A dry ash loading device for coal-fired power plants

A technology of coal-fired power plants and dry ash bulk machines, which is applied in the field of factory transportation equipment, can solve problems such as environmental pollution, equipment wear, and blockage, and achieve the effects of improving the loading environment, reducing investment costs, and solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

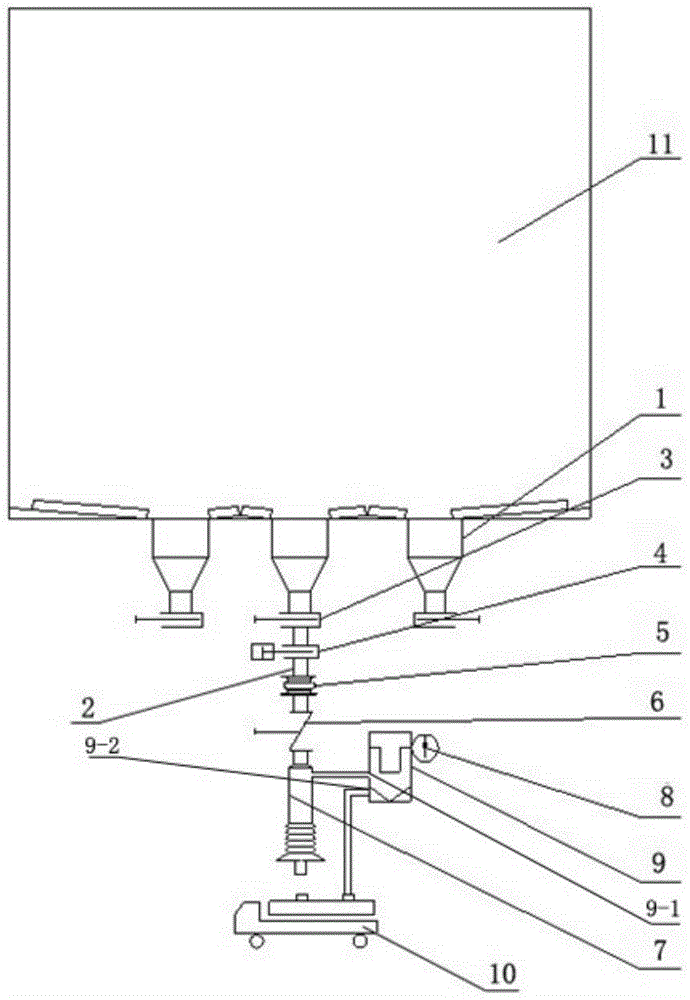

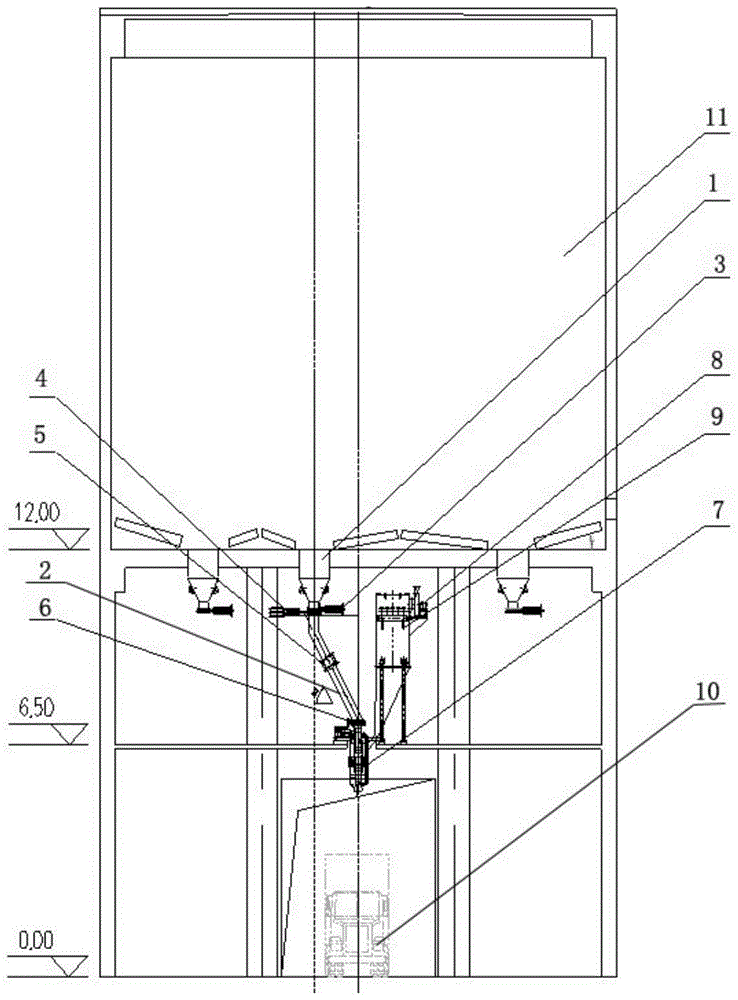

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 and figure 2 A dry ash loading device for a coal-fired power plant is shown, including an ash storehouse 11, in which several ash hoppers 1 are arranged, and a manual gate valve is provided at the ash outlet at the bottom of the ash hopper 1 3. The outlet end of the manual gate valve 3 is sequentially connected to the pneumatic gate valve 4 and the expansion joint 5 through the ash falling pipe 2, and the outlet end of the expansion joint 5 is connected to the ash inlet of the dry ash bulk machine 7 through the manual butterfly valve 6, and the dry ash bulk machine 7 There is a bulk head at the ash outlet, which cuts off and throttles the material in the ash fall pipe 2 through the manual butterfly valve 6; the ash fall pipe 2 is arranged at an inclination angle greater than 60 degrees; by changing the angle of the fall pipe, the direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com