Preparation method of high-density ITO target molded by slip casting

A slip-casting, high-density technology, applied in ceramic molding machines, manufacturing tools, ion implantation plating, etc., can solve the problems of low relative density of target materials and high waste rate of green bodies, and achieve good stability and low viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for preparing a high-density ITO target by slip casting, which includes the following steps:

[0029] (1) Preparation of the premix: take the dispersant and add it to water, stir evenly, adjust the pH value to 9 with ammonia water to obtain the premix; the amount of the dispersant added is 2.2% of the mass of the ITO powder, and the amount of water added is the ITO powder 15% of mass;

[0030] (2) Preparation of suspension slurry: add ITO powder to the premixed liquid, and then carry out wet grinding through a ball mill; the viscosity value of the prepared ITO slurry is 195mPa s (room temperature, rotating speed 20s -1 )

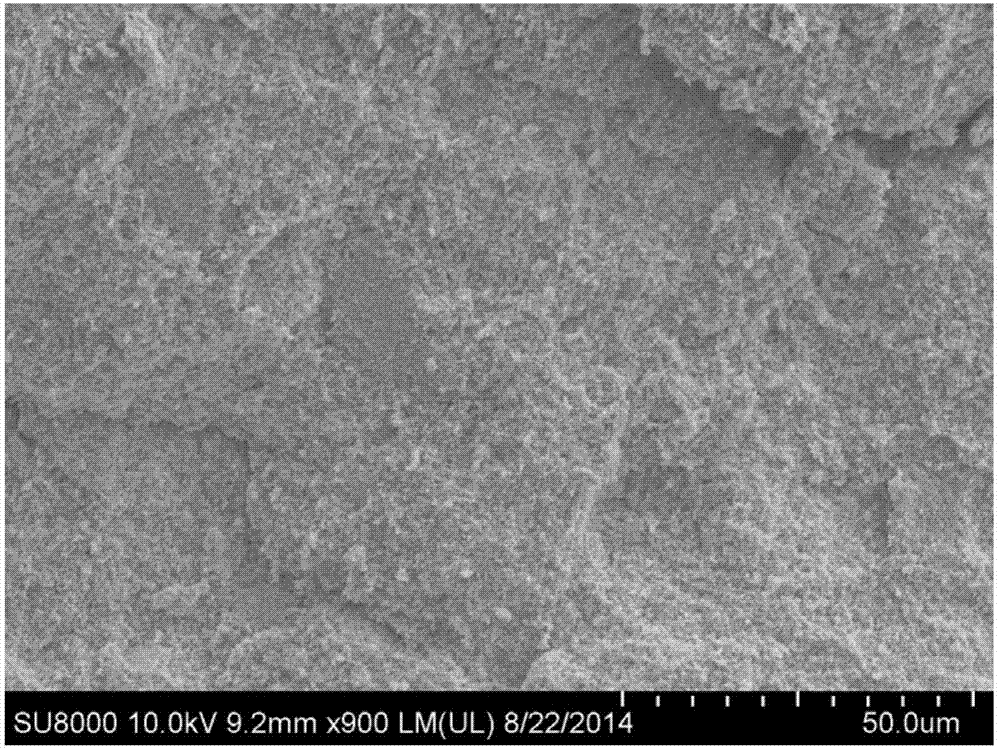

[0031] (3) Green body molding: vacuum degass the slurry after ball milling, inject the degassed slurry into a gypsum mold; remove the mold after suction molding, and dry the green body for 72 hours to obtain an ITO green body (see figure 1 );

[0032] (4) Degreasing: place the dried ITO green body in a degreasing f...

Embodiment 2

[0040] This embodiment provides a method for preparing a high-density ITO target by slip casting, which includes the following steps:

[0041] (1) Preparation of the premix: take the dispersant and add it to water, stir evenly, adjust the pH value to 8 with ammonia water to obtain the premix; the amount of the dispersant is 3.0% of the mass of the ITO powder, and the amount of water is 3.0% of the ITO powder 10% of mass;

[0042] (2) Preparation of suspension slurry: add ITO powder to the premixed liquid, and then carry out wet grinding through a ball mill; the viscosity value of the prepared ITO slurry is 240mPa s (room temperature, rotating speed 20s -1 )

[0043] (3) Body molding: vacuum degass the slurry after ball milling, inject the degassed slurry into a gypsum mold; remove the mold after suction molding, and dry the green body for 80 hours to obtain an ITO body;

[0044] (4) Degreasing: place the dried ITO green body in a degreasing furnace to raise the temperature t...

Embodiment 3

[0052] This embodiment provides a method for preparing a high-density ITO target by slip casting, which includes the following steps:

[0053] (1) Preparation of the premix: take the dispersant and add it to water, stir evenly, adjust the pH value to 11 with ammonia water to obtain the premix; the amount of the dispersant is 1.5% of the mass of the ITO powder, and the amount of water is 1.5% of the ITO powder 20% of mass;

[0054] (2) Preparation of suspension slurry: add ITO powder to the premixed liquid, and then carry out wet grinding through a ball mill; prepare the ITO slurry with a viscosity value of 140mPa s (room temperature, rotating speed 20s -1 )

[0055] (3) Body molding: vacuum degass the slurry after ball milling, inject the degassed slurry into a gypsum mold; remove the mold after suction molding, and dry the green body for 84 hours to obtain an ITO body;

[0056] (4) Degreasing: place the dried ITO green body in a degreasing furnace to raise the temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com