Opencast combined mining method of steeply inclined coal seam groups

A technology of combined mining and steep inclination, applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of low open-pit mining depth, uneconomical cost, and reduced design life of open-pit coal mines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

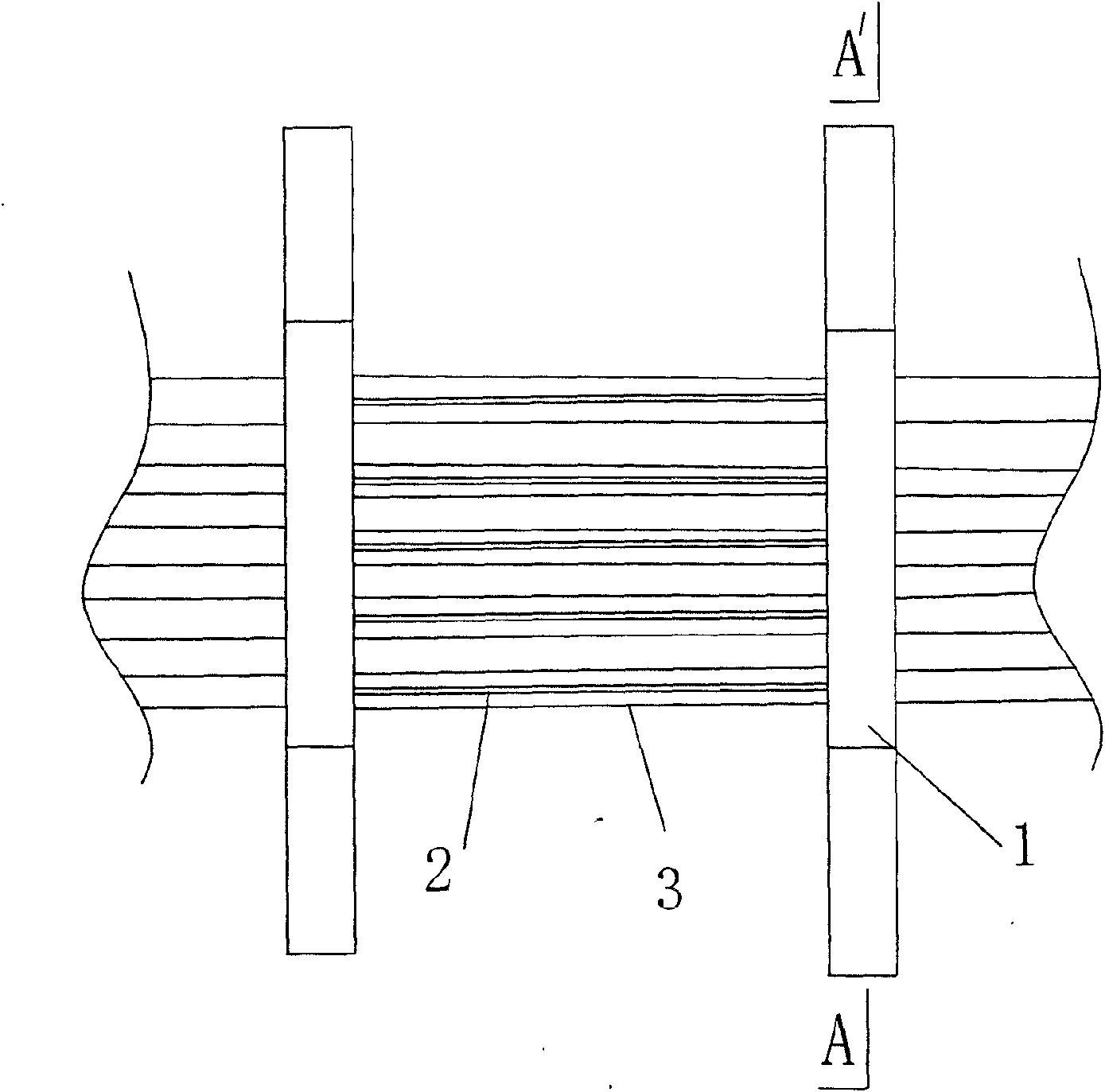

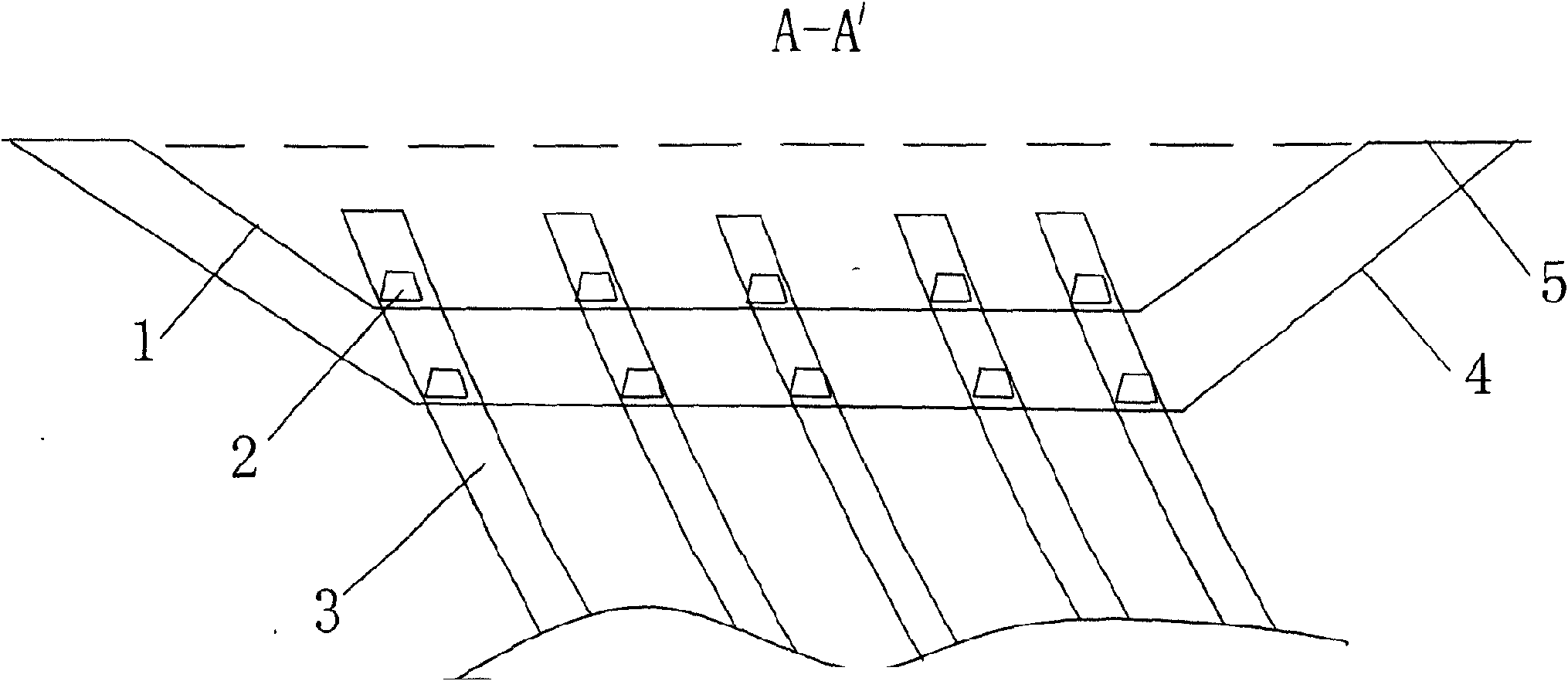

[0011] Technical scheme of the present invention is made up of following steps:

[0012] Step 1: Excavate several V-shaped open-air construction roads 1 downward at a certain angle in the inclined direction of the coal seam. The depth of the construction road 1 is about 10-15 meters below the coal seam 3, and then horizontally penetrate all the steeply inclined coal seams , and then return to the surface 5 at a certain angle, and the distance between the two construction roads 1 is about 300-1000 meters.

[0013] Step 2: Excavating several roadways 2 along the direction of the coal seam 3 at the bottom of the ditch of the construction road 1 to connect with the coal seam 3 at the bottom of the ditch of the opposite construction road 1.

[0014] Step 3: Install a local fan at one end of the opening of the roadway 2 to make the inside of the roadway 2 well ventilated.

[0015] Step 4: Install transportation equipment in the roadway 2, such as belt and scraper conveyors, etc.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com