High-temperature-resistant ultraviolet-resistant epoxy resin prepolymer and preparation method thereof

A technology of epoxy resin and prepolymer, which is applied in the field of high temperature-resistant and UV-resistant epoxy resin prepolymer and its preparation, can solve the problems of limited use of epoxy resin, poor high-temperature aging resistance and UV resistance, and the like, Achieve excellent high temperature aging resistance and anti-ultraviolet performance, improve high temperature aging resistance and anti-ultraviolet performance, and control the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

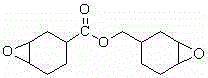

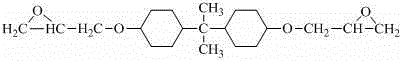

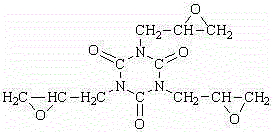

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in more detail below by way of examples, but the present invention is not limited to the examples consisting of the following experimental examples.

[0029] In the following examples, embodiment 1 is an embodiment of the present invention, and embodiment 2 is a comparative example.

[0030] According to the proportion, mix the epoxy resin and antioxidant evenly at 80°C-130°C, and then add the acid anhydride curing agent, coupling agent and polyol at 40°C-80°C for 30min-4h to obtain epoxy resin prepolymerization Finally, post-cure the above prepolymer at 40°C-80°C for 8h-18h to obtain the final epoxy resin prepolymer.

[0031] components Example 1 Example 2 Epoxy resin (Ⅰ) 34 0 Epoxy resin (Ⅳ) 0 50 Anhydride curing agent 60 44 Polyol 3 3 antioxidant 2 2 coupling agent 1 1

[0032] Note: The epoxy resin (Ⅳ) is bisphenol A type epoxy resin.

[0033] The epoxy resin prepoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com