SCR (selective catalytic reduction) nitrogen oxide catalyst, and preparation method and application thereof

A nitrogen oxide and catalyst technology, applied in the field of manganese-based transition metal composite oxide catalysts, can solve the problems of poor low temperature activity, low selectivity, and narrow temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

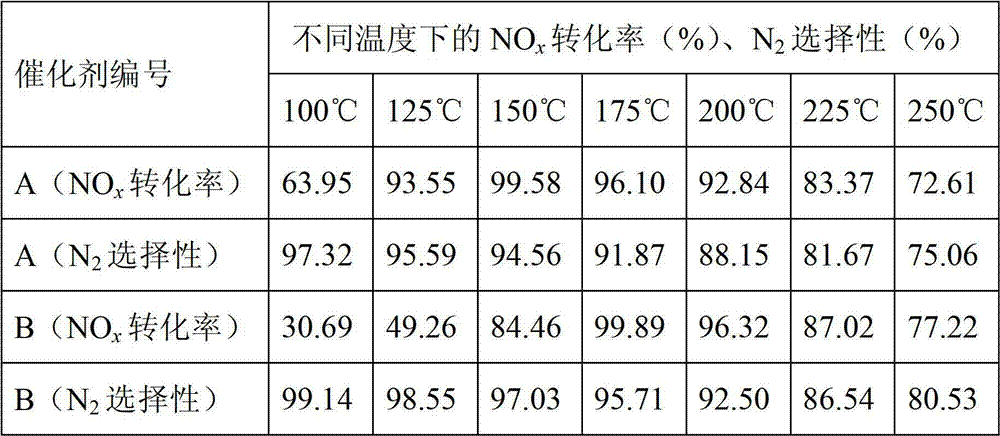

Embodiment 1

[0058] Dissolve manganese nitrate and niobium pentachloride in water respectively, prepare a solution with a molar ratio of Mn / Nb of 2 and mix evenly, add excess urea to the solution, and continuously stir at 90°C for 12h, then carry out suction filtration and Wash the filter cake three times to obtain the filter cake, put the filter cake in an oven and dry it at 100°C for 10 hours, and finally roast it in the air at 500°C in a muffle furnace for 5 hours to obtain a powder catalyst. The prepared catalyst was pressed into tablets, crushed, sieved, and 20-40 meshes were taken for later use, called catalyst A.

Embodiment 2

[0060] Dissolve manganese nitrate and niobium pentachloride in water respectively, prepare a solution with a molar ratio of Mn / Nb of 1 and mix evenly, add excess urea to the solution, and continuously stir at 90°C for 12 hours, then carry out suction filtration and Wash the filter cake three times to obtain the filter cake, put the filter cake in an oven and dry it at 100°C for 10 hours, and finally roast it in the air at 500°C in a muffle furnace for 5 hours to obtain a powder catalyst. The prepared catalyst was pressed into tablets, crushed, sieved, and 20-40 meshes were taken for later use, which was called catalyst B.

Embodiment 3

[0062] Dissolve manganese sulfate, manganese nitrate and niobium pentachloride in water respectively, prepare a solution with a molar ratio of Mn / Nb of 4 and mix well, add excess urea to the solution, and stir continuously at 60°C for 48h, then carry out Suction filtration and washing once to obtain a filter cake, put the filter cake in an oven to dry at 105°C for 33 hours, and finally bake it in a muffle furnace at 380°C in air for 8 hours to obtain a powder catalyst. The prepared catalyst is pressed into tablets, crushed, sieved, and 20-40 meshes are taken for use to obtain a manganese-niobium composite oxide catalyst for selective catalytic reduction of nitrogen oxides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com