Intelligent detection method for conveyor belt damage conditions

A technology of conveyors and belts, applied in image data processing, instruments, calculations, etc., can solve the problems of low detection accuracy, increase the complexity of system structure, and high image dependence, and achieve high accuracy of detection results and implementation means Novel and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention is described in detail below in conjunction with accompanying drawing:

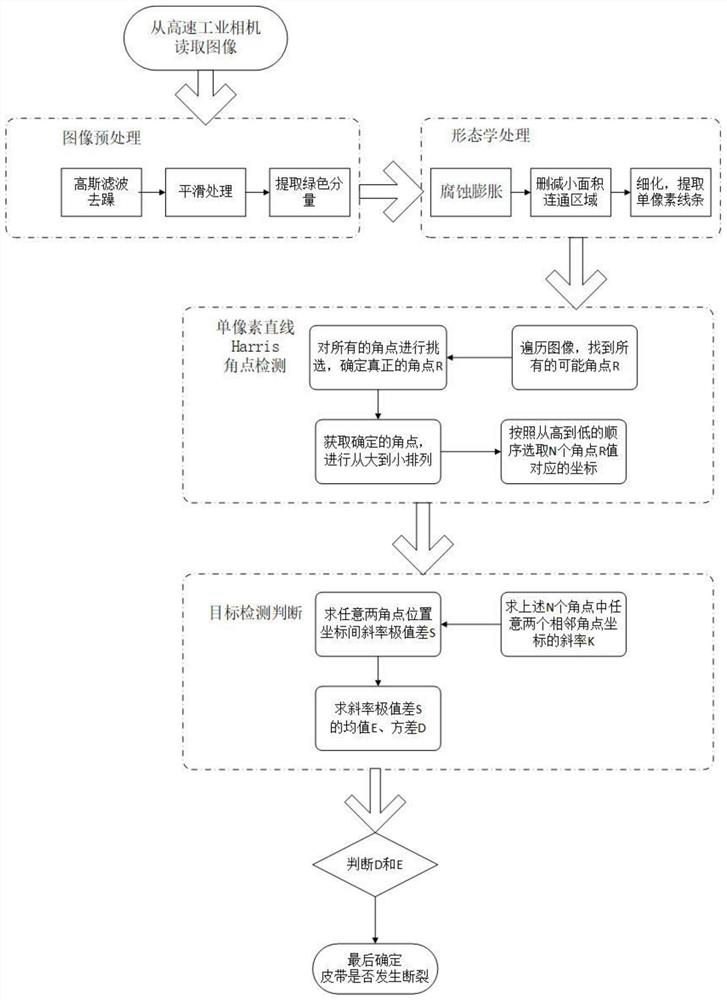

[0036] refer to figure 1 In this example, the method for detecting the damage status of the conveyor belt is carried out, and the implementation steps are as follows:

[0037] Step 1, collect the image of the belt to be tested.

[0038] 1.1) Install the test device:

[0039] Load the linear laser generator and adjust it to the position to ensure that the emitted green laser beam can be irradiated on the side of the belt, and at the same time connect its control circuit to the test box;

[0040] Load a high-speed industrial camera and adjust its position to ensure that the detection target image with the best viewing angle can be captured, and at the same time connect it to the test box;

[0041] The test box sends control instructions to make the linear laser generator generate a linear green laser beam whose intensity meets the best resolution of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com