Molybdenum disilicide/silicon carbide three-dimensional polymer precursor ceramic and preparation method thereof

A molybdenum disilicide and precursor technology, applied in the field of molybdenum disilicide/silicon carbide three-dimensional polymer precursor ceramics and their preparation, can solve the problems of excessive residual silicon content, ceramic cracks, poor mechanical properties of silicon carbide ceramics, etc. Achieve uniform and dense microstructure, high thermal and electrical conductivity, and good composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

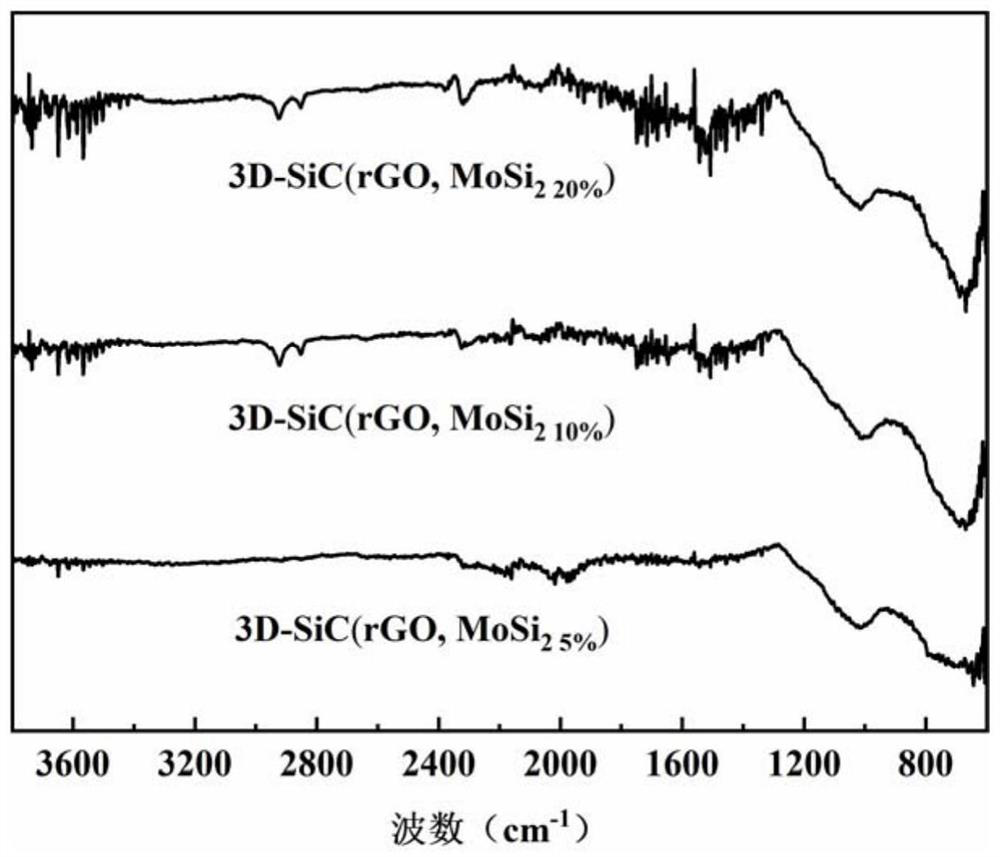

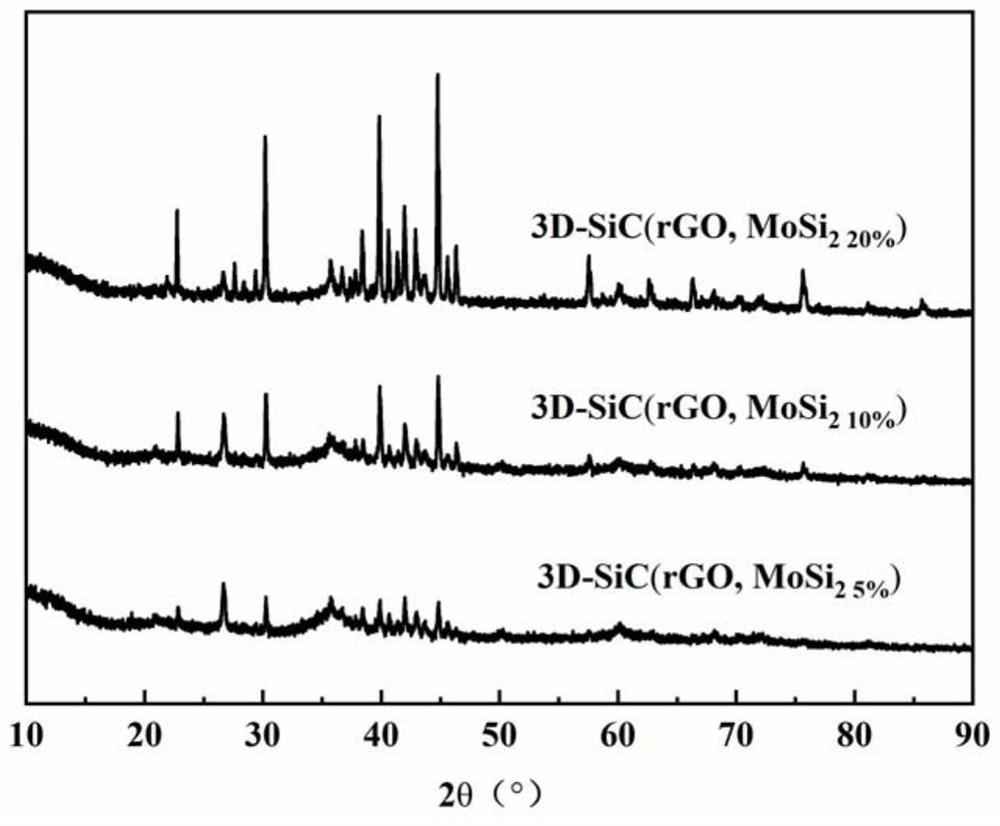

Embodiment 1

[0038] 1. Dissolve 2g of PCS powder in 40mL of xylene, disperse 0.02g of GO powder in 40mL of purified water, and ultrasonically disperse the above two solutions for 30min. Add 0.05mL Castel platinum catalyst to the PCS solution, add 2mL vinyltriethoxysilane and a proper amount of 5wt% dilute hydrochloric acid to the GO dispersion to adjust the pH value of the solution to 1-3.

[0039] 2. Mix the above two solutions into a beaker and place it in a 60°C constant temperature water bath for heating in a water bath, and magnetically stir at a speed of 30 rpm, and keep warm for 30 minutes. After the reaction, the mixture was left to stand for 5 minutes to separate layers, and the upper layer product was taken and subjected to vacuum distillation at 70° C. to obtain PVG solid and ground into powder.

[0040] 3. Take part of the PVG powder and place it in a graphite paper boat and pyrolyze it at 1300°C under the protection of argon atmosphere. The heating rate is 4°C / min, the holding...

Embodiment 2

[0045] 1. Dissolve 2g of PCS powder in 40mL of xylene, disperse 0.02g of GO powder in 40mL of purified water, and ultrasonically disperse the above two solutions for 30min. Add 0.05mL Castel platinum catalyst to the PCS solution, add 2mL vinyltriethoxysilane and a proper amount of 5wt% dilute hydrochloric acid to the GO dispersion to adjust the pH value of the solution to 1-3.

[0046] 2. Mix the above two solutions into a beaker and place it in a 60°C constant temperature water bath for heating in a water bath, and magnetically stir at a speed of 30 rpm, and keep warm for 30 minutes. After the reaction, the mixture was left to stand for 5 minutes to separate layers, and the upper layer product was taken and subjected to vacuum distillation at 70° C. to obtain PVG solid and ground into powder.

[0047] 3. Take part of the PVG powder and place it in a graphite paper boat and pyrolyze it at 1300°C under the protection of argon atmosphere. The heating rate is 4°C / min, the holding...

Embodiment 3

[0052] 1. Dissolve 2g of PCS powder in 40mL of xylene, disperse 0.02g of GO powder in 40mL of purified water, and ultrasonically disperse the above two solutions for 30min. Add 0.05 mL of Custer platinum catalyst to the PCS solution, add 2 mL of vinyltriethoxysilane and an appropriate amount of dilute hydrochloric acid with a concentration of 5 wt % to the GO dispersion to adjust the pH value of the solution to 1-3.

[0053] 2. Mix the above two solutions into a beaker, place in a 60°C constant temperature water bath for heating, and magnetically stir at a speed of 30 rpm, and keep warm for 30 minutes. After the reaction, the mixture was left to stand for 5 minutes to separate layers, and the upper layer product was taken and subjected to vacuum distillation at 70° C. to obtain PVG solid and ground into powder.

[0054] 3. Take part of the PVG powder and place it in a graphite paper boat and pyrolyze it at 1300°C under the protection of argon atmosphere. The heating rate is 4°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com