Patents

Literature

44results about How to "Improve coal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

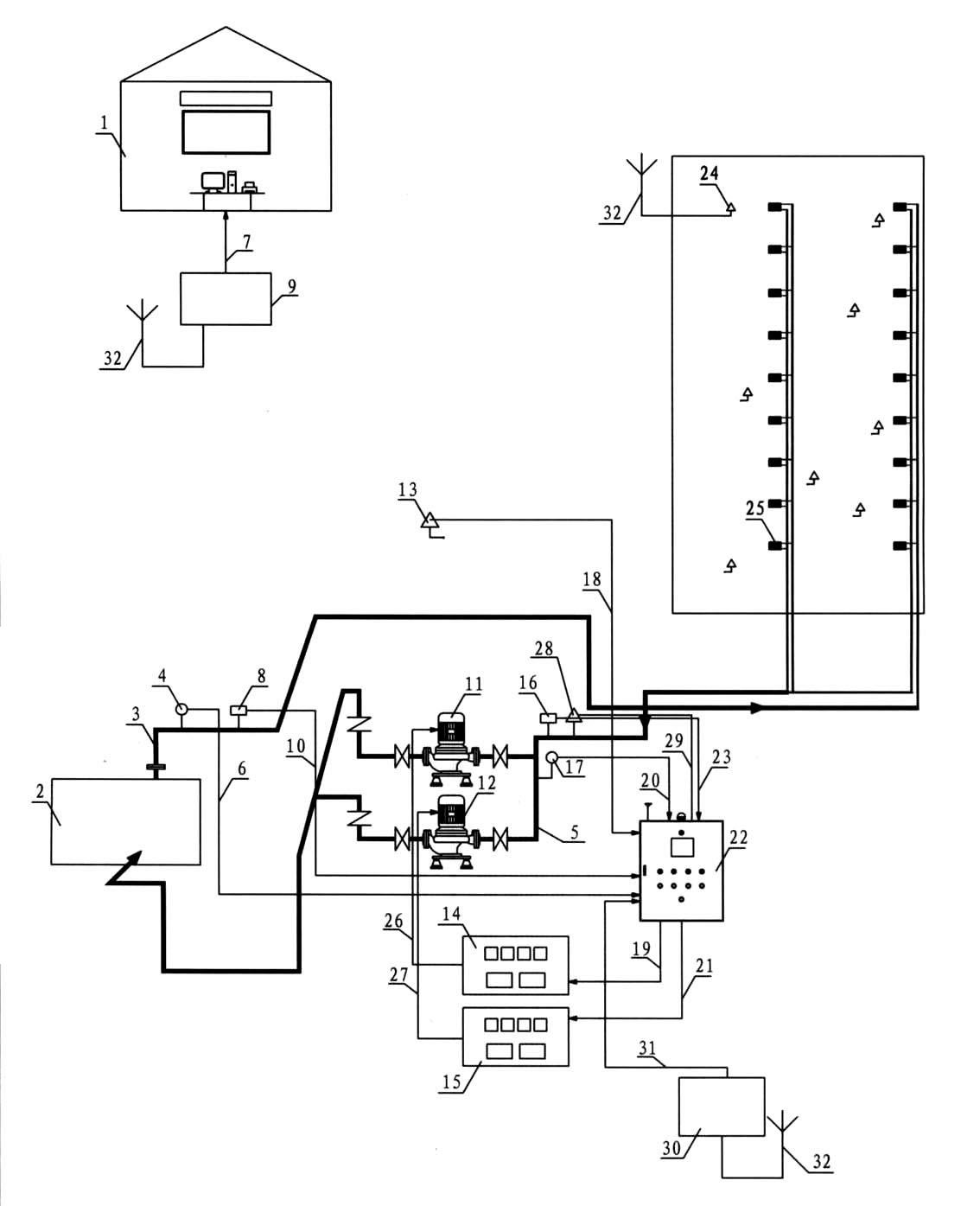

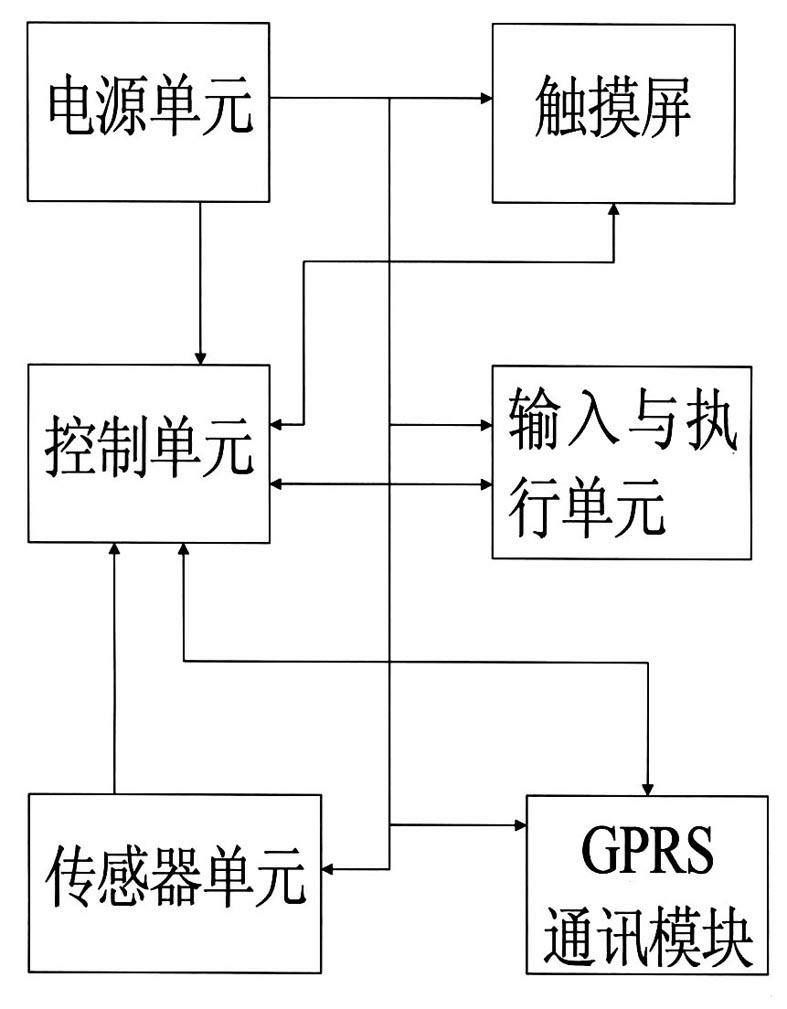

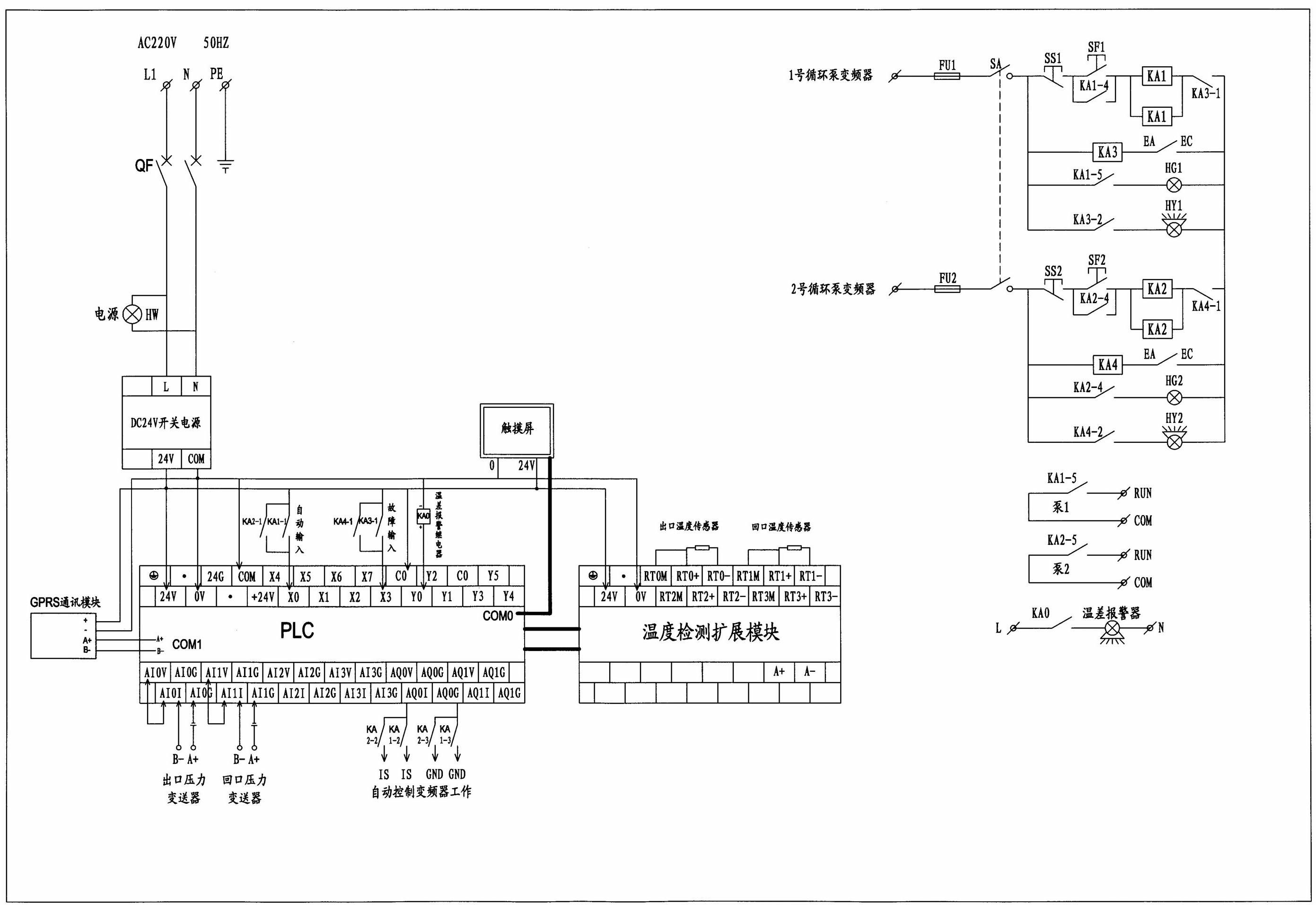

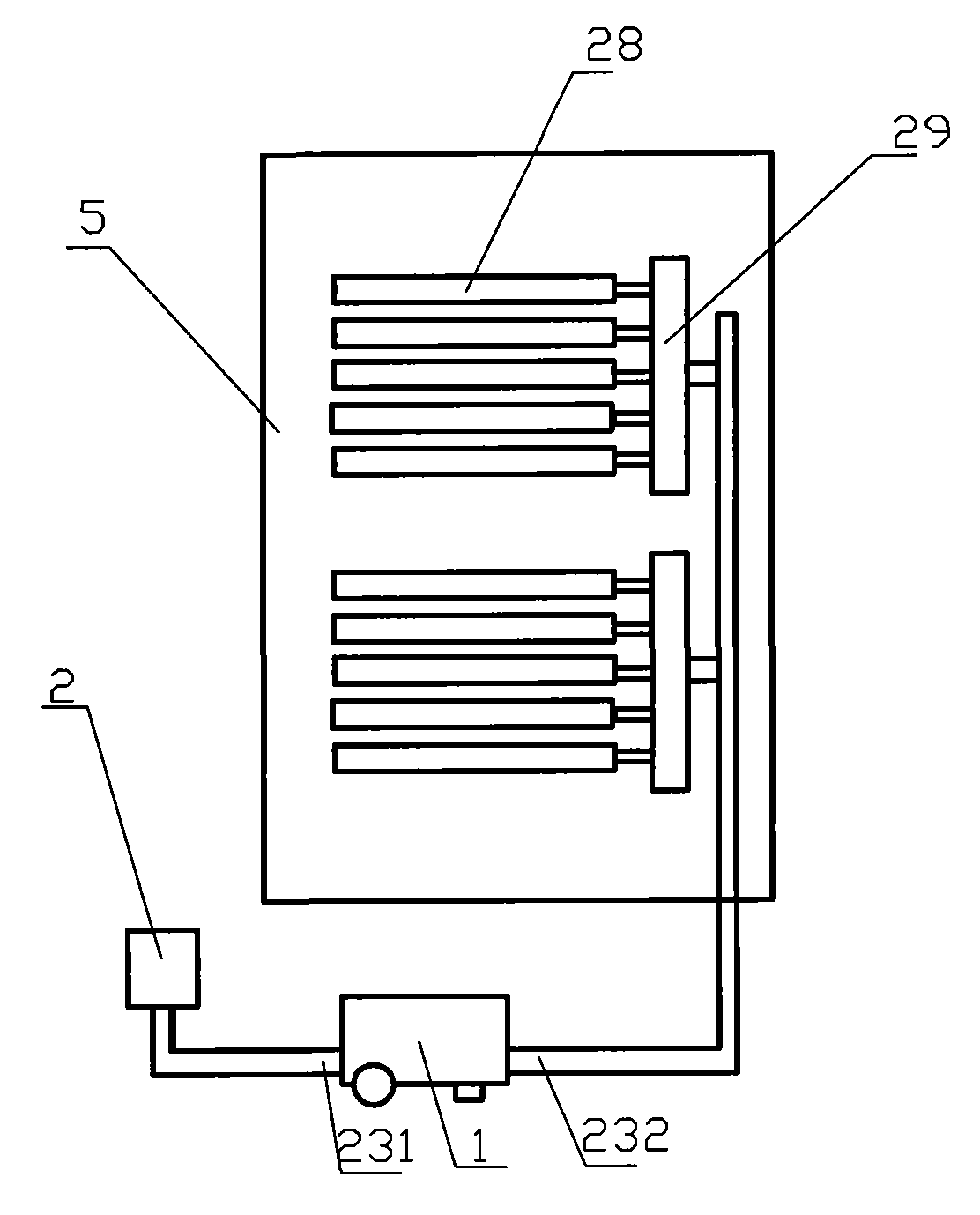

Intelligent controller of heating system network

InactiveCN102207307AImprove coal efficiencyReduce power consumptionLighting and heating apparatusSpace heating and ventilation detailsGeneral Packet Radio ServiceThe Internet

The invention discloses an intelligent controller of a heating system network, which can be used for adjusting and completely recording the running states of a heating system in real time, realizing remote monitoring and control and ensuring the heating system is in a satisfied running state, has a high coal combustion efficiency, less power consumption and improved heating quality. A temperaturesensor and a pressure transmitter are arranged at a heat supply outlet and a heat supply return hole of a heating pipe network of the intelligent controller; the controller is respectively connected with the sensors, the transmitters, a temperature collector and a circulating pump in the heating pipe network; a network management and monitor center internally provided with a computer, a printer and a display screen is connected with a GSM (global system for mobile communications) network through an internet; a GPRS (general packet radio service) communication module is accessed to the internet through the GSM network and connected with controller; the network management and monitor center is connected with a GPRS network temperature collector through an antenna, and the internet is connected with the antenna; the GPRS communication module is connected with a PLC (programmable logic controller); the data in the PLC is transmitted to the network management and monitor center; a touch screen is connected with the PLC; and an alarming short message is sent to a mobile phone through the GPRS communication module to inform the alarming state in a short message manner.

Owner:CHUANYU ELECTRICAL DANDONG CITY

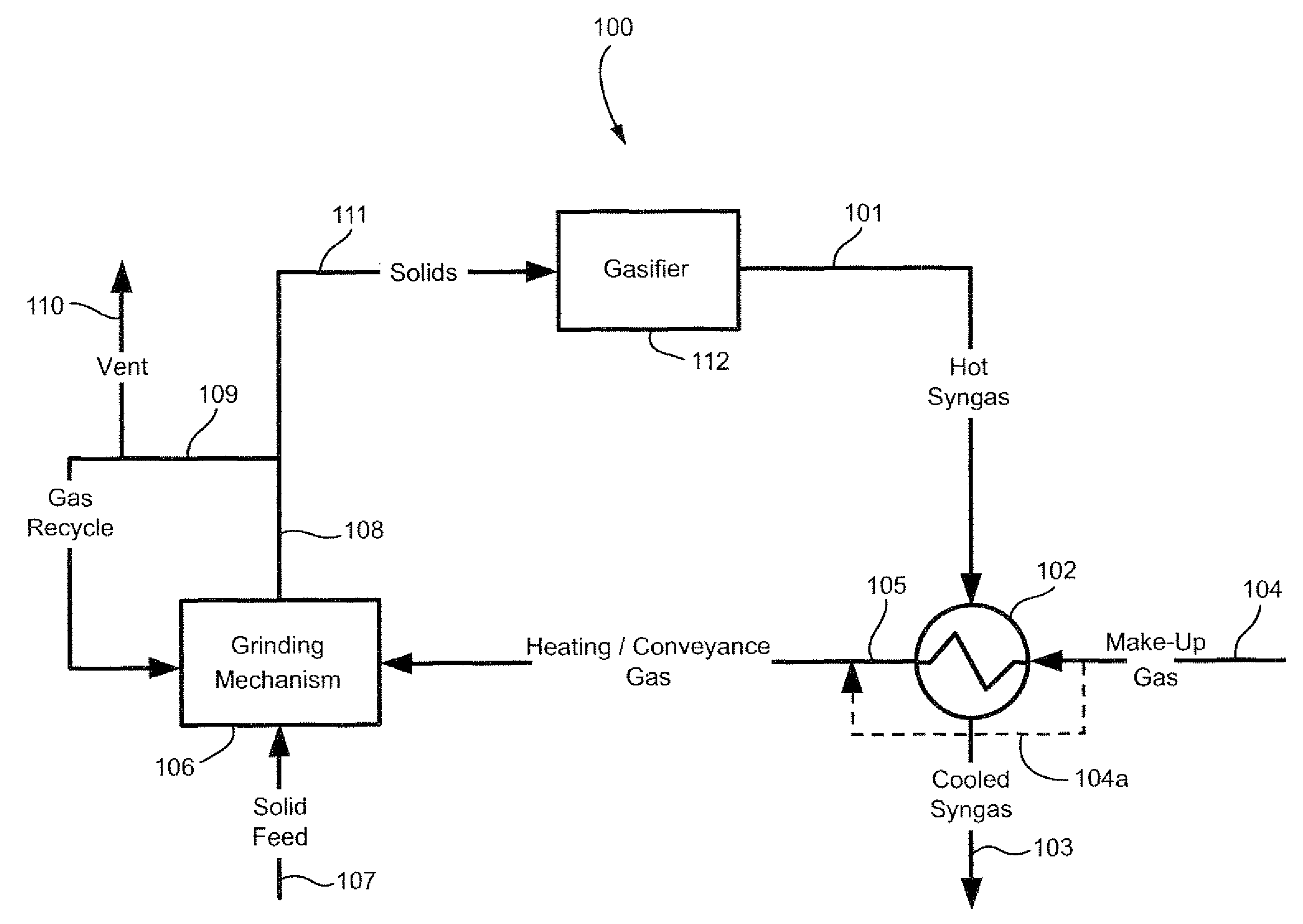

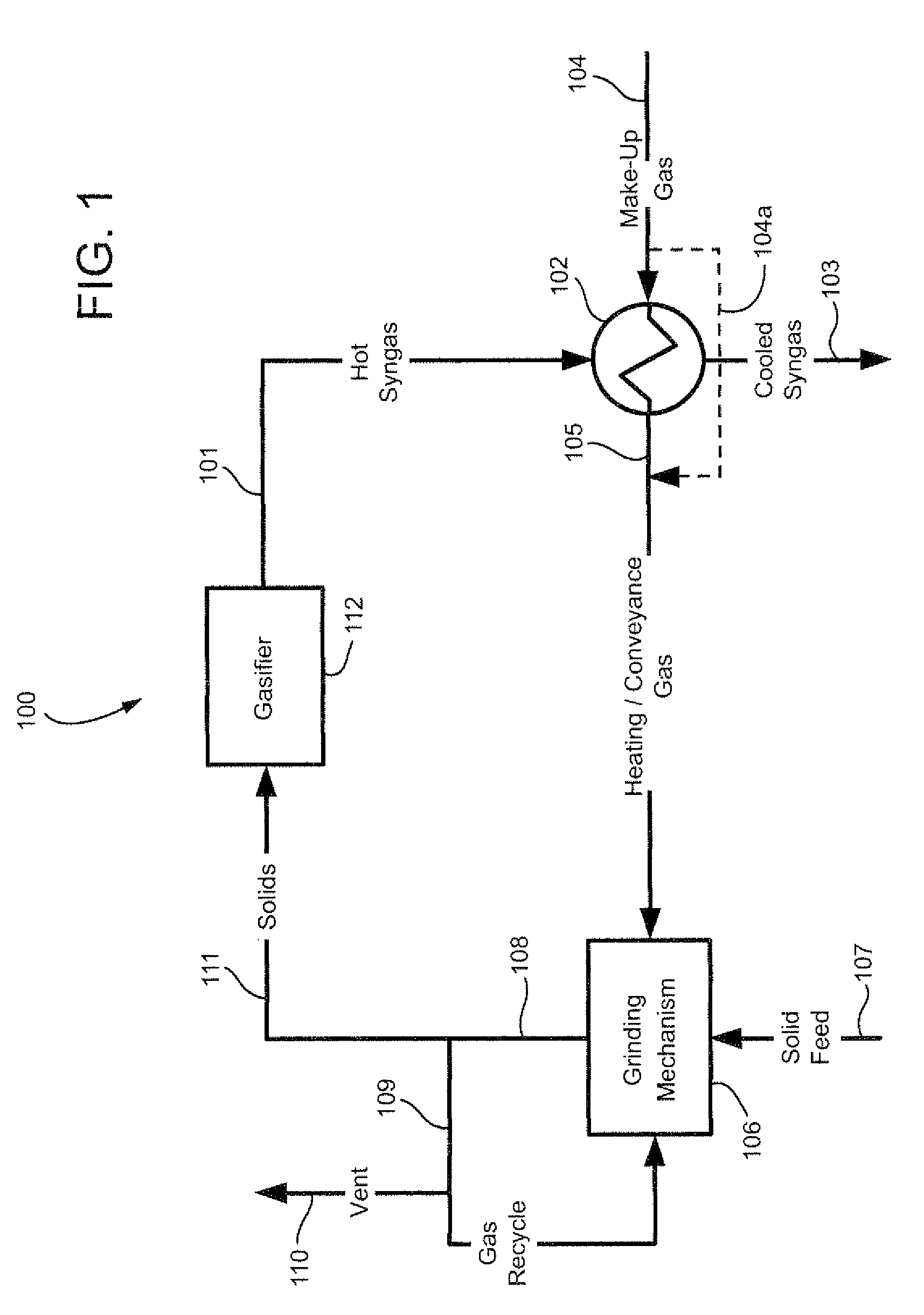

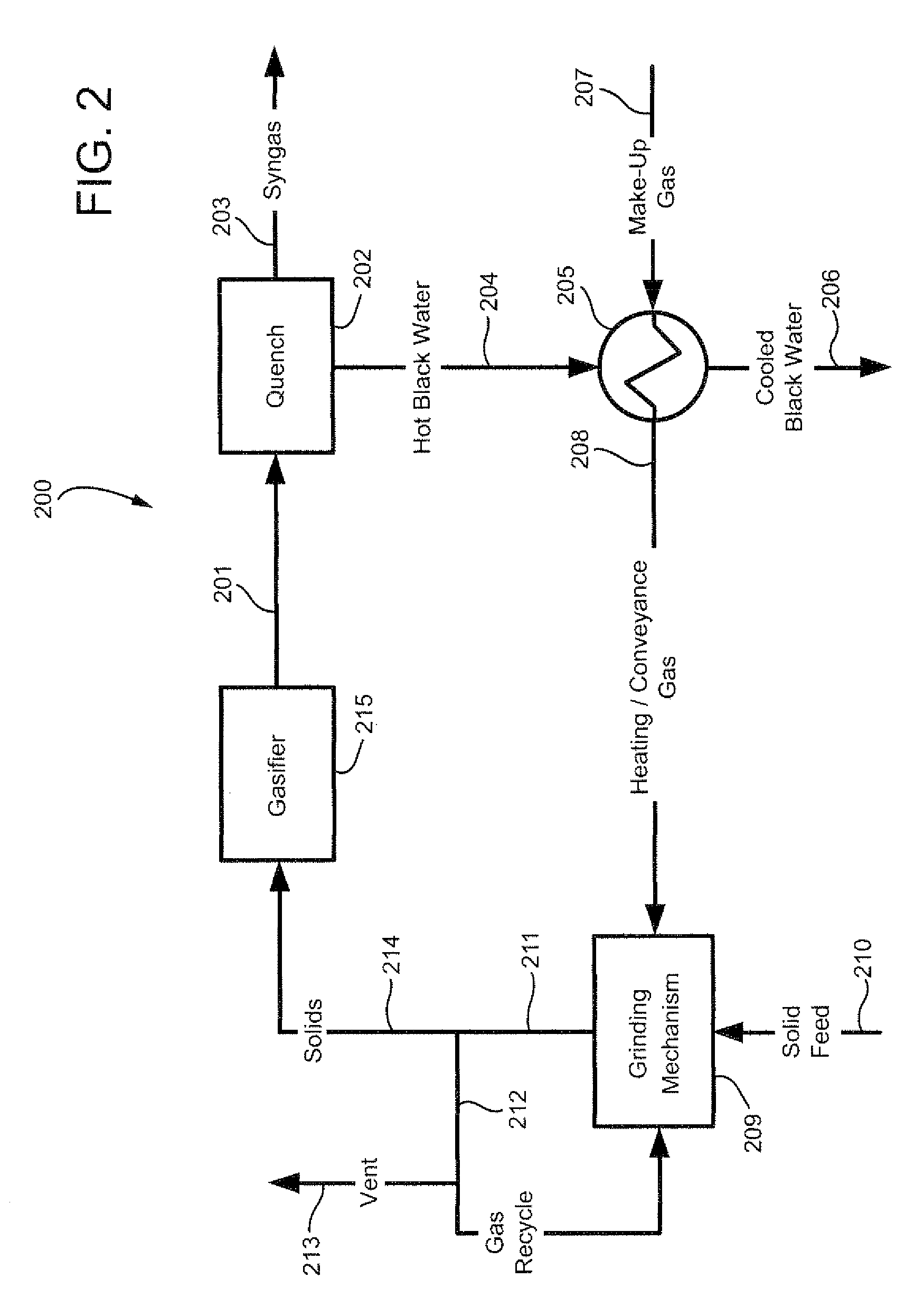

Method of using syngas cooling to heat drying gas for a dry feed system

InactiveUS20100313442A1Improve coal efficiencyDrying solid materials with heatDrying gas arrangementsSyngasParticulates

A method for improving the overall thermal efficiency of a coal power generation plant by transferring heat from a raw synthesis gas stream to solid fuel used as the primary feed to the gasifier, comprising the steps of initially cooling the syngas exhaust by transferring heat to a makeup conveyance gas feed to the dry feed preparation system, feeding a solid fuel component and a portion of the makeup gas stream into a grinding mechanism for the solid feedstock, forming a two-phase solids / gas stream comprising ground feedstock particulates and makeup gas, heating and drying the ground solid feedstock particulates to remove water, separating and removing water vapor formed in the heating and drying step, and feeding the heated and dried solids / gas stream to the gasifier.

Owner:GENERAL ELECTRIC CO

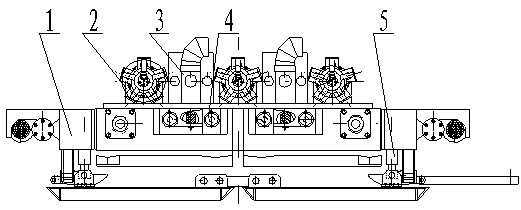

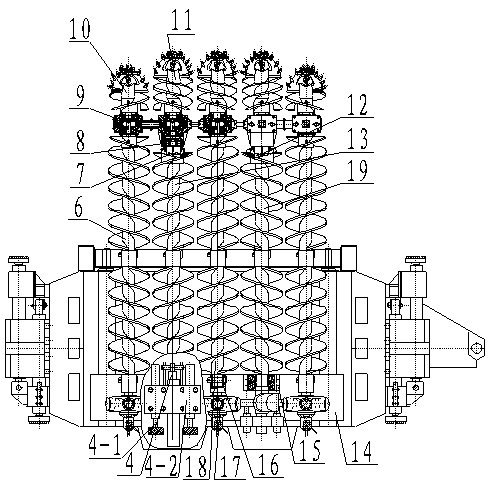

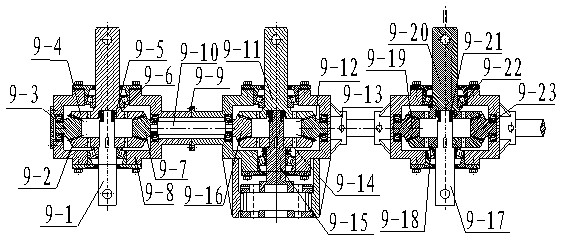

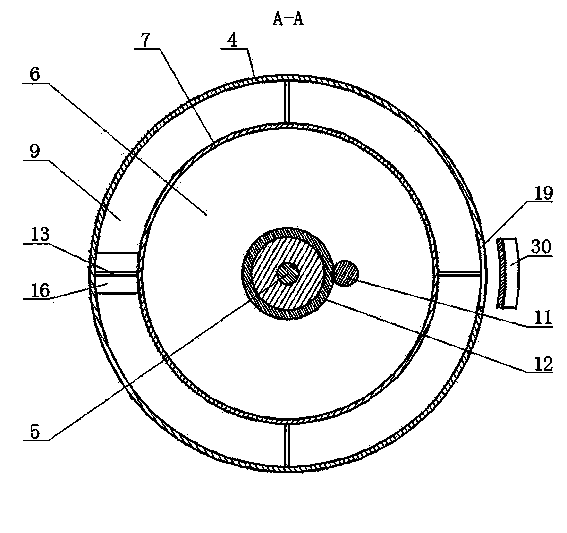

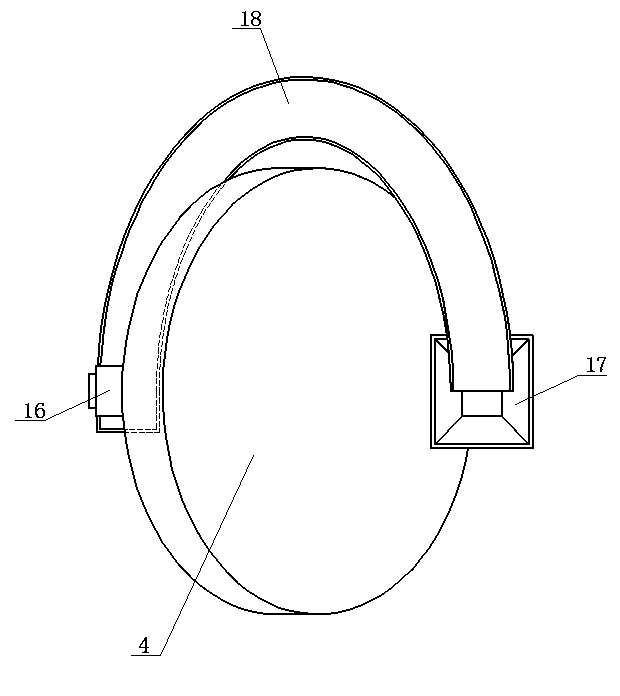

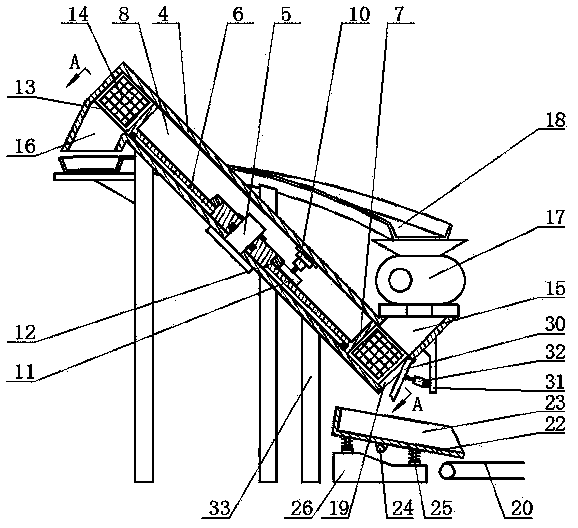

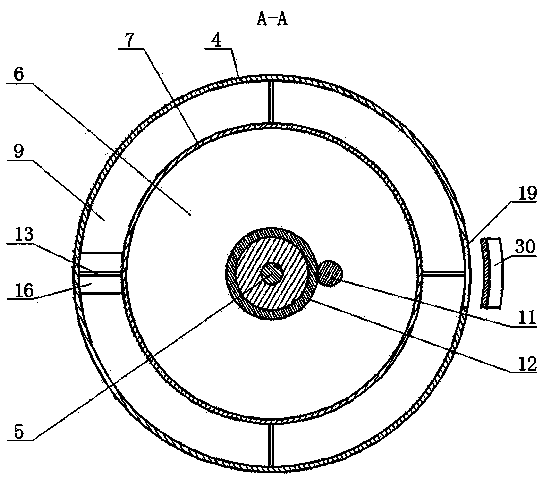

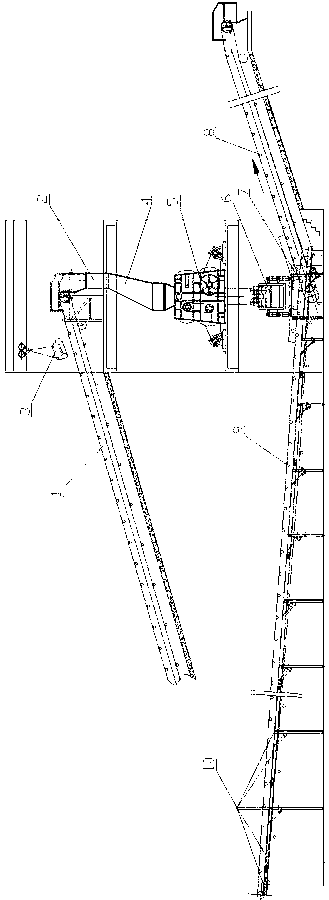

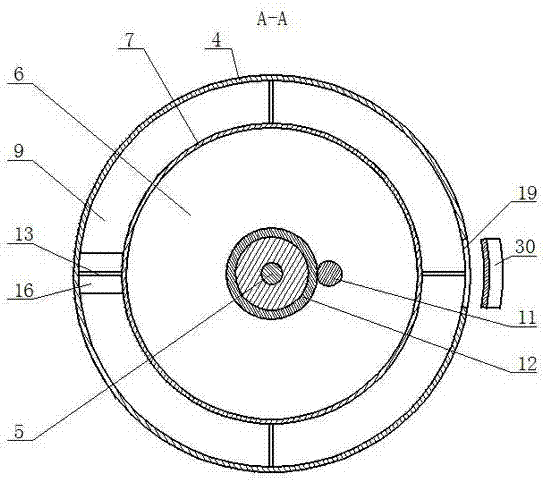

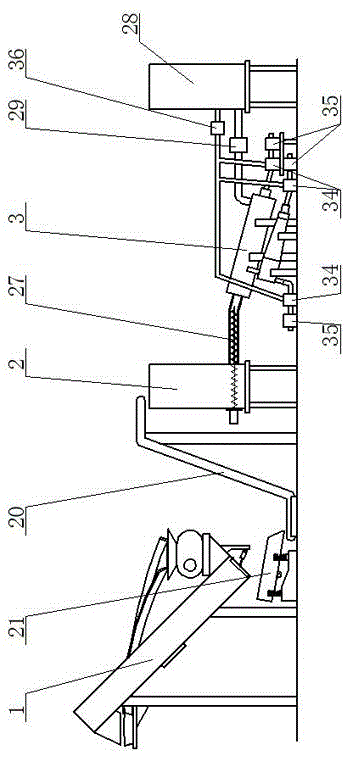

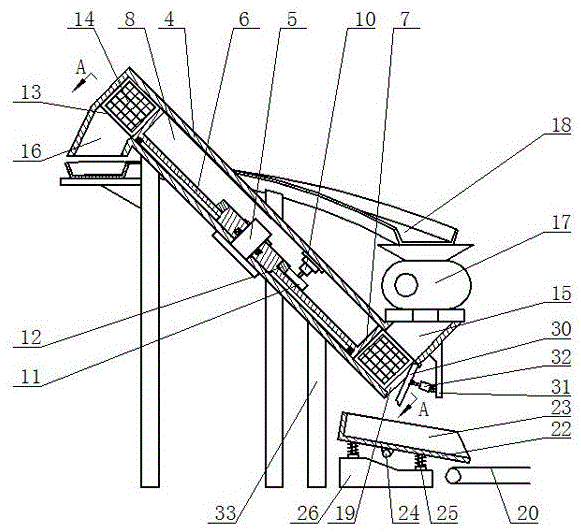

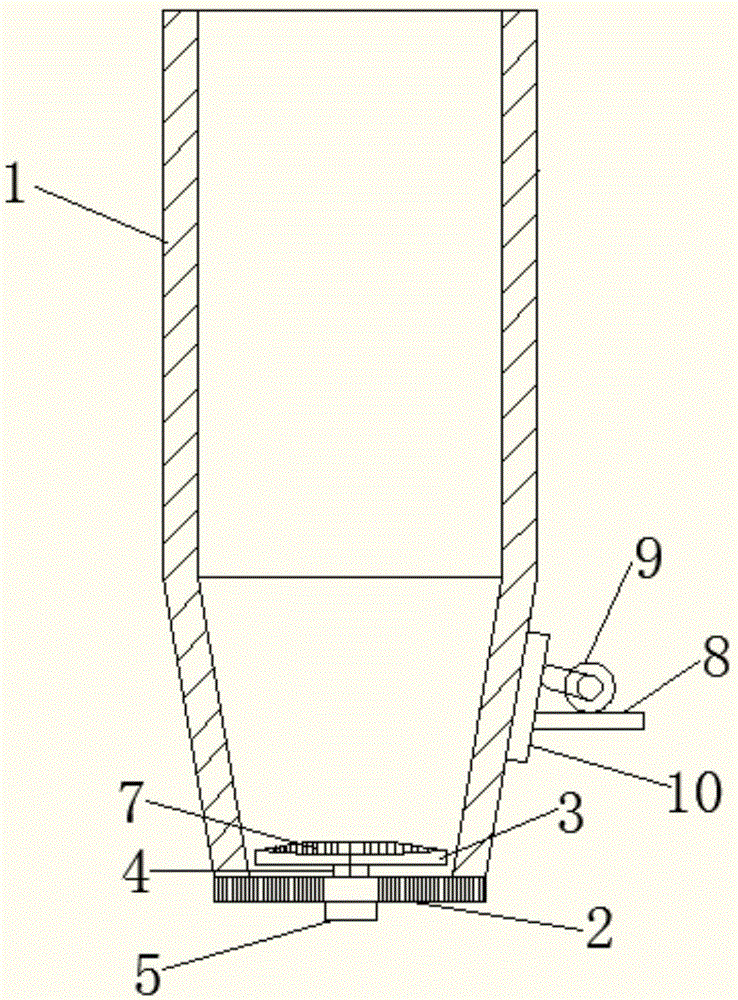

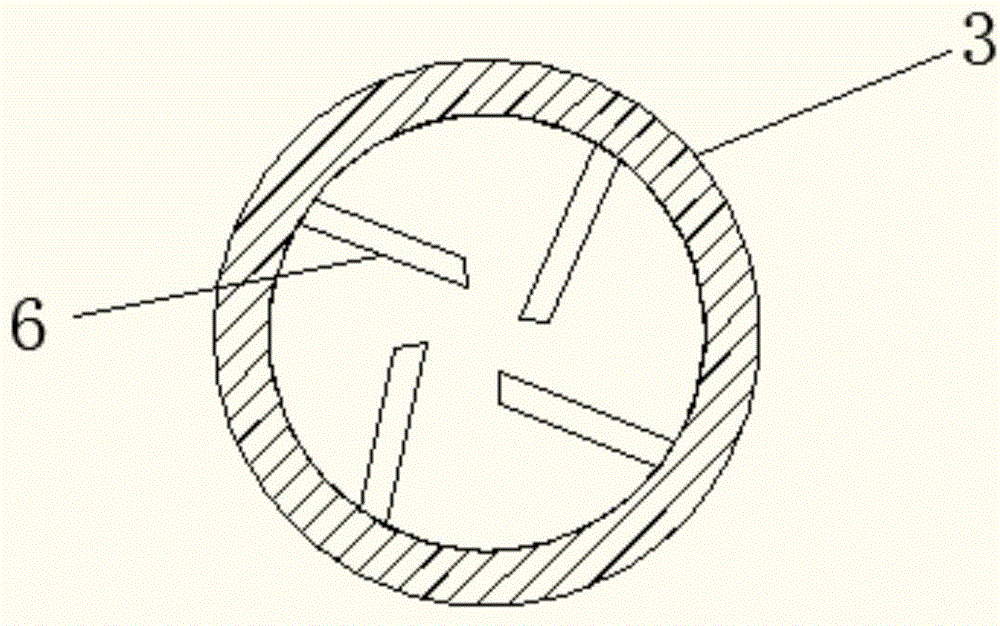

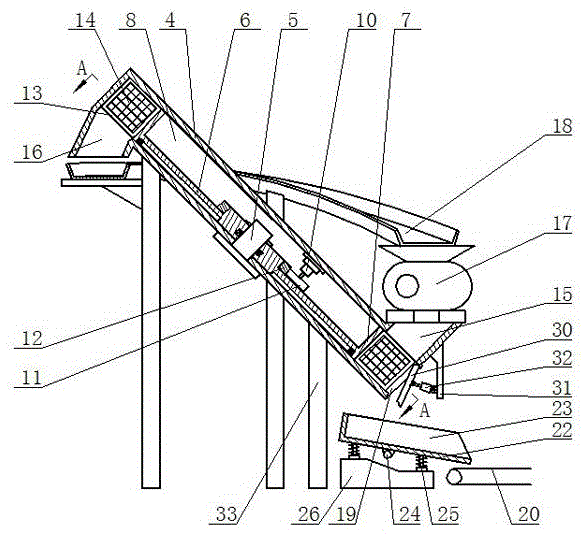

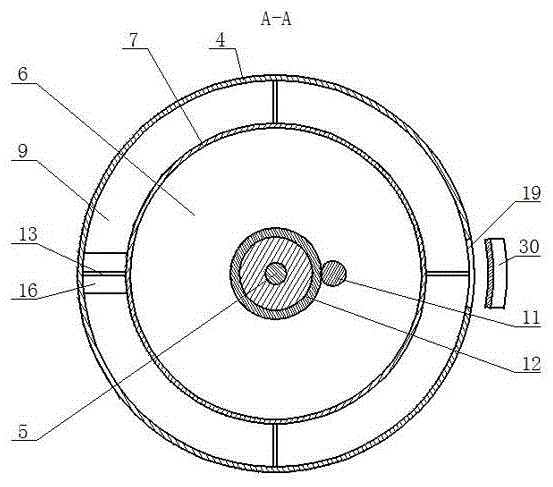

Five-drill air inlet and outlet type coal mining machine

The invention relates to a five-drill air inlet and outlet type coal mining machine, applicable to mining of a coal bed with pitch of 0-25 degrees, thin and extremely thin coal beds containing gas and a liberation coal bed. The five-drill air inlet and outlet type coal mining machine mainly comprises a hydraulic motor, a bracket, a thrust cylinder, a transmission case and a spiral bit. Five drills are transversely arranged, thus mining efficiency of the coal mining machine is improved; and three intermediate drills are arranged in advance, and mining energy consumption is reduced by utilizing a crisp pressing effect of the coal bed. A machine set is provided with a blast fan and an induced-draft fan to realize ventilation of a working surface, and gas concentration is diluted, thus the machine set can mine a high-gas coal bed. A transmission drill rod and a ventilation drill rod convey coal at the same time, thus coal conveying efficiency of the coal mining machine is greatly improved. The transmission case adopts a bevel gear driving manner, a transmission case body is of a sectional type structure, volume of the transmission case is reduced, and coal passing efficiency of the transmission case is improved, thus the drills are avoided from being blocked and turning. The machine set can realize ventilation of a mining working surface, efficient mining of high-gas thin and extremely thin coal beds is realized, and the machine set has high working stability, reasonable structural arrangement, strong component interchangeability and easiness in maintenance.

Owner:CHINA UNIV OF MINING & TECH +1

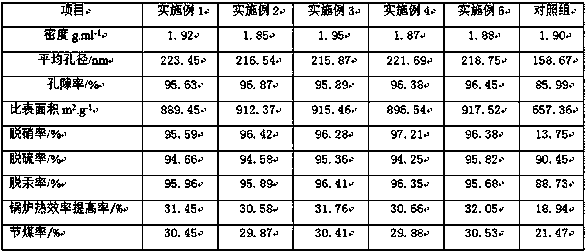

Composite additive

ActiveCN105567375AHigh activityIncrease the effective areaSolid fuelsFuel additivesInorganic compoundOrganic compound

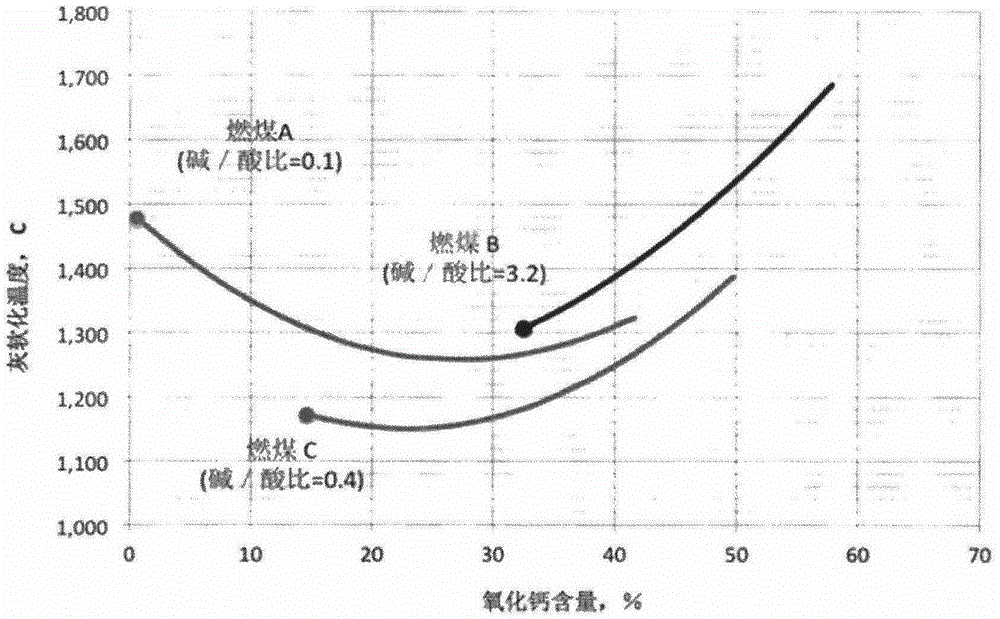

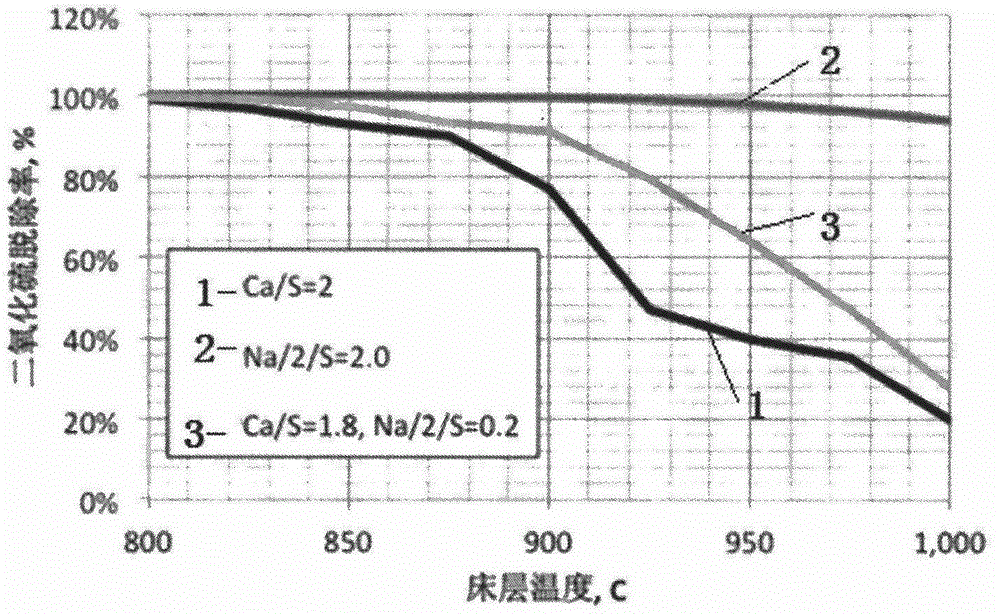

Embodiments of the invention provide a composite additive, which comprises a calcium-based additive and a sodium-based additive, wherein the calcium-based additive comprises an inorganic calcium compound, an organic calcium compound or a combination of an inorganic calcium compound and an organic calcium compound, and the sodium-based additive comprises at least one selected from baking soda powder (NaHCO3), at least soda ash (Na2CO3) and caustic soda (NaOH). According to the present invention, the composite additive provided by the embodiments and coal are doped, and the obtained mixture is burned, such that SO2, HCL, HF, NOx and other toxic and harmful gases produced during the coal burning can be reduced, and the environmental pollution can be reduced.

Owner:YANKUANG GRP CO LTD +1

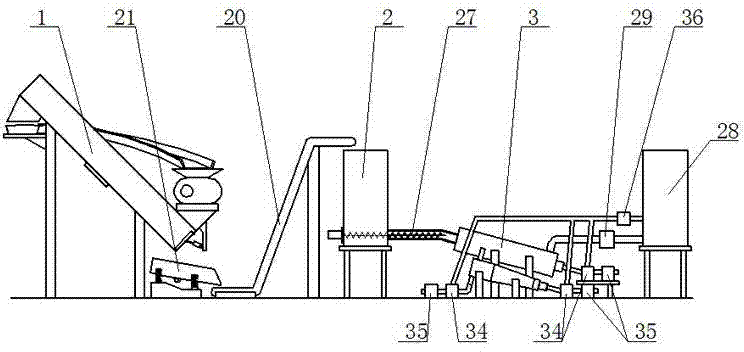

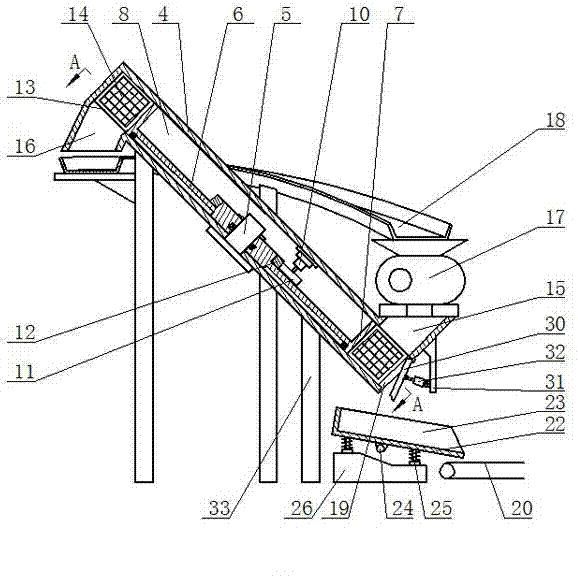

Raw coal washing system

ActiveCN103846145AReduce pollutionReduce processing timeGrain treatmentsWet separationScrew conveyorCoal

The invention discloses a raw coal washing system. The raw coal washing system comprises circulating coal crushing equipment, wherein a vibrating drop guide is arranged below a discharging gate of the circulating coal crushing equipment; a belt conveyor is arranged between the vibrating drop guide and a raw material storage tank; the raw material storage tank is communicated with the raw coal inlet of a three-product dense medium cyclone through a screw conveyer; the suspension inlet of the three-product dense medium cyclone is communicated with a medium storage tank through a medium pump; the outlet of the three-product dense medium cyclone is communicated with medium drainage equipment and dehydration equipment; the medium drainage equipment is communicated with the medium storage tank through a medium recovery pump. The raw coal washing system has the advantages that the coal is continuously washed and is not needed to be manually transferred between the equipment, the labor force and transportation equipment cost of coal production enterprises are reduced, and the raw coal treatment time is shortened, so that the coal washing process is easily accepted by the coal production enterprises, the system is suitable for large-scale popularization and application in coal industry, the overall raw coal washing rate in the coal industry is improved, the environmental pollution degree is reduced, the fire coal efficiency is improved, and transport capacity waste is reduced.

Owner:南通市通州区麦畅纺织品有限公司

Dense medium continuous coal washing process and raw coal continuous crushing method

The invention provides a dense medium continuous coal washing process and a raw coal continuous crushing method. The dense medium continuous coal washing process comprises the following steps that (1) dense medium suspension liquid is configured in a medium storage tank for standby application; (2) raw coal is conveyed into a raw coal crusher in circulating coal crushing equipment to be crushed and enters a classifier; (3) the raw coal crushed in the step 2 is picked out through the classifier; (4) raw coal materials stored in a raw material storage tank are conveyed into a three-product dense medium hydrocyclone; (5) coal washing media in the step four are recycled through medium removing equipment to obtain water contained clean coal, water contained middling coal and water contained gangue with the media removed; (6) dehydration treatment is carried out on the water contained clean coal, the water contained middling coal and the water contained gangue with the media removed in the step 5 through dehydration equipment, and the finished products of the clean coal, the middling coal and the gangue are respectively obtained. The coal can be washed continuously, the coal does not need to be manually transferred between all the equipment in the coal washing process, the dense medium continuous coal washing process and the raw coal continuous crushing method are suitable for being popularized and applied in a large range in coal industries, and the overall raw coal washing rate of the coal industries is improved.

Owner:内蒙古维维能源有限公司

Coal washing medium powder and coal washing process

The invention provides a coal washing medium powder and a coal washing process. The coal washing medium powder contains magnetic material larger than 97.8% in content, particles 91.3% in content and sulfur less than 0.1% in content. The coal washing process includes the steps of 1), feeding the coal washing medium powder into a medium storage tank for standby; 2), feeding raw coal into a circulating coal crushing device prior to being fed into a classifier; 3), allowing the classifier to pick out crushed raw coal in the step 2); 4), feeding the raw coal materials stored in the medium storage tank into a three-product dense medium cyclone; 5), using a medium removing unit to have coal washing medium obtained in the step 4) recycled and reconfiguring dense medium suspension liquid; 6), using a dewatering unit to have watery coal subjected to medium removing in the step 5) dewatered to obtain clean coal, middlings and gauge products. By application of the coal washing process, the clean coal obtained by raw coal washing contains ash content stably around 0.5%, continuous coal washing can be achieved, and the coal washing process is suitable for being widely promoted and applied in the coal industry.

Owner:高峰

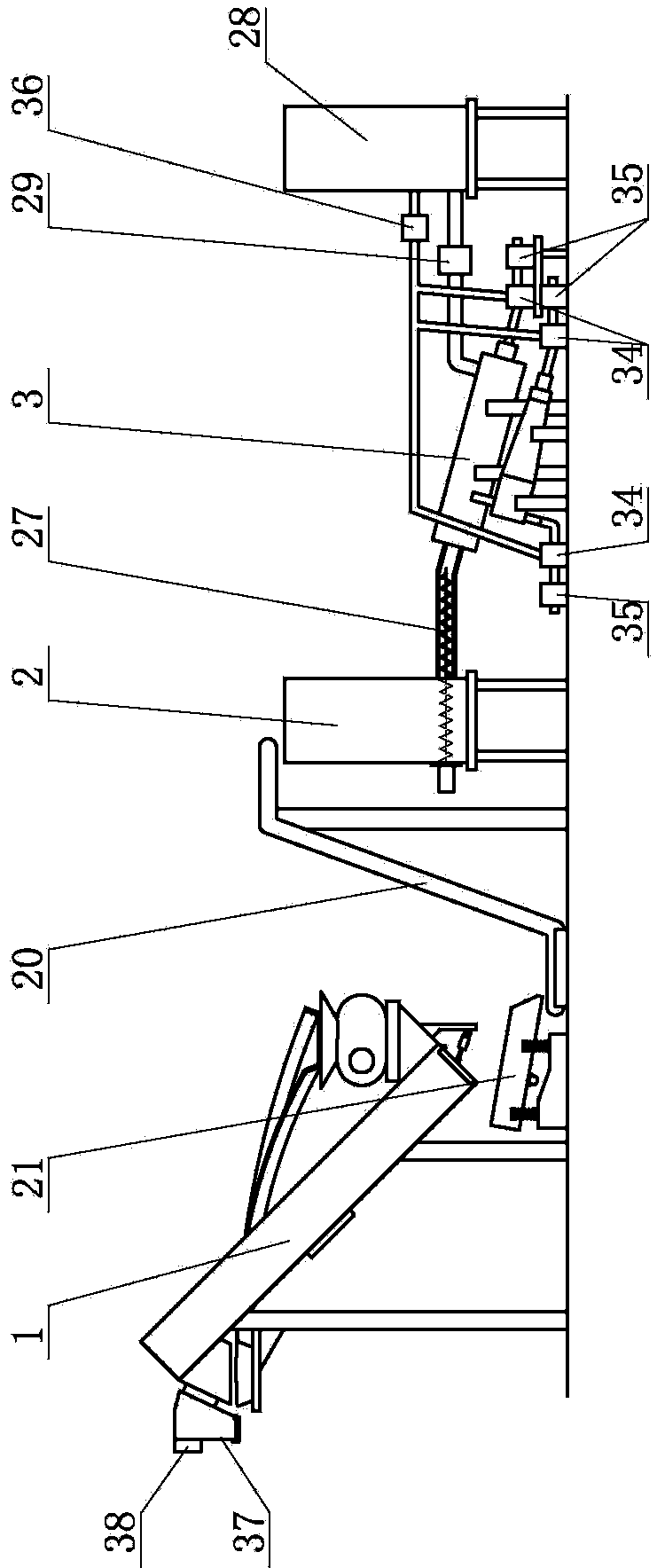

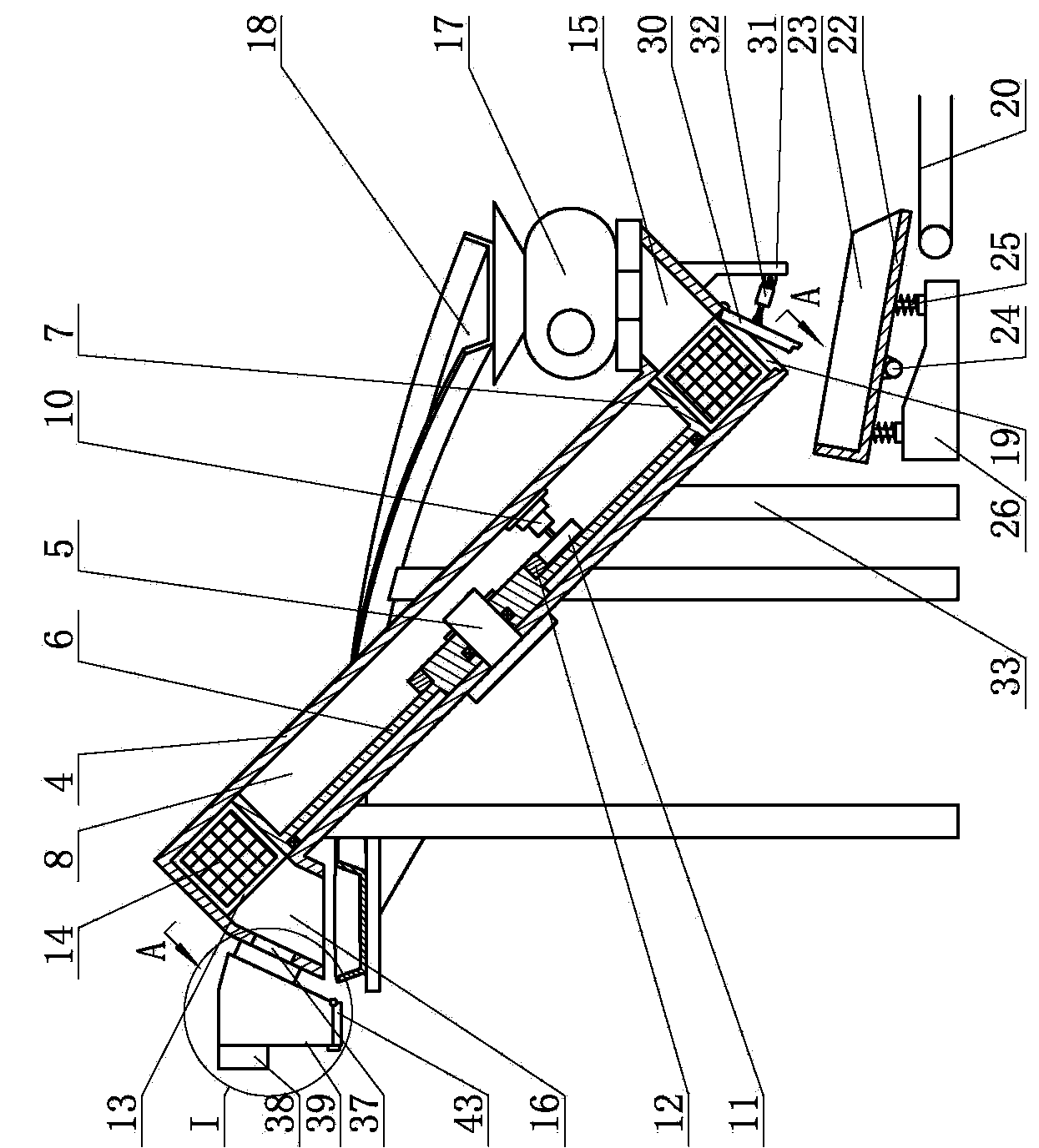

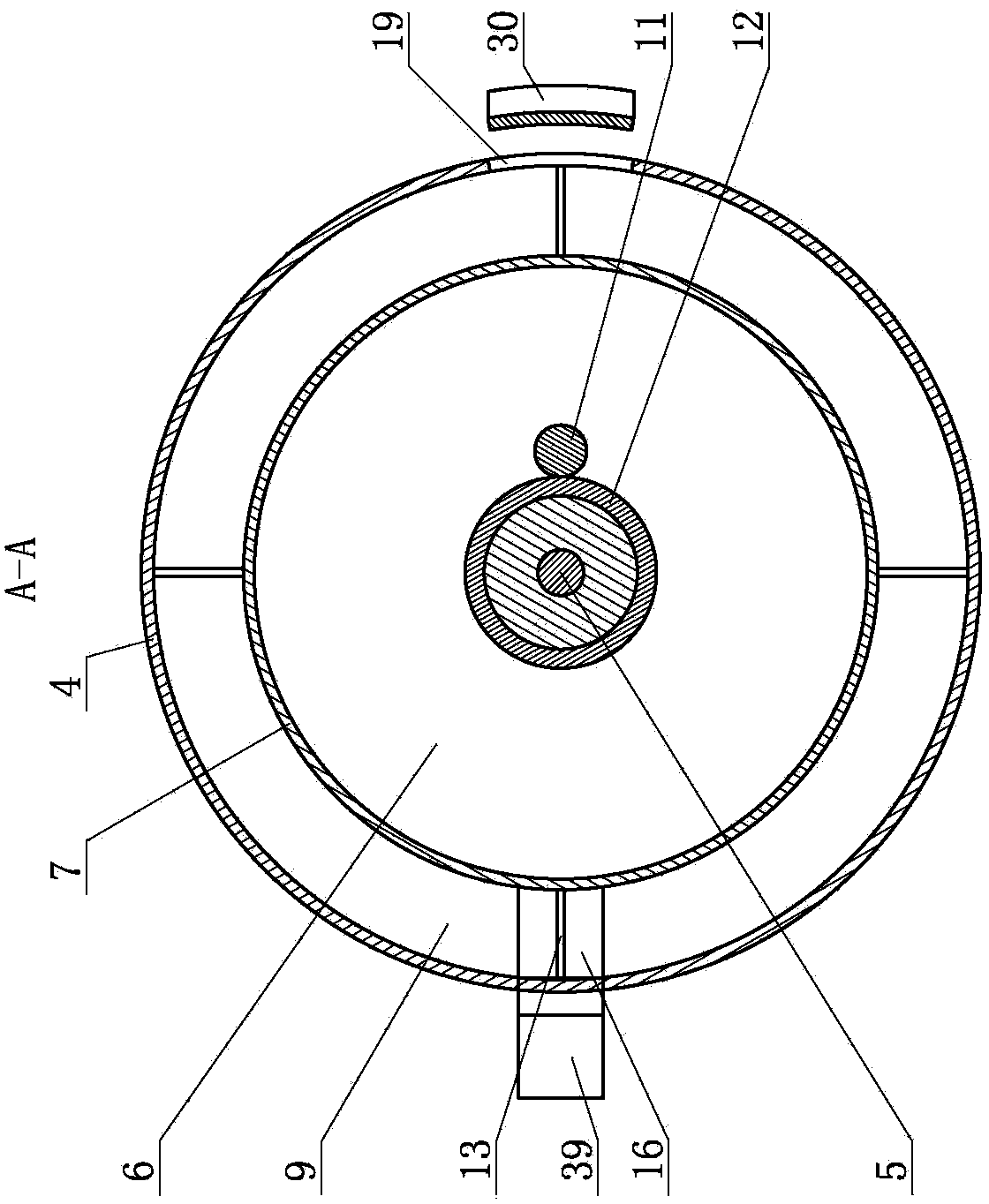

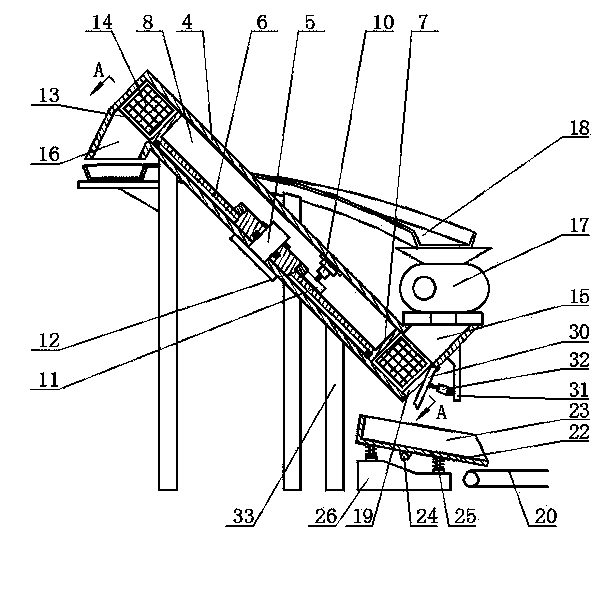

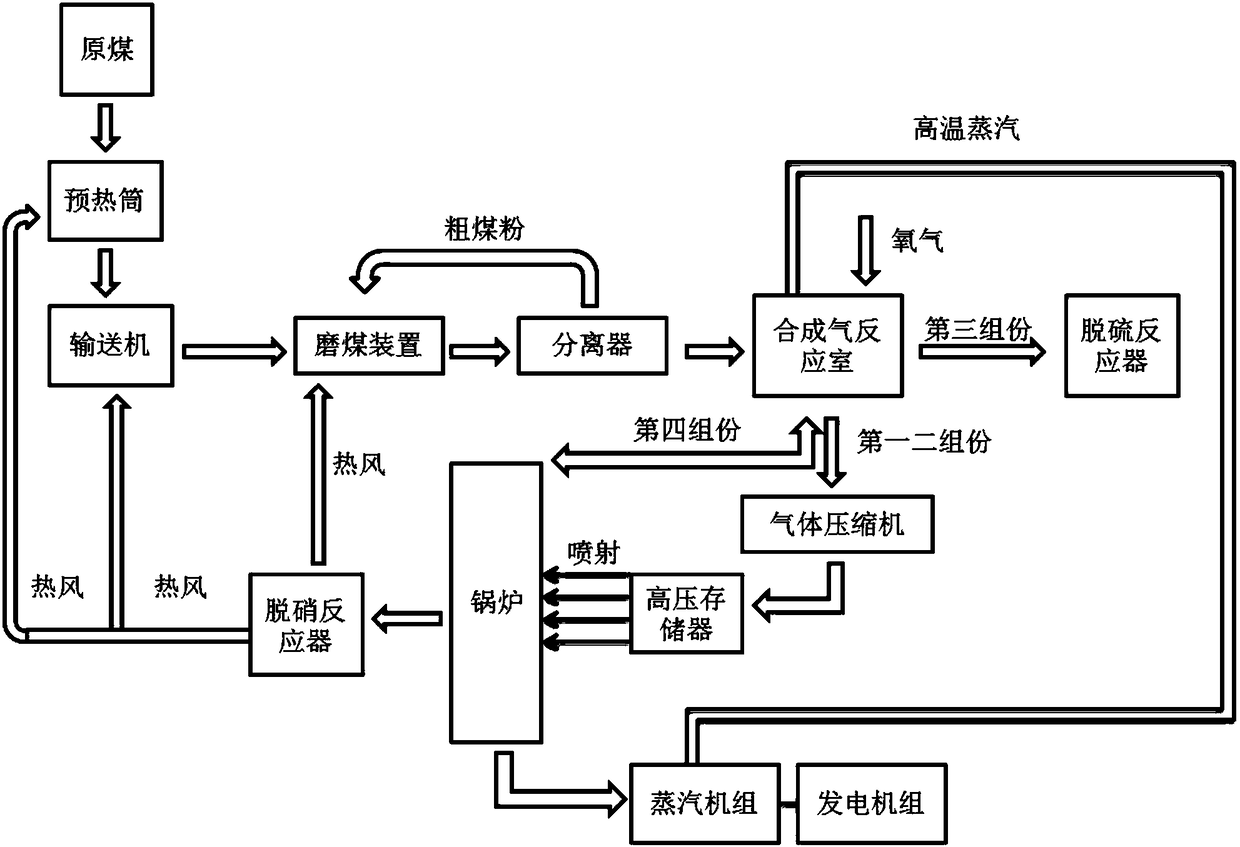

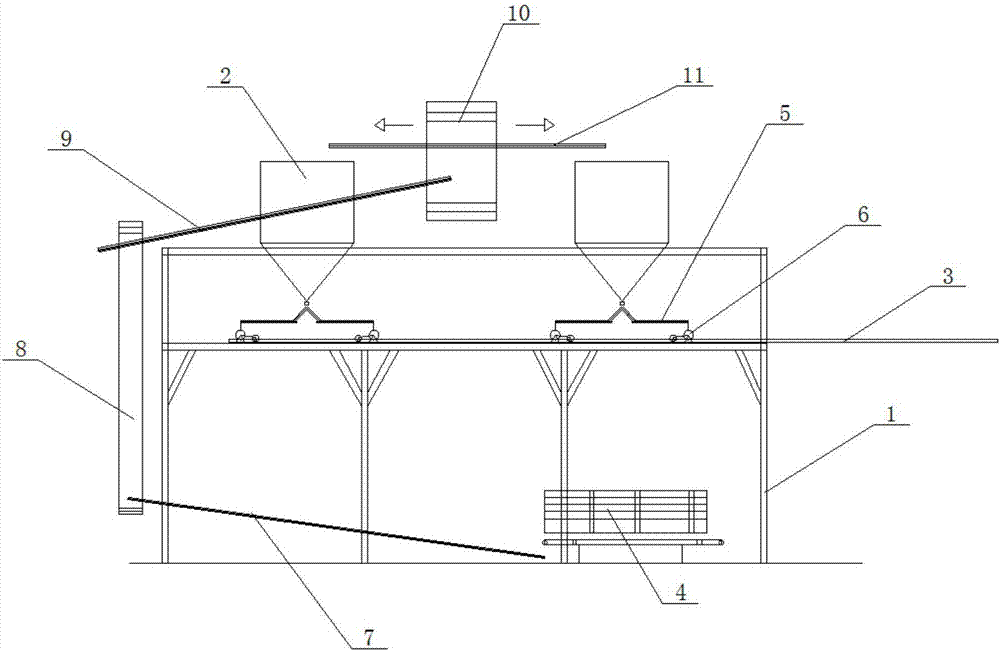

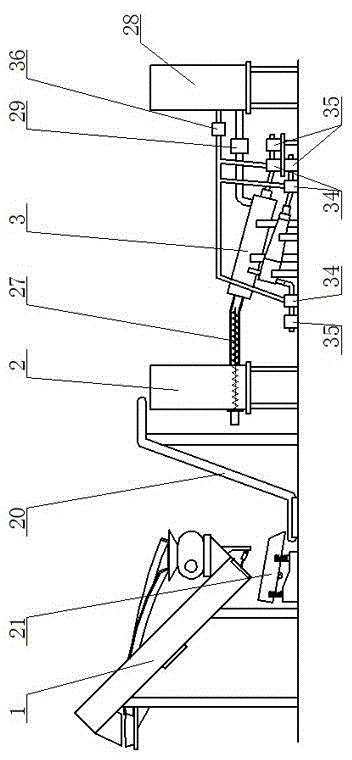

Smashing, screening and circulating coal feeding system

InactiveCN103292341AReduce insecuritySolve the problem of easy wear and tearLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationCoal briquetteThermodynamics

The invention relates to a smashing, screening and circulating coal feeding system which comprises a mixed coal bunker, a coal feeding material nozzle, an iron separator, a smasher and a number one coal feeding belt conveyor. The lower portion of the number one coal feeding belt conveyor is connected with the mixed coal bunker, the coal feeding material nozzle is positioned at the bottom of the mixed coal bunker, the lower portion of the coal feeding material nozzle is connected with the smasher, and materials after being processed are conveyed to a boiler by the belt conveyor. The smashing, screening and circulating coal feeding system is characterized in that a vibratory screening machine is additionally arranged at an outlet of the smasher, a material separating nozzle is arranged on the lower portion of the vibratory screening machine and connected with a number two below-screen belt conveyor, coal briquette with qualified granularity is conveyed to the boiler by the number two below-screen belt conveyor, materials on a screen of the vibratory screening machine are conveyed to a number three above-screen belt conveyor, and a hanging rack is arranged on the end portion of the number three above-screen belt conveyor. By the smashing, screening and circulating coal feeding system, resource waste caused by incomplete burning of large-sized coal is effectively reduced, burning efficiency of the coal briquette is improved, production cost of the boiler is reduced, and the problems of difficulty in raw coal separating and high load of the coal smasher are solved. The smashing, screening and circulating coal feeding system is suitable for closed cycle processes like smashing, screening, separating and the like of bulky materials.

Owner:TAIYUAN IRON & STEEL GROUP

High-performance biomass solid fuel and preparation method thereof

The invention relates to the technical field of biomass fuel, in particular to high-performance biomass solid fuel and a preparation method thereof. The high-performance biomass solid fuel is preparedfrom the following components in parts by weight: 120 to 150 parts of straws, 30 to 45 parts of fruit peels, 4 to 8 parts of synergistic agent, 5 to 9 parts of combustion-supporting adhesive, 8 to 14parts of magnesium oxide, and 6 to 12 parts of carbide slag. The high-performance biomass solid fuel has the beneficial effects that the crop wastes such as the straws and the fruit peels are used asmain raw materials, so that the raw material is wide in source and low in price, not only can the waste be comprehensively utilized, the environmental pollution be reduced and the sustainable development of the resource be realized, but also the energy crisis problem at present can be effectively alleviated, and the charcoal ash after the biomass solid fuel is combusted to be used as fertilizer;and the carbide slag can reduce a combustion point of formed fuel and increase a melting point of the fuel ash, so that the problems that the existing biomass solid fuel is easy to slag, easy to accumulate and insufficient in combustion in the combustion process, and aids in the ignition of the solid fuel by arranging the magnesium oxide.

Owner:桂林市安琪玫瑰农业发展有限公司

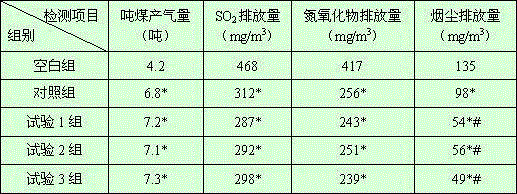

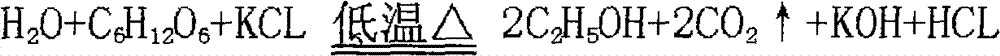

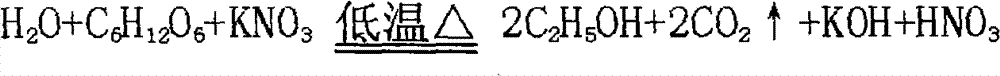

Coal additive for reducing smoke dust discharging quantity

The invention provides a coal additive, which is mainly prepared from the following ingredients in parts by weight: 10 parts of nanometer silicon dioxide, 10 to 20 parts of furnace slag, 4 to 10 parts of sodium percarbonate, 1 to 5 parts of triethanolamine acetate, 2 to 8 parts of manganese oxide, 2 to 6 parts of magnesium oxide, 2 to 8 parts of calcium hydroxide, 0.2 to 0.8 parts of sodium dodecyl benzene sulfonate, 1 to 5 parts of sodium chloride, 1 to 5 parts of nitrate, 2 to 6 parts of polyacrylamide and 8 to 16 parts of high-alumina bauxite. Compared with the prior art, the coal additive provided by the invention has the advantages that the nanometer silicon dioxide is used for replacing the common nanometer titanium dioxide in common use in the prior art; the effects of coal firing efficiency improvement, desulfurization and denitrification can be achieved; in addition, the smoke dust discharging quantity can also be obviously reduced; the environment pollution is reduced.

Owner:镇江华龙煤质制样设备有限公司

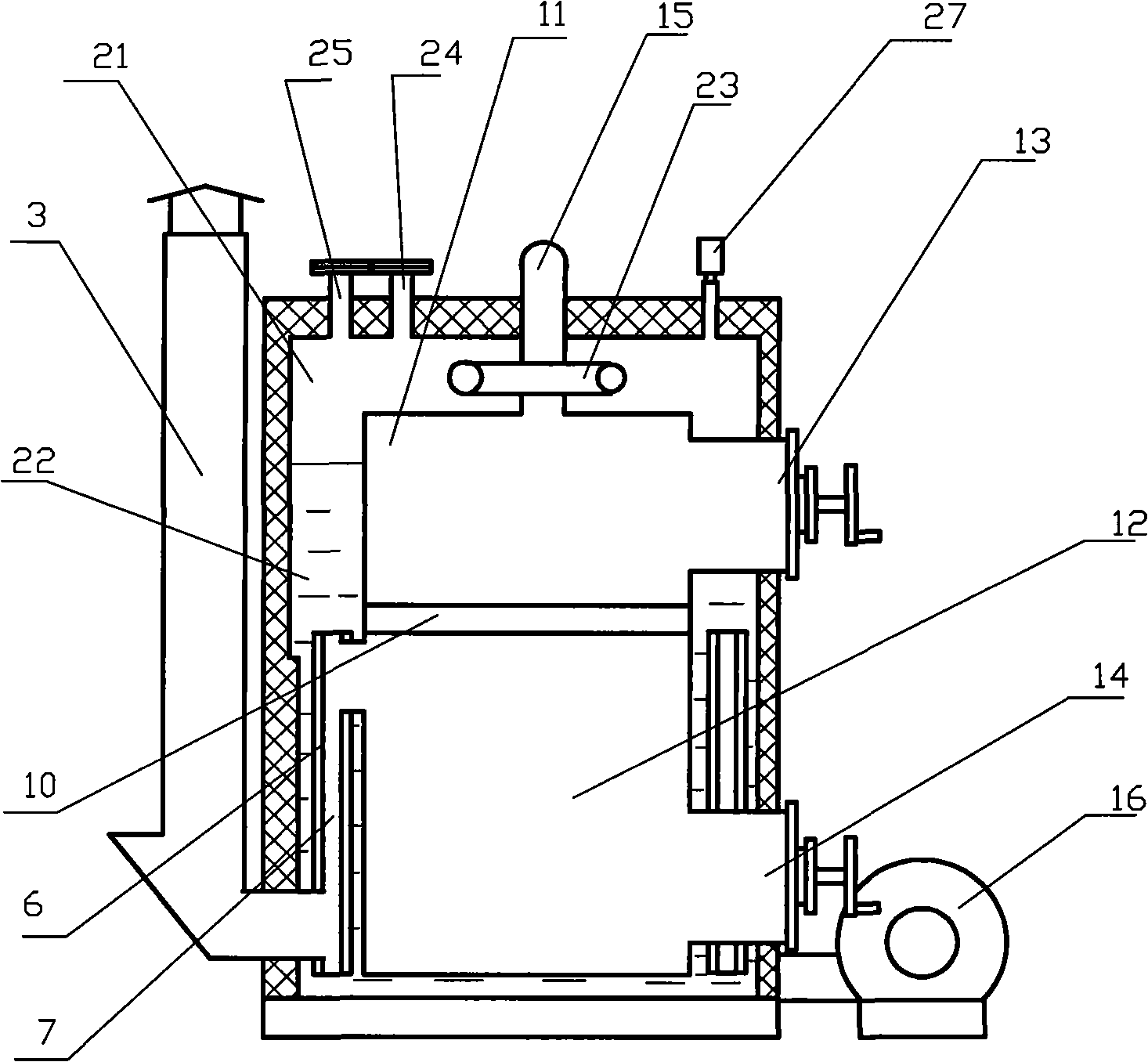

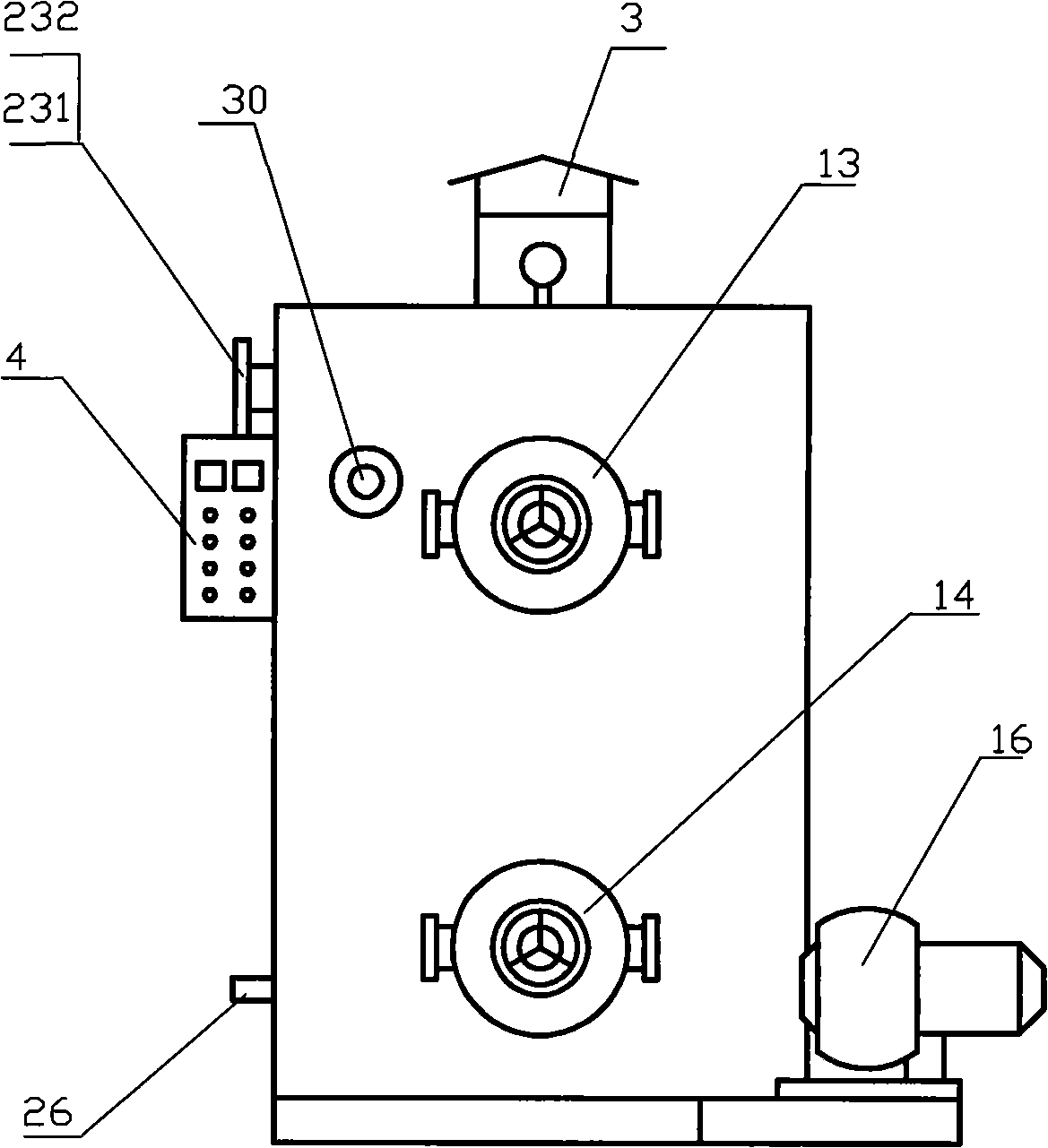

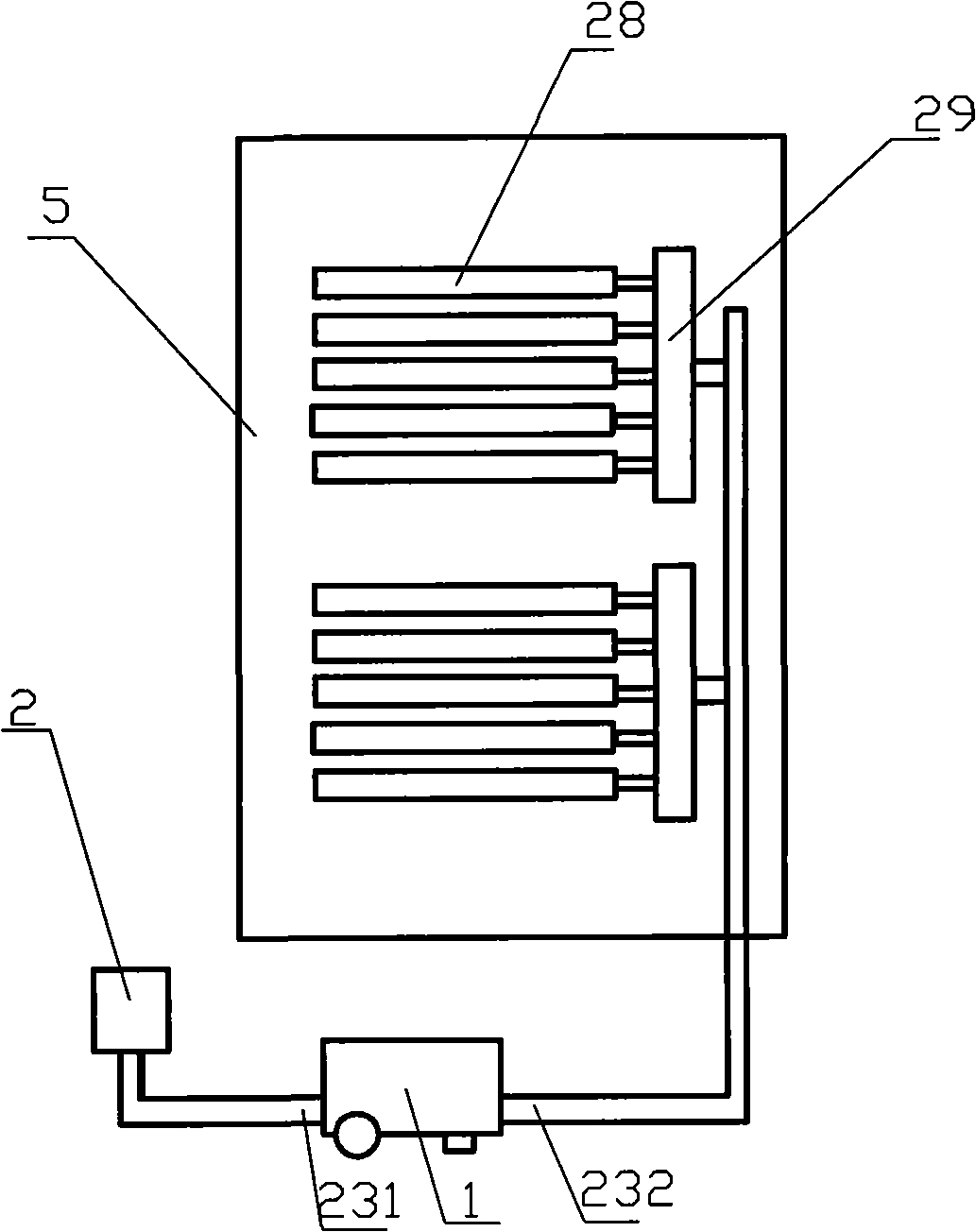

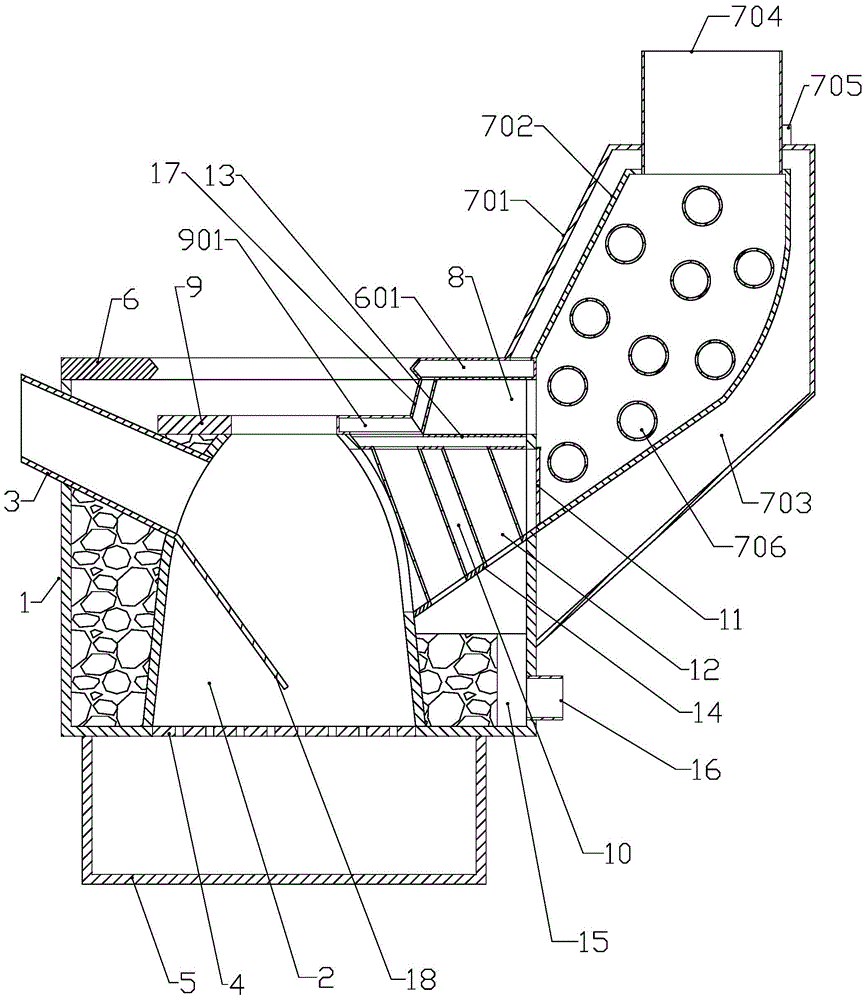

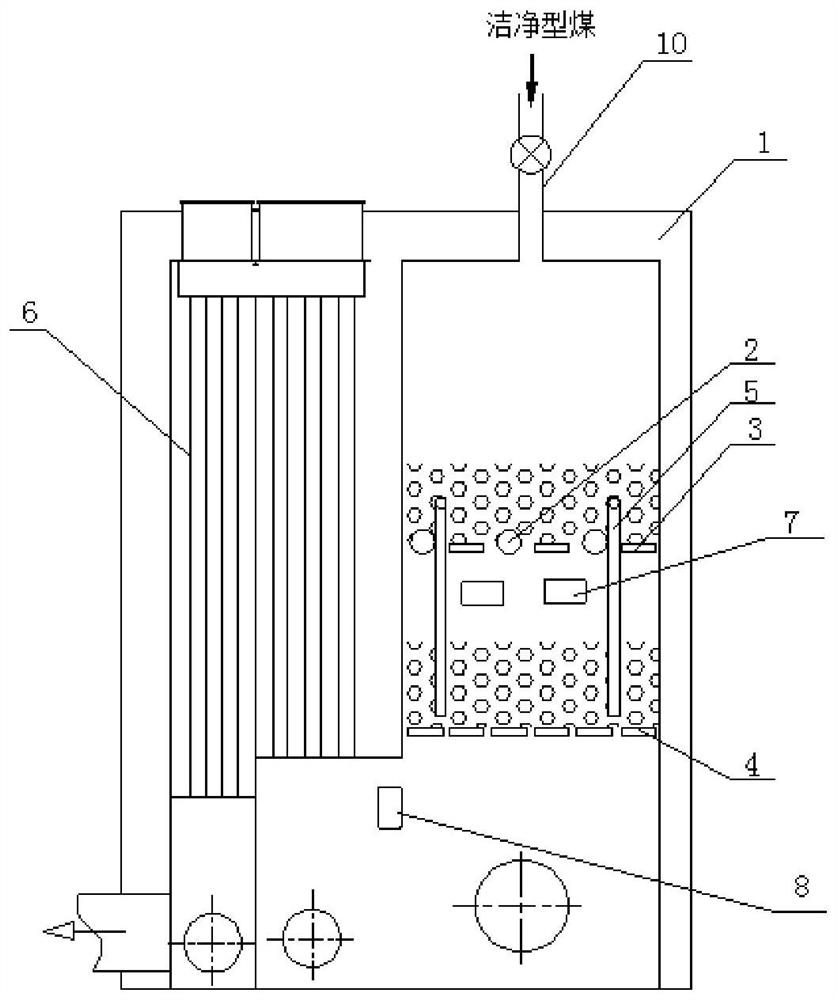

Coal-firing agricultural soil hot water sterilization machine

InactiveCN101493262AImprove coal thermal efficiencyRestorationSteam soil sterilisationWater heatersEngineeringRecuperator

The invention relates to a hot water sterilizing machine applied to agriculture by burning coal, belonging to the field of agriculture equipment. A furnace of the sterilizing machine of the invention is divided into a coal furnace and a fire furnace by a fire grate, the top of the coal furnace is connected with an air inlet pipe, a boiler barrel comprises water space in the lower part and negative pressure vacuum space in the upper part, the negative pressure vacuum space is internally provided with a recuperator tube connected with the outside, the water space is internally provided with heat pipe bundles to form a gas duct. The hot water sterilizing machine applied to agriculture by burning coal can combine a vacuum boiler, gasification wraparound burning and a membrane wall heat transmission structure and continuously provide hot water with the temperature of 90-95 DEG C, has high thermal utilization factor and generates little pollution to the environment, in addition, optimal combination is carried out on the structure of the invention, so that the sterilizing machine has small volume, high thermal efficiency and good mobility. With a membrane-beneath irrigation system adopted, the high temperature hot water obtained in the invention is irrigated in soil or ground substances to heat the soil or ground substances to 50-60 DEG C which lasts for 1-2 hours, thus killing a large amount of mixed fungus in the soil and restoring land capability of the soil.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

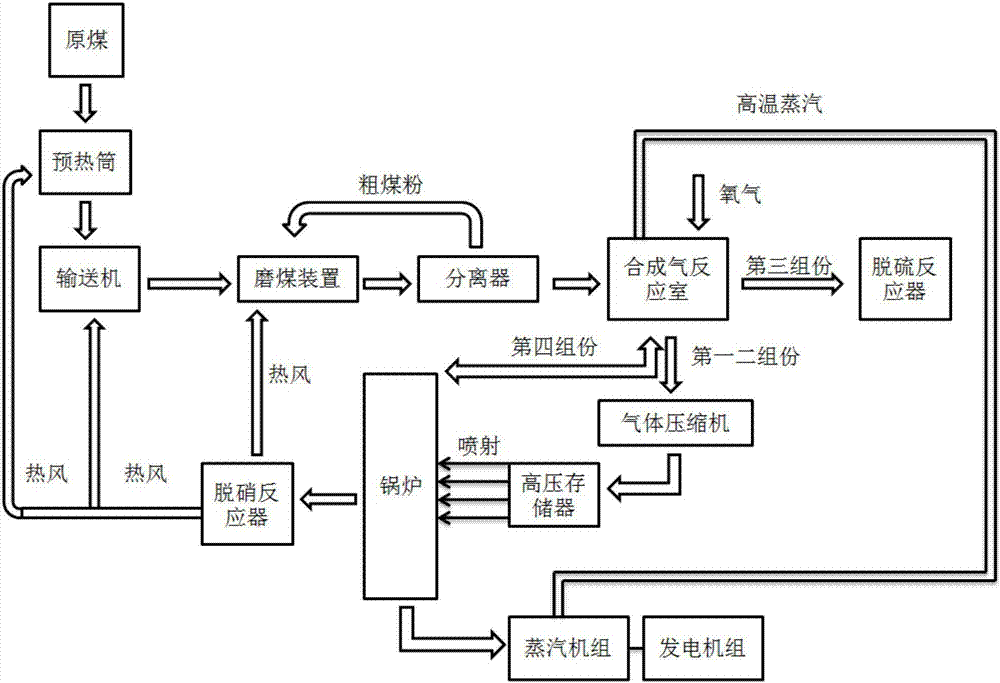

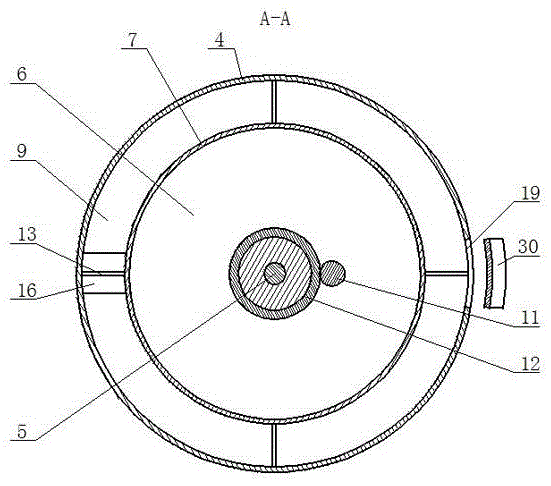

Dust-free environment-friendly coal firing power generation method

ActiveCN107541297AReduce dustReduce consumptionFuel feedersSteam engine plantsGas compressorWater vapor

The invention relates to a dust-free environment-friendly coal firing power generation method. The method comprises the steps that 1, feed coal is conveyed, wherein the feed coal is preheated and enters a conveyor for feeding; 2, the conveyor conveys the feed coal into a coal grinding device to be smashed, and meanwhile hot wind is introduced to dry smashed coal dust; 3, the coal dust which passesthrough the coal grinding device is driven to enter a separator by the hot wind to be graded, qualified coal dust is grinded along air flow, and unqualified rough coal dust is grinded with the feed coal again under the effect of separator blades; 4, fine coal dust reacts with high-temperature steam and oxygen with the temperature above 200 DEG C to generate combustible synthesis gas; 5, the combustible synthesis gas is compressed by a gas compressor and sprayed into a boiler by an ejector for combustion; 6, high-temperature and high-pressure water vapor is used for driving a steam electric generating set to work and accordingly driving an electric generator to generate electricity. According to the dust-free environment-friendly coal firing power generation method, the fine coal dust is subjected to reaction and generates the synthesis gas, the coal firing efficiency is improved, the following flue gas and dust are reduced, burning is sufficient through spraying, through desulfurization and denitration reaction, toxic gas in mixed gas and flue gas is removed, the flue gas and water vapor are recycled, and the economic benefit is improved.

Owner:恒盛能源股份有限公司

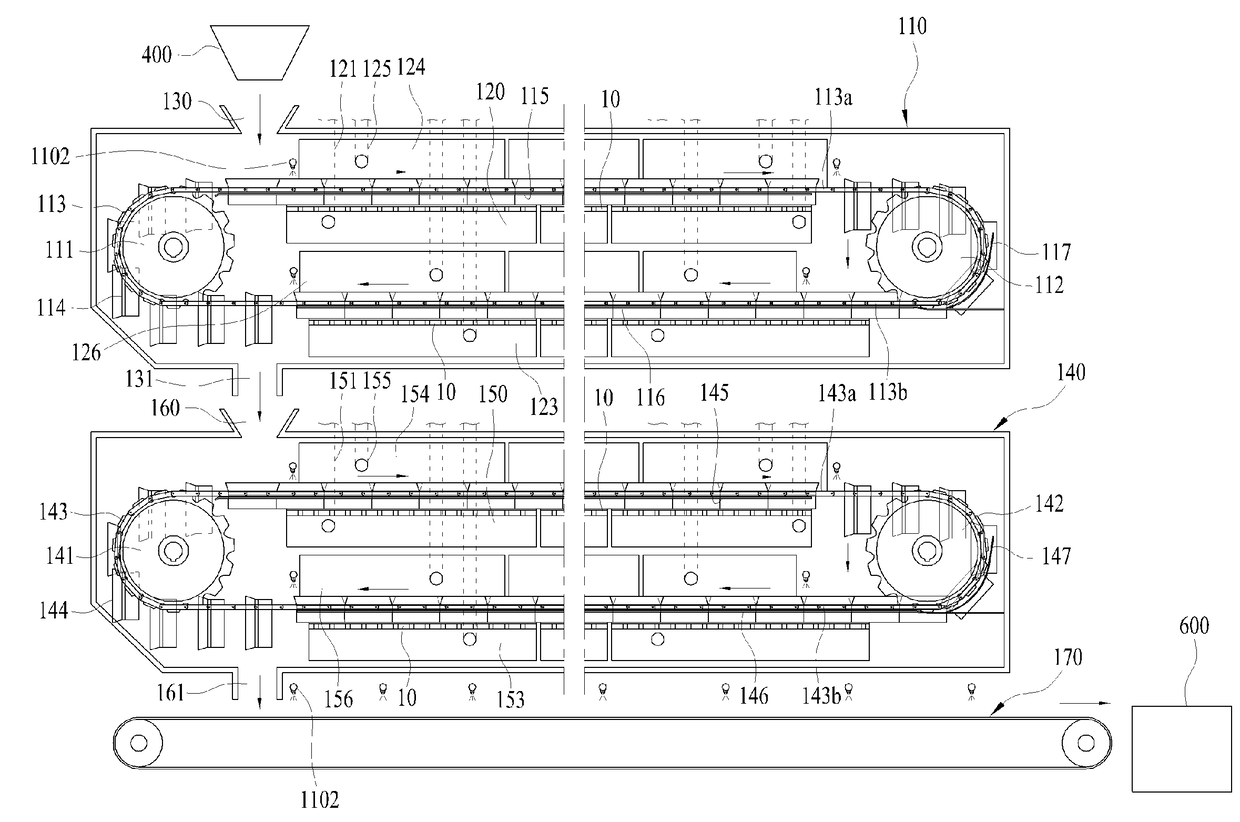

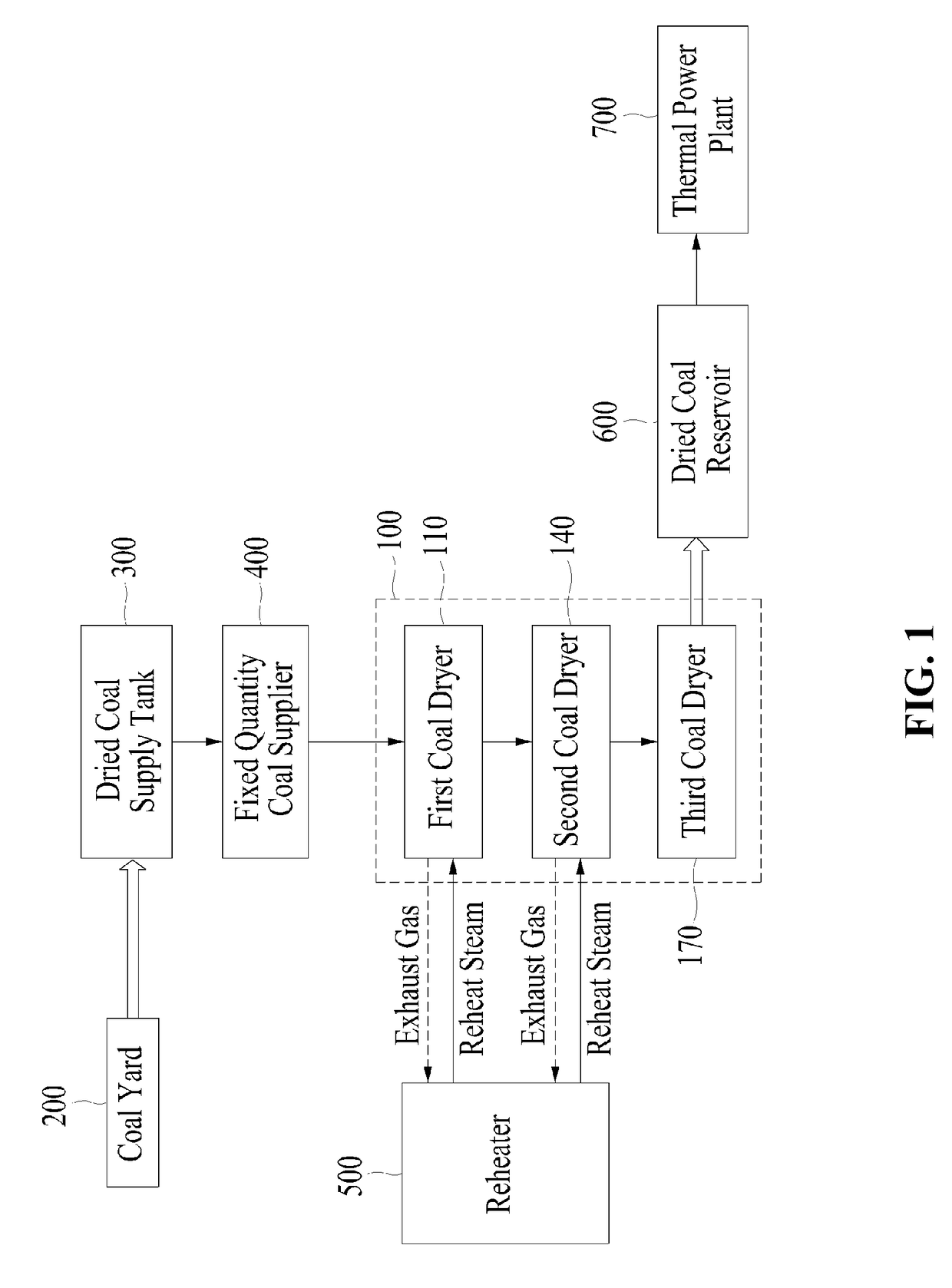

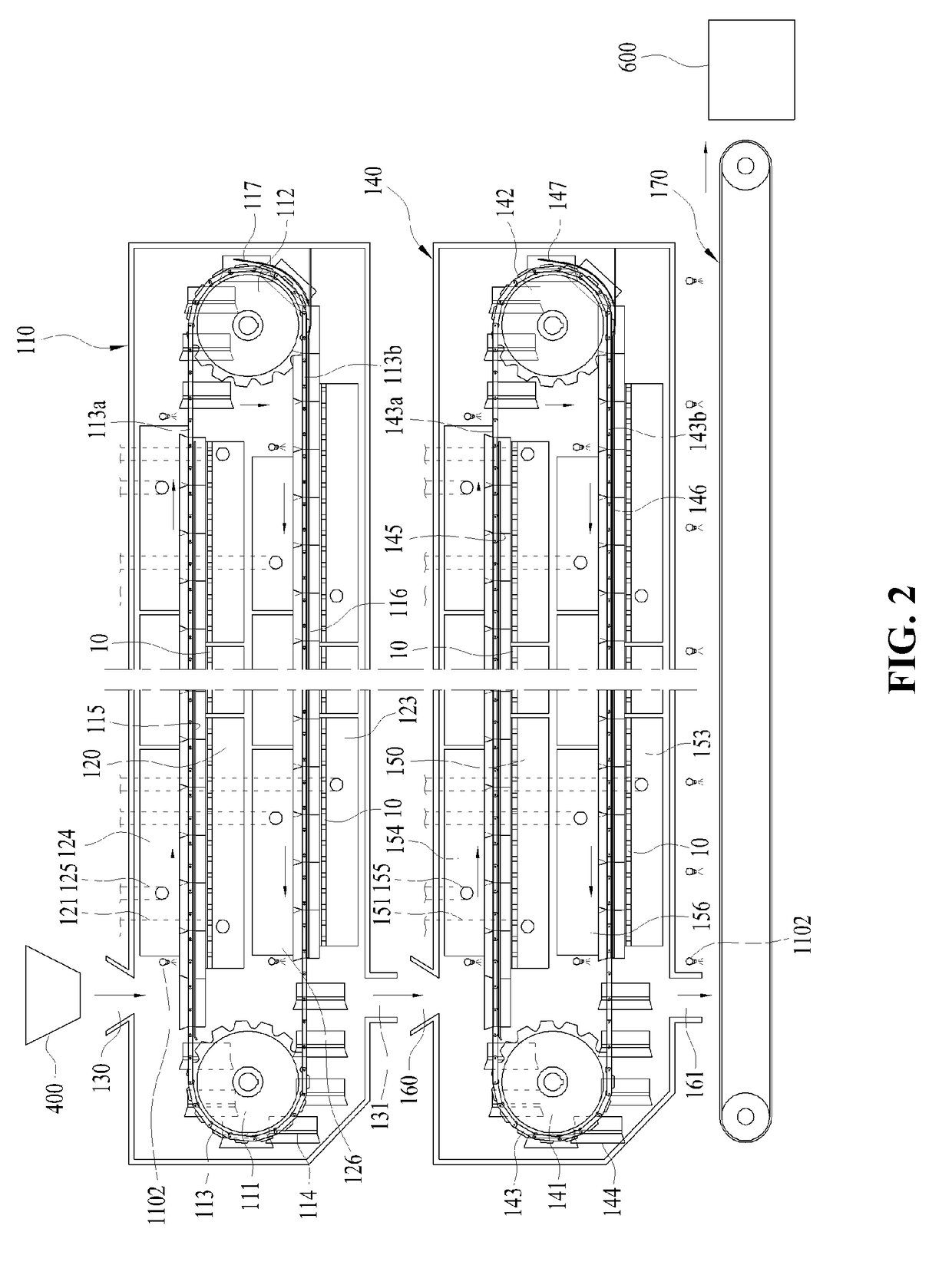

Apparatus for preventing spontaneous ignition of transferred coal in apparatus for drying coal using reheat steam

InactiveUS20170145315A1Maximize useMinimize occurrenceDrying solid materials with heatCoke ovensFour-way valveNitrogen

The present invention relates to an apparatus for preventing, in a multi-stage dryer for drying coal using reheat steam, spontaneous ignition caused by oxidation of coal when coal is transferred to the multi-stage dryer from a fixed quantity coal supplier by way of a pulverizer. The present invention relates to an apparatus for drying coal using reheat steam, the apparatus being configured so that coal which has been dried primarily in a first coal dryer is inputted into a second coal dryer and thus is secondarily dried, wherein reheat steam generated from a reheater is supplied through a reheat steam supply pipe; a nitrogen supplier supplies nitrogen through a nitrogen supply pipe; saturated steam generated from a saturated steam generator is supplied through a saturated steam supply pipe; the reheat steam supply pipe, the nitrogen supplier, and the saturated steam supply pipe are connected to a 4-way valve; and the 4-way valve supplies nitrogen and saturated steam, or nitrogen or saturated steam, along with reheat steam, to first to fourth steam chambers through the steam supply pipe, and injects steam into coal which is transferred to a first transfer plate and a second transfer plate so that spontaneous ignition of coal is prevented in the course of drying and transferring coal.

Owner:HANKOOK TECH

Heavy medium continuous coal washing unit and continuous raw coal crushing method

The invention provides a heavy medium continuous coal washing unit and a continuous raw coal crushing method. The heavy medium continuous coal washing unit comprises a cyclic coal crusher; a vibrating guiding device is disposed below the cyclic coal crusher; a belt conveyor is disposed between the vibrating guiding device and a raw material storage tank; the raw material storage tank is communicated with a raw coal entry of a tri-product heavy medium cyclone through a spiral conveyor; a suspension inlet of the tri-product heavy medium cyclone is communicated with a medium storage tank through a medium pump; a washed coal exit, a middling exit and a gangue exit of the tri-product heavy medium cyclone are respectively communicated with a medium removal device and a dewatering device; the medium removal device is communicated with the medium storage tank through a medium recovery pump. The heavy medium continuous coal washing unit and the continuous raw coal crushing method are available for continuous coal washing, labor cost and transport equipment cost for coal washing can be greatly reduced for enterprises, raw coal handling time is shortened, product structure optimization is facilitated for coal manufacturers, market competitiveness is improved, selling profit in products is increased, and washing rate of raw coal is increased for the whole coal industry.

Owner:南通市通州区麦畅纺织品有限公司

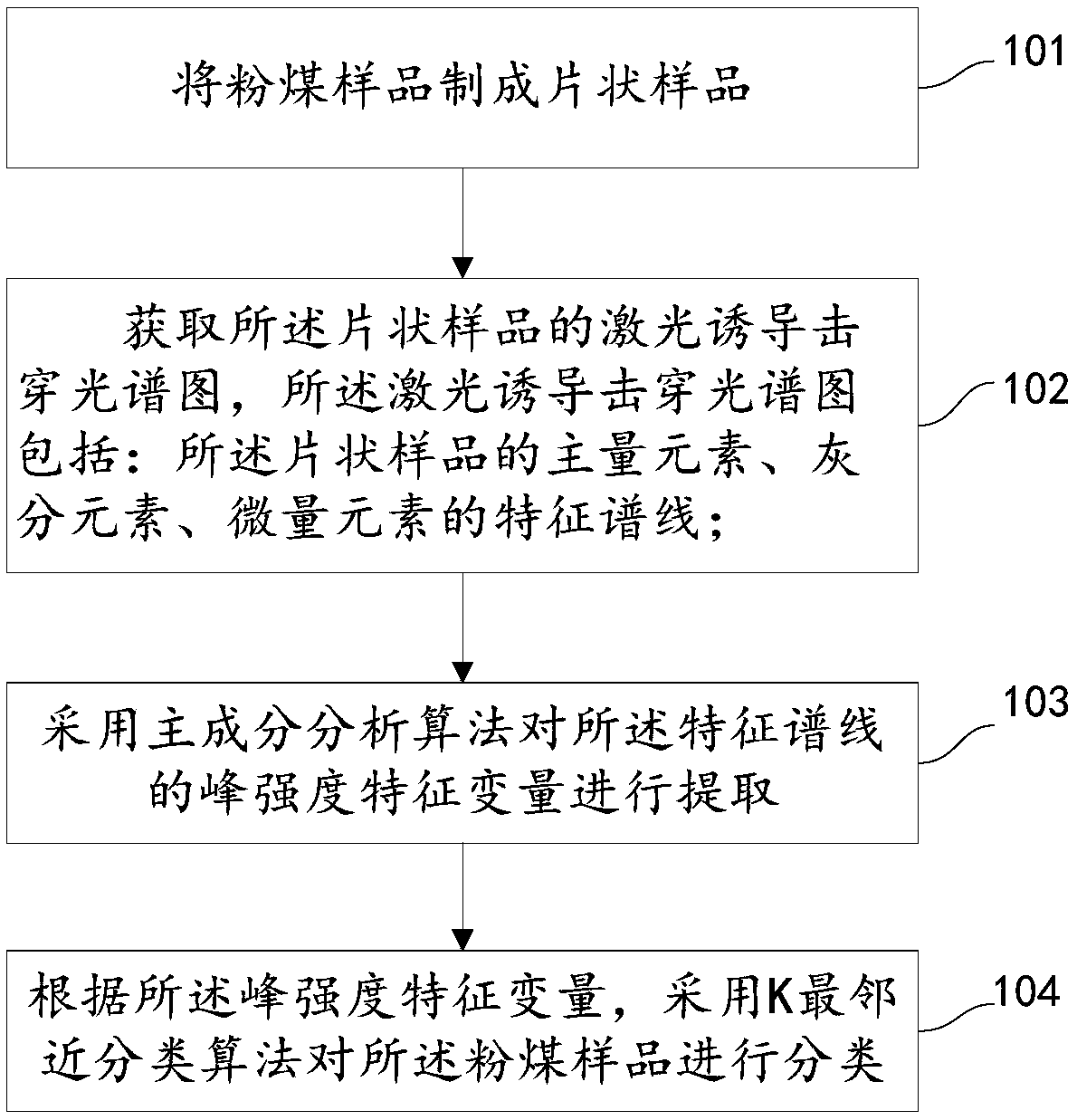

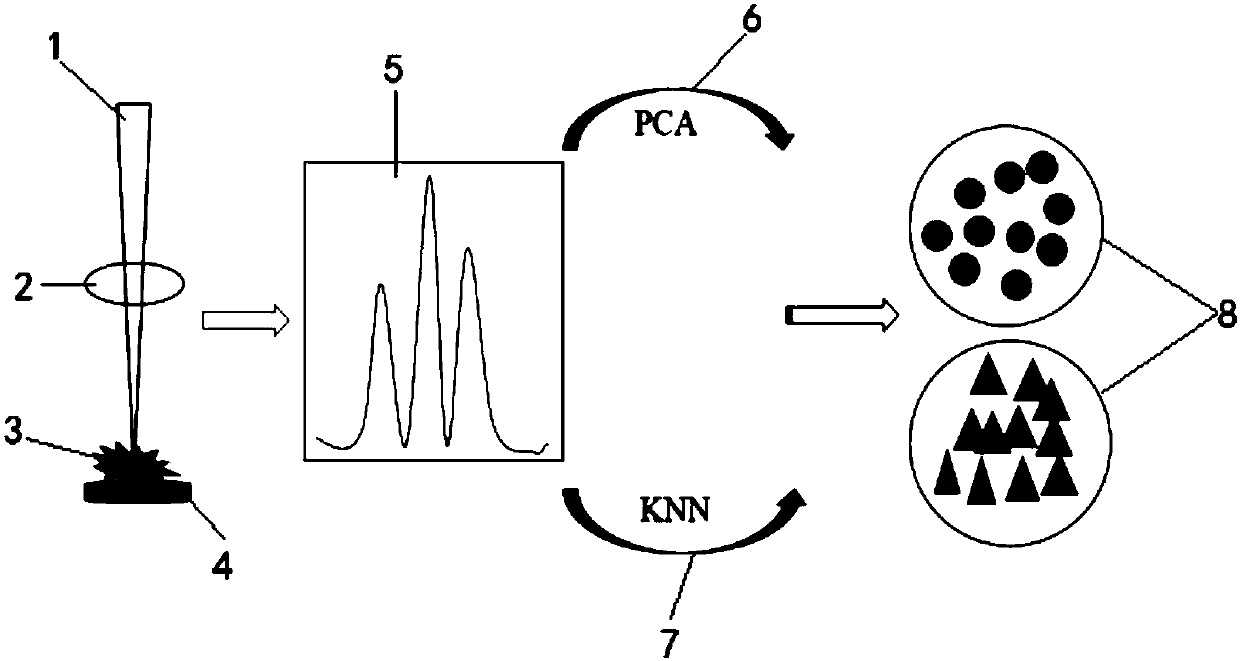

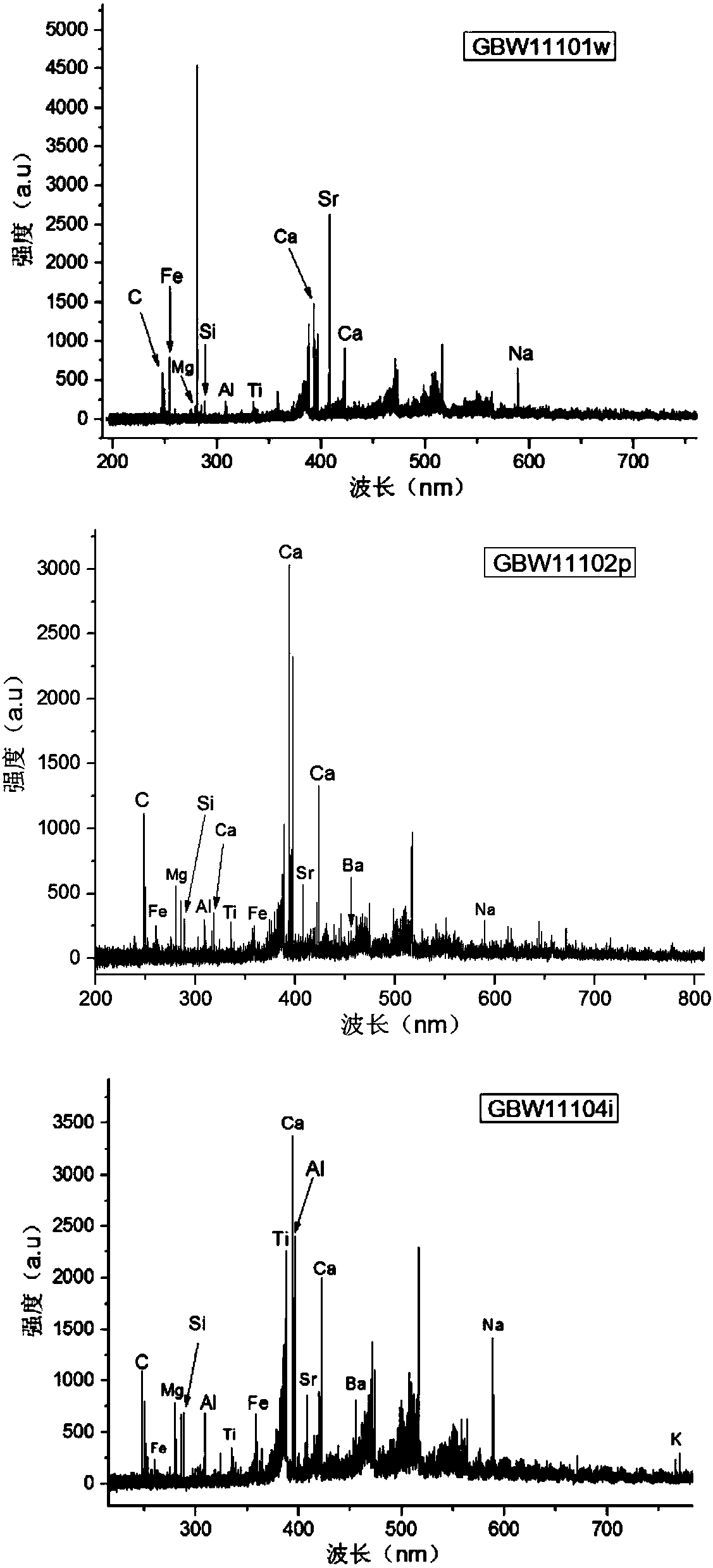

Pulverized coal classification method based on laser induced breakdown spectroscopy

InactiveCN110196247AHigh speedImprove accuracyAnalysis by thermal excitationTrace elementNear neighbor

The invention discloses a pulverized coal classification method based on a laser induced breakdown spectroscopy. The method comprises: preparing a sheet sample based on a pulverized coal sample; acquiring a laser induced breakdown spectroscopy, including characteristic spectral lines of a main element, an ash element, and a trace element of the sheet sample, of the sheet sample; on the basis of aprincipal component analysis algorithm, extracting peak intensity characteristic variables of the characteristic spectral lines; and according to the peak intensity characteristic variables, classifying the pulverized coal sample based on a K nearest neighbor classification algorithm. Therefore, the pulverized coal can be classified rapidly and accurately; and thus the industrial coal burning parameters can be adjusted timely and the coal burning efficiency can be improved.

Owner:CHENGDU ALIEBN SCI & TECH CO LTD

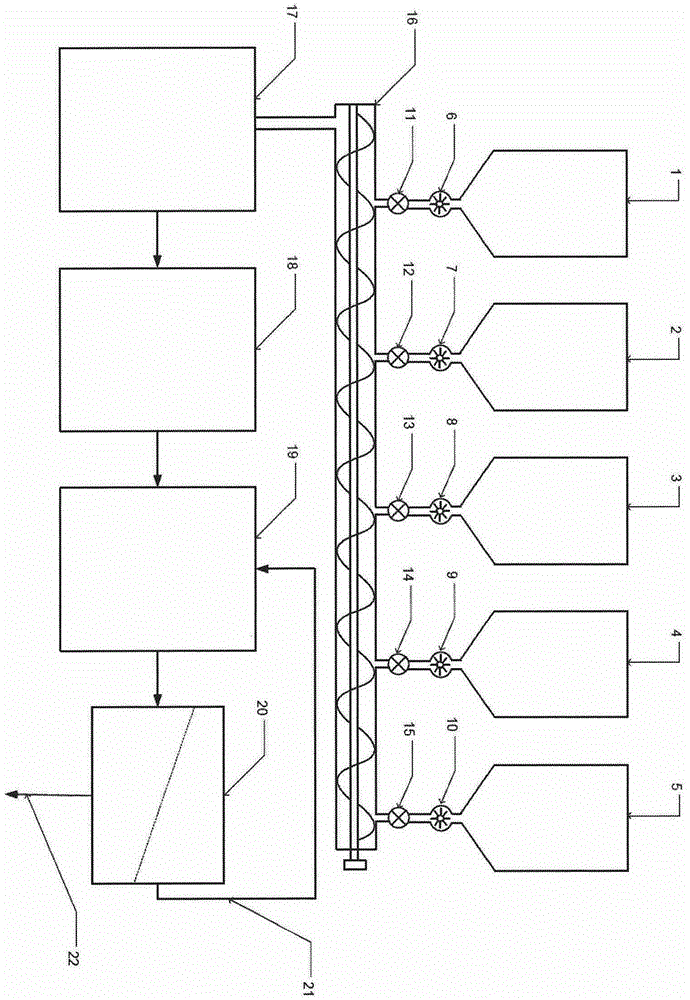

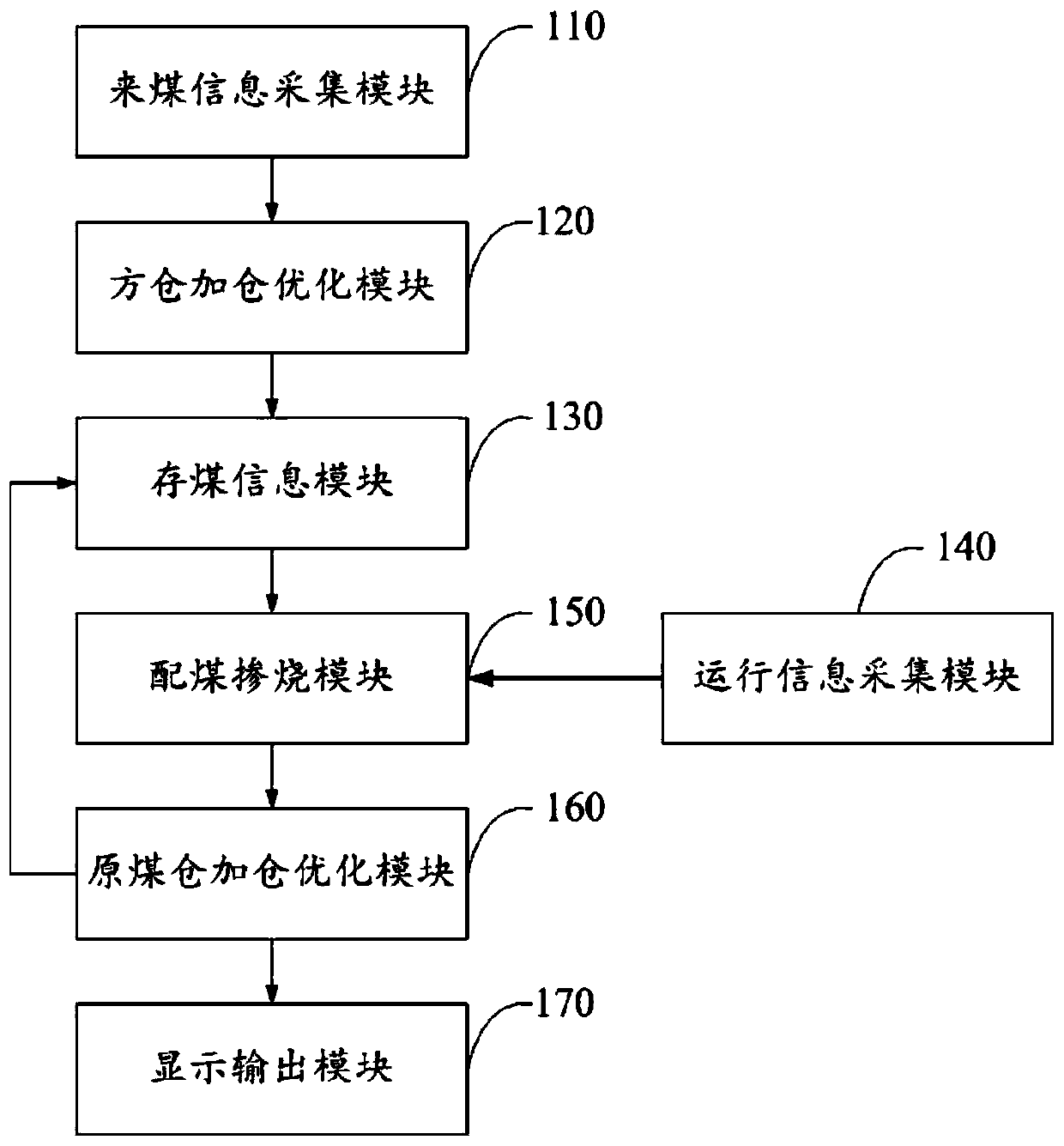

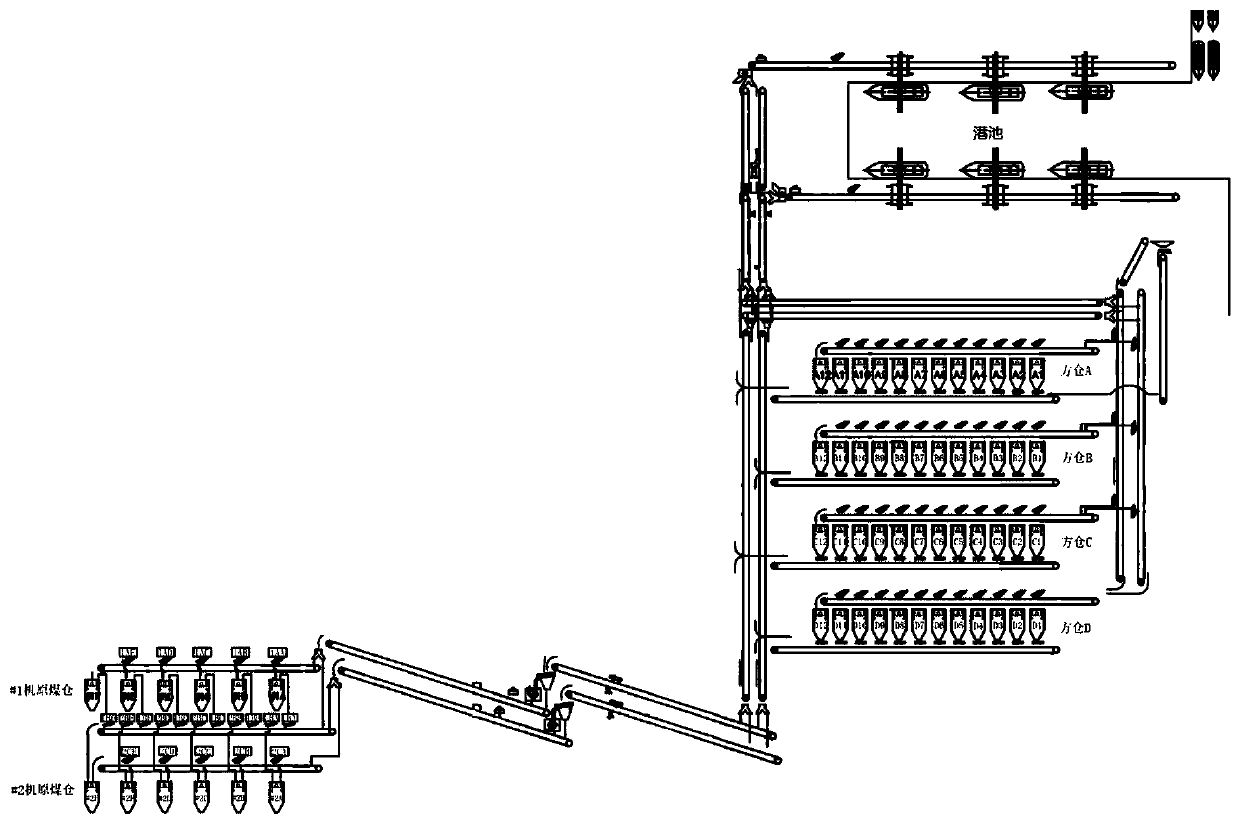

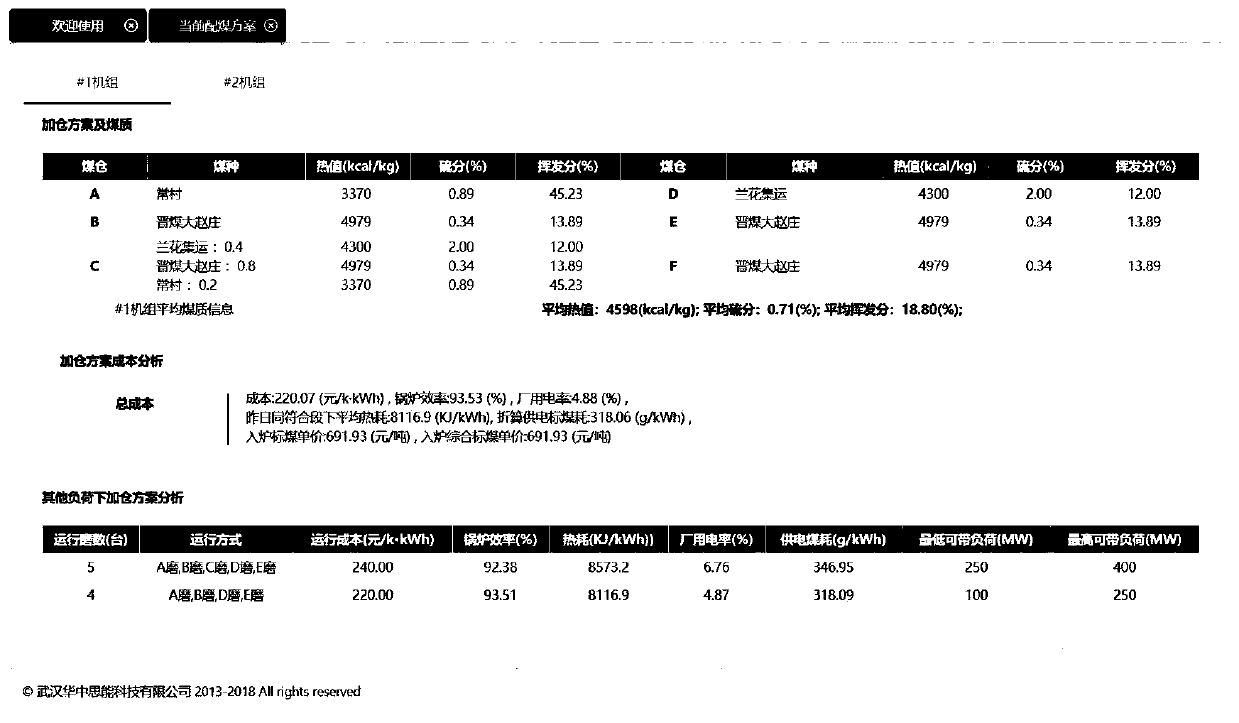

Coal dispatching system and method for cluster type coal plant

InactiveCN111506028ARealize reasonable schedulingImprove coal efficiencyTotal factory controlProgramme total factory controlCoal plantBunker

The invention provides a coal dispatching system and method for a cluster type coal plant. The system comprises an incoming coal information collection module which is used for collecting the incomingcoal information of the coal plant, a bunker adding optimization module which is used for generating a bunker adding strategy, a coal storage information module which is used for acquiring and counting the coal storage information of each bunker of the coal plant, an operation information acquisition module which is used for acquiring the operation information of a coal generator set, a coal blending combustion module which is used for generating a coal blending combustion strategy according to the unit operation information and the coal storage information, a raw coal bunker adding optimization module which is used for generating a final raw coal bunker adding strategy based on the coal blending combustion strategy and updating the coal storage information of each bunker, and a display output module which is used for displaying the coal storage information of each bunker, the bunker adding strategy information and the coal blending combustion strategy information. According to the technical schemes, the problems of low unit coal efficiency and high power supply coal consumption existing in existing coal dispatching of the cluster honeycomb type coal plant are solved, the coal efficiency of the generator set can be improved, the power supply coal consumption is reduced, and economic benefits are guaranteed.

Owner:HUANENG POWER INT INC +1

A coal washing medium powder and coal washing process

ActiveCN103611620BReduce processing timeImprove the washing rateWet separationProcess engineeringStorage material

The invention provides a coal washing medium powder and a coal washing process. The content of magnetic substances in the coal washing medium powder is greater than 97.8%, the particle content in the coal washing medium powder is 91.3%, and the sulfur content of the coal washing medium powder is less than 0.1%. The coal washing process includes the following Steps: ① Send the above-mentioned coal washing medium powder into the medium storage tank for standby; ② Send the raw coal into the circulating coal crushing equipment and enter the sorter; ③ The sorter will select the raw coal after being crushed in step ②; ④ Put the raw coal in the raw material storage tank The raw coal materials stored in the internal storage are sent to the three-product dense medium cyclone; ⑤The coal washing medium obtained in step ④ is used to recover the coal washing medium obtained in step ④, and the dense medium suspension is reconfigured; Water-containing coal is dehydrated to obtain clean coal, medium coal and gangue products; the invention can stabilize the ash content in the clean coal obtained after raw coal washing at about 0.5%, and can continuously wash coal, which is suitable for large-scale popularization and application in the coal industry .

Owner:高峰

Boiler decoking agent

The invention discloses a boiler decoking agent and belongs to the field of decoking agents. According to the boiler decoking agent, zinc powder and flake graphite are used as raw materials, and concentrated nitric acid is used for carrying out intercalation on the flake graphite and expanding to prepare expanded graphene; ball-milled zinc powder is ultrafine powder and is used as a zinc source; ethanol is used as a dispersant to prepare a composite material with a good structure; in a preparation process, starch is used and pores of starch colloid can be filled with the composite material andis used as a crosslinking agent, and a molecular chain of the starch is crossly linked, so that the surface of the starch with a porous structure is more dense; effective components deposited in thestarch are prevented from losing in preparation and storage processes. By adopting the boiler decoking agent, the problem of a current boiler decoking agent that the efficiency of removing coked fouling of a boiler wall is low is solved.

Owner:北京可林维尔化工有限公司

A dust-free and environmentally friendly coal-fired power generation method

ActiveCN107541297BReduce dustReduce consumptionFuel feedersSteam engine plantsWater vaporGas compressor

The invention relates to a dust-free environment-friendly coal firing power generation method. The method comprises the steps that 1, feed coal is conveyed, wherein the feed coal is preheated and enters a conveyor for feeding; 2, the conveyor conveys the feed coal into a coal grinding device to be smashed, and meanwhile hot wind is introduced to dry smashed coal dust; 3, the coal dust which passesthrough the coal grinding device is driven to enter a separator by the hot wind to be graded, qualified coal dust is grinded along air flow, and unqualified rough coal dust is grinded with the feed coal again under the effect of separator blades; 4, fine coal dust reacts with high-temperature steam and oxygen with the temperature above 200 DEG C to generate combustible synthesis gas; 5, the combustible synthesis gas is compressed by a gas compressor and sprayed into a boiler by an ejector for combustion; 6, high-temperature and high-pressure water vapor is used for driving a steam electric generating set to work and accordingly driving an electric generator to generate electricity. According to the dust-free environment-friendly coal firing power generation method, the fine coal dust is subjected to reaction and generates the synthesis gas, the coal firing efficiency is improved, the following flue gas and dust are reduced, burning is sufficient through spraying, through desulfurization and denitration reaction, toxic gas in mixed gas and flue gas is removed, the flue gas and water vapor are recycled, and the economic benefit is improved.

Owner:恒盛能源股份有限公司

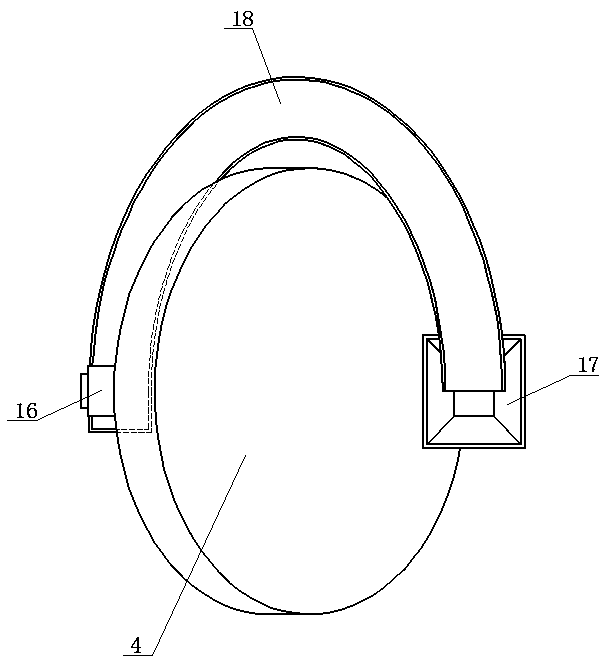

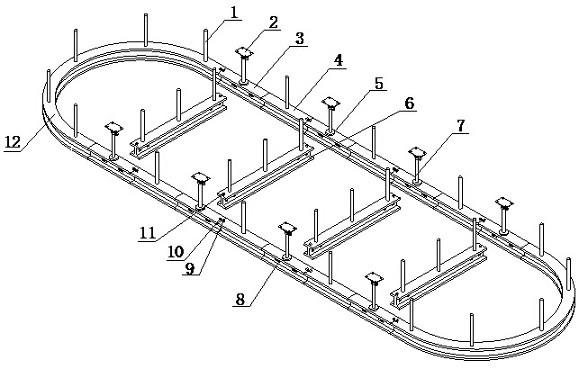

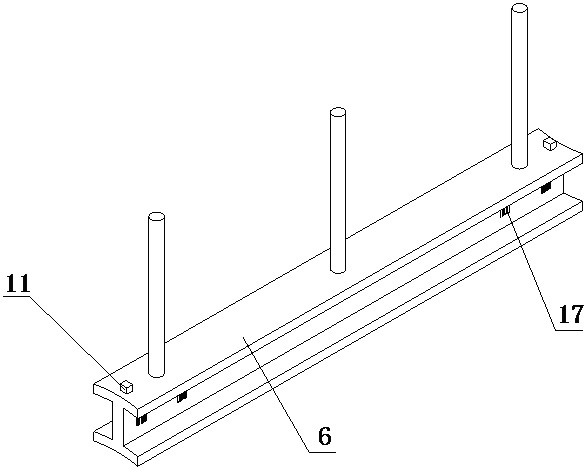

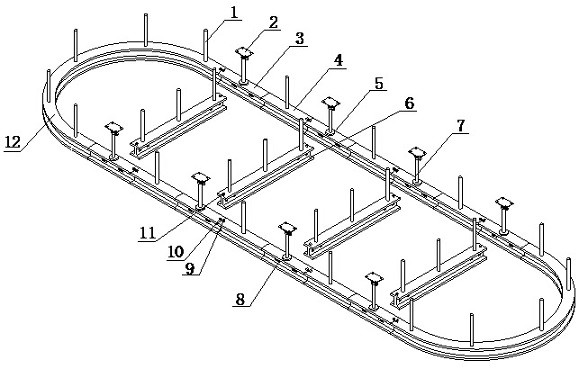

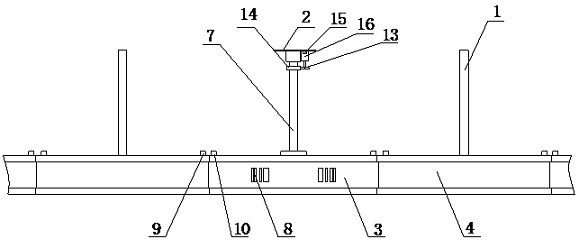

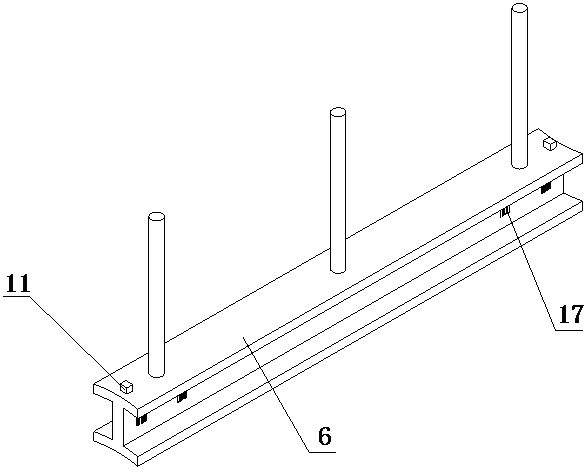

Efficient track structure for coal inventory track robot

The invention discloses an efficient track structure for a coal inventory rail robot. The track structure can be flexibly changed according to requirements. According to the track structure, the steering track is rotated and adjusted to be matched with the transverse track to guide the walking change direction of the coal inventory robot and coal inventory walking time is reduced. The track structure is characterized in that two fixed tracks and two U-shaped tracks are combined to form a straight circular track; the two U-shaped tracks are located at the two ends of the straight circular trackrespectively. The two fixed rails are parallel to each other; the two ends of the U-shaped rail are connected with the corresponding ends of the two fixed rails correspondingly. A plurality of positions on the fixed rail are broken to form a plurality of notches, the sections of the notches are arc-shaped surfaces, a plurality of suspensions are arranged on the fixed rails, a plurality of suspensions are arranged on the U-shaped rails, a first infrared receiver is arranged on the fixed rails, and the first infrared receiver is close to the notches.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

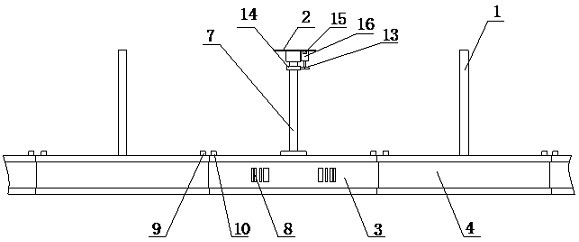

Direct combustion type pulverized coal supply system

PendingCN106979532ARealize automatic transmissionRealize the automation of coal deliveryFuel feeding arrangementsSolid fuel pretreatmentCoal briquetteThermodynamics

The invention discloses a direct combustion type pulverized coal supply system which comprises a platform support. Transfer barrels are arranged at the top of the platform support. A conveying pipeline is arranged in the middle of the platform support. A coal feeder is arranged at the bottom of the platform support. The coal feeder is connected with the transfer barrels through a conveying mechanism. The bottom of each transfer barrel is connected with a screw propeller. A coal mill is connected to each screw propeller and communicates with the conveying pipeline. Automatic conveying of coal briquettes is achieved through the conveying mechanism, the coal briquettes are milled into powder through the screw propellers and the coal mills and are conveyed to a conveying rail, and the aims of improving coal firing efficiency, achieving coal supply automation and improving production efficiency and enterprise competitiveness are achieved.

Owner:高安市成兴实业有限公司

Coal combustion catalyst with demercuration effects and preparation method thereof

The invention belongs to the technical field of catalyst processing, and particularly relates to a coal combustion catalyst with demercuration effects and a preparation method thereof. The invention particularly relates to the high-activity coal combustion catalyst and the preparation method thereof. The catalyst is prepared from the following raw material ingredients: a cerous nitrate solution, Al2O3, ferric nitrate, CuCl2, a yttrium nitrate solution, a gadolinium nitrate solution, MnO2, diatom ooze, hydrotalcite, palygorskite, calcium carbonate, loofah sponge, straw, corn stalks, chitosan, citric acid, hexahydrocresol, polyoxyethylene ether and a raising agent. The catalyst has high chemical stability; the activity can be maintained in a long time; the catalyst can be recovered to be repeatedly used; by using the catalyst, the combustion speed of fire coal can be effectively accelerated; the effects of denitration, sulfur fixation and demercuration can be achieved; the discharge quantity of smoke can be reduced; the environment pollution is reduced, and the application value is high.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

Fire coal device capable of removing coal ash

InactiveCN106439929AEasy to separateBurn fullyDomestic stoves or rangesLighting and heating apparatusImpellerCombustion chamber

The invention relates to a combustion furnace, in particular to a fire coal device capable of removing coal ash. The fire coal device can achieve the aim of effectively separating the coal ash from a coal stove hearth and comprises a coal stove with an internal combustion chamber, a coal outlet communicated with the internal combustion chamber of the coal stove is formed in the lower portion of the coal stove, and a screen plate is arranged on the coal outlet and provided with a plurality of fine holes. The fire coal device further comprises an impeller arranged above the screen plate and an impeller shaft arranged below the impeller, a driving device in transmission connection with the impeller shaft is arranged below the screen plate, blades are arranged on the impeller, and densely-distributed through holes are formed in the impeller. According to the fire coal device capable of removing the coal ash, the driving device drives the impeller to rotate through the impeller shaft; and through two times of ash discharging through the impeller and the screen plate, the coal ash is effectively discharged from the coal stove hearth, briquette burning is more sufficient, and the fire coal efficiency is greatly improved.

Owner:攀枝花市旭鼎机械制造有限公司

Combustion-supporting adhesive for fire coal

The invention discloses a preparation method of a fire coal type boiler for fire coal increasing effect and bonding of crushed coal, belongs to the technical field of organic or inorganic synthesis, and in particular relates to a method using sulphur as an initiating agent and potassium carbonate, potassium nitrate, sodium nitrite, potassium permanganate, cellulose and maltodextrin as a combustion-supporting adhesive.

Owner:黄少云

A high-efficiency track structure for Panmei orbital robot

The invention discloses a high-efficiency track structure for a Panmei track robot, which discloses a track structure that can be flexibly changed according to requirements, through the rotation adjustment of the steering track and the horizontal track to guide the Panmei robot to change its walking direction, and reduce the Panmei walking time The track structure is characterized in that two fixed tracks and two U-shaped tracks are combined to form a straight circular track, and the two U-shaped tracks are respectively located at both ends of the straight circular track, and the two fixed tracks are parallel to each other. The two ends of the U-shaped track are respectively connected to the corresponding ends of the two fixed tracks, and multiple places on the fixed track are broken to form a plurality of slots, and the section of the slots is an arc surface, and the fixed track is equipped with A plurality of suspensions, a plurality of suspensions are arranged on the U-shaped track, a first infrared receiver is arranged on the fixed track, and the first infrared receiver is close to the slot.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

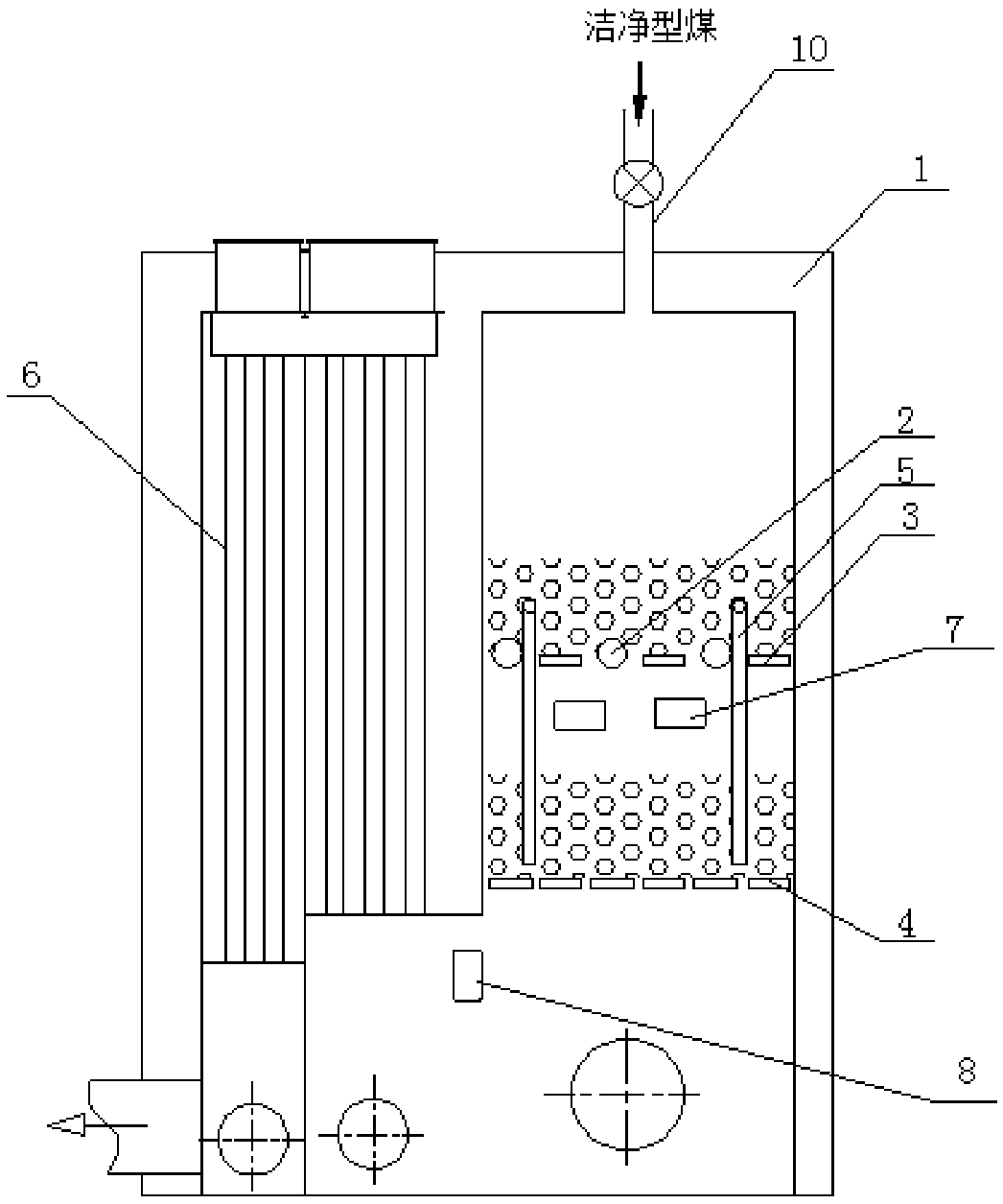

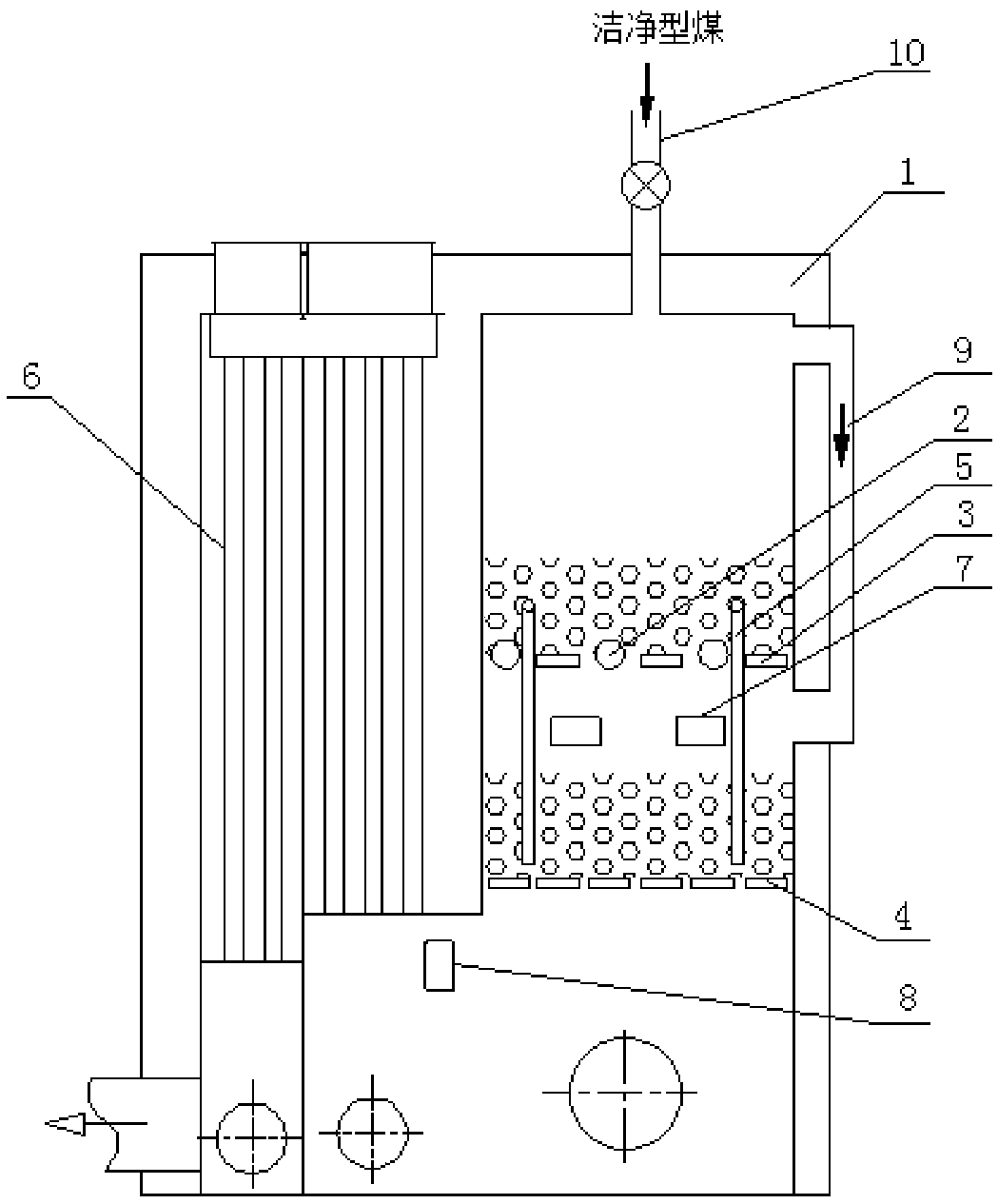

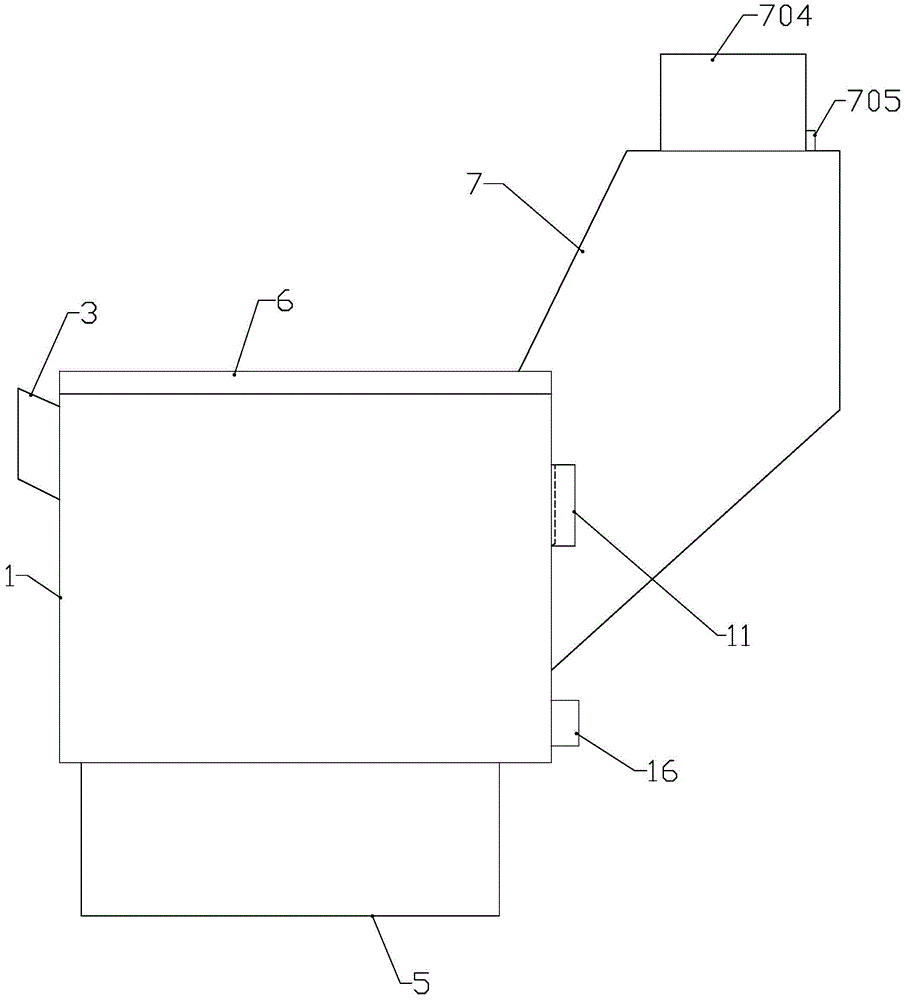

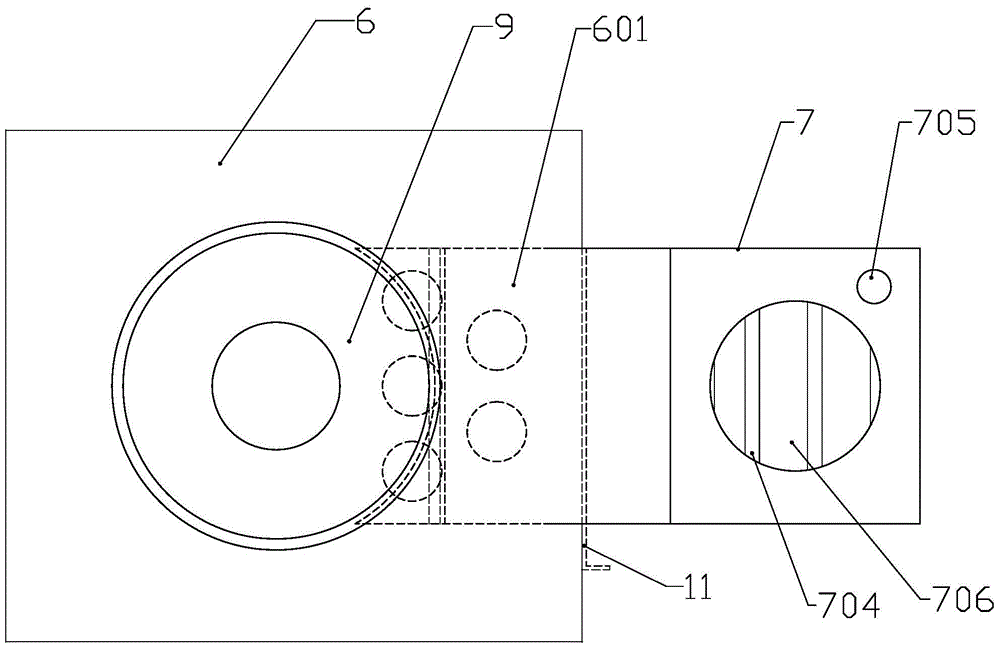

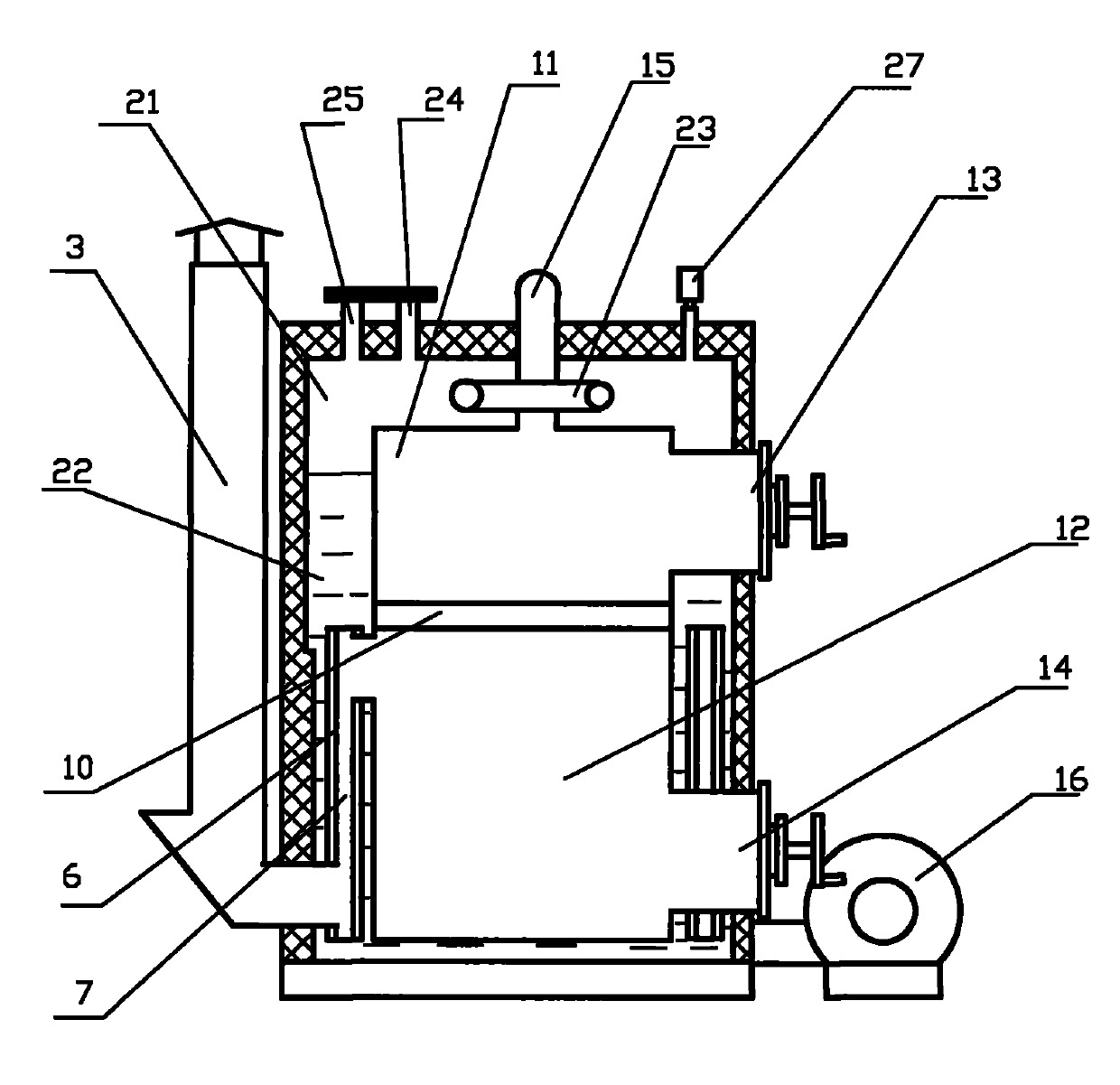

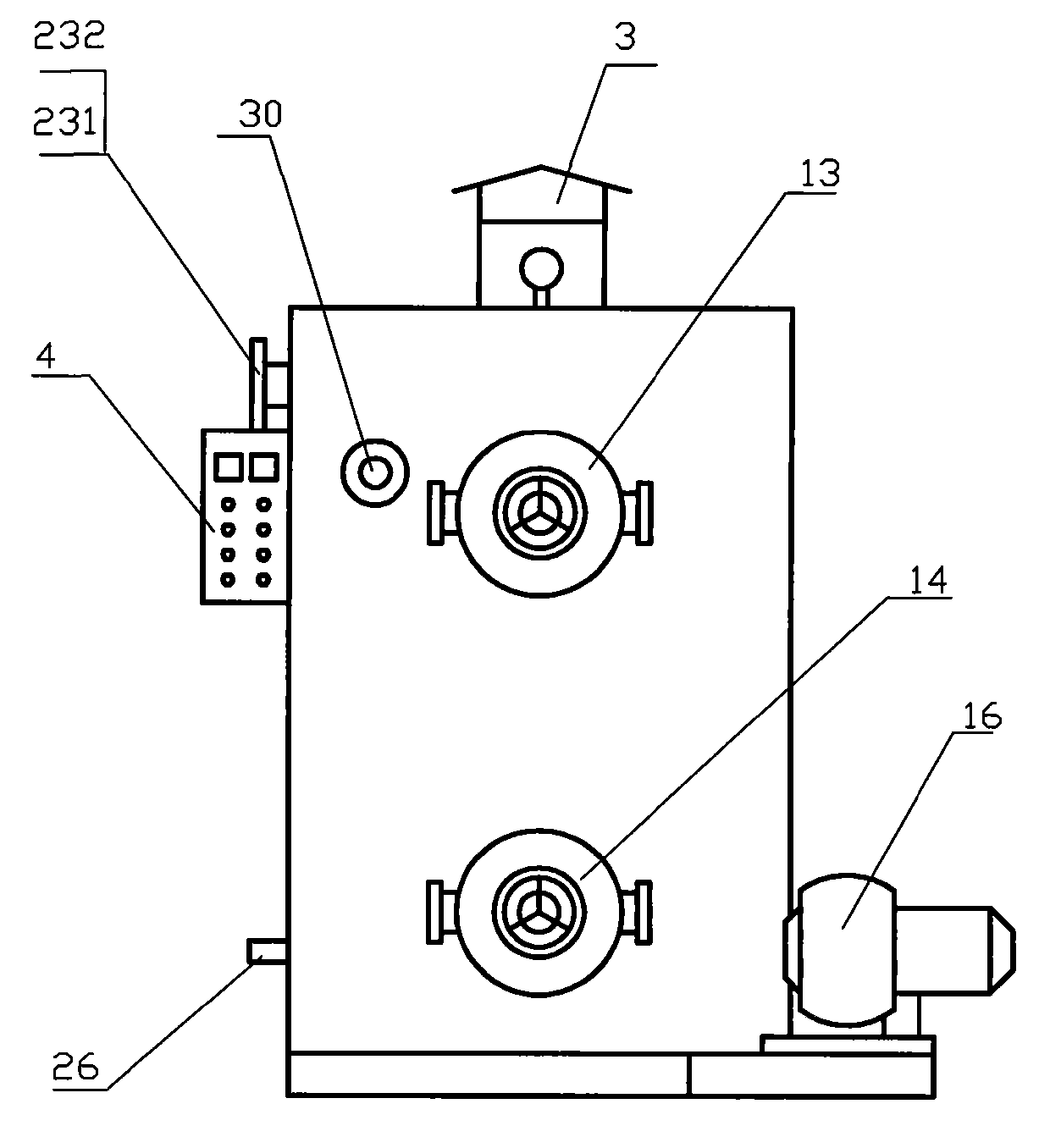

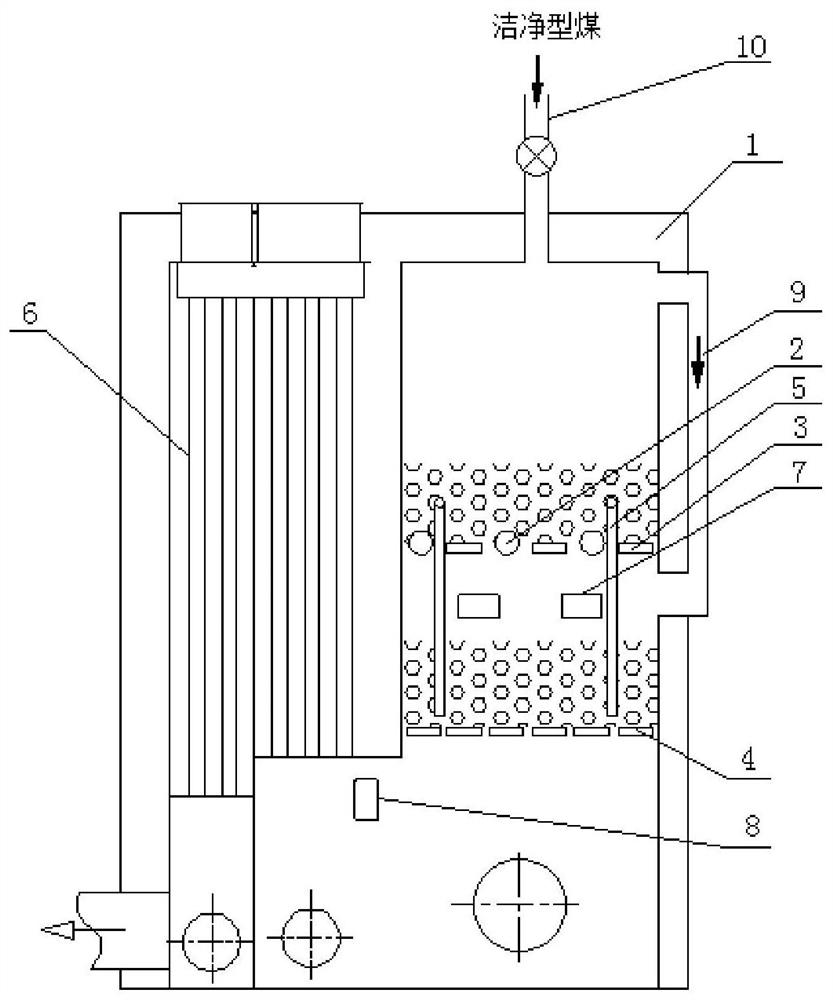

Pre-pyrolysis type heating stove for civil use and heating method thereof

ActiveCN109579290AEmission reductionReduce operating labor intensitySolid fuel combustionWater heatersCombustionConvection heat

The invention provides a pre-pyrolysis type heating stove for civil use and a heating method thereof. The pre-pyrolysis type heating stove for civil use comprises a stove body, a longitudinal separating plate is arranged on the stove top wall positioned in the stove body, the inner part of the stove body is divided into a first cavity chamber and a second cavity chamber, and the bottom of the first cavity chamber communicates with the bottom of the second cavity chamber; the first cavity chamber is a convection heat transfer zone, grates are arranged on the middle part of the second cavity chamber, and the second cavity chamber is divided into an upper zone and a lower zone by the grates; the zone above the grates is an oxygen-free pyrolysis zone, and the zone under the grates is a semi-coke combustion zone; a feed inlet is formed in the stove wall positioned on the oxygen-free pyrolysis zone, primary air openings are formed between the oxygen-free pyrolysis zone and the semi-coke combustion zone and located under the grates, heat pipes are arranged in the second cavity chamber, and the oxygen-free pyrolysis zone communicates with the semi-coke combustion zone through the heat pipes; a communicating zone between the bottoms of the first cavity chamber and the second cavity chamber is a burnout zone, the deslagging grate is arranged between the semi-coke combustion zone and theburnout zone, and a second wind opening is formed in the burnout zone. According to the pre-pyrolysis type heating stove for civil use and the heating method thereof, the heating stove body is improved and optimized, the pollutant discharging of the heating stove is reduced, the combustion is controlled, and the operation labor intensity is reduced.

Owner:YANKUANG GRP CO LTD +1

Double flue direct-fired heating furnace

InactiveCN104764048BTake advantage ofReduce lossLighting and heating apparatusStove/ranges for heating waterEngineeringHeating furnace

The invention discloses a double-flue direct burning type heating furnace, and belongs to heating furnaces. The double-flue direct burning type heating furnace structurally comprises a furnace body, a hearth and a feeding opening. A box is arranged on the outer side of the furnace body, and comprises an outer-layer box body, an inner-layer box body and an interlayer, and a smoke outlet and a hot water outlet pipe are arranged at the top of the box. An upper smoke outlet channel is arranged at the position, between an upper furnace ring and the hearth, of the furnace body, a lower smoke outlet channel is arranged between one side of the upper portion of the hearth and the furnace body, a plurality of vertical hot water circulating pipes are arranged in the lower smoke outlet channel, an upper separation plate and a lower separation plate are arranged on the upper portion and the lower portion of the lower smoke outlet channel respectively, a water inlet cavity of the furnace body is communicated with a water return pipe, a lower furnace ring hot water circulating channel is arranged in a lower furnace ring, an upper furnace ring hot water circulating channel is arranged in the upper furnace ring, a connecting pipe is arranged between the upper furnace ring and the lower furnace ring, and a plurality of horizontally-arranged horizontal hot water circulating pipes are arranged in the inner-layer box body. The double-flue direct burning type heating furnace has the advantages of being capable of improving coal-fired heating efficiency and saving fire coal, being compact and reasonable in structure and the like.

Owner:济南炳乾机械有限公司

A heavy medium continuous coal washing equipment and raw coal continuous crushing method

Owner:南通市通州区麦畅纺织品有限公司

Coal-firing agricultural soil hot water sterilization machine

InactiveCN101493262BRestorationReduce pollutionSteam soil sterilisationWater heatersEngineeringRecuperator

The invention relates to a hot water sterilizing machine applied to agriculture by burning coal, belonging to the field of agriculture equipment. A furnace of the sterilizing machine of the invention is divided into a coal furnace and a fire furnace by a fire grate, the top of the coal furnace is connected with an air inlet pipe, a boiler barrel comprises water space in the lower part and negative pressure vacuum space in the upper part, the negative pressure vacuum space is internally provided with a recuperator tube connected with the outside, the water space is internally provided with heat pipe bundles to form a gas duct. The hot water sterilizing machine applied to agriculture by burning coal can combine a vacuum boiler, gasification wraparound burning and a membrane wall heat transmission structure and continuously provide hot water with the temperature of 90-95 DEG C, has high thermal utilization factor and generates little pollution to the environment, in addition, optimal combination is carried out on the structure of the invention, so that the sterilizing machine has small volume, high thermal efficiency and good mobility. With a membrane-beneath irrigation system adopted, the high temperature hot water obtained in the invention is irrigated in soil or ground substances to heat the soil or ground substances to 50-60 DEG C which lasts for 1-2 hours, thus killing a large amount of mixed fungus in the soil and restoring land capability of the soil.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

A prepyrolysis type civil heating furnace and heating method thereof

ActiveCN109579290BImprove coal efficiencyBurn fullySolid fuel combustionWater heatersSlagConstruction engineering

The invention provides a pre-pyrolysis type civil heating furnace and its heating method. The heating furnace includes a furnace body, and the furnace body is provided with a longitudinal partition on the top wall of the furnace, which divides the interior of the furnace body into a first cavity connected at the bottom. Chamber and the second chamber, the first chamber is a convective heat exchange area, the middle of the second chamber is equipped with a fire grate, which divides the chamber into upper and lower areas, above the fire grate is an oxygen-free pyrolysis area, and below the fire grate It is a semi-coke combustion zone, and a feeding port is set on the furnace wall exiting the anaerobic pyrolysis zone, a primary tuyere is set under the grate between the anaerobic pyrolysis zone and the semi-coke combustion zone, and a communication port is set in the second chamber. The heat pipe of the anaerobic pyrolysis zone and the semi-coke combustion zone; the area connected to the bottom of the first chamber and the second chamber is the burnout zone, and the slagging grate is arranged between the semi-coke combustion zone and the burnout zone, so The second tuyere is set in the burnout zone. The invention improves and optimizes the furnace body of the heating furnace, reduces the emission of pollutants from the heating furnace, controls the combustion, and reduces the labor intensity of operation.

Owner:YANKUANG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com