A kind of self-adhesive waterproof glue applied on metal roof and preparation method thereof

A self-adhesive waterproof and metal roofing technology, applied in the direction of adhesives, adhesive types, asphalt material adhesives, etc., can solve the problems of poor peel strength and poor high temperature resistance, and achieve good aging resistance, high peel strength, Excellent flame resistance and electrical insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

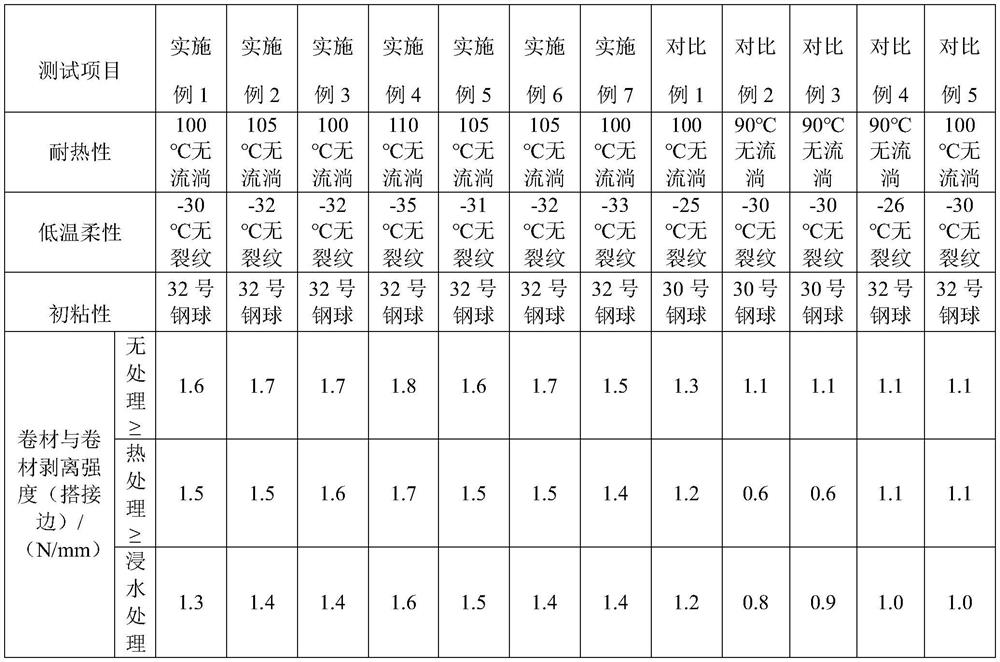

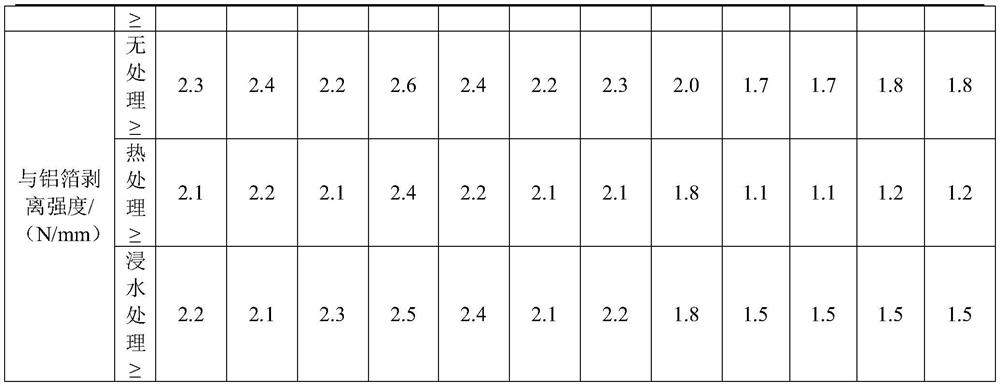

Examples

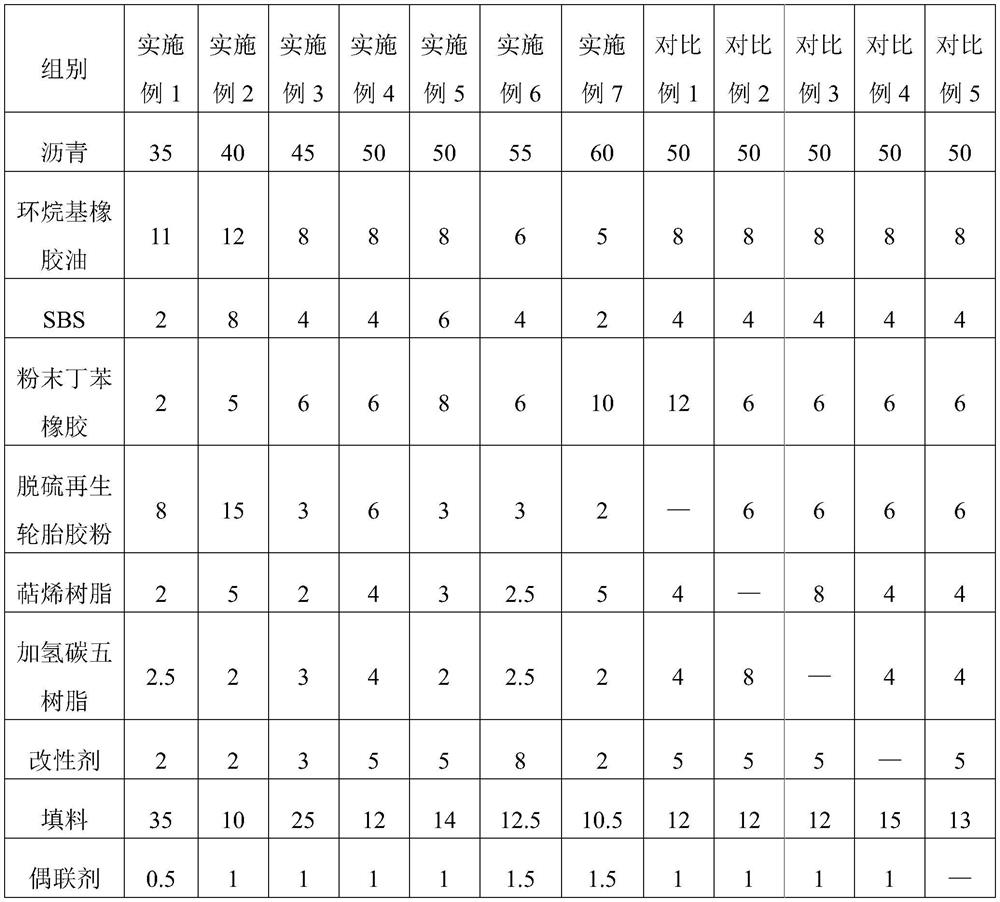

Embodiment 1

[0034] A self-adhesive waterproof adhesive applied on metal roofing consists of the following components by weight percentage:

[0035] 90# asphalt 35%, naphthenic rubber oil 11%, SBS1603 2%, powdered styrene-butadiene rubber 2%, desulfurized recycled tire rubber powder 8%, terpene resin 2%, hydrogenated carbon five resin 2.5%, modifier 2%, heavy calcium carbonate 35%, coupling agent KH5500.5%,

[0036] Wherein, the desulfurized recycled tire rubber powder is 40 mesh desulfurized recycled tire rubber powder, the pour point of naphthenic rubber oil is lower than -30°C, and the modifier consists of the following components by weight:

[0037] 100 parts of chlorosulfonated polyethylene, 8 parts of sulfinyl chloride, 40 parts of refined aromatic oil, 3 parts of antioxidant BA,

[0038] Its preparation method comprises the following steps:

[0039] S1. According to the above formula, weigh each component for later use;

[0040] S2. Refining chlorosulfonated polyethylene, sulfiny...

Embodiment 2

[0048] A self-adhesive waterproof adhesive applied on metal roofing consists of the following components by weight percentage:

[0049] 90# asphalt 40%, naphthenic rubber oil 12%, SBS1603 8%, powdered styrene-butadiene rubber 5%, desulfurized recycled tire rubber powder 15%, terpene resin 5%, hydrogenated carbon five resin 2%, modifier 2%, light calcium carbonate 10%, coupling agent KH5501%,

[0050] Wherein, the desulfurized recycled tire rubber powder is 40 mesh desulfurized recycled tire rubber powder, the pour point of naphthenic rubber oil is lower than -30°C, and the modifier A consists of the following components in parts by weight:

[0051] 100 parts of chlorosulfonated polyethylene, 8 parts of sulfinyl chloride, 40 parts of refined aromatic oil, 3 parts of antioxidant BA,

[0052] Its preparation method is with embodiment one.

Embodiment 3

[0054] A self-adhesive waterproof adhesive applied on metal roofing consists of the following components by weight percentage:

[0055] 90# asphalt 45%, naphthenic rubber oil 8%, SBS1603 4%, powdered styrene-butadiene rubber 6%, desulfurized recycled tire rubber powder 3%, terpene resin 2%, hydrogenated carbon five resin 3%, modifier 3%, talcum powder 25%, coupling agent KH550 1%,

[0056] Wherein, the desulfurized recycled tire rubber powder is 40 mesh desulfurized recycled tire rubber powder, the pour point of naphthenic rubber oil is lower than -30°C, and the modifier consists of the following components by weight:

[0057] 100 parts of chlorosulfonated polyethylene, 8 parts of sulfinyl chloride, 40 parts of refined aromatic oil, 3 parts of antioxidant BA,

[0058] Its preparation method is with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com