Cerium-based composite oxide catalyst for catalyzing and purifying nitric oxide

A composite oxide and nitrogen oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst activation/preparation, etc., can solve the problem of narrow operating temperature window and sensitive reaction space velocity. , poor low temperature activity and other problems, to achieve the effect of improving service life, reducing damage, and good resistance to high temperature sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0016] Dissolve ammonium tungstate in oxalic acid solution (mass ratio of ammonium tungstate to oxalic acid is 1:1), and add cerium nitrate solution to the solution to prepare a solution with a Ce / W molar ratio of 0.5 and mix evenly. Add excess urea to the mixture, and continuously stir at 90°C for 12 hours, then perform suction filtration and washing, put the filter cake in an oven and dry it overnight at 100°C, and finally calcinate it in the air at 500°C in a muffle furnace for 5 hours. A powdered catalyst was obtained. The prepared catalyst was pressed into tablets, crushed, sieved, and 40-60 meshes were taken for later use, which was called catalyst A. Catalysts B and C were prepared respectively by changing the Ce / W molar ratio to 1.0 and 2.0 while other conditions remained unchanged. Catalyst D was prepared by calcining catalyst B in air at 800°C for 1 h.

Embodiment 5

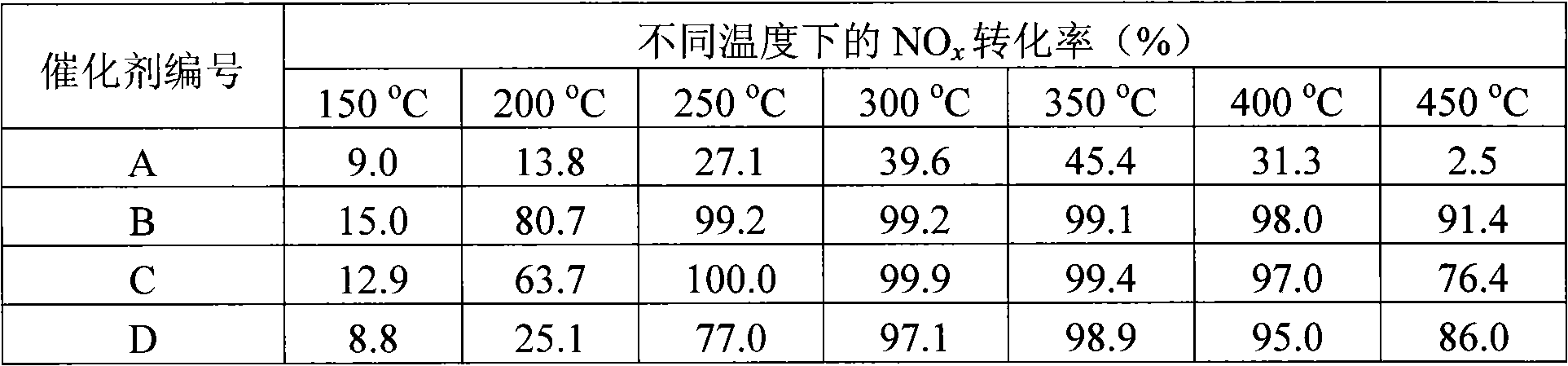

[0018] With the cerium-tungsten composite oxide catalyst A, B, C and D that embodiment 1-4 makes, carry out NH on self-made miniature fixed-bed reactor 3 Selective Catalytic Reduction of NO x The investigation of reactivity. The consumption of catalyst is 0.12ml, and the composition of reaction gas mixture is: [NO]=[NH 3 ]=500ppm, [O 2 ] = 5%, N 2 As balance gas, the total gas flow rate is 500ml / min, and the space velocity is 250,000h -1 , The reaction temperature is 150-450°C. NO and NH 3 and by-product N 2 O, NO 2 All were measured using an infrared gas cell. The reaction results are shown in Table 1.

[0019] Catalyst B at 250,000h -1 Under the condition of space velocity, more than 80% NO can be achieved in the temperature range of 200-450°C x conversion rate, and at N 2 The selectivity is greater than 97%. Catalyst D calcined at 800°C can still be used at 250,000h -1 Under space velocity conditions, over 80% NO can be achieved within the temperature range of...

Embodiment 6

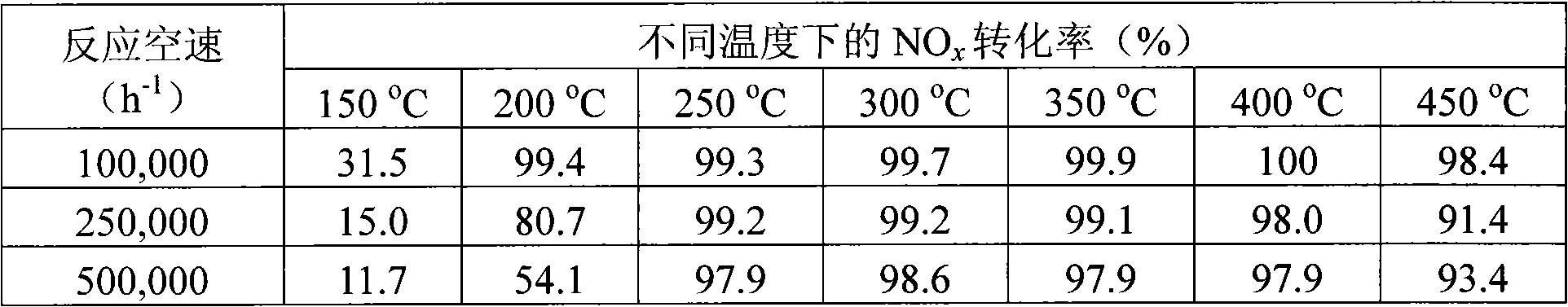

[0021] Using catalyst B, the effect of reaction space velocity on catalyst activity was investigated in a self-made miniature fixed-bed reactor. The consumption amount of catalyst is respectively 0.3ml, 0.12ml, 0.06ml, and the composition of reaction gas mixture is: [NO]=[NH 3 ]=500ppm, [O 2 ] = 5%, N 2 As balance gas, the total gas flow rate is 500ml / min, and the corresponding space velocity is 100,000h -1 、250,000h -1 , 500,000h -1 , Reaction temperature 150 ~ 450 ℃. NO and NH 3 and by-product N 2 O, NO 2 All were measured using an infrared gas cell. The reaction results are shown in Table 2.

[0022] Catalyst B at a space velocity of 100,000h -1 Under certain conditions, more than 98% of NO can be achieved in the temperature range of 200-450°C x conversion rate, and N 2 The generation selectivity is greater than 98%, showing a very wide operating temperature window; even at 500,000h -1 Under the condition of high space velocity, Catalyst B can still achieve mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com