High-temperature-aging-resistant chloroprene rubber windshield wiper rubber strip and preparation method thereof

A neoprene rubber and high temperature resistant technology, applied in the field of wiper strips, can solve the problems of strip strength, flexibility and wiper characteristics loss, the inability of wiper strips to be used for a long time, shortening the service life of wipers, etc., and achieve good mixing and extrusion characteristics, good thermal stability and aging resistance, little effect of hardness change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

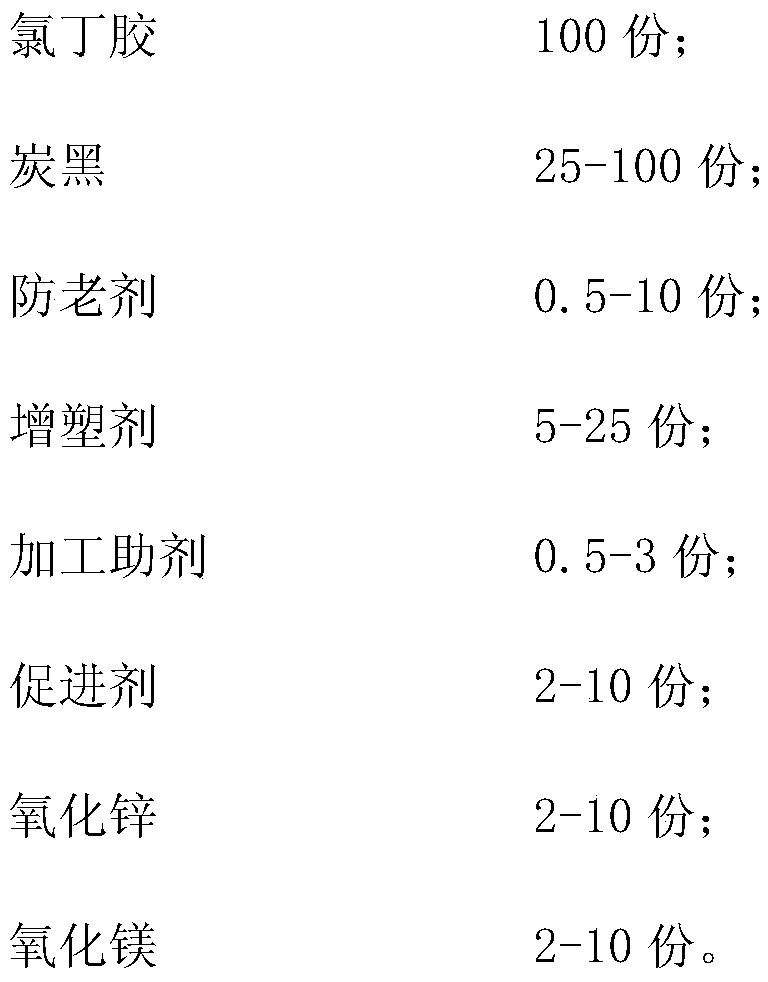

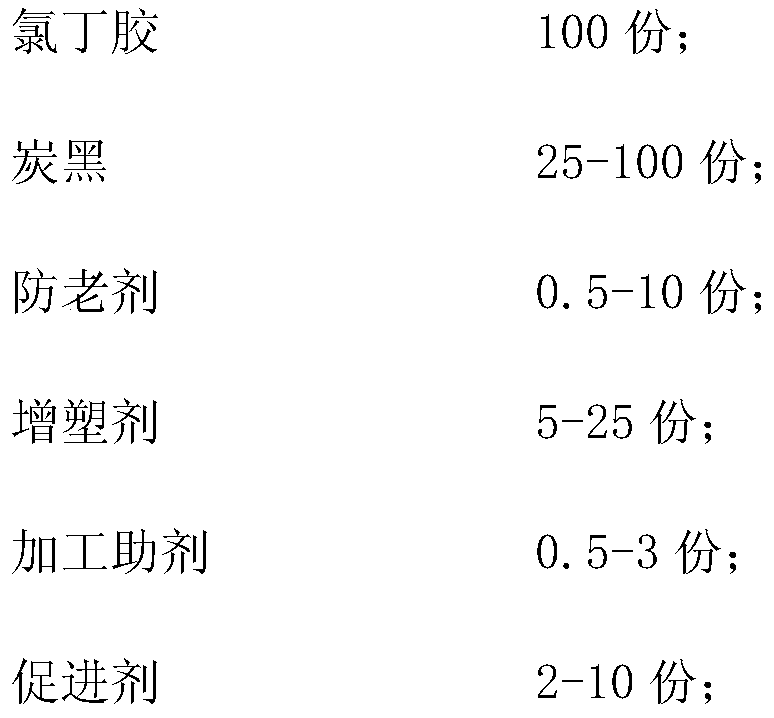

Method used

Image

Examples

Embodiment 1

[0023] Step A: After masticating 100 parts of Baypren 110 neoprene, carry out pressure mixing with 2 parts of DDA, 2 parts of DTPD, 1 part of microcrystalline wax, and 5 parts of DOS, and then mix 15 parts of N550, 15 parts of N774, and 30 parts Add N990, 1 part of SA and 4 parts of magnesium oxide into the barrel of the internal mixer for internal mixing, put down the pressure hammer and mix for 2 minutes, when the temperature reaches 90 ° C, add 5 parts of zinc oxide and 2.5 parts of TMU densely Refining for 4 minutes, when the temperature reaches 120°C, discharge the lump rubber, then move the lump rubber to the open mill, and refine in the open mill, with a thickness of 2mm. The gap between the two rollers of the open mill is adjusted to the minimum distance, and the thin pass is carried out 3 times, which takes a total of 3 minutes, and then the refined rubber is put into the tablet machine, and pressed into a suitable size (length, Thickness, width) of the film, parked f...

Embodiment 2

[0029] Step A: After masticating 100 parts of Baypren 110 neoprene, carry out pressure banburying with 2.5 parts of DDA, 1 part of DTPD, 1.5 parts of microcrystalline wax and 6 parts of DOS, and then mix 10 parts of N550, 5 parts of N774, 40 parts Add N990, 1.5 parts of SA and 4 parts of magnesium oxide into the barrel of the internal mixer for banburying, put down the pressure hammer and mix for 3 minutes, when the temperature reaches 90°C, add 5 parts of zinc oxide and 2 parts of TMU successively Refining for 5 minutes, when the temperature reaches 140°C, discharge the lump rubber, then move the lump rubber to the open mill, and refine in the open mill, with a thickness of 5mm. The gap between the two rollers of the mill is adjusted to the minimum distance, and the thin pass is carried out 3 times, which takes a total of 6 minutes, and then the refined rubber is put into the tablet machine, and pressed into a suitable size (length, Thickness, width) of the film, parked for u...

Embodiment 3

[0035] Step A: After masticating 100 parts of Baypren 110 neoprene, carry out pressure mixing with 0.25 parts of DDA, 0.1 parts of DTPD, 0.15 parts of microcrystalline wax, and 5 parts of DOS, and then mix 5 parts of N550, 2 parts of N774, and 18 parts Add N990, 0.5 parts of SA and 2 parts of magnesium oxide into the barrel of the internal mixer for internal mixing, put down the pressure hammer and mix for 2 and a half minutes. When the temperature reaches 90°C, add 2 parts of zinc oxide and 2 parts of TMU internal mixing for 4 and a half minutes, when the temperature reaches 100°C, discharge the lump rubber, then move the lump rubber to the open mixer, and refine it in the open mixer, the thickness is 3mm, and manually carry out triangular bag refining for 5 Once, adjust the gap between the two rollers of the mill to the minimum distance, and carry out thin pass 3 times, which takes a total of 4 minutes, and then put the refined rubber into the tablet machine, and press it int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com