Ratproof cable rubber sheath material as well as preparation method and application thereof

A technology of sheath material and anti-rodent cable, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of softness, weather resistance, elasticity, flame retardancy and oil resistance, and can not meet the requirements of cable performance, etc., to achieve The effect of long safe flat period, long vulcanization scorch time and fast vulcanization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

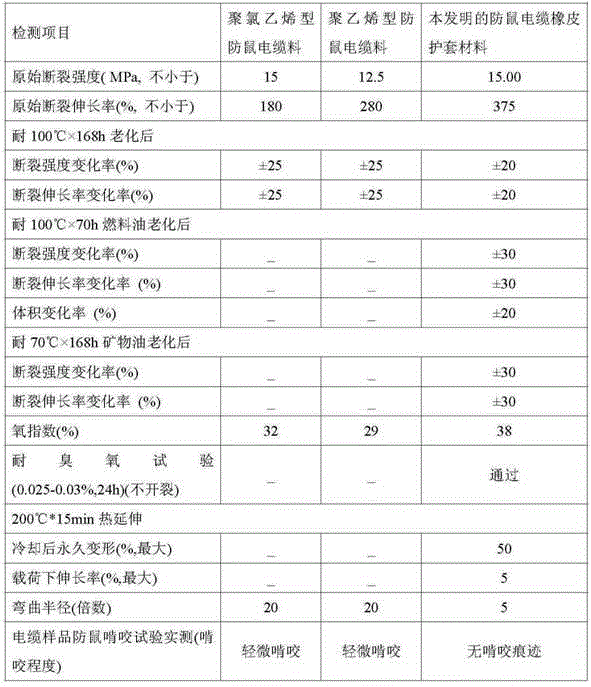

Method used

Image

Examples

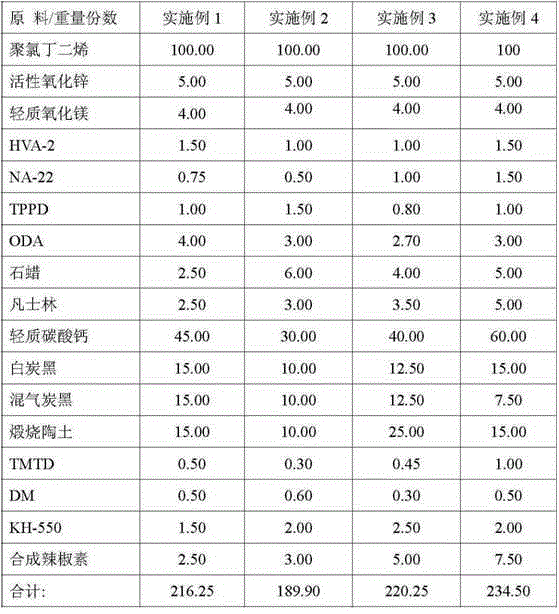

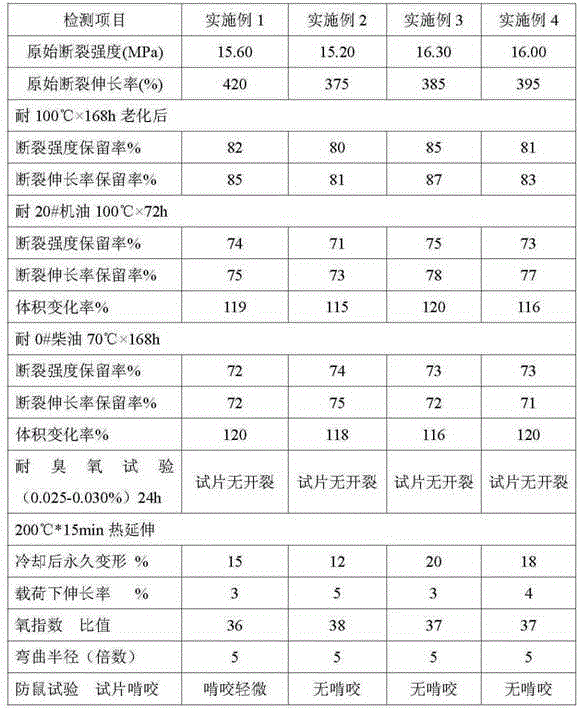

Embodiment 1

[0061] Raw materials are prepared according to the proportioning of Table 2 Example 1, and the anti-rat cable rubber sheath material is prepared as follows:

[0062] First take the basic rubber polychloroprene that has been masticated, knead it on a small open mill, and then add stabilizer light magnesium oxide, anti-aging agent TPPD and ODA, filler light calcium carbonate, reinforcing filler Agent white carbon black, gas-mixed carbon black and calcined clay, anti-rodent agent synthetic capsaicin, operating agent paraffin and vaseline, anti-scorch agent TMTD and DM, silane coupling agent KH-550, vulcanizing agent active zinc oxide and vulcanization accelerator For HVA-2 and NA-22, when the mixing temperature is lower than 40°C, the rubber material is obtained by mixing and molding, and the distance between the rollers of the small open mill is reduced, and the rubber material is thinly sliced, that is, the rubber is triangular bagged for 3 times, and then the sheet is produced....

Embodiment 2

[0065] Raw materials are prepared according to the proportioning of Table 2 Example 2, and the anti-rat cable rubber sheath material is prepared as follows:

[0066] Put the basic rubber polychloroprene that has been masticated first into the internal mixer, the mixing temperature is lower than 40°C, and knead for about 30 seconds, then add anti-aging agents TPPD and ODA, stabilizers light magnesium oxide, anti-scorch Agent TMTD and DM, operating agent paraffin and vaseline, filler light calcium carbonate, reinforcing filler silica, aerated carbon black and calcined clay, rodent control agent synthetic capsaicin and silane coupling agent KH-550, mixed After smelting for about 3 minutes, add the vulcanizing agent system composed of active zinc oxide, HVA-2 and NA-22, and knead for about 25 seconds, then discharge, compress, and open strips, and then cool the sheets for later use. The thickness of the rubber sheet is about 2mm, and the width is 250mm. It is used after parking fo...

Embodiment 3

[0069] Raw materials are prepared according to the proportioning of table 2 embodiment 3, and the anti-rat cable rubber sheath material is prepared as follows:

[0070] Put the basic rubber polychloroprene that has been masticated first into the internal mixer, the mixing temperature is lower than 40°C, and knead for about 1 minute, then add anti-aging agent TPPD and ODA, stabilizer light magnesium oxide, anti-scorch Agent TMTD and DM, operating agent paraffin and vaseline, filler light calcium carbonate, reinforcing filler silica, aerated carbon black and calcined clay, rodent control agent synthetic capsaicin, silane coupling agent KH-550, mixed After smelting for about 5 minutes, add the vulcanizing agent system composed of active zinc oxide, HVA-2 and NA-22, and knead for about 35 seconds, then discharge, compress, and open strips, and then cool the sheets for later use. The thickness of the rubber sheet is about 2mm, and the width is 250mm. It is used after parking for at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com