Method for treating organic waste residues in sorbic acid production

A technology of organic waste residue and treatment method, which is applied in the petroleum industry, coking ovens, etc., can solve the problems of high difficulty in recycling, waste of resources, waste of energy, etc., and achieve the effect of realizing recyclable utilization, reducing coking costs, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

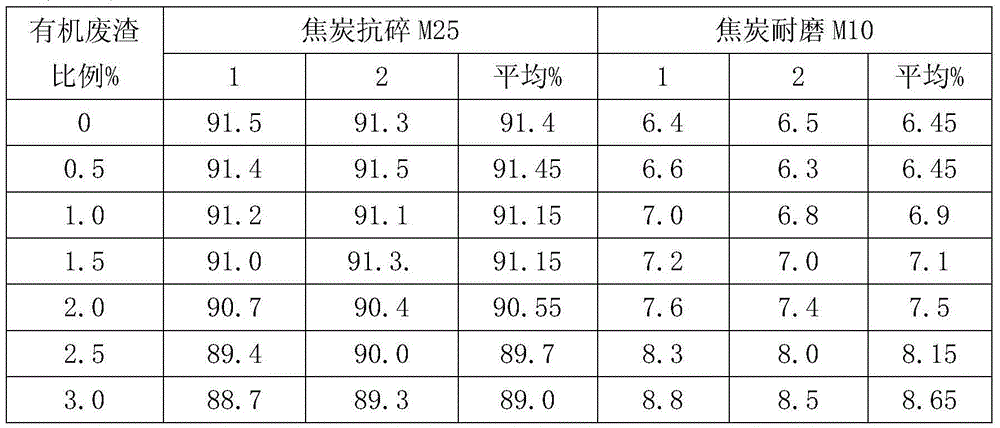

Embodiment 1

[0017] The processing method of organic waste residue in the described sorbic acid production, at first sorbic acid organic waste residue is transported to the coal plant, according to the composition of blending coal, the control organic waste residue addition amount is 0.2% of blending coal gross weight, when coal plant puts coal The organic waste slag is evenly added to the lean coal, and then sent to the lean coal bunker through the coal conveyor belt. After being measured by a belt scale, it will account for 14.8% of the total weight of the blended coal, 27% of the gas coal, and 33% of the coal. 1 / 3 of the coking coal and 25% of the fat coal are mixed and pulverized to obtain the blended coal, which is then sent to the coal tower, and finally the blended coal is loaded into the coke oven by a coal loading car for coking.

Embodiment 2

[0019] The processing method of organic waste residue in the described sorbic acid production, at first the sorbic acid organic waste residue is transported to the coal plant, according to the composition of blending coal, the control organic waste residue addition is 0.5% of the total weight of blending coal, when the coal plant puts coal The organic waste slag is evenly added to the lean coal, and then sent to the lean coal bunker through the coal conveyor belt. After being measured by a belt scale, it will account for 14.5% of the total weight of the blended coal, 27% of the gas coal, and 33% of the coal. 1 / 3 of the coking coal and 25% of the fat coal are mixed and pulverized to obtain the blended coal, which is then sent to the coal tower, and finally the blended coal is loaded into the coke oven by a coal loading car for coking.

Embodiment 3

[0021] The processing method of the organic waste residue in the described sorbic acid production, at first the sorbic acid organic waste residue is transported to the coal plant, according to the composition of the blended coal, the organic waste residue addition amount is controlled to be 1.0% of the total weight of the blended coal, and when the coal plant puts coal The organic waste slag is evenly added to the lean coal, and then sent to the lean coal bunker through the coal conveyor belt. After being measured by a belt scale, 14% of the total weight of the mixed coal will account for lean coal, 27% of gas coal, and 33% of coal. 1 / 3 of the coking coal and 25% of the fat coal are mixed and pulverized to obtain the blended coal, which is then sent to the coal tower, and finally the blended coal is loaded into the coke oven by a coal loading car for coking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com