Iron cerium tungsten ternary composite oxide with high heat stability as well as synthesis and application thereof

A high thermal stability, ternary composite technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, chemical instruments and methods, etc., can solve problems such as narrow temperature window and poor thermal stability, Achieve the effects of wide operating temperature window, excellent thermal stability, simple preparation process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

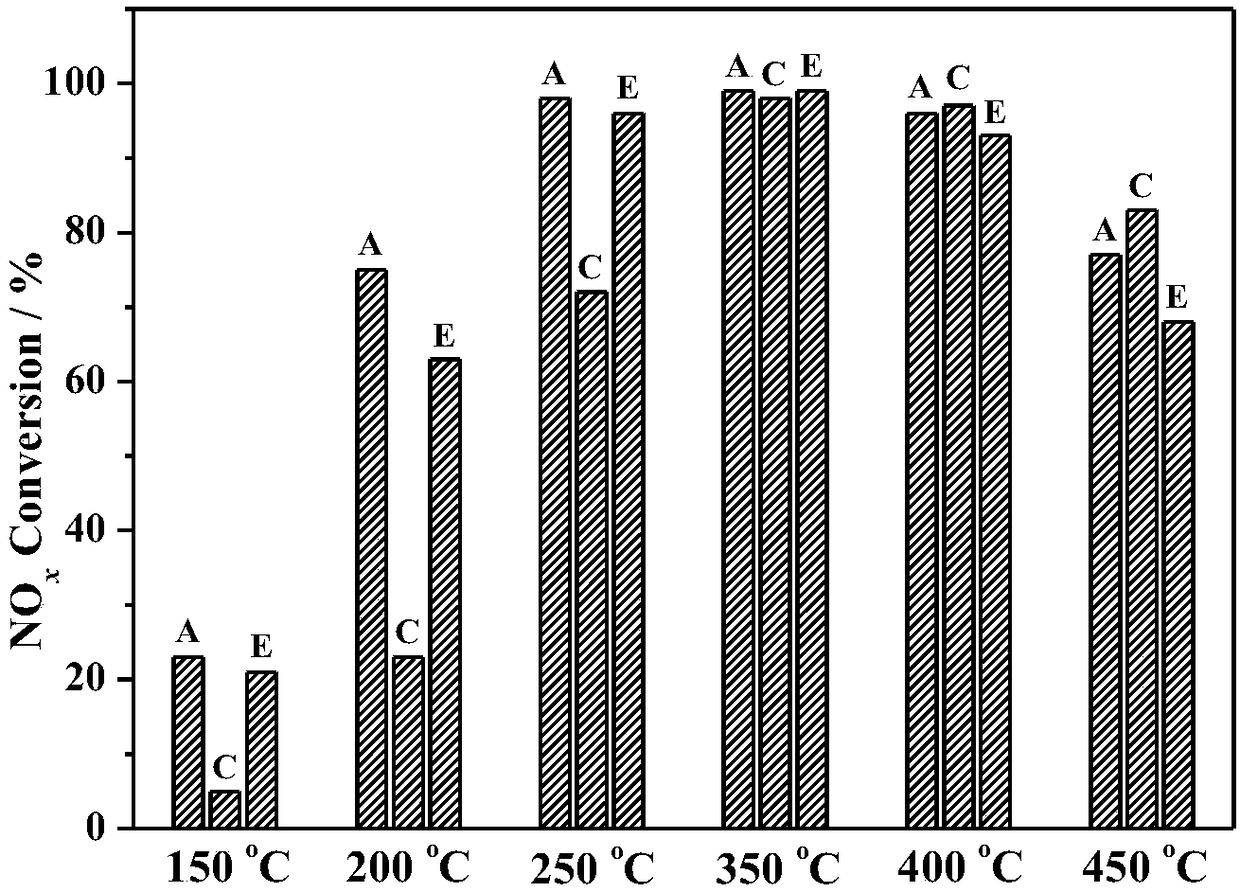

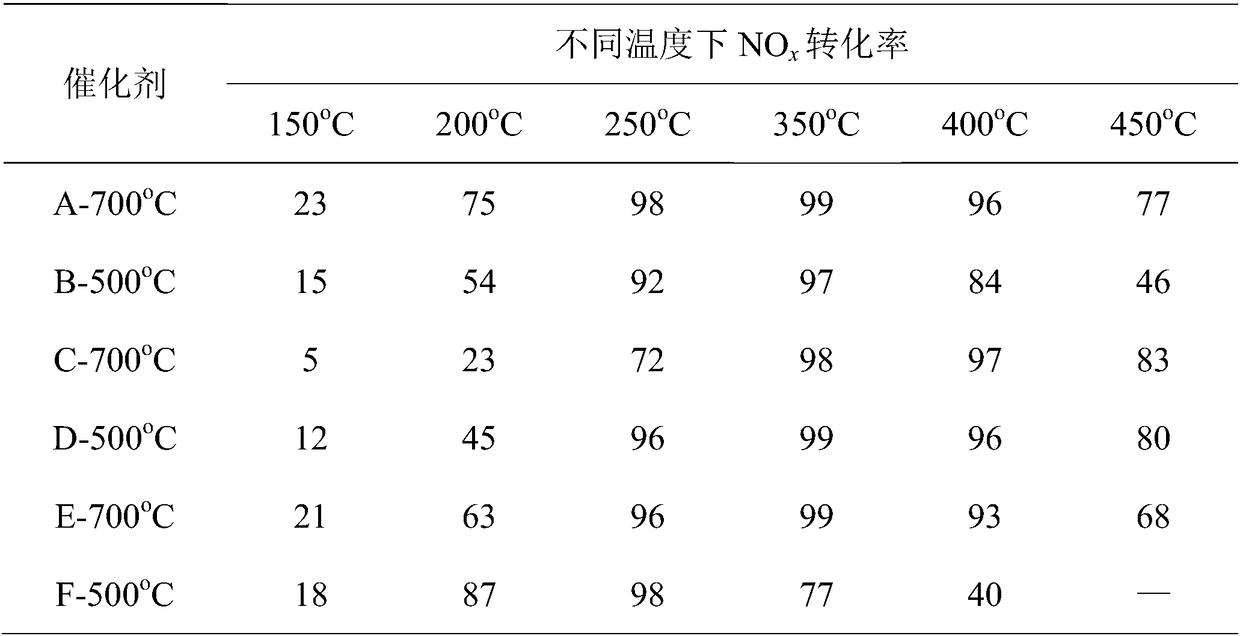

[0022] Preparation of ternary composite oxide: Weigh 9.0g of urea, add it into deionized water, and stir continuously for 1h under the condition of 20°C water bath; then add 1.21g of ferric nitrate nonahydrate and 3.908g of nitric acid hexahydrate to the urea solution in sequence Cerium and 0.74g of ammonium metatungstate were stirred continuously for 3 hours to form a uniform suspension; continued to stir for 24 hours in a water bath at 90°C, then the temperature of the water bath dropped to room temperature, and aged for 12 hours; °C for 12 hours, and finally the dried sample precursor was calcined in a muffle furnace at 700 °C for 5 h to obtain a powder catalyst A-700 °C.

Embodiment 2

[0024] According to the preparation method of the ternary composite oxide of the present invention in Example 1, other conditions remained unchanged, only the calcination temperature was changed to 500° C., and the calcination time was 5 hours to obtain the catalyst.

Embodiment 3

[0026] To better demonstrate the advantages of the ternary composite catalyst, it was compared with the binary composite oxide catalyst. According to the preparation method of the composite oxide of the present invention in Example 1, other conditions remained unchanged, only cerium nitrate hexahydrate was removed, and a catalyst C-700° C. was prepared. According to the preparation method of the composite oxide of the present invention in Example 2, other conditions remained unchanged, only cerium nitrate hexahydrate was removed, and the catalyst D-500°C was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com