Uniform-load cerium-based molecular sieve catalyst, preparation method and application thereof

A uniform loading and catalyst technology, applied in the direction of molecular sieve catalysts, separation methods, chemical instruments and methods, etc., can solve the problem of Ce backlog of light rare earth elements, and achieve wide operating temperature window, excellent N2 generation selectivity, and excellent SCR activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

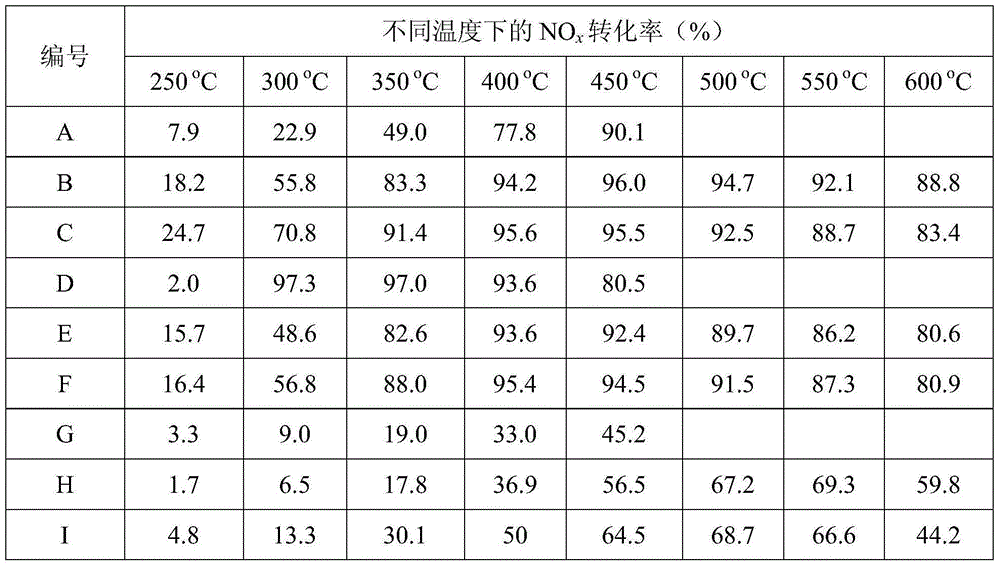

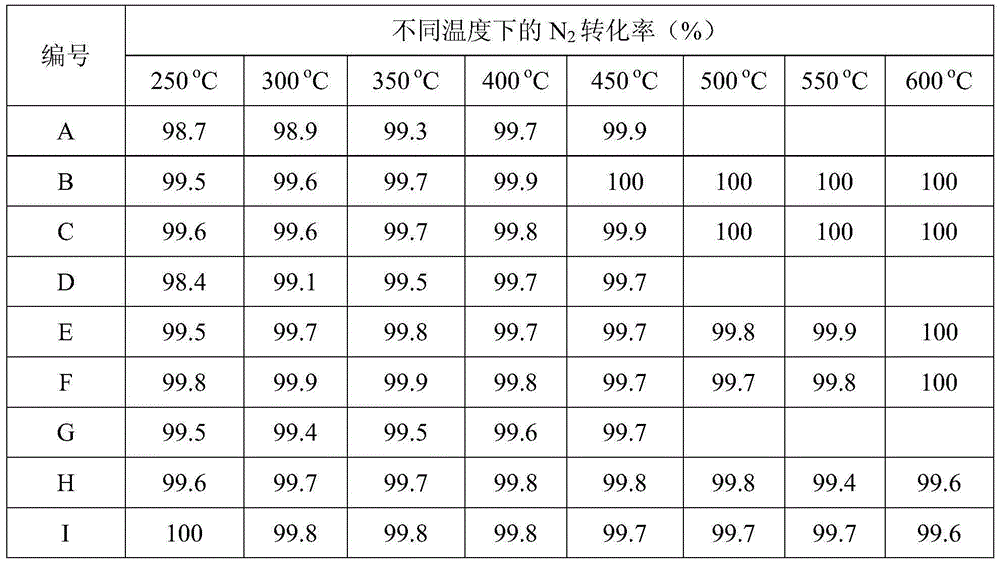

Embodiment 1

[0030] According to the Ce:ZSM-5 mass ratio of 1:20, prepare a cerium nitrate solution, and then evenly drop it on the ZSM-5, knead the sample repeatedly for 20-30min, so that the solution and ZSM-5 are mixed and impregnated evenly, and the obtained sample is placed in Dry it in an oven at 100-110°C for 12 hours, and finally roast it in air at 600°C for 3 hours in a muffle furnace to obtain a powder catalyst, which is called catalyst A.

Embodiment 2

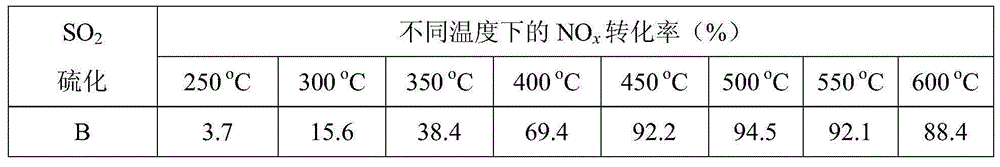

[0032] Other conditions were unchanged as in Example 1, and the mass ratio of Ce:ZSM-5 was changed to 1:10 to obtain catalyst B.

Embodiment 3

[0034] Other conditions were unchanged as in Example 1, and the mass ratio of Ce:ZSM-5 was changed to 1:5 to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com