Coarse coal slime sorting equipment and technology of coarse coal slime sorting equipment

A technology of coarse coal slime and coal slime, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of centrifuge running water, high ash content of clean coal, and easy blockage of screen holes, etc., and achieves simple process, The recovery rate of clean coal is high and the effect of improving the quality of clean coal products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

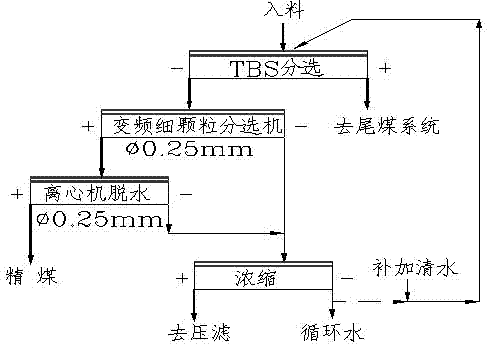

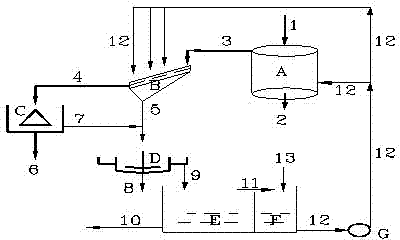

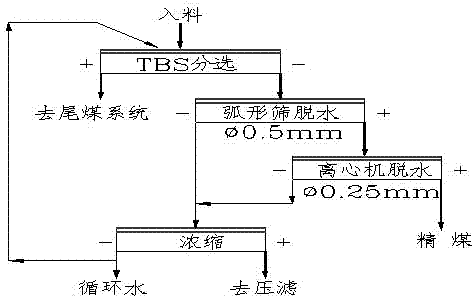

[0025] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment is: a) feed the selected coal slime 1 and clean water 12 into the TBS coal slime separator A for sorting. It consists of actuator, discharge valve and overflow weir.

[0026] b) The tailings 2 separated by the TBS slime separator A enter the tailings system, and the TBS overflow 3 automatically flows to the frequency conversion fine particle separator B for further separation.

[0027] c) Clean water 12 is laid in 3 lanes along the length direction of the frequency conversion fine particle separator B, each of which is sprayed against the coal flow along the full width direction of the frequency conversion fine particle separator B, so that the coal seam is continuously turned over, and the high ash fine mud enters through the screen The sieved water 5 flows to the coal slime thickener D by itself. Frequency conversion fine particle separator B sieve 4 Enter the slime cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com