Iron-tungsten-titanium composite oxide catalyst, and preparation method and purpose thereof

A composite oxide and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the reduction of catalyst specific surface area, unfavorable industrial application, purification efficiency problems such as decline, to achieve the effect of overcoming the shortcomings of corrosiveness and volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

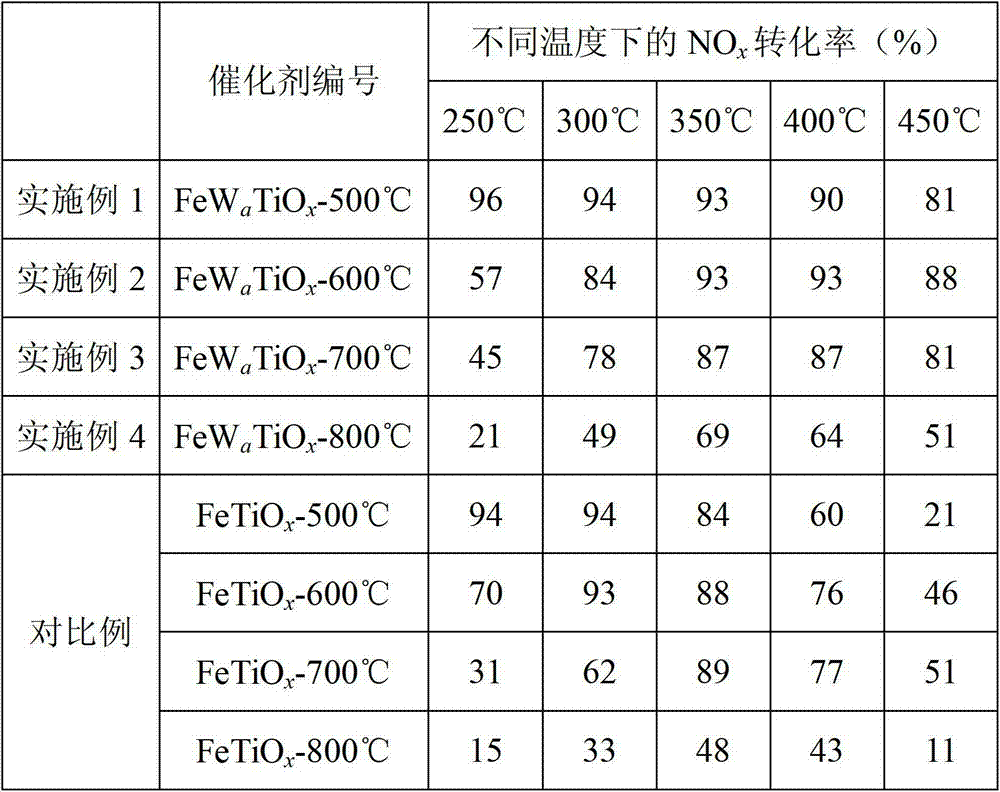

Embodiment 1

[0038] An iron-tungsten-titanium composite oxide catalyst, the catalyst has the following chemical composition: FeW a TiO x , where a is 1.0.

[0039] The preparation method of above-mentioned catalyst comprises the steps:

[0040] (1) Prepare ferric nitrate, ammonium tungstate and titanium sulfate solutions in the presence of oxalic acid, mix ferric nitrate, ammonium tungstate and titanium sulfate solutions to obtain a mixed solution, and control the molar ratio of Fe and Ti in the mixed solution to 1:1, the molar ratio of W element to Fe element is 1:1;

[0041] (2) Add excess urea precipitant to the mixed solution, the molar ratio of urea / (Fe source + W source + Ti source) is 10:1, and stir continuously for 12 hours in a water bath at 90°C to precipitate Fe, W and Ti ions Completely, the obtained precipitated product was suction-filtered, washed, dried in an oven at 100°C for 5h, and then calcined in a muffle furnace at 500°C for 3h in an air atmosphere to obtain the iro...

Embodiment 2

[0043] An iron-tungsten-titanium composite oxide catalyst, the catalyst has the following chemical composition: FeW a TiO x , where a is 1.0.

[0044] The preparation method of above-mentioned catalyst comprises the steps:

[0045] (1) Prepare ferric nitrate, ammonium tungstate and titanium sulfate solutions in the presence of oxalic acid, mix ferric nitrate, ammonium tungstate and titanium sulfate solutions to obtain a mixed solution, and control the molar ratio of Fe and Ti in the mixed solution to 1:1, the molar ratio of W element to Fe element is 1:1;

[0046] (2) Add excess urea precipitant to the mixed solution, the molar ratio of urea / (Fe source + W source + Ti source) is 10:1, and stir continuously for 12 hours in a water bath at 90°C to precipitate Fe, W and Ti ions Completely, the obtained precipitated product was suction-filtered, washed, dried in an oven at 100°C for 5 hours, and then calcined in a muffle furnace at 600°C for 3 hours in an air atmosphere to obta...

Embodiment 3

[0048] An iron-tungsten-titanium composite oxide catalyst, the catalyst has the following chemical composition: FeW a TiO x , where a is 1.0.

[0049] The preparation method of above-mentioned catalyst comprises the steps:

[0050] (1) Prepare ferric nitrate, ammonium tungstate and titanium sulfate solutions in the presence of oxalic acid, mix ferric nitrate, ammonium tungstate and titanium sulfate solutions to obtain a mixed solution, and control the molar ratio of Fe and Ti in the mixed solution to 1:1, the molar ratio of W element to Fe element is 1:1;

[0051] (2) Add excess urea precipitant to the mixed solution, the molar ratio of urea / (Fe source + W source + Ti source) is 10:1, and stir continuously for 12 hours in a water bath at 90°C to precipitate Fe, W and Ti ions Completely, the obtained precipitated product was suction-filtered, washed, dried in an oven at 100°C for 5h, and then calcined in a muffle furnace at 700°C for 3h in an air atmosphere to obtain the iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com