Polymer-ceramic composite dielectric energy storage material and preparation method thereof

A technology of ceramic composite and energy storage materials, which is applied in the manufacture of cables/conductors, equipment and circuits for the manufacture of conductive/semiconductive layers, etc. Low and other problems, to achieve the effects of easy operation, high charge and discharge efficiency, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

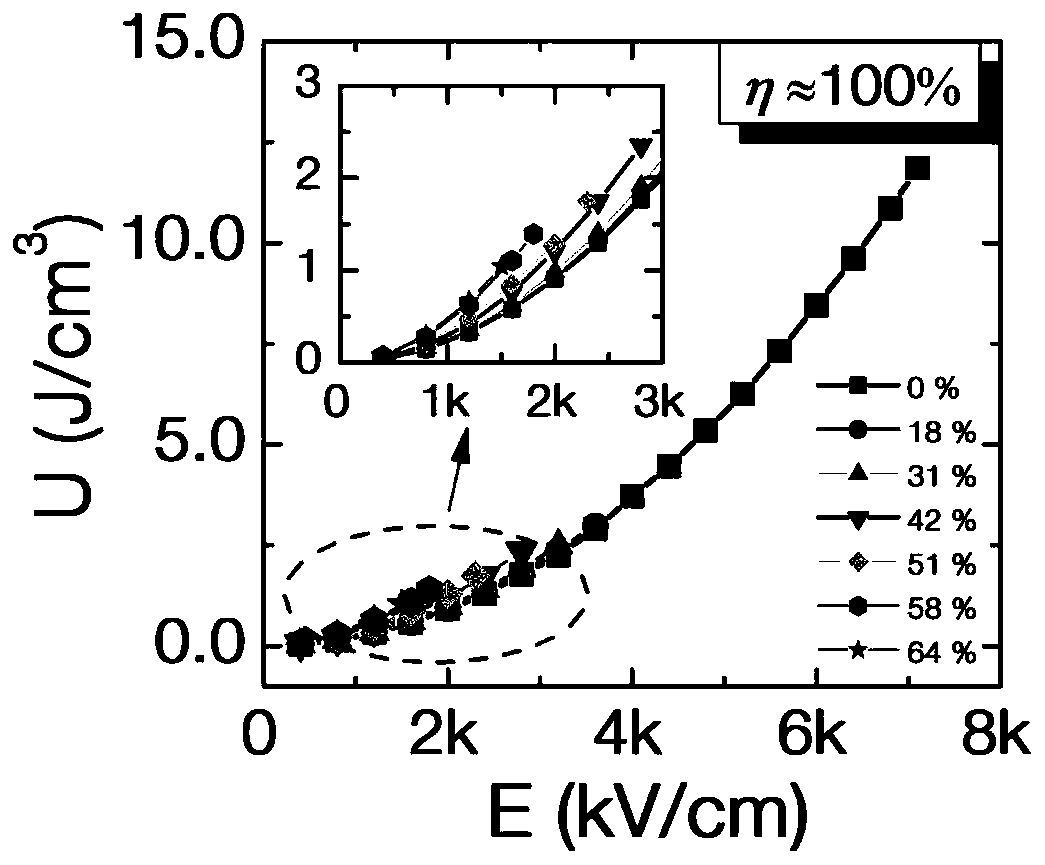

Embodiment 1

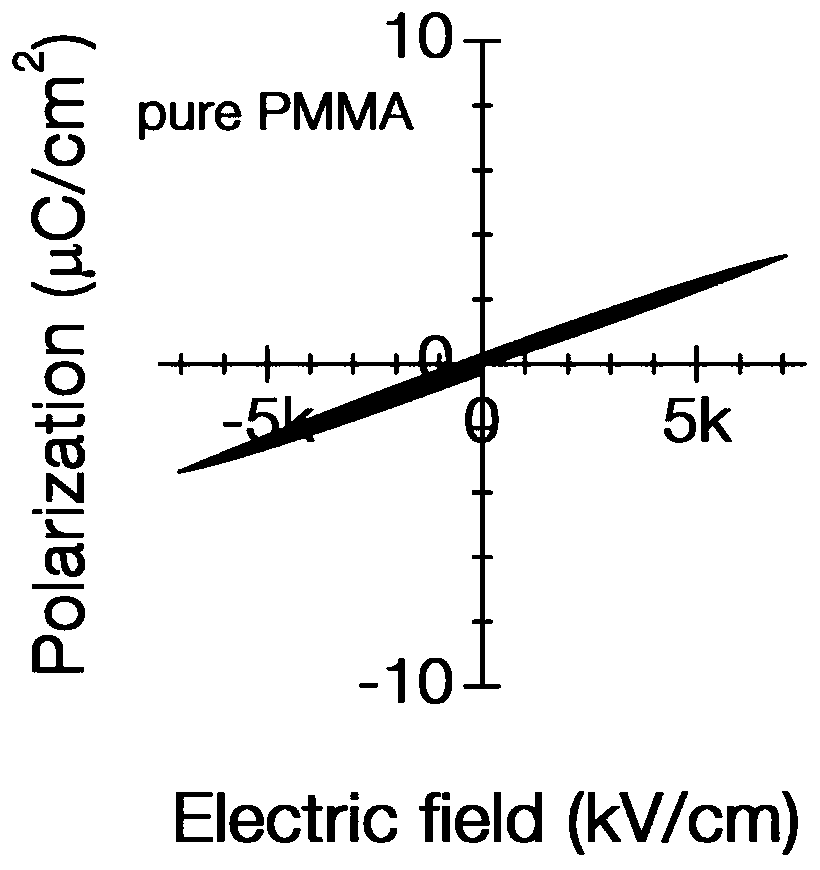

[0025] A polymer-ceramic composite dielectric energy storage material, comprising the following components:

[0026] With polymethyl methacrylate (PMMA) as the matrix, its mass fraction in the composite material is 99%;

[0027] Barium strontium titanate (BST) nanoparticles are used as filler, and its mass fraction in the composite material is 1%.

Embodiment 2

[0029] A polymer-ceramic composite dielectric energy storage material, comprising the following components:

[0030] Taking polymethyl methacrylate (PMMA) as the matrix, its mass fraction in the composite material is 69%;

[0031] Barium strontium titanate (BST) nanoparticles are used as filler, and its mass fraction in the composite material is 31%.

Embodiment 3

[0033] A polymer-ceramic composite dielectric energy storage material, comprising the following components:

[0034] Taking polymethyl methacrylate (PMMA) as the matrix, its mass fraction in the composite material is 49%;

[0035] Barium strontium titanate (BST) nanoparticles are used as filler, and its mass fraction in the composite material is 51%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com