Transition metal oxide composite catalyst, preparation method thereof and application of catalyst

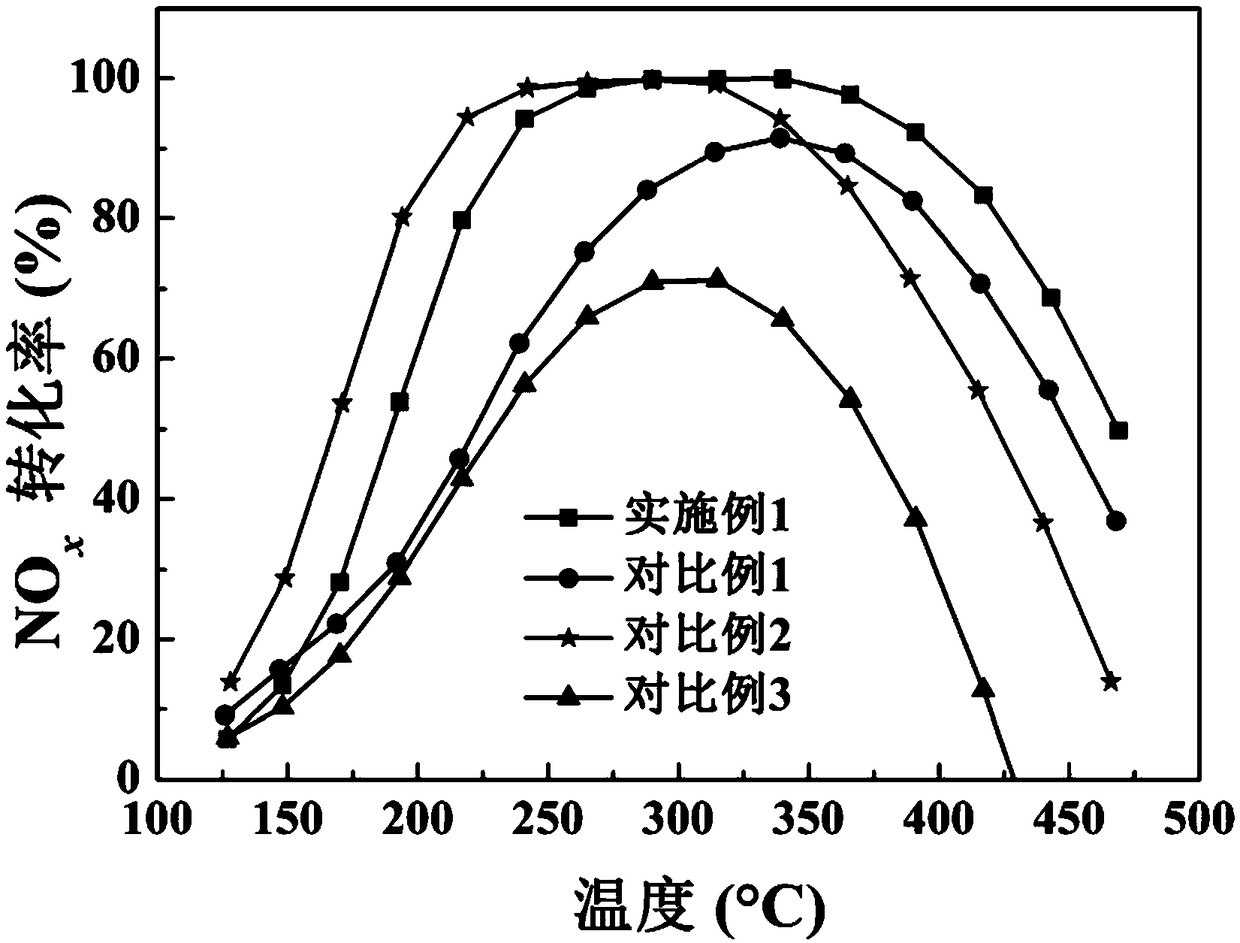

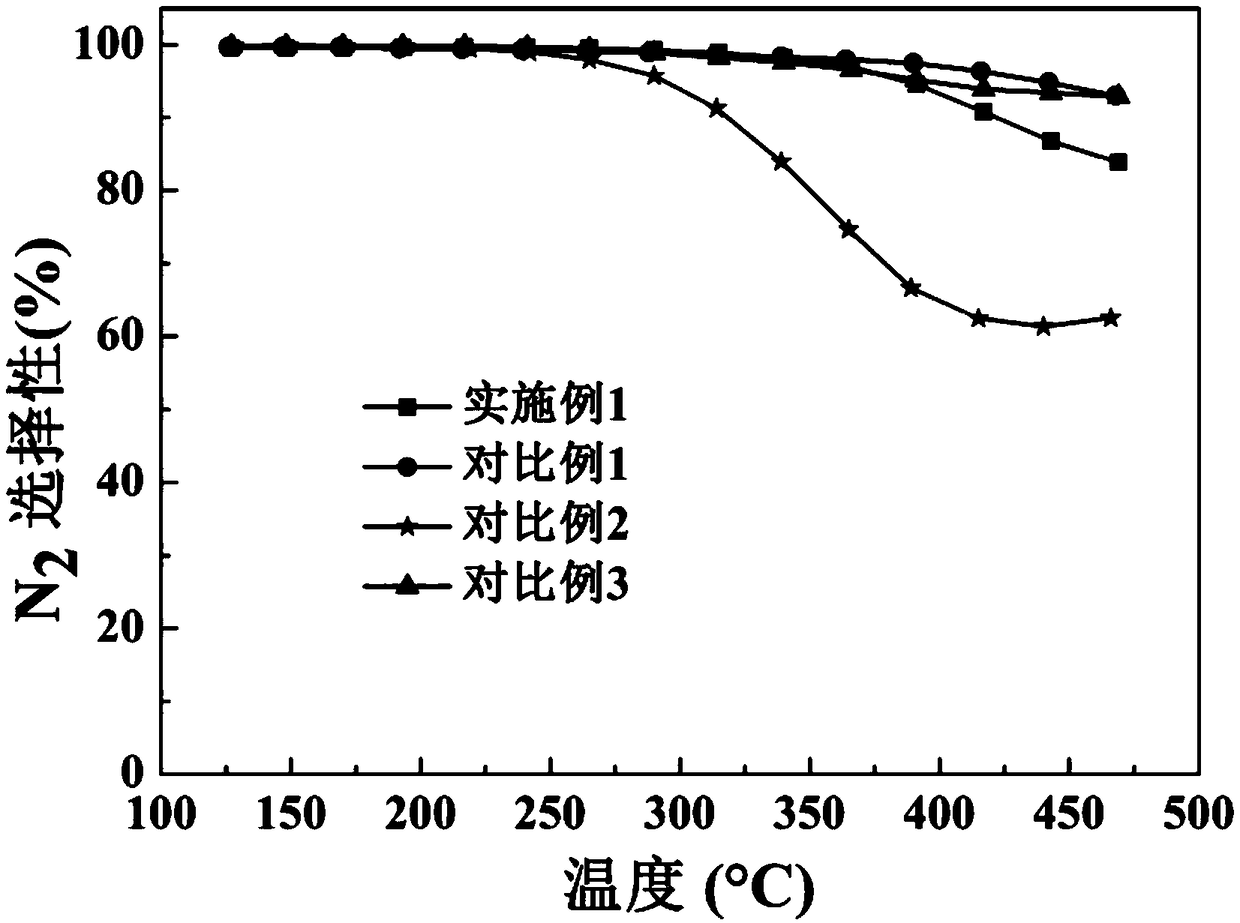

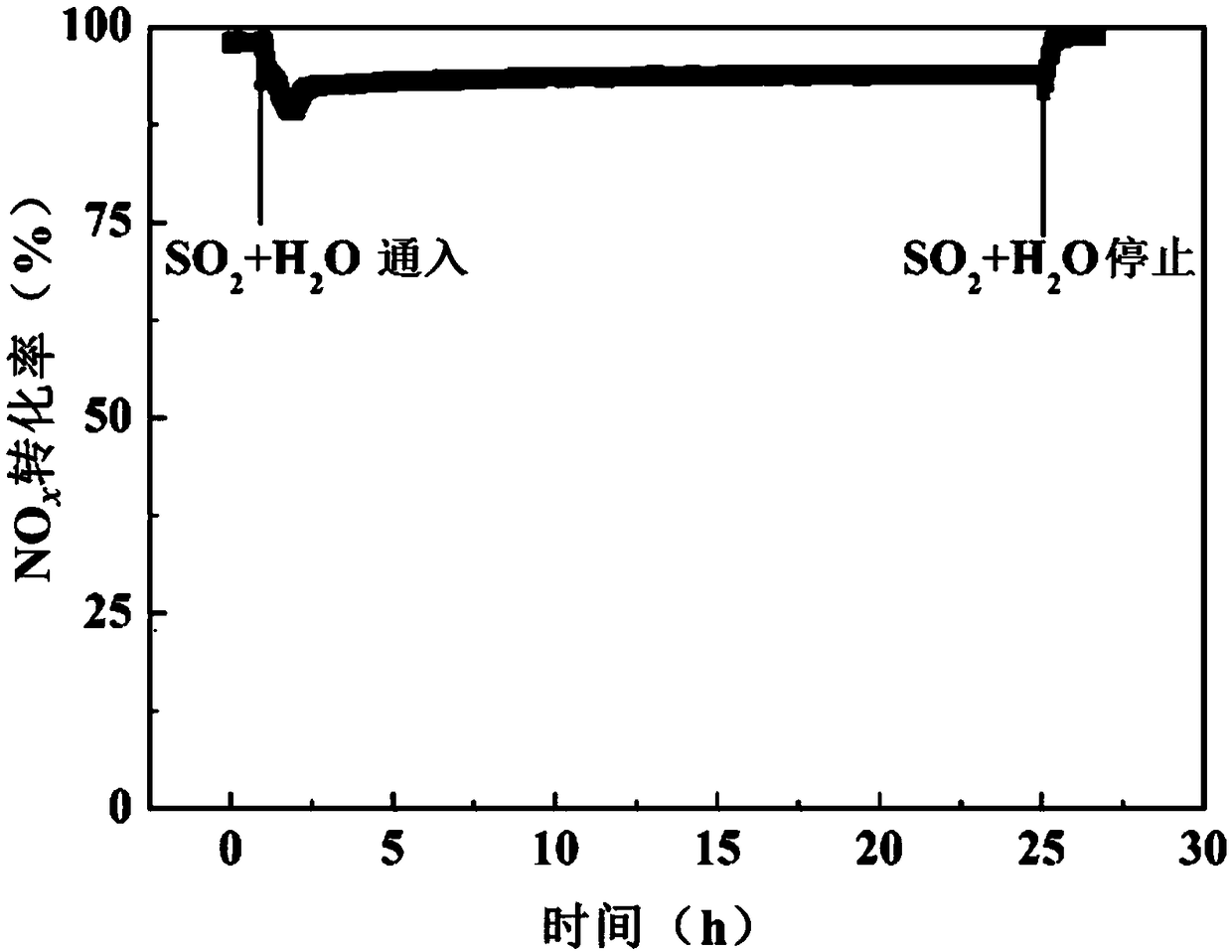

A composite catalyst and transition metal technology, which is applied in the field of flue gas denitrification and catalyst, can solve the problems of high cost and increased catalyst cost, and achieve enhanced stability, improved removal rate and nitrogen selectivity, overall stability and sulfur resistance. Excellent effect on water performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of described catalyst comprises:

[0056] (1) Add slow-release precipitant to the mixed solution of iron source, vanadium source and titanium source, and react to obtain solid precipitate;

[0057] (2) Calcining the solid precipitate obtained in step (1) to obtain the transition metal oxide composite catalyst.

Embodiment 1

[0060] This example provides a transition metal oxide composite catalyst and its preparation method. The catalyst includes an iron-vanadium composite oxide active component and a titanium dioxide carrier, wherein the molar ratio of iron, vanadium and titanium is 0.1:0.1:1.

[0061] The preparation method of described catalyst comprises:

[0062] (1) Prepare a solution with ammonium metavanadate as a vanadium source, add oxalic acid to promote dissolution, then add iron nitrate and titanium sulfate to the ammonium metavanadate solution, stir and dissolve to obtain a mixed solution, wherein ammonium metavanadate, iron nitrate, sulfuric acid The molar ratio of titanium is 0.1:0.1:1. Add urea to the mixed solution. The molar number of urea is 10 times the total molar number of ammonium metavanadate, ferric nitrate and titanium sulfate. React for 12 hours in a water bath at 90°C, filter Separated to obtain a solid precipitate;

[0063] (2) Dry the solid precipitate obtained in ste...

Embodiment 2

[0071] This example provides a transition metal oxide composite catalyst and its preparation method. The catalyst includes an iron-vanadium composite oxide active component and a titanium dioxide carrier, wherein the molar ratio of iron, vanadium and titanium is 0.05:0.05:1.

[0072] The preparation method of described catalyst comprises:

[0073] (1) Take vanadyl oxalate as the vanadium source preparation solution, add oxalic acid to promote dissolution, then add ferric chloride and titanium tetrachloride to the vanadyl oxalate solution, stir and dissolve to obtain a mixed solution, wherein vanadyl oxalate, ferric chloride, The molar ratio of titanium tetrachloride is 0.05:0.05:1. Add ammonium carbonate to the mixed solution. The molar number of ammonium carbonate is 15 times the total molar number of vanadyl oxalate, ferric chloride and titanium tetrachloride. Reacted for 16 hours under water bath conditions, separated by filtration to obtain a solid precipitate;

[0074] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com