Preparation method and applications of monolithic catalyst used for catalyzing and purifying ammonia-containing waste gas

A monolithic catalyst, monolithic catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of increased pressure drop of catalytic reactor and catalyst utilization rate Low, high catalyst loss rate and other issues, to achieve the effect of N2 selectivity and high low temperature conversion rate, low complete conversion temperature, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

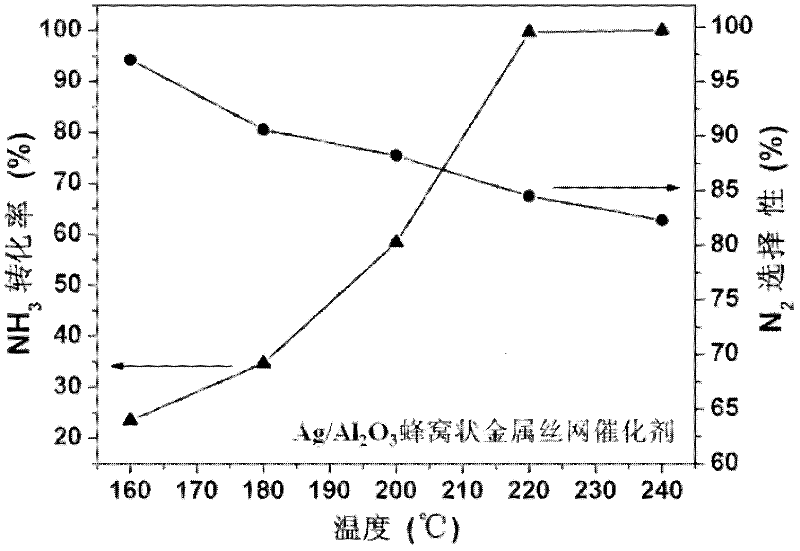

[0027] Weigh 4g 10wt.%Ag / Al 2 o 3 Catalyst, mixed with 50ml deionized to make Ag / Al 2 o 3 Catalyst slurry; the quality is 4.4692g, the volume is 8cm 3 The cube-shaped honeycomb wire mesh carrier was immersed in it, and it was taken out after 10 minutes. First, it was dried at 100°C; then, the sample was immersed in the above-mentioned Ag / Al 2 o 3 In the catalyst slurry, repeated 3-4 times; then, the Ag / Al 2 o 3 The honeycomb wire mesh catalyst was calcined at 600°C for 3h to obtain Ag / Al 2 o 3 Honeycomb wire mesh catalyst. Ag / Al 2 o 3 Honeycomb wire mesh catalyst for NH 3 Conversion rate and N 2 The selectivity curve as a function of temperature figure 1 shown.

Embodiment 2

[0029] According to the preparation method of the monolithic catalyst of the present invention in Example 1, the catalytically active component of the monolithic catalyst is changed to 10wt.%Cu / TiO 2 , where the mass of the honeycomb wire mesh carrier is 5.0215g, the drying temperature is 120°C, the Cu / TiO 2 The honeycomb wire mesh catalyst is calcined at 450°C to obtain Cu / TiO 2 Honeycomb wire mesh catalyst.

Embodiment 3

[0031] According to the preparation method of the monolithic catalyst of the present invention in Example 1, the catalytically active component of the monolithic catalyst is changed to 3wt.%Cu / CeO 2 , where the mass of the honeycomb wire mesh carrier is 4.4031g, the Cu / CeO 2 The honeycomb wire mesh catalyst is calcined at 500°C to obtain Cu / CeO 2 Honeycomb wire mesh catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com