High-conductivity corrosion-resistant aluminum alloy and preparation method thereof

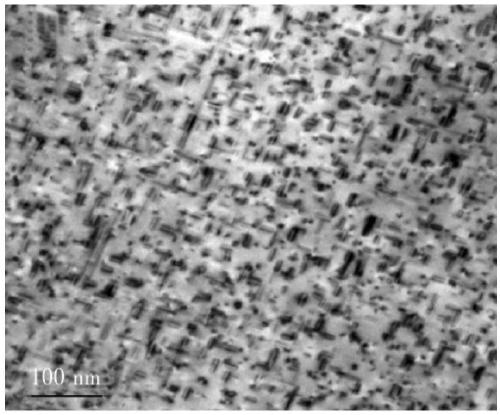

An aluminum alloy and corrosion-resistant technology, which is applied in the field of aluminum alloys, can solve the problems of not reflecting corrosion resistance, increasing material production control costs, and poor product quality uniformity, so as to improve strength and corrosion resistance, and compact microstructure Uniformity, porosity and oxide content reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

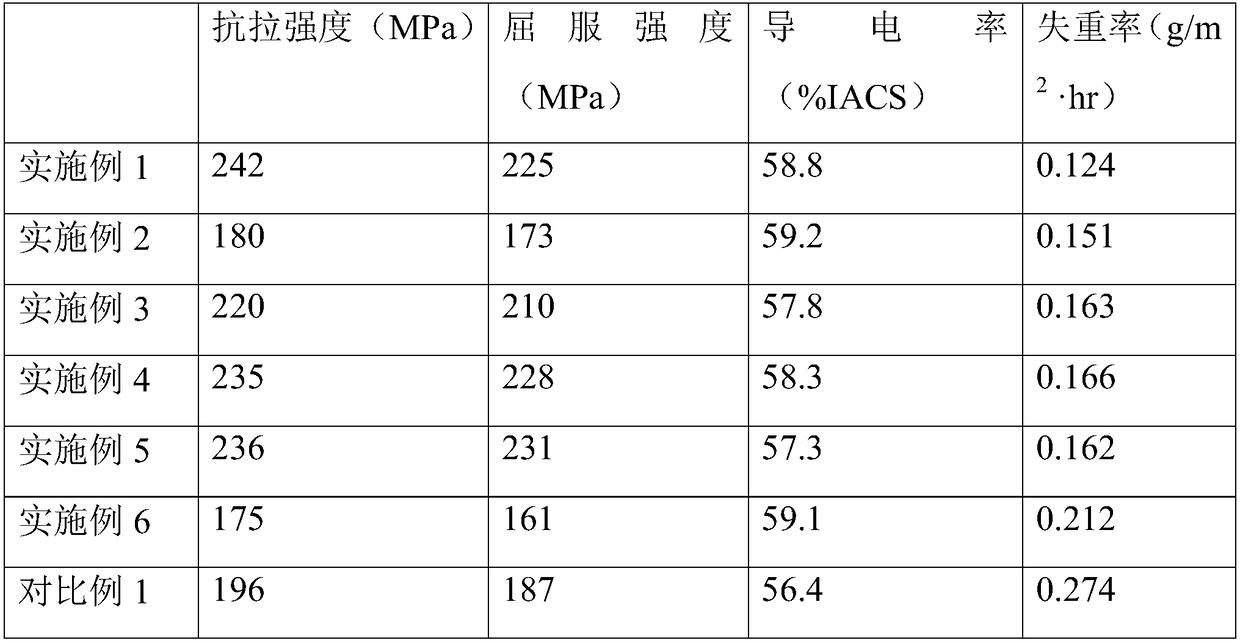

Examples

Embodiment 1

[0035] A highly conductive and corrosion-resistant aluminum alloy consisting of the following elements by weight percentage:

[0036] Si:0.4%;Mg:0.8%;B:0.02%;Ti:0.015%;Sr:0.0075%;Pr:0.003%;Er:0.06%;Fe:0.3%;Mn:0.005%;Cr:0.05%; Zr: 0.01%; Cu: 0.035%; Zn: 0.05%; the remainder is aluminum and unavoidable impurities.

[0037]Wherein, the unavoidable impurities are not more than 0.1wt%, and each element in the unavoidable impurities is not more than 0.03wt%.

[0038] A method for preparing a highly conductive and corrosion-resistant aluminum alloy as described above comprises the following steps:

[0039] (1) Heat the aluminum ingot to 700°C to form aluminum liquid, and add Al-Si master alloy, Al-B master alloy, Al-Ti master alloy, Al-Sr master alloy, Al- Pr master alloy, Al-Er master alloy, Al-Fe master alloy, Al-Mn master alloy, Al-Cr master alloy, Al-Zr master alloy, Al-Cu master alloy, Al-Zn master alloy and Mg are mixed, Prepare alloy liquid;

[0040] (2) heating the alloy ...

Embodiment 2

[0050] A highly conductive and corrosion-resistant aluminum alloy consisting of the following elements by weight percentage:

[0051] Si: 0.3%; Mg: 0.6%; B:0.01%; Ti: 0.01%; Sr: 0.005%; Pr: 0.001%; Er: 0.02%; Fe: 0.2%; Mn: 0.01%; Cr: 0.01%; Zr: 0.005%; Cu: 0.02%; Zn: 0.03%; the remainder is aluminum and unavoidable impurities.

[0052] Wherein, the unavoidable impurities are not more than 0.1wt%, and each element in the unavoidable impurities is not more than 0.03wt%.

[0053] A method for preparing a highly conductive and corrosion-resistant aluminum alloy as described above comprises the following steps:

[0054] (1) Heat the aluminum ingot to 700°C to form aluminum liquid, and add Al-Si master alloy, Al-B master alloy, Al-Ti master alloy, Al-Sr master alloy, Al- Pr master alloy, Al-Er master alloy, Al-Fe master alloy, Al-Mn master alloy, Al-Cr master alloy, Al-Zr master alloy, Al-Cu master alloy, Al-Zn master alloy and Mg are mixed, Prepare alloy liquid;

[0055] (2) ...

Embodiment 3

[0065] A highly conductive and corrosion-resistant aluminum alloy consisting of the following elements by weight percentage:

[0066] Si: 0.6%; Mg: 0.9%; B: 0.04%; Ti: 0.02%; Sr: 0.01%; Pr: 0.005%; Er: 0.1%; Fe: 0.4%; Mn: 0.02%; Cr: 0.02%; Zr: 0.015%; Cu: 0.05%; Zn: 0.07%; the remainder is aluminum and unavoidable impurities.

[0067] Wherein, the unavoidable impurities are not more than 0.1wt%, and each element in the unavoidable impurities is not more than 0.03wt%.

[0068] A method for preparing a highly conductive and corrosion-resistant aluminum alloy as described above comprises the following steps:

[0069] (1) Heat the aluminum ingot to 680°C to form molten aluminum, and add Al-Si master alloy, Al-B master alloy, Al-Ti master alloy, Al-Sr master alloy, Al- Pr master alloy, Al-Er master alloy, Al-Fe master alloy, Al-Mn master alloy, Al-Cr master alloy, Al-Zr master alloy, Al-Cu master alloy, Al-Zn master alloy and Mg are mixed, Prepare alloy liquid;

[0070] (2) hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com