A kind of atmospheric pressure sintering preparation method of feal/tic composite material

A technology of atmospheric pressure sintering and composite materials, which is applied in the field of atmospheric pressure sintering preparation of FeAl/TiC composite materials, can solve the problems of product shape and size limitation, high preparation cost, complicated operation process, etc., and achieves high wear resistance, The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

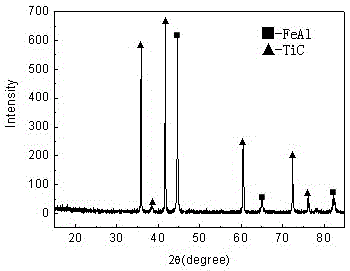

Image

Examples

Embodiment 1

[0014] 1) Mix pure Fe powder and pure Al powder according to Fe:Al=60:40 molar ratio to form Fe-Al mixed powder, put Fe-Al mixed powder into QM-1SP2 planetary ball mill, and grind balls and powder The mass ratio of Fe-Al intermetallic compound is 10:1, the ball mill speed is 350 rpm, the ball milling time is 60h, and the Fe-Al intermetallic compound powder is obtained after dry milling at room temperature;

[0015] 2) The Fe-Al intermetallic compound powder prepared in step 1) is subjected to a heat treatment process, the heat treatment temperature is 800 ° C, and the holding time is 1 h to obtain the FeAl intermetallic compound powder;

[0016] 3) Mix the FeAl intermetallic compound powder obtained in step 2) with TiC powder to form FeAl / TiC composite powder, wherein the content of FeAl intermetallic compound powder in FeAl / TiC composite powder is 10wt%, FeAl / TiC composite powder Strip specimens are formed by pressure forming with a forming pressure of 200MPa;

[0017] 4) Pu...

Embodiment 2

[0019] 1) Mix pure Fe powder and pure Al powder according to the molar ratio of Fe:Al=60:40 to form Fe-Al mixed powder, put Fe-Al mixed powder into QM-1SP2 planetary ball mill, and grind the ball and powder The mass ratio of the material is 10:1, the speed of the ball mill is 300 rpm, the ball milling time is 80h, and the Fe-Al intermetallic compound powder is obtained after dry grinding at room temperature;

[0020] 2) The Fe-Al intermetallic compound powder obtained in step 1) is subjected to heat treatment, the heat treatment temperature is 800°C, and the holding time is 0.5h to obtain the FeAl intermetallic compound powder;

[0021] 3) Mix the FeAl intermetallic compound powder prepared in step 2 with TiC powder to make FeAl / TiC composite powder, wherein the content of FeAl intermetallic compound powder in the FeAl / TiC composite powder is 20wt%, and FeAl / TiC composite The powder is made into a strip sample by pressure molding, and the molding pressure is 200MPa;

[0022] ...

Embodiment 3

[0024] 1) Mix pure Fe powder and pure Al powder according to the molar ratio of Fe:Al=60:40 to form Fe-Al mixed powder, put Fe-Al mixed powder into QM-1SP2 planetary ball mill, and grind the ball and powder The mass ratio of the material is 10:1, the speed of the ball mill is 400 rpm, the ball milling time is 40h, and the Fe-Al intermetallic compound powder is obtained after dry grinding at room temperature;

[0025] 2) The Fe-Al intermetallic compound powder obtained in step 1) is subjected to heat treatment, the heat treatment temperature is 800°C, and the holding time is 1.5h to obtain the FeAl intermetallic compound powder;

[0026] 3) Mix the FeAl intermetallic compound powder obtained in step 2 with TiC powder to make FeAl / TiC composite powder, wherein the content of FeAl intermetallic compound powder in the FeAl / TiC composite powder is 30wt%, and FeAl / TiC composite The powder is made into a strip sample by pressure molding, and the molding pressure is 300MPa;

[0027] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com