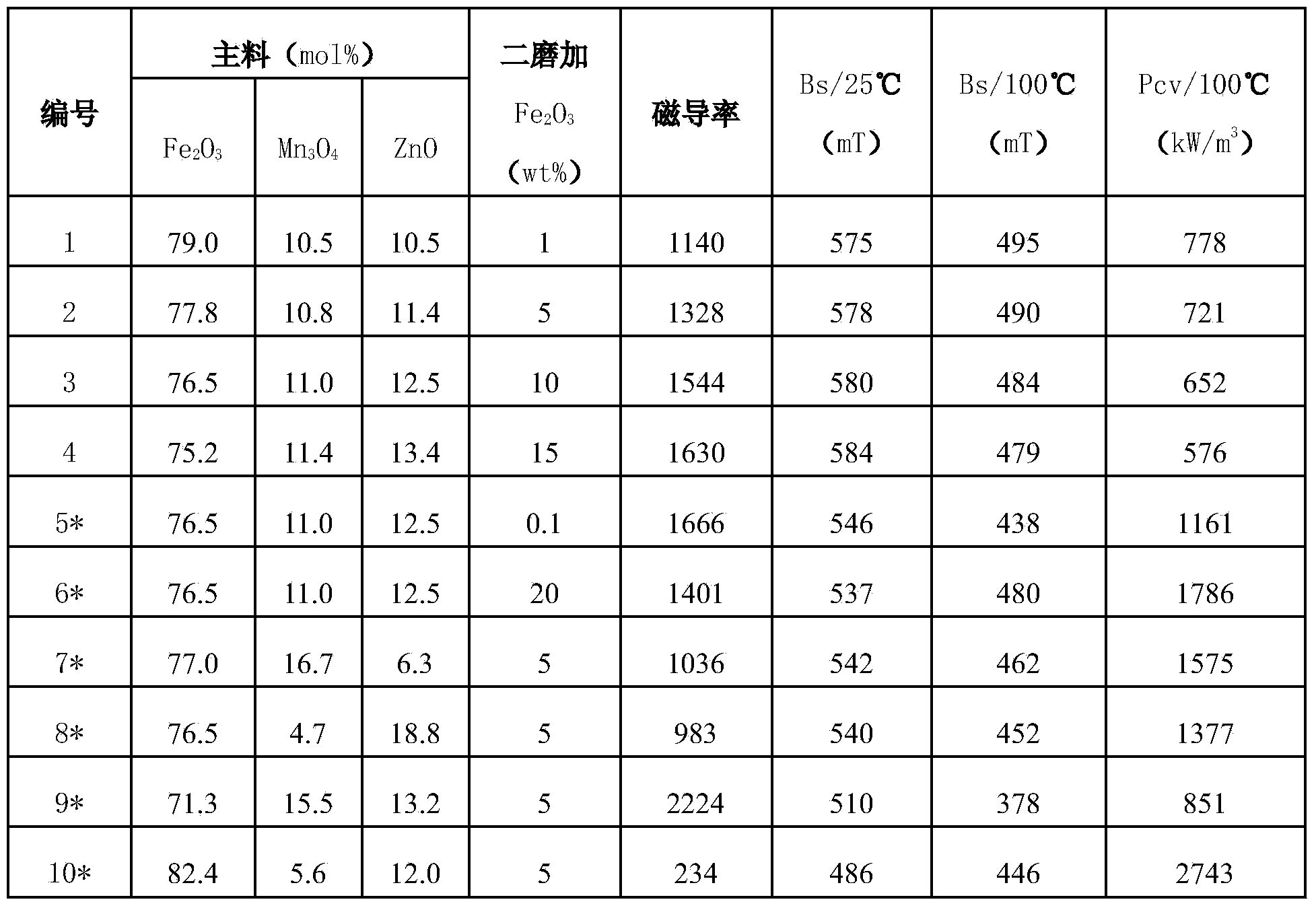

example 1-10

[0037] 1) Using commercially available Fe 2 o 3 (purity ≥ 99.3%), Mn 3 o 4 (Mn content ≥ 71%), ZnO (purity ≥ 99.7%) as the main components, according to the amount shown in Table 1 Fe 2 o 3 , Mn 3 o 4 , ZnO is placed in a sand mill, stirred and ground to mix evenly; after drying, the temperature is raised to 900°C at a speed of 250°C / h and pre-fired for 2 hours;

[0038] 2) Based on the total weight of the pre-burned powder, add additives: Fe 2 o 3 (the amount added is listed in Table 1), 60ppm of SiO 2 , 500ppm of CaCO 3 and deionized water, dispersant, and defoamer for secondary grinding, until the particle size of the powder is D50=0.90μm, D90<2.5μm;

[0039] 3) Based on the total weight of the powder after ball milling, add 9.5wt% polyvinyl alcohol solution to the powder, mix and granulate evenly, and use a 45-ton dry powder press to press the granules into a green compact with a density of 3.0±0.2 g / cm 3 green samples of

[0040] 4) Finally, sinter at a sinte...

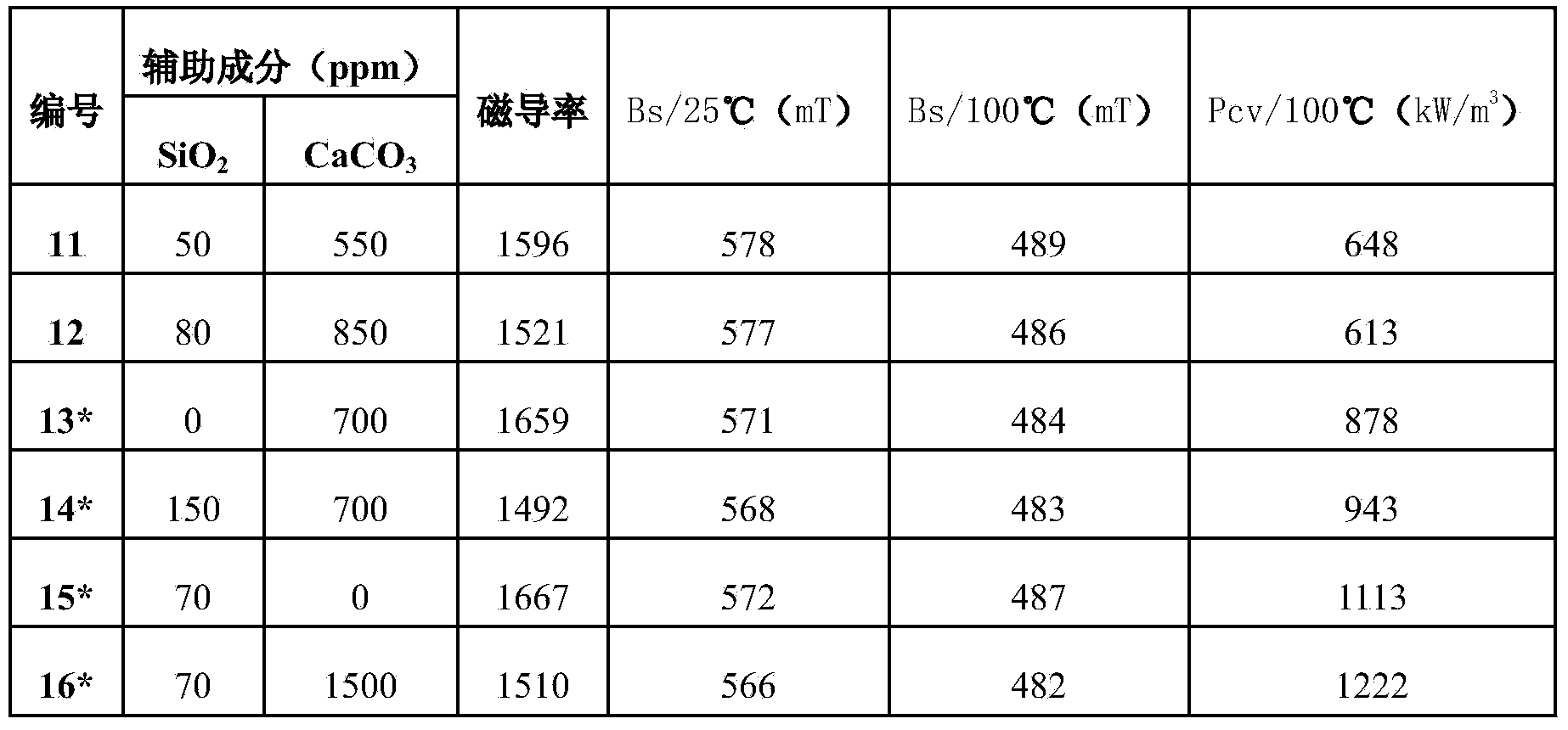

example 11~16

[0052] 1) Fe 2 o 3 76.6wt%, Mn 3 o 4 Fe 2 o 3 (purity ≥ 99.3%), Mn 3 o 4 (Mn content ≥ 71%), ZnO (purity ≥ 99.7%) raw materials are placed in a sand mill, stirred and ground to mix and dry evenly, then heat up to 800 ℃ at a speed of 280 ℃ / h and pre-fire for 3 hours;

[0053] 2) Based on the total weight of the powder after pre-burning, add 10wt% Fe 2 o 3 , and add auxiliary ingredients according to the addition amount shown in Table 2, then add deionized water, dispersant, and defoamer to carry out the second grinding, and grind until the particle size of the powder is D50=0.87μm, D90<2.3μm;

[0054] 3) Based on the total weight of the powder after ball milling, add 8.5wt% polyvinyl alcohol solution to the powder, mix and granulate evenly, and use a 45-ton dry powder press to press the granules into a green compact with a density of 3.0±0.2 g / cm 3 green samples of

[0055] 4) Finally, sinter at a sintering temperature of 1370°C, keep the temperature at the sinteri...

example 17~18

[0064] The raw material composition, powder preparation and molding process are the same as in Example 11, the difference lies in whether ZnO compact is placed in the kiln cavity or not.

[0065] Use HP4294A impedance analyzer (Agilent Technology4294A) and special fixture (Agilent Technology16047E) to measure the normal temperature inductance L of the sample magnetic ring under 10kHz weak field, and calculate the initial permeability of the material; use SY-8258 B-H tester at 50Hz, 1200A / m test the Bs of the sample magnetic ring at 25°C and 100°C; use the Model2335Watt Meter to test the power loss of the sample magnetic ring at 100kHz, 200mT, and 100°C, and the results are listed in Table 3.

[0066] table 3

[0067]

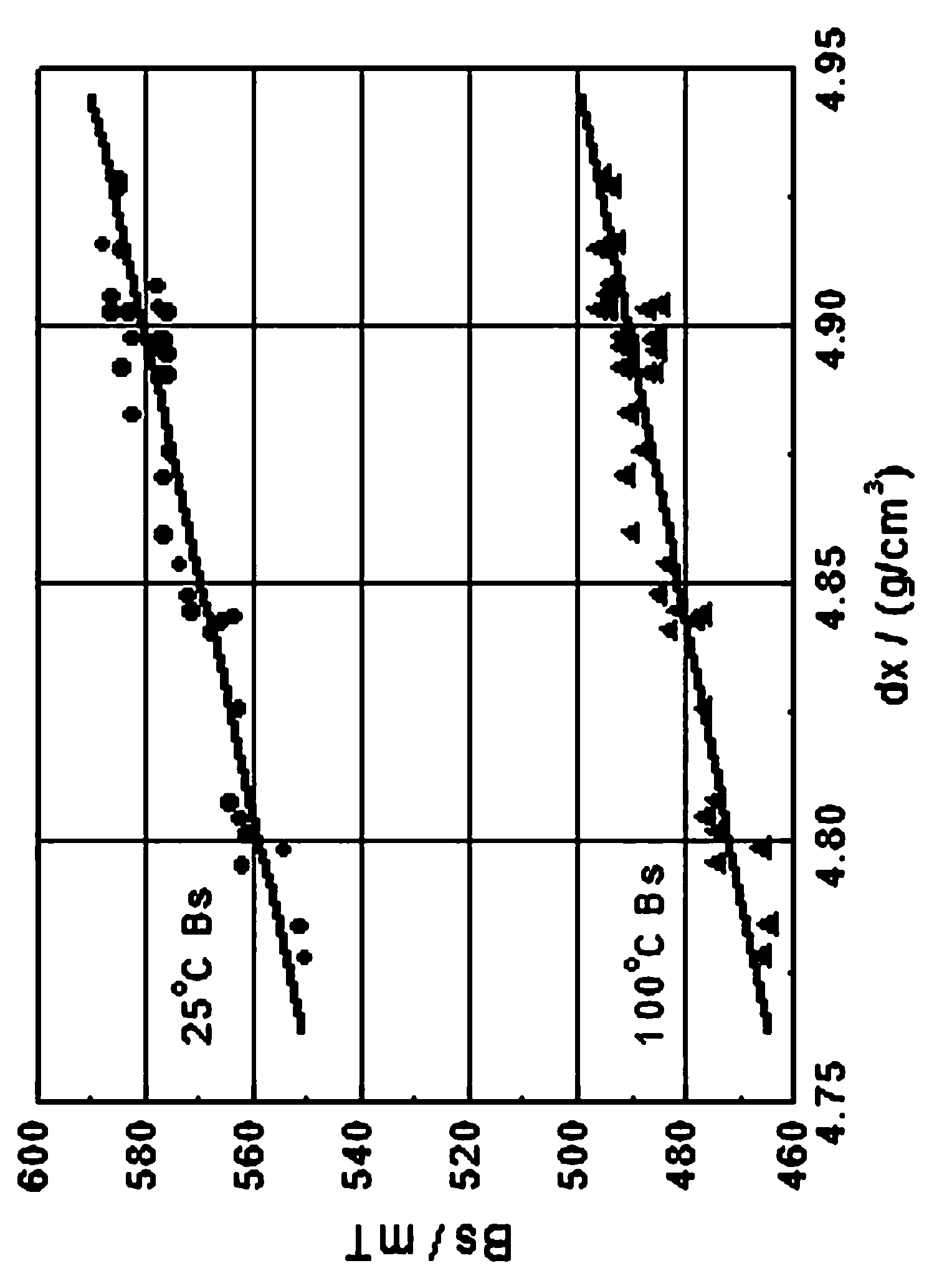

[0068] For MnZn ferrite materials, in order to obtain high saturation magnetic flux density, it is very effective to increase the content of Fe2O3 in the main component, but on the other hand, because Fe 2 o 3The content of Bs is too high, and it is easy to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com