Manganese-based oxide catalyst with wide temperature window and preparation method thereof

A manganese-based oxide and window manganese-based technology is applied in the field of preparation of manganese-cerium-tungsten oxide catalysts for catalyzing and purifying nitrogen oxides. Performance, effect of excellent N2 generation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

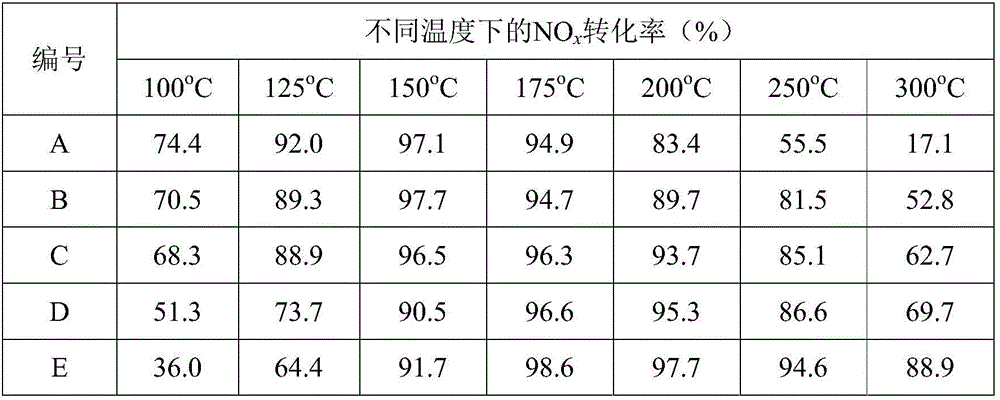

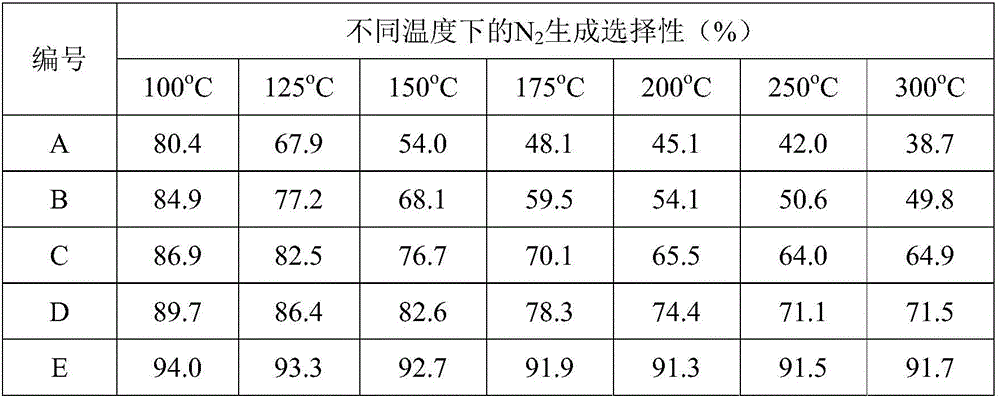

[0029] According to the Mn:Ce:W molar ratio of 3:1:0.1, dissolve ammonium tungstate in oxalic acid, stir continuously until the ammonium tungstate is completely dissolved, then add manganese nitrate and cerium nitrate to the solution, and add manganese source, cerium 18 times the total moles of tungsten source and tungsten source as precipitating agent, then heated to 90°C and continuously stirred for 12h, then filtered and washed, put the obtained solid in an oven and dried at 100°C for 12h, and finally passed through muffle The catalyst was calcined in air at 500°C for 5 hours to obtain a powdered catalyst, called catalyst B.

Embodiment 3

[0031] Other conditions were unchanged as in Example 2, and the molar ratio of manganese, cerium, and tungsten was changed to 3:1:0.3 to obtain catalyst C.

Embodiment 4

[0033] Other conditions were unchanged as in Example 2, and the molar ratio of manganese, cerium, and tungsten was changed to 3:1:0.5 to obtain catalyst D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com