Shaft and drift injection concrete material with washery rejects and washed sand as aggregates

A shotcrete and concrete technology, which is applied in the field of concrete materials for shaft support, can solve the problems of environmental protection and energy saving, the cost of concrete is expensive, etc., and achieves the effect of wide field practicability, improving mine efficiency, environmental protection and energy saving cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

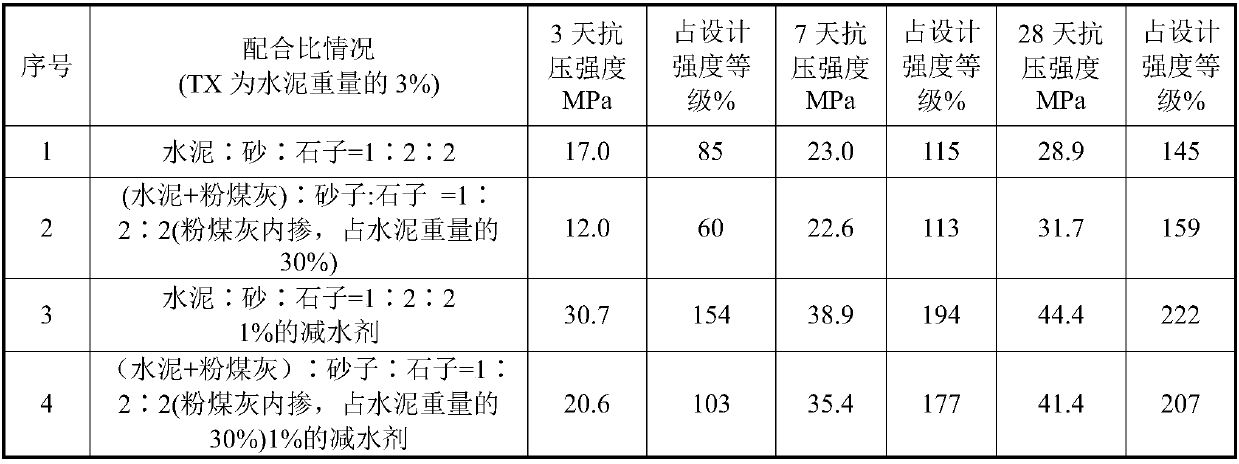

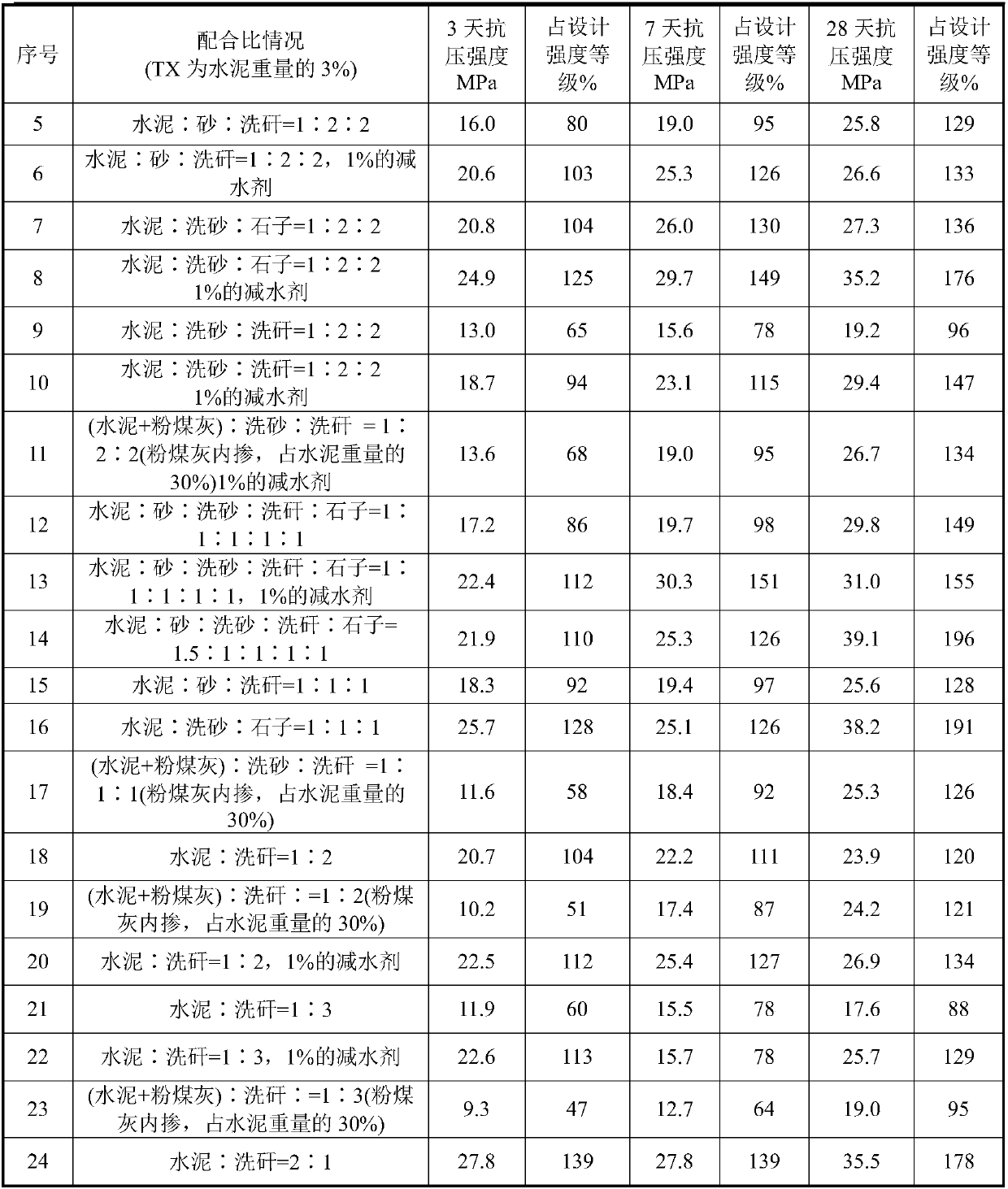

[0019] Example 1: Taking Zhaizhen Coal Mine as an industrial test site, a total of 24 different mix ratios were designed and tested. Each mix ratio was formed into 9 test blocks, each of which was a group of 3, a total of 3 groups, respectively The compressive strength test of concrete cubes with ages of 3 days, 7 days, and 28 days is carried out. Since the test block is formed, it is placed in a standard curing box for curing: the temperature is 19.5-20.5 °C, and the relative humidity is above 95%. Whether the strength meets the requirements is finally subject to the 28-day concrete cube compressive strength value.

[0020] The specific process is as follows:

[0021] (1) Raw material selection and testing

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com