A kind of high thermal conductivity and high temperature resistant polysiloxane ceramic composite material and its preparation method and application

A ceramic composite material, polysiloxane technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of violent volatilization, increased thermal resistance, difficult cleaning, etc., and achieves excellent high temperature aging resistance and elasticity. Good, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

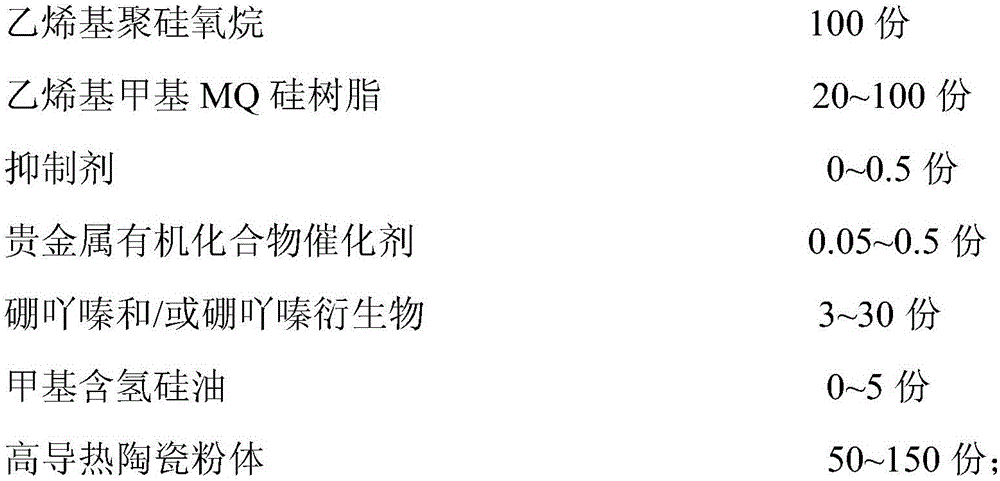

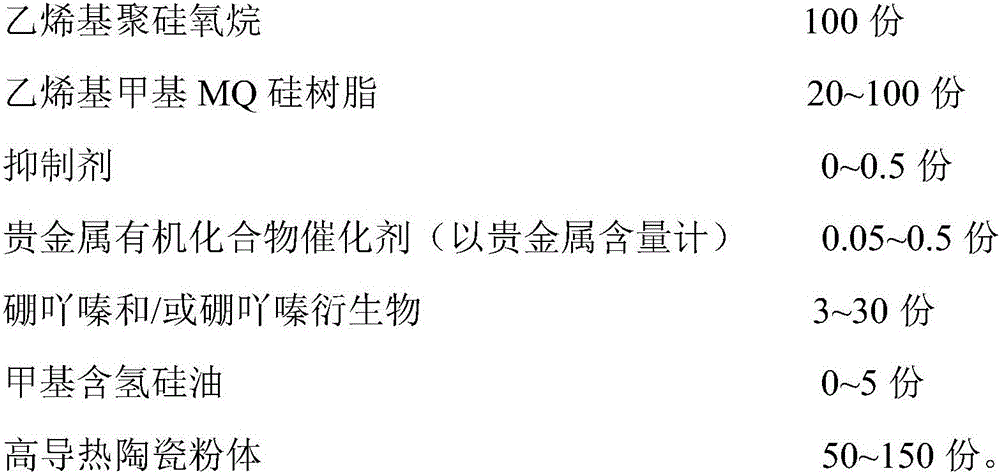

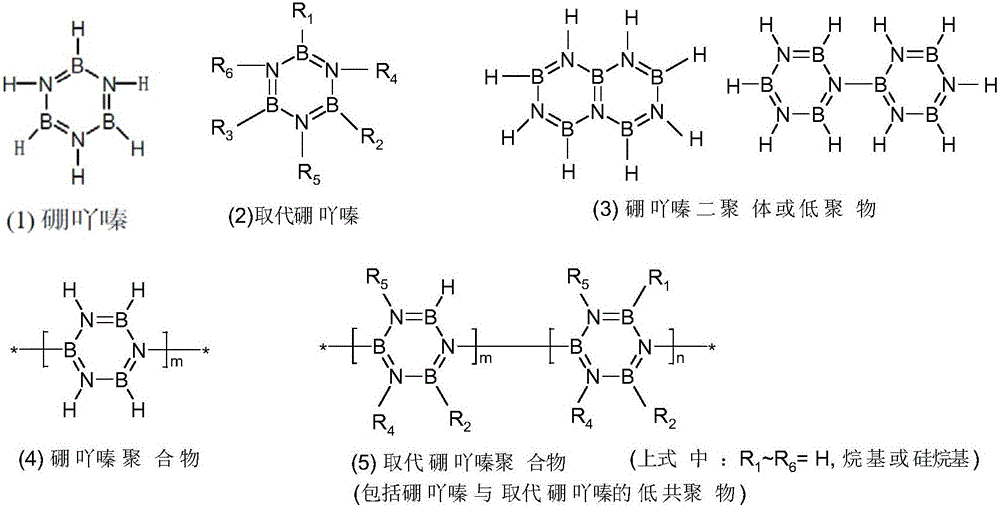

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: raw material preparation

[0034] (1) Put boron nitride, aluminum nitride, silicon carbide, and silicon nitride, which are thermally conductive and high-temperature resistant ceramic powder fillers with an average particle size of 1 to 50 μm, in a vacuum drying oven, vacuumize, and heat up to 150°C , keep the vacuum (-101.3KPa) for 3 hours, then take it out after cooling, put it in a dry box, and set it aside.

[0035] (2) Preparation of silyl borazine: take out 40.3g of borazine from the storage room at -5°C at low temperature, pour it into a 1000mL three-necked bottle equipped with a drying device, add 200g of dry dichloromethane, Add 0.4 g of RhH(CO)(PPH 3 ) 3 , keep stirring and slowly add 322g of vinyl tris(trimethylsiloxy)silane, stir and react at room temperature for 8 hours, then add 0.2g of ethynyl cyclohexanol, distill under reduced pressure, remove low boiling point solvent, and prepare disilane The base-based silyl borazine BZ2 is stored at ...

Embodiment 2

[0054] A method for preparing a high thermal conductivity and high temperature resistant polysiloxane ceramic composite material, the specific steps are as follows:

[0055] At room temperature, 100 g of terminal vinyl methyl silicone oil (viscosity 50000 mPa·s), 30 g of vinyl methyl MQ silicone resin (4.0 wt% vinyl content, M / Q=1.5), 30 g of tris(triphenylphosphine) carbonyl rhodium hydride (I)RhH(CO)(PPH 3 ) 3 (The content of metal rhodium is 11.2wt%) After 0.45g, borazine 3g and the boron nitride ceramic powder (average particle diameter 50 μ m) 100g of embodiment 1 drying treatment are mixed uniformly, be placed in 50 ℃ of environments and keep warm for 5 Hours, the high thermal conductivity and high temperature resistant polysiloxane ceramic composite material was obtained.

[0056] After the composite material was cooled, its Shore hardness, thermal conductivity and high temperature aging resistance were measured. The experimental test results are listed in Table 1. ...

Embodiment 3

[0061] A method for preparing a high thermal conductivity and high temperature resistant polysiloxane ceramic composite material, the specific steps are as follows:

[0062] At room temperature, 100 g of terminal vinyl methyl silicone oil (viscosity 3000 mPa·s), 100 g of vinyl methyl MQ silicone resin (vinyl content 2.4 wt%, M / Q=0.75), 0.48 g of ethynyl cyclohexanol, and tri( Triphenylphosphine) rhodium carbonyl hydride (I) RhH (CO) (PPH 3 ) 3 (the content of metal rhodium is 11.2wt%) 4.3g, disilyl borazine BZ2 (prepared in embodiment 1) 30g and the boron nitride ceramic powder (average particle diameter 10 μ m) 100g mixing of embodiment 1 dry treatment After uniformity, it was placed in an environment of 150° C. for 2 hours to obtain the polysiloxane ceramic composite material with high thermal conductivity and high temperature resistance.

[0063] After the composite material is cooled, its hardness, thermal conductivity and high-temperature aging resistance are measured, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com