Technology for processing audio directional loudspeaker film

A processing technology and audio frequency orientation technology, applied in the processing technology field of PZT piezoelectric transducer film, to achieve good crystallization, reduce shrinkage, and prevent cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

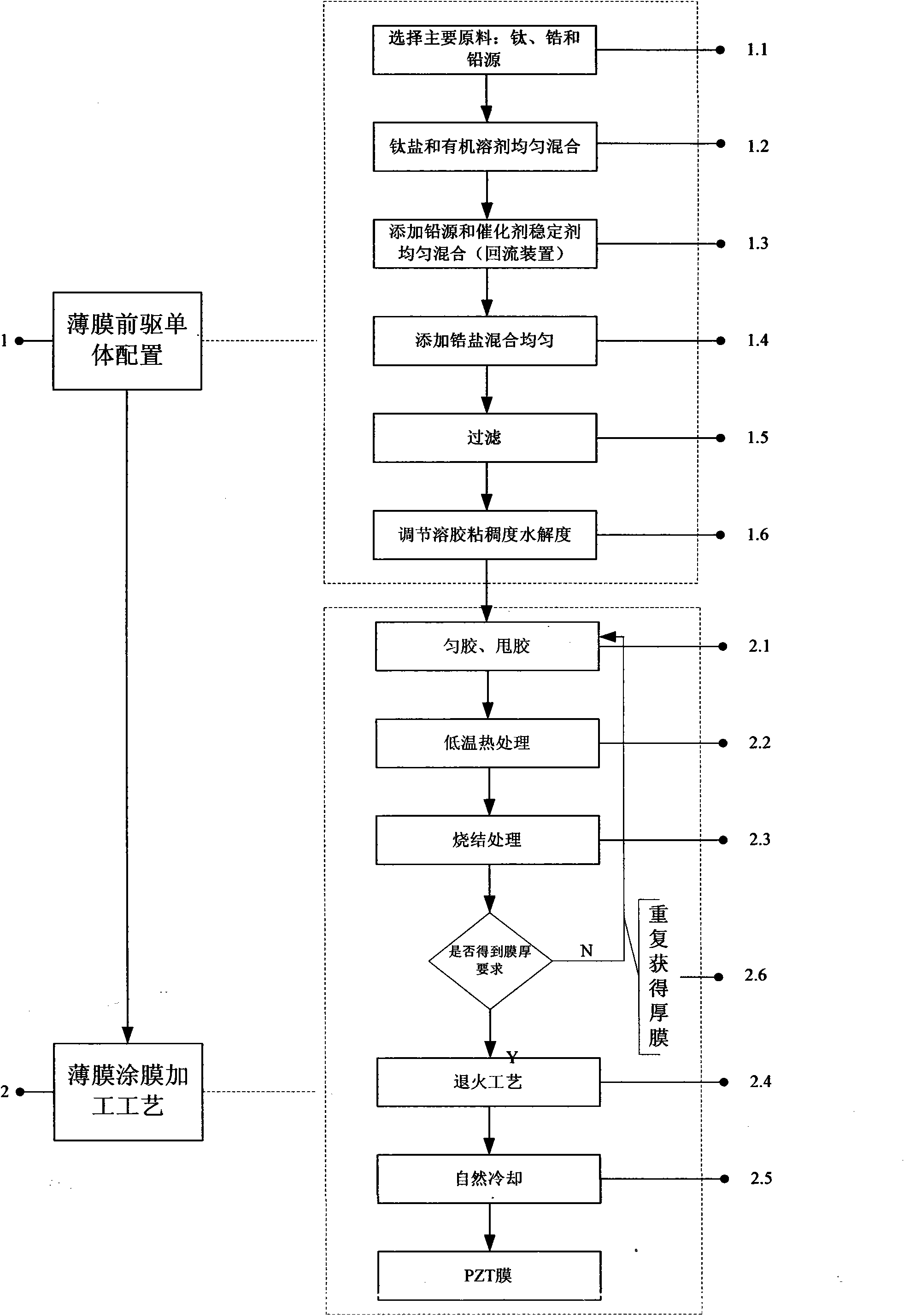

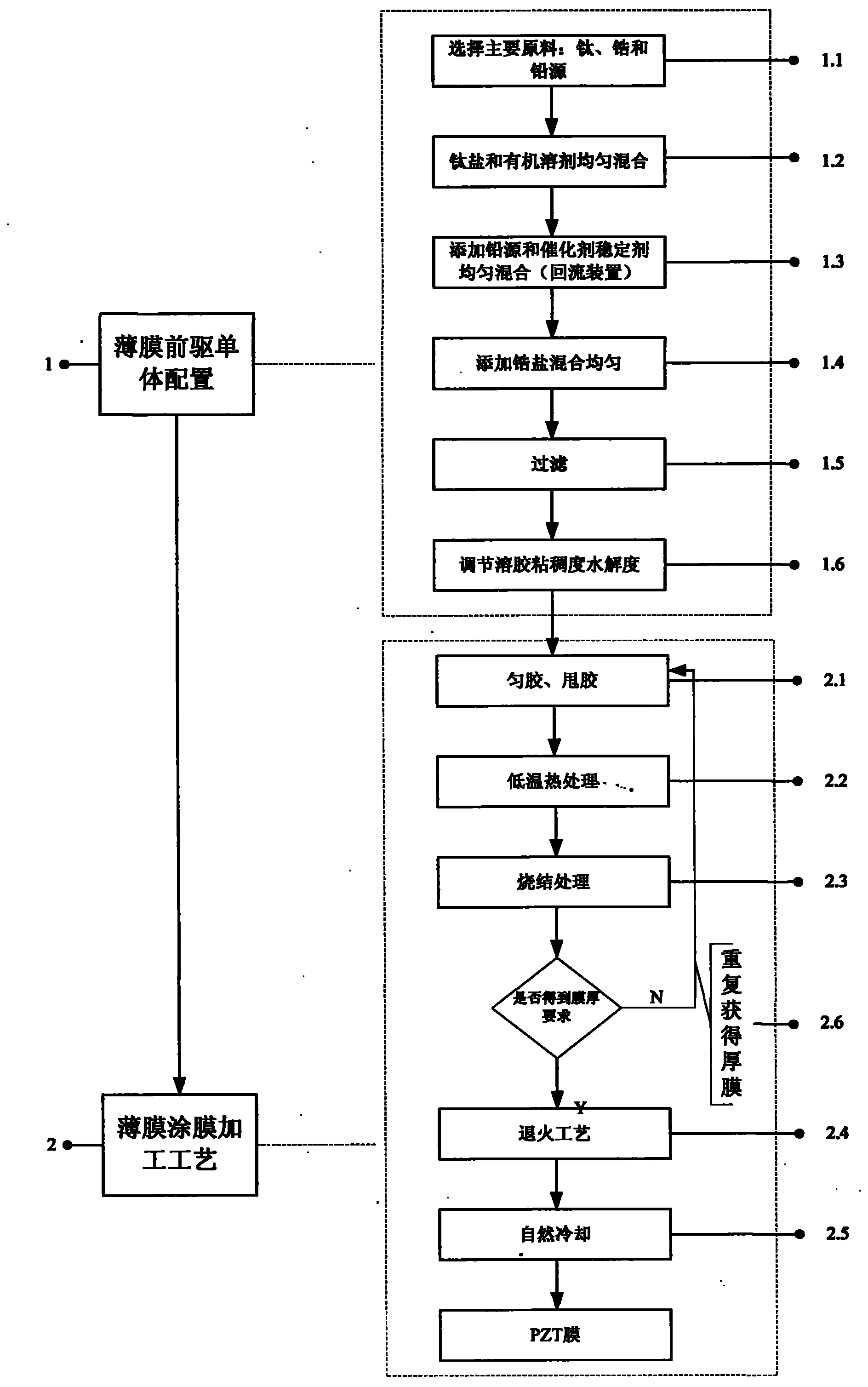

[0037] The technical solution of the present invention will be described in further detail below with reference to the drawings and specific embodiments. Such as figure 1 Shown, a kind of processing technique of PZT piezoelectric thin film comprises the following steps:

[0038] 1), the specific steps of thin film precursor monomer (Solution) configuration:

[0039] Step 1.1: Select raw materials: industrial reagents lead acetate, tetrabutyl titanate and tetra-n-butoxy zirconium salt produced by chemical plants as main raw materials; organic solvent with ethylene glycol methyl ether as main raw material; acetylacetone as solution metal stabilizer; glacial acetic acid as precursor monomer solution catalyst;

[0040] Step 1.2: According to the volume of the solution to be configured, measure a certain amount of tetrabutyl titanate organic solvent with a graduated cylinder of an appropriate range, and then measure a certain amount of metal stabilizer acetylacetone, and mix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com