Simple device and method for physically separating coal slime of power coal plant

A physical separation and dynamic technology, applied in solid separation, grain processing, flotation, etc., can solve the problems of poor flotation, high cost, and low flotation separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

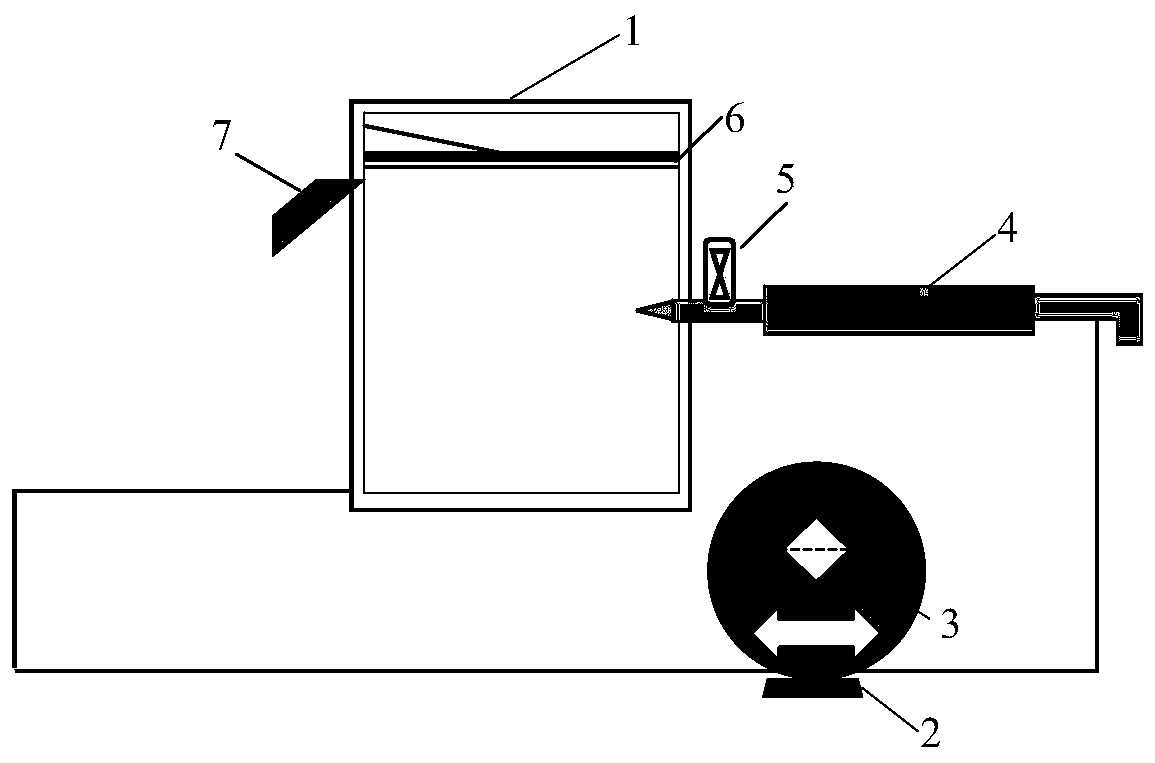

[0022] see figure 1 , a simple device for physically separating coal slime in thermal coal plants, including a mud tank 1, the outlet of the lower part of the mud tank 1 is connected to a high-pressure pump 2 through a high-pressure pump inlet pipe, and the high-pressure pump 2 is provided with a current overload protection device 3, and the high-pressure pump 2 The outlet of the spray gun 4 is connected to the spray gun 4 through the high-pressure pump outlet pipe. The spray gun 4 is provided with a flow monitor 5. The tip outlet of the spray gun 4 is inserted into the entrance of the middle part of the mud tank 1. The mud tank 1 is provided with a bubble scraper 6. The mud tank 1 There is also a foam outlet that cooperates with the bubble scraper 6, and a collection tank 7 is arranged at the foam outlet. The diameter of the high-pressure pump inlet pipe is 2-4 cm, and the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com