Chemical preparation method of piezoelectric ceramic with high Curie temperature of composite system

A piezoelectric ceramic and system technology, applied in the new chemical field of high Curie temperature piezoelectric ceramics, can solve the problems of difficult control of composition, poor process repeatability, high reaction temperature, etc., and achieve low cost, stable process, and low preparation temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

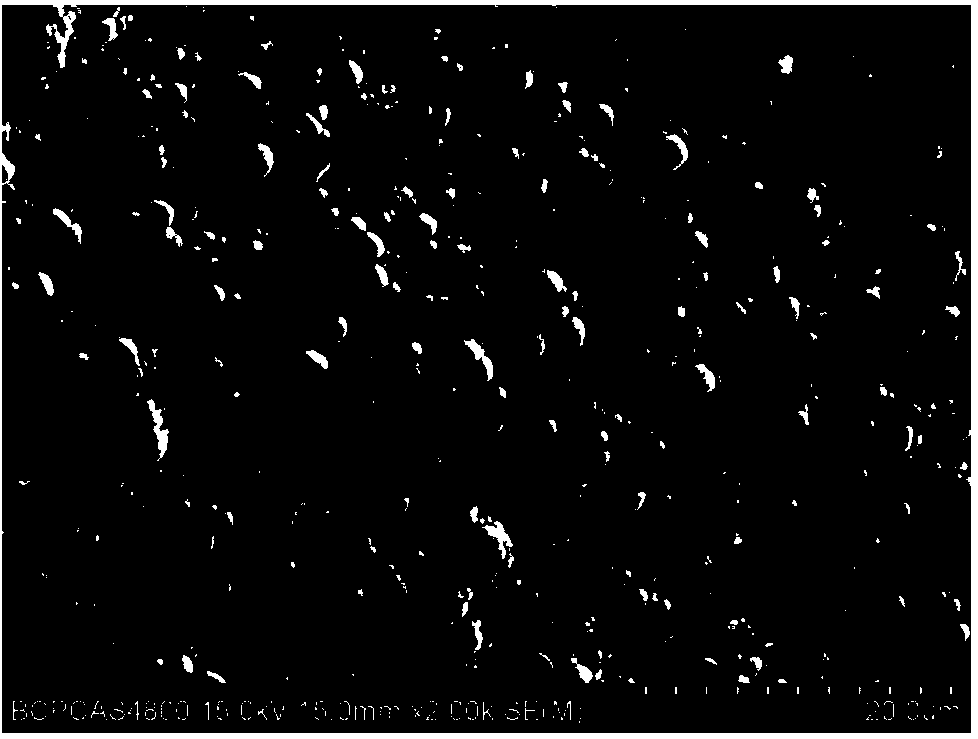

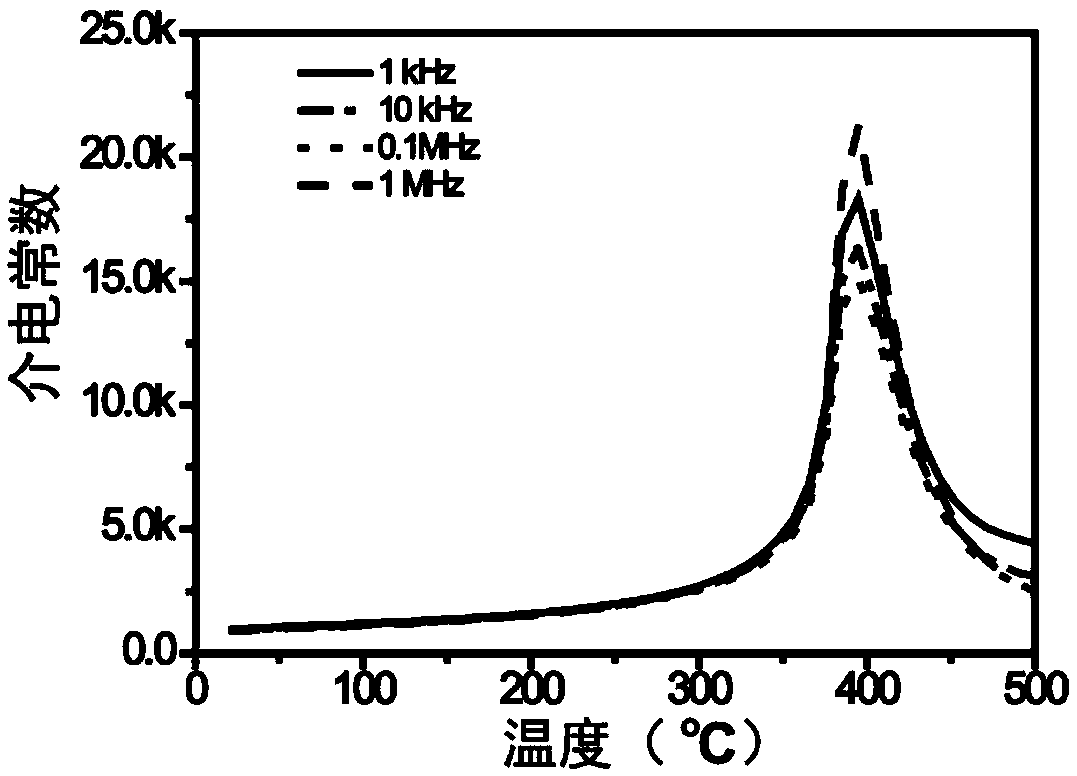

[0030] The preparation composition is 0.55(0.1BiYbO 3 -0.9PbTiO 3 )-0.45PbZrO 3Ceramics, the starting materials are bismuth nitrate, ytterbium nitrate, lead acetate, zirconium nitrate and tetrabutyl titanate. Concrete steps: 1) Add required amount of bismuth nitrate, ytterbium nitrate, zirconium nitrate successively under stirring in 5mol / L dilute nitric acid, and heat and stir to make clear solution; Add required amount of lead acetate in 50% acetic acid Stir to make a solution; make a solution of the required amount of tetrabutyl titanate in ethanol. 2) Add citric acid monohydrate in above-mentioned bismuth nitrate, ytterbium nitrate, zirconium nitrate solution, stirring and dissolving, the ratio of the amount of substance of citric acid monohydrate and the sum of the amount of substance (number of moles) of scandium, bismuth, zirconium is 2.5:1. Add citric acid monohydrate to the above-mentioned lead acetate solution, stir to dissolve, the molar ratio of the amount of c...

Embodiment 2

[0032] Preparation of 0.6(0.1BiYbO 3 -0.9PbTiO 3 )-0.4PbZrO 3 Ceramics, the starting raw materials are bismuth nitrate, ytterbium nitrate, zirconium nitrate, lead acetate and tetrabutyl titanate, the specific steps are: 1) Add the required amount of bismuth nitrate and ytterbium nitrate in sequence with stirring in 6mol / L dilute nitric acid , zirconium nitrate, and heated and stirred to make a clear solution; the required amount of lead acetate was stirred in 30% acetic acid to make a solution; and the required amount of tetrabutyl titanate was made into a solution in ethanol. 2) Add citric acid monohydrate to the above-mentioned bismuth nitrate, ytterbium nitrate, and zirconium nitrate solutions, and stir to dissolve. The ratio of the amount of citric acid monohydrate to the sum of the moles of scandium, bismuth, and zirconium is 2:1. Add citric acid monohydrate to the above lead acetate solution, stir to dissolve, the molar ratio of the amount of citric acid monohydrate to...

Embodiment 3

[0034] Preparation of 0.5(0.1BiYbO 3 -0.9PbTiO 3 )-0.5PbZrO 3 Ceramics, the starting materials are bismuth nitrate, ytterbium nitrate, zirconium nitrate, lead acetate, and tetrabutyl titanate, the specific steps are: 1) add the required amount of bismuth nitrate, Ytterbium nitrate and zirconium nitrate are heated and stirred to make a clear solution; the required amount of lead acetate is stirred in 70% acetic acid to make a solution; and the required amount of tetrabutyl titanate is made into a solution in ethanol. 2) Add citric acid monohydrate in above-mentioned bismuth nitrate, ytterbium nitrate, zirconium nitrate solution, stirring and dissolving, the ratio of the amount of substance of monohydrate citric acid and the amount of substance of scandium, bismuth, zirconium that is the sum of moles is 3 :1. Add citric acid monohydrate to the above lead acetate solution, stir to dissolve, the molar ratio of the amount of citric acid monohydrate to lead is 3:1; add citric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com